Abstract

To explore particulate movement near the plasma of chemical explosions, rugged tracer particles were placed within and on the exterior of metal charges and electrically detonated. The particles were collected on/in the porous walls of plastic cylinders at diameters that correlated to the plasma width during different phases of the explosion. The particles’ positions were determined by Boolean logic analysis of their luminescent intensity. The cylinders which caught particles from the initial phases of the explosion retained placement information, while wider cylinders showed uniform mixing. These results/analysis methodology can help improve the understanding of particulate mixing in harsh environments.

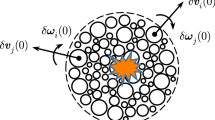

Graphical abstract

Similar content being viewed by others

Introduction

Cylindrical enclosures are ubiquitous in human industrial design. As such, understanding the distribution of mass as it pertains to cylindrically contained explosions is needed for such broad topics as application safety determination Ogunfuye et al.,[1] mass migration in underground/contained channels,[2,3] forensic analysis,[4,5] and analysis of debris fields.[6] Explosions contained in cylindrical enclosures have many applications such as food processing, rocket design, resilient armor, geologic and atmospheric migration, and industrial safety in areas such as grain elevators, oil rigs, and mining.[1,7,8,9,10,11] Contained explosions can generate many particulates, which can be difficult to track; therefore, a surrogate that survives the explosion and retains placement information is needed to help build that understanding base.

Predicting and modeling the particulate material dispersal during explosions is difficult in many circumstances.[4,12,13] The dispersive potential of explosives is dependent on many variables,[14] and explosive dispersal can vary from the propagation of the blast wave.[15] Researchers have developed collection methods for dispersed mass,[6,15] but many methods only collect a small portion of material from many meters (typically ranging from 1 to 20) away from the blast. A direct surrogate, which can be added to the charge, is needed to explore the explosive dispersal of material from the charge in a more complete way.

Previous work has detailed the survivability of particulate tracers in contained-spherical enclosures.[16,17] It showed that hydrated-silica-encased quantum dots of zinc sulfide can survive exploding bridge wire (EBW) detonations to a high degree and can endure in the environment. Prior to encapsulated tracers, Anderson et al.,[18] Eilers et al., [19] and Myint et al.[20] completed work using luminescent-doped glasses as particle tracers for room-sized contained explosions.

The tracer particles in this work were collected on and in the porous walls of ABS plastic cylinders at diameters that correlated to the plasma width during different phases of the explosion. The deposition and mixing of the particles were determined by optical Boolean logic analysis of the luminescent intensity of the particles. In most cases, the larger-diameter cylinders showed uniform deposition and mixing with some aberrations seen in the deposition of the center tracer particles. These results and the tracer particle analysis can help improve the understanding of particulate mixing in harsh environments. Previous results have shown that particulate tracers can be used to characterize the movement of mass in contained explosions. As previous particle tracking work has been focused on particle survivability and a large room-sized enclosure, this work seeks to inform mass mixing in enclosures that are within or slightly larger than the generated plasma field of the explosion (0–2.5 cm radius from the charge). This centimeter scale distance range is significantly smaller than the meter-scale ejected material studies of previous work[15,18] and focuses on particulate mixing and movement closer to the explosion.

This article reports on work that seeks to inform the use of particulate tracers to study the movement of particles near the generated plasma of the explosion. Specifically, we hypothesize that

-

1.

Centimeter-scale diameter cylinders of porous polymer (12 µm nominal open-face diameter) can catch the explosively dispersed particles (100–1000 nm nominal diameter) from thin cylindrical steel tubes (0.04 in. outer diameter [OD], 10 cm long, 50–150 mg) detonated by EBW (100–1000 J) at different phases of an electrically driven explosion.

-

2.

Position placement (three positions relative to the charge, each covering 33% of the surface) of the particles influences their debris location for depositions occurring on the hundreds-of-microsecond time scales in the above cylindrically enclosed detonations.

Through this work, we seek to inform the particle movement in cylindrical enclosures near the plasma of the explosion. The particles are shown to move in a way that is traceable to their original position, as long as they were deposited on the hundreds-of-microsecond time scales. Longer deposition times lead to particles that are well mixed within the enclosures.

Experimental

Materials and methods

Explosive charges preparation

The detonated material consisted of 10-cm-long thin stainless steel tubes inserted into plastic cylinders of varying diameters from a radius of 0.01 to 2.5 cm (Fig. S1a). The tubes used for detonations were 21 gauge, 304 stainless steel tubes measuring 10 cm in length, with an outer diameter of 0.0245 to 0.0260 in., and a wall thickness of 0.0032 to 0.00325 in. (Component Supply: HTX-21X-60). The research team connected each end of the tube to a wire stop (dual-rated splicer reducer, Home Depot part #202207169) to enable the further connection.

The research team coated the tubes on each third of the length on the outside by 0.10 g of 1-µm-diameter particles, sized according to Hubbard et al.[17] and housed in a mixture of 200 k Dalton polyethylene glycol (CAS: 25322-68-3, > 95%) and water (as solvent). They painted each third of the tubes in a different color-emitting particle, see Figure S1b. The positive bias side of the tubes was painted in blue-emitting particles, the negative in green, and the center of the tube in red. The internal volume of the tubes was filled with a mixture of saturated sodium metasilicate and 200 mg/ml 100-nm-diameter particles, which emitted an orange color. The research team produced the particles according to Hubbard et al.,[17] pressure sealing the end 1 mm of the tubes to contain the inner tracer. Figure S1b shows the painted tubes. After the outer coatings had dried, the research team carefully inserted the tubes into their respective cylinders.

Particle capture cylinders preparation

A Stratasys F170 3D printer from ABS-M30 polymer (Stratasys AS-333-60300, “ivory” color) printed the tested cylinders as two interlocking halves. Figure S1a shows assorted cylinder halves on the print plate. The internal length of all cylinders was 7.5 cm with internal radii from 0.04 to 2.5 cm. The wall thickness of the cylinders was 2.5 mm. The inner surfaces were painted with a diffusive white barium sulfate paint (Avian B, Edmund Optics stock #83-890) according to vendor painting specifications.

The ends of the cylinders were convex cone-shaped around the wire, which stops to limit the amount of material emitted into the cylinders through the explosive mounting holes.[21,22] The research team created this convex enclosure to keep the internal volume of the cylinders isolated until pressure loss occurred through the seam. Each cylinder was interlocked around the tube and then was secured with six polymer ties (Home Depot part: T-370STUV-20/307799374) to make sure that the halves did not separate in a dangerous manner during the explosion.

Sample measurement conditions

Exploding bridge wire

The tracer-filled tubes were detonated by an exploding bridge wire setup, please see Liezers et al.,[23] for details about the system. In short, the exploding bridge wire setup has four main components:

-

The high-voltage charging unit

-

The energy storage capacitors

-

A triggered spark gap

-

The assembly that holds the exploding wire (a thin tube in the case of this work).

The power supply of the exploding wire system consists of a charger unit; three energy storage capacitors (ZD452EW030S21A, Aerovox, New Bedford, MA, USA) each rated at 30 µF, and 4500 V; and mounted in parallel with a triggered spark gap (HEP50, Information Unlimited, Amherst, NH, USA). Fully charged, all three capacitors can store up to 900 J in total, and when triggered to discharge through a target wire or section of thin-walled stainless steel tube, deliver a primary current/voltage pulse of around 30 µsec duration. The wires or tubes loaded with the nanoparticle tracers were mounted in a jig located about 40 cm from the capacitor bank with the electrical supply and ground return connections each made with two pieces of 10 kV-rated 12-gauge cable. The capacitor charging voltage is continuously variable between 0 and 4500 V, allowing experiments to be performed over a range of energies.

To discharge the stored energy rapidly through the wire on microsecond timescales, a low-current high-voltage spark is used to break down the air in the spark gap. This effectively connects the charged capacitors to the target wire, which is then very rapidly heated and explosively vaporized by the stored energy. The entire EBW setup is contained in an isolated enclosure to prevent debris from getting into the adjacent laboratory space.

For the course of this work, the research team fixed the energy dissipated by the EBW at 500 J, which was approximately 80% that of the upper limit of the tubes. The fixed energy of 500 J provided a common energy from which to compare the results of each cylinder’s mixing and a repeatable platform from which to study the particulate mixing in the cylinders.

Optical

The research team used Photron Inc.’s FASTCAM Mini AX100 540 K-C-32 GB camera with a vendor-supplied lens (Nikon – 24–85 mm Micro/Macro Zoom Lens F/2.8) and tripod to record the high-speed video. They placed the end of the camera lens 3 ft from the explosive platform and centered the explosive charge in the image. During the explosions, they used video speeds from 4000 to 100,000 frames per second (fps).

The research team took optical luminescence images with a 50-megapixel ISOCELl JN1 containing camera at a working distance of 12 in. The luminescence of the particles was excited with two 7 W 365 nm bulbs (Sunlite 80114-SU) in an aluminum housing (ASIN: B01M0R9F71). The bulbs were placed 8 in. above the center of the workpiece and 8 in. to either side along the center axis of the workpiece.

Optical flash data were taken with an Ocean Insight’s OceanHDX spectrometer (OceanHDX-UV–Vis). The research team took the measurement at 6 ms intervals with optically matched, vendor-supplied fiber optics and a 0.25-in. diameter fused-silica collimating lens. They placed the collimating lens 12 in. from the explosive platform and pointed toward the center of the detonation. Optical microscopy was taken with a Dino-Lite Inc.’s ultraviolet (UV) microscope (AM4115T-CFVW). The 400 nm LEDs were used to excite the polymers to luminesce.

Electronic

A 1000:1 high-voltage probe (P6015A, Tektronix Inc, Beaverton, OR, USA) and Rogowski coil (CWT 60B, Power Electronic Measurements Ltd., Nottingham, UK) coupled to digital storage oscilloscope (DSOX1204G, Keysight, Colorado Springs, CO, USA) captured the current/voltage discharge parameters. The research team used the exploding wire system and conducted all experiments in a laboratory fume hood.

Measurement analysis

The high-speed video (4–100 kfps) of the explosions was processed with FASTCAM Viewer v. 4.0.5.0 (Photron, Inc.). The optical flash data were taken with Ocean Insights’ Ocean View v. 2.0.8. Optical UV microscopy was taken with AnMo Electronics Corp.’s DinoCapture software v. 1.5.42. Lastly, image processing was completed with the National Institute of Health’s ImageJ (Fiji) v.1.53.c.

The image calculator feature of Fiji was used to analyze the images. First, each image was split into its constituent color-pixel maps (red = R, green = G, blue = B). Next, Boolean logic gate analysis[24,25] was used to map the optical intensity to the x–y location inside the image. The logic gate algorithms by emitted color are as follows:

-

Red = (R-G)-B

-

Blue = (B-G)-R

-

Green = (G-R)-B

-

Orange = (R&G)-B

Figure S2 shows the resultant spectral sensitivity of the above algorithms, based on the analysis completed by Ji et al.[26] By applying the logic gate functions to the processed luminescent images, the spatial location of each particle type can be located within an image. To further process the x–y images into datasets, the plot profile function in Fiji was used to create average optical intensities per pixel column of each image.

Results

Figure 1 depicts the detonation current and bias with time. Inlaid on Fig. 1 are high-speed stills that depict the various expansion and mixing events. The time duration and relative magnitude of each event are depicted by Gaussian fitting of the current versus time data and are shown in Fig. S3. The initial explosion phases seen in Fig. 1 correlate well with Frost[27] and the latter phases with contained explosions such as Frost et al.[15] and Smirnov.[28] Measurements of the size of the plasma at each phase of the explosion were made with high-speed imaging.

The research team used measurements on the high-speed imaging of the plasma size and diameter to calculate the size of the cylinders. This calculation was used as a first pass approximation of when particles would be deposited on or within the walls of the cylinders and were used to size cylinders that ostensibly would collect particles during the different phases of the explosion. Using these plasma widths, the research team sized the cylinders to appropriate diameters to collect mass during the different phases of the explosion as seen in the insets of Fig. 1. The resultant cylindrical radii from 0.04 to 2.5 cm then became the basis for the high-speed and luminescent analyses presented in Fig. 2 through Fig. 4.

Figure 2 shows the time-to-leak, denoted mix time of the cylinders. Note that the trend in deposition energy between cylinder diameters follows the same general inclination as the impulse of modeled cylindrically contained explosions.[1,4,29,30] The time-to-leak from the imaging (a still depicting a pressure leak is inset into Fig. 2) is used as an approximation of the mixing time that the particles and explosive gases have within the local environment before mass loss causes pressure and energy to escape the system.

This time-to-leak is a measure of the time that the particles had to mix or deposit on the walls of the chambers, shown in Fig. 3. Figure S4a shows a line of orange- and green-emitting dots deposited along the track of the pressure loss vent shown in the inset of Fig. 2. This mass track is an indication that during venting, mass is pulled out of the system, thus limiting further deposition.

Post detonation, the research team opened the cylinders and examined them for luminescent evidence of the tracer particles. To study the particle deposition, they plotted total integrated intensity from the side of the cylinder that was connected to the positive bias toward the ground-connected side (Fig. 3) and from the top of the cylinders (gravity wise) to the bottom (Fig. 4). In this way, the deposition of the particles can be compared to the placed condition and the signal that an evenly deposited coating of particles would produce. Line guides that show how the particles were placed (solid black line) and the response from a uniform distribution of deposited particles (dotted black line) are included.

Figure 4 shows the top-down investigation of mixing and deposition of particles along the cylinder wall. The particles placed at the ends of the charge and those placed within give an expected even particle distribution throughout the cylinders, Fig. 4(a, b, d). The particles placed in the center of the charge appear to be deposited more along the ends caps of the cylindrical chambers with an apparent deposition of particles toward the bottom of the cylinders (the portion resting on the blasting stage), seen in Fig. 4(c).

Discussion

As can be seen in Fig. 3(a–c), the 1-µm-diameter particles placed outside the tube retain some spatial placement information for the two cylinders closest to the charges. The particles are driven into the pores shown in Fig. S5. For cylinders farther away, the mass distribution results of each particle appear to be relatively evenly deposited on the wall of the cylinders. This assertion is supported by Fig. 3(d), in which the particles contained within the charge are uniformly distributed along the cylinder walls. These findings support the first hypothesis that states that particles are caught by the cylinders at different phases of the explosion.

The leak time measurements in Fig. 2 corroborate this positional information in the debris field’s finding. Those cylinders that began to deposit particles before the complete disintegration of the charge (from the analysis summarized in Fig. 1) maintain some position information. While those tubes, which take from about 0.4–3 ms to leak (4–30× longer than the charge disintegration), had ample time to mix particles and gases inside the enclosed cylinders.

Moving to the radial mixing in the chambers in Fig. 4, it can be seen that the particles are evenly distributed along the walls of the chamber in all but one case. In Fig. 4(c) the red particles that were positioned outside the center of the charge appear to be deposited more toward the ends of the chambers than in the middle. This effect is seen as an initial rise in the red luminescence of the debris followed by a relative dearth of new signals in the middle and drastic rises at the right-hand sides of the chambers. Visually, this effect is evident in comparing the locations of the red hues in the bottom figure of the graphical abstract and Figure S4b.

Much of the red luminescent signal is located on the circular end walls with the rest centered toward what would be the bottom of the chambers (relative to gravity). While some particulate mixing models show center voids,[14,18,31] some of the red particles seem to be settling with respect to gravity. Although this finding warrants further research, the portions of the hypotheses around particle placement predicting the general position in the debris field are supported by these findings.

A possible explanation for the odd center particle distribution can be seen from the high-speed analysis. The mixing data in both Figs. 3 and 4 suggest that the red center particles are being deposited onto the end walls and bottoms of the cylinders. The high-speed videos suggest that while the initial detonation point is random and the initial expansion is ubiquitous along with the cylindrical charge (Fig. S6), the subsequent environmental mixing appears to originate from the ends of the cylinder and then from the center of the charge (see the environmental mixing inset of Fig. 1).

As the end particles (blue and green) are deposited earlier than the red particles, there may be reduced pressure at the ends of the cylinders, which enables the flow of particles and gases from the center of the charge to deposit onto the ends of the cylinders. In the literature, the pressure wave shapes due to cylindrical containment[28] support this assertion. The assertion of end-point deposition occurring earlier is also corroborated by the leak times in Fig. 2. Those detonations which had millisecond scales of time to mix presented far more red particles in the bottoms of the cylinders than the thinner-diameter and faster-depositing cylinders.

Lastly, the time for which the optical flash endured in each explosion hints that the thinner cylinders catch particles in these earlier phases for far longer than wider-diameter cylinders. The optical flash emits from the initial phases of the detonation and is used to approximate the time duration of these phases. It is possible that the wider cylinders (with diameters from 1.5 to 2.5 cm) had more time for dispersive mixing, thus more time for the particles to be influenced by gravity (Figs. S7 and 2). The timing of the dispersive mixing can partly explain the distributions of the particles; the apparent gravity-influenced deposition of center particles warrants further research.

Conclusions

Tracer particles from cylindrical explosions were captured in and on the walls of porous plastic cylinders placed with the local plasma field. The particulate location within the debris field maintained some placement information for cylinders with diameters from 0 to 0.5 cm, while larger cylinders showed well-mixed particles in most cases. The preferential deposition of center tracer particles in the bottom (by gravity) of the cylinders was interesting and warrants further investigation as a positional indicator. The tracers demonstrated herein, and subsequent optical measurement and analysis can be used to help verify experimental models and create laboratory-scale experiments for applications where direct measurements may not be possible, or where pre-determination of measurement points is needed. As cylindrical enclosures are common (i.e., pipes), these tracer particles and analysis methodology can help determine the hostile environmental transport of particulates in common industrial/geologic conditions. This can lead to improved understanding of material movement in the hostile environments of industrial applications like food processing, forensics, oil, gas, and mining, and atmospheric and geologic transport.

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

S. Ogunfuye, H. Sezer, F. Kodakoglu, H.F. Farahani, A.S. Rangwala, V. Akkerman, Fire (2021). https://doi.org/10.3390/fire4010009

M.A. Price, Effects of Cylindrical Charge Geometry and Secondary Combustion Reactions on the Internal Blast Loading of Reinforced Concrete Structures (thesis for Master of Science in Engineering Mechanics, Department of Mechanical Engineering, New Mexico Institute of Mining and Technology, Socorro, New Mexico). https://www.osti.gov/servlets/purl/841586

A.A. Saeed, N.N. Saimon, M.W. Ali, K. Kidam, Y.M. Jusoh, M. Jusoh, Z.Y. Zakaria, Chem. Eng. Trans. (2008). https://doi.org/10.3303/CET1863096

X. Chen, Z. Wang, E. Yang, J. Li, ACS Omega (2021). https://doi.org/10.1021/acsomega.0c05128

S. Datta, Quantum transport: atom to transistor. Comput. Eng. (2005). https://doi.org/10.1017/CBO9781139164313

F. Zhang, F. Shen, B. Li, B. Yuan, B. Li, Int. J. Aerosp. Eng. (2020). https://doi.org/10.1155/2020/8895404

N. Abdul-Karim, C.S. Blackman, P.P. Gill, E.M.M. Wingstedt, B.A.P. Reif, RSC Adv. (2014). https://doi.org/10.1039/c4ra04195j

B.E. Feldman, J.F. O’Brien, O. Arikan, ACM Siggraph (2003). https://doi.org/10.1145/1201775.882336

M.A.M. Huri, U.K. Ahmad, R. Ibrahim, M. Omar, Malays. J. Anal. Sci. (2017). https://doi.org/10.17576/mjas-2017-2102-01

F. Ouellet, B. Rollin, R.B. Koneru, J. Garno, S. Balachandar, Shock Waves (2021). https://doi.org/10.1007/s00193-021-01023-9

X. Zhang, Y. Ding, Y. Shi, J. Loss Prev. Process Ind. (2020). https://doi.org/10.1016/j.jlp.2021.104432

Y. Grégoire, D.L. Frost, O. Petel, AIP Conf. Proc. (2012). https://doi.org/10.1063/1.3686596

F. Zhang, D.L. Frost, P.A. Thibault, S.B. Murray, Shock Waves (2001). https://doi.org/10.1007/PL00004050

D. Frem, Def. Technol. (2020). https://doi.org/10.1016/j.dt.2019.07.002

D.L. Frost, C. Ornthanalai, Z. Zarei, V. Tanguay, F. Zhang, J. Appl. Phys. (2007). https://doi.org/10.1063/1.2743912

L. Hubbard, C. Reed, N. Uhnak, R. Sumner, T. Cell, E. Kinney, N. Smith, C. Allen, M. Foxe, A. Carman, MRS Commun. (2022). https://doi.org/10.1557/s43579-022-00150-3

L. Hubbard, R. Sumner, M. Liezers, T. Cell, C. Reed, N. Uhnak, C. Allen, B. Berry, H. Currah, E. Fuller, E. Kinney, N. Smith, M. Foxe, A. Carman, MRS Commun. (2020). https://doi.org/10.1557/mrc.2020.70

B.R. Anderson, R. Gunawidjaja, H. Diez-Y-Riega, H. Eilers, F.R. Svingala, A. Daniels, J.M. Lightstone, AIP Conf. Proc. (2017). https://doi.org/10.1063/1.4971574

H. Eilers, R. Gunawidjaja, T. Myint, J. Lightstone, J. Carney, AIP Conf. Proc. (2012). https://doi.org/10.1063/1.3686585

T. Myint, R. Gunawidjaja, H. Eilers, J. Phys. Chem. C (2012). https://doi.org/10.1021/jp307092b

J.F. Molinari, Finite Elem. Anal. Des. (2002). https://doi.org/10.1016/S0168-874X(02)00085-9

M.G. Vigil, Optimized conical shaped charge design using the SCAP code (1988) Sand88—1790 • Uc—35, September, 1–87. http://prod.sandia.gov/techlib/access-control.cgi/1988/881790.pdf

M. Liezers, A. Carman, G. Eiden, J. Radioanal. Nucl. Chem. (2018). https://doi.org/10.1007/s10967-018-6047-2

M.M. Dashtpagerdi, A. Nohegar, H. Vagharfard, A. Honarbakhsh, V. Mahmoodinejad, A. Noroozi, D. Ghonchehpoor, Water Resour. Manage. (2013). https://doi.org/10.1007/s11269-013-0333-0

H. Yousefi, H. Hafeznia, A. Yousefi-Sahzabi, Energies (2018). https://doi.org/10.3390/en11071648

Y. Ji, Y. Kwak, S.M. Park, Y.L. Kim, Opt. Express (2021). https://doi.org/10.1364/oe.420069

D.L. Frost, Shock Waves (2018). https://doi.org/10.1007/s00193-018-0825-1

N.N. Smirnov, Int. J. Heat Mass Transfer (1988). https://doi.org/10.1016/0017-9310(88)90135-4

Y. Fan, L. Chen, Z. Li, H. Xiang, Q. Fang, Def. Technol. (2022). https://doi.org/10.1016/j.dt.2022.02.005

H. Matsuo, K. Fujiwara, Phys. Fluids A (1990). https://doi.org/10.1063/1.857775

A.N. Huang, H.P. Kuo, Adv. Powder Technol. (2014). https://doi.org/10.1016/j.apt.2013.10.007

Acknowledgments

This research was funded by the National Nuclear Security Administration, Defense Nuclear Nonproliferation Research and Development (NNSA DNN R&D). The authors acknowledge important interdisciplinary collaboration with scientists and engineers from LANL, LLNL, MSTS, PNNL, and SNL.

Funding

Funding was provided by Office of Defense Nuclear Nonproliferation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is released by PNNL as: PNNL-SA-177766.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hubbard, L., Reed, C., Bautista, A. et al. Particulate mass migration and mixing in cylindrically contained explosions. MRS Communications 13, 63–69 (2023). https://doi.org/10.1557/s43579-022-00312-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43579-022-00312-3