Abstract

The RILEM AAR-13 test procedure is not a test method by itself; rather it is a procedure applying alkali wrapping to concrete prisms during test exposure to assess the expansion potential of alkali-silica reaction. When combined with procedures of other test methods, for example AAR-10 or AAR-11, it becomes a full test procedure. The wrapping procedure described was originally proposed by a technical committee of the Japan Concrete Institute “Technical Committee on Performance Based Design and Maintenance Scenario with Controlling ASR Deterioration”. The procedure includes a detailed description of the materials to be used for wrapping, procedures for calculation of alkalinity of the solution that aims to simulate the pore solution of the concrete prism depending on the alkali content of the concrete, and finally specific procedures for storage and measurements of the prisms. The procedure of calculating the alkalinity of the solution to be applied for the wrapping is assumed to be conservative because no subtraction is made for assumed alkali binding by the hydrates or alkali absorption by the aggregates. The alkali content is estimated by adding the alkali contribution from all concrete constituents (except the aggregates) including the supplementary cementitious materials (SCMs).

Similar content being viewed by others

1 Foreword

For every concrete prism test assessing the expansion potential of alkali-silica reaction (ASR), there can be some uncontrolled effects of alkali leaching from concrete prisms during the test and/or of insufficient moisture supply. This can be mitigated by a wrapping procedure called “alkali-wrapping”, which is described in this recommendation.

The wrapping procedure described herein was originally proposed by a technical committee of the Japan Concrete Institute “Technical Committee on Performance Based Design and Maintenance Scenario with Controlling ASR Deterioration” [1]. In that test method, alkali leaching and potentially insufficient moisture supply are mitigated by wrapping the concrete prisms with wrapping material containing alkali solution that simulates the alkali concentration of the concrete pore solution.

Note 1: Alkali concentration is defined here as the concentration of alkali metal ions (Na+ + K+), balanced with hydroxide ions (OH−) in the pore solution. Note that in the presence of other ion species such as silicate, chloride, and sulfate anions, this balance might not be kept.

The wrapping method described herein only covers the specific part of alkali-wrapping of concrete prisms, and it is important to note that this procedure needs to be combined with the procedures of other test methods to become a “full” test procedure.

2 Scope

RILEM AAR-13 provides a wrapping method that aims to prevent loss of alkalis by providing an equilibrium of alkali concentration at the specimen surface while also supplying additional moisture for concrete prisms during expansion tests for ASR. This may be of particular relevance if the internal alkali content risks being reduced to a level below the alkali threshold level of the aggregate, or if the internal moisture level may drop, thus preventing further reaction.

The procedure includes a detailed description of the materials to be used for wrapping, procedures for calculation of alkalinity of the solution that aims to simulate the pore solution of the concrete prism depending on the alkali content of the concrete, and finally specific procedures for storage and measurements of the prisms.

The procedure of calculating the alkalinity of the solution to be applied for the wrapping is conservative because no subtraction is made for assumed alkali binding by the hydrates or alkali absorption by aggregates. The alkali content is estimated by adding the alkali contribution from all concrete constituents (except the aggregates) including the supplementary cementitious materials (SCMs). When all alkalis in the wrapping material are absorbed by a concrete prism until equilibrium is reached at the interface, the total alkali content may increase as much as 20% [2].

AAR-13 should be used in combination with various concrete prism tests such as RILEM AAR-3 & AAR-4.1 and CSA-A23.2-14A-14 for aggregate testing, RILEM AAR-10 & AAR-11 for performance testing, and JASS5N T603 for actual concrete mixture with combinations of aggregate and binders considering various pessimum effects, as well as other ASR prism tests. When using AAR-13, for example, in combination with AAR-10 (either application 1 or 2), most details on apparatus, materials, mix design etc., stated in AAR-10 apply, while all details regarding alkali wrapping including some extra steps in measurement etc. is stated in AAR-13.

3 Principle

This procedure covers the wrapping of a concrete prism with wrapping material containing a water-based alkali solution. Unique to this procedure is the use of a solution that simulates the alkali concentration of the pore solution to saturate the wrapping material. By using alkali-wrapping, ideally, it is possible to control the alkali content in concrete without loss or gain of alkalis provided the alkali concentration of the pore solution of the concrete and the solution-holding wrapping material are designed to be in equilibrium.

The method is meant to minimize the exchange of alkalis in the concrete with its surroundings (ingress or leaching), while maintaining the supply of water to make sure ASR can progress. The method describes how to determine the alkali concentration of the solution used for wrapping.

From the water-based alkali solution in the wrapping material, some amount of alkalis can be absorbed by the concrete prisms through solution transport due to the consumption of water by cement hydration and ASR reaction in the concrete prisms. Due to the potential for loss of solution in the wrapping material itself, the mass of the wrapping material shall be determined for loss of solution every time a length measurement is taken. In case of mass loss, the reduced amount in the wrapping material shall be compensated for by adding water only (also see note 5).

Using AAR-13 together with any concrete prism test may, depending on conditions and mixture design, increase the expansion compared to expansion tests without alkali-wrapping. Limit values to maintain adequate laboratory/field correlation need to be considered on a national level for every method and climate aspects should also be considered.

4 Materials

4.1 Alkaline solution

To determine the alkali concentration of the solution used for wrapping, an estimate based on the actual mixture design must be done. An extensive overview with background information is given in Appendix A. A conservative approach is to consider that all alkalis from the binder (i.e. both Portland cement and SCMs) are available for dissolution in the pore solution.

To calculate the total Na2Oeq of the binder, following the conservative approach, Eq. (1) can be used:

where Na2Oeq,binder is the equivalent alkali content of the total binder (%), Na2Oeq,cem is the equivalent alkali content of the Portland cement (%), Na2Oeq,scm1 is the equivalent alkali content of the supplementary cementitious material 1 (SCM1, %), Na2Oeq,scm2 is the equivalent alkali content of the supplementary cementitious material 2 (SCM2, %), and so on for additional SCM. B is the total unit content of the binder per cubic meter of concrete (kg/m3), C is the unit content of the Portland cement per cubic meter of concrete (kg/m3), S1 is the unit content of SCM1 per cubic meter of concrete (kg/m3), S2 is the unit content of SCM2 per cubic meter of concrete (kg/m3), NaOH is the unit content of added NaOH per cubic meter of concrete (kg/m3) for alkali boosting, and so on. The factor \(\frac{61.98}{39.997\times 2}\) converts the unit of added NaOH (kg/m3) to Na2Oeq (kg/m3).

Note 2: Sodium hydroxide of at least technical grade (not less than 98% sodium hydroxide by mass) should be used.

Next, the alkali concentration (in mol/l) of the solution simulating the pore solution of the concrete can be calculated using Eq. (2):

W is the unit content of water (kg/m3). In case of no SCMs present in the concrete this equation reduces to:

To provide an example, a Portland cement is assumed with a Na2Oeq = 0.60%. The concrete is made with 320 kg/m3 cement and a water-to-cement ratio of 0.50, thus the water content is 160 kg/m3 without alkali boosting. Following Eq. (3), the alkali concentration is then [OH−] = (0.386 × 0.60 × 320)/160 = 0.46 mol/L.

The concentration of 0.46 mol/L corresponds to the alkali concentration of relatively low alkali Portland cement paste.

For an example using fly ash, a Portland cement with a Na2Oeq = 0.60% and fly ash with a Na2Oeq = 1.00% are assumed. The concrete is made with 280 kg/m3 cement, 40 kg/m3 fly ash and a water-to-binder ratio of 0.50, thus the water content is 160 kg/m3. Following Eq. (2) the alkali concentration is then [OH−] = {0.386 × (0.60 × 280 + 1.00 × 40)}/160 = 0.50 mol/L.

If the total alkali content is boosted by adding NaOH solution, the equivalent alkali content of the total binder is also calculated according to Eq. (2). For an example of alkali boosting, a Portland cement is assumed with a Na2Oeq = 0.60%. The concrete is made with 320 kg/m3 cement and a water-to-cement ratio of 0.50, thus the water content is 160 kg/m3. The total alkali content of concrete is boosted to 5.50 kg/m3 by adding 4.62 kg/m3 NaOH, resulting in an equivalent alkali content of the total binder (Na2Oeq,binder) of (5.50 / 320) × 100% = 1.72%. Following Eq. (2) the alkali concentration is then [OH−] = (0.386 × 1.72 × 320)/160 = 1.33 mol/L.

4.2 Wrapping material and cling film

The concrete prisms are wrapped with wrapping material containing the simulated alkaline pore solution. The material shall be large enough to wrap the concrete prism. Furthermore, the material shall be able to withstand high pH while also able to absorb and contain a high alkaline solution for the duration of the test and at elevated temperatures.

Wrapping material of natural fiber or cotton cloth are unsuitable materials for this purpose because they will be disintegrated at high alkali concentration over the duration of the test. Good results have been obtained with a polypropylene fiber-based wrapping material, see Note 3. For the remaining part of this document, wrapping material will be used as the general term.

Note 3: As an example of wrapping material that has provided acceptable results is the non-woven cloth KimTeX© Pop-up White wipers (355 × 425 mm) made from polypropylene fiber (product ID 60,701, Nippon Paper Crecia Co., Ltd.). This size is fit for 75 × 75 × 250 mm prism by a single sheet and for 100 × 100 × 400 mm prisms by two sheets. For reference, the weight of one sheet is 12.6 g and nearly 50 g of water can be retained when a sheet fully absorbs the water.

After the specimens have been wrapped in wrapping material containing simulated alkaline pore solution, they are next wrapped in cling film to keep the specimen from drying out. Ordinary kitchen cling film can be used for this purpose.

5 Sample preparation

5.1 Alkali-supplying of the wrapping material

Each specimen must be wrapped in wrapping material containing NaOH solution of appropriate concentration. To calculate the appropriate concentration, see Sect. 4.1.

To be able to calculate if any solution is lost from the wrapping material during the accelerated ASR exposure testing, the mass of the wrapping material must be determined at every measurement.

The NaOH solution simulating the pore solution concentration is prepared and an appropriate amount is supplied to the wrapping material: the wrapping material should contain sufficient amount of solution in order to supply moisture to the specimen. A sheet of 100 cm2 must be able to maintain an amount of 3.3 g of alkali solution without significant dripping (see Note 4).

Note 4: Caution: The NaOH solution is highly alkaline; therefore, this step must always be done wearing proper protective personal equipment (PPE).

Note 5: 3.3 g of alkaline solution per 100 cm2 of a sheet of wrapping material corresponds to the maximum amount of solution absorbed in a sheet of wrapping material (50 g per sheet as shown in Note 3). If the wrapping material is much thicker or if the density is lower, it will absorb more solution. The thickness and density may have an influence on the moisture supply to a concrete prism to some extent and further investigations will be necessary for thick wrapping material to be applied.

5.2 Wrapping procedure

Each prism is wrapped in a single piece of wrapping material for the size of 75 × 75 × 250 mm and in two pieces of wrapping material for concrete prisms of 100 × 100 × 400 mm. After the concrete prisms have been wrapped in wrapping material, they should next be wrapped in cling film to prevent drying out.

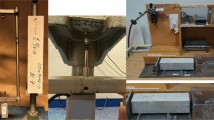

Examples of wrapping procedure of a concrete prism of 75 × 75 × 250 mm and 100 × 100 × 400 mm by wrapping material with alkali solution are shown in Figs. 1 and 2, respectively.

-

(1)

Measure the wrapping material’s mass before supplying NaOH solution.

-

(2)

Prepare a plastic sheet to avoid contamination of the benchtop or floor by alkali solution during the wrapping process.

-

(3)

Lay one piece (Fig. 1a) or two pieces (Fig. 2a) of wrapping material on top of a cling film over the plastic sheet and pour the prepared NaOH solution of appropriate amount and concentration to the wrapping material (Fig. 1b), Fig. 2 (b)).

-

(4)

Place a prism in the center of the solution-holding wrapping material (Fig. 1c), Fig. 2c).

-

(5)

Wrap the longitudinal side of the prism with the solution-holding wrapping material (Fig. 1d), Fig. 2d), taking care to leave no space between the prism and the solution-holding wrapping material. Then tape the wrapping material together (Fig. 1e), Fig. 2e).

-

(6)

Wrap both ends of the prism with the wrapping material and tape (Fig. 1f–g, Fig. 2f–g).

-

(7)

Wrap the long and short axes in two turns of cling film firmly (Fig. 1h–m, Fig. 2h–m).

-

(8)

Tape all the ends of the film firmly to avoid leaking of moisture through them (Fig. 1n–o, Fig. 2n–o).

5.3 Storage

The wrapped concrete prism should then be stored at the temperature and relative humidity for the duration of the testing period as specified in the (parent) ASR test method (e.g. AAR-10 or another test method). The specimens shall be removed from storage in accordance with the steps stated in Sect. 6 at the specified testing dates.

6 Additional steps in the measuring process

6.1 Cooling down before length measurement

Prior to each measurement, the prisms must be cooled to be able to handle the wrapping material as follows:

-

24 h prior to the measurement moment, remove the container from the storage room or cabinet. DO NOT OPEN the container!

-

Allow the prisms to cool down for 24 ± 2 h in the measuring room that is maintained at 20 ± 2 °C while the prisms remain inside the closed container.

Then the following additional steps are needed before taking a length measurement:

6.2 Unwrapping, rewrapping and length-change measurement

As the concrete prisms are wrapped, before any length measurement can be made, the specimens need to be unwrapped as follows:

-

1.

The cling film and the wrapping material must be removed carefully because the wrapping material should be reused.

-

2.

Measure length-change as described in the regular measurement procedures for the applied method.

-

3.

Determine the wrapping material’s mass to 1 g accuracy.

After length measurement, rewetting the wrapping material and rewrapping the specimen is required as follows:

-

4.

Re-wet the wrapping material with water (not alkaline solution) to keep the initial content of solution (3.3 g of per sheet of 100 cm2).

-

5.

Re-wrap the prism with the wrapping material and next by the cling film as described in 5.2

-

6.

Continue with the regular procedure for storing samples.

Note 6: If alkali solution would be used instead of pure water to compensate for the loss of liquid, the total amount of alkalis content in the concrete would increase by the uptake of solution with alkalis.

Note 7: Sometimes the wrapping material sticks firmly to the concrete and is broken into fine pieces, especially when alkali silica gel is exuded; this makes it difficult to remove the wrapping material. In general, this phenomenon happens after significant expansion. However, if new wrapping material (for any reason) is applied prior to reaching the critical expansion limit, whether wetted with water or with alkalis, test results may be affected. Therefore, the results after replacing the wrapping material can be reported but should be excluded from the basic test results; i.e. later test results should be discarded.

Note 8: If the amount of alkali leaching and/or supplying from the prims is to be determined, measure the alkali content of the water in the bottom of the container (see detailed procedure in RILEM AAR-10 annex F) as well as that of the wrapping material (see detailed procedure in [2]).

7 Additional reporting

In addition to the standard report for the applied method, the test report should also include the following items:

-

(a)

Mass change of the wrapping material at each measurement to 1 g.

-

(b)

Observations regarding the wrapping materials (broken, color-change, etc.).

References

Japan Concrete Institute: Committee report of JCI-TC-152A (2017) Technical committee on performance based design and maintenance scenario with controlling ASR deterioration, (in Japanese)

Kawabata Y, Yamada K, Sagawa Y, Ogawa S (2018) Alkali-wrapped concrete prism test—new testing protocol toward a performance test against alkali-silica reaction. J Adv Concr Technol 16:441–460

Yamada K, Kawabata Y, Kawakami T, Sagawa Y, Ogawa S (2021) AW-CPT as an ideal laboratory potential expansion test for ASR with constant alkali content and maximized water supply and the design of an alkali solution for wrapping. Proceedings of 16th International Conference on Alkali Aggregate Reaction in Concrete.

Kawabata Y, Yamada K (2015) Evaluation of alkalinity of pore solution based on the phase composition of cement hydrates with supplementary cementitious materials and its relation to suppressing ASR expansion. J Adv Concr Technol 13:538–553

Plusquellec G, Geiker MR, Lindgård J, Duchesne J, Fournier B, De Weerdt K (2017) Determination of the pH and the free alkali metal content in the pore solution of concrete: Review and experimental comparison. Cem Concr Res 96:13–26

Helmuth R (1993) Alkali-Silica Reactivity: An Overview of Research. SHRP-C-342, Strategic Highway Research Program, National Research Council, Washington, D. C.

Thomas M, Fournier B, Folliard K, Ideker J, Shehata M (2006) Test methods for evaluating preventive measures for controlling expansion due to alkali–silica reaction in concrete. Cem Concr Res 36:1842–1856

Vollpracht A, Lothenbach B, Snellings R, Haufe J (2016) The pore solution of blended cements: a review. Mater Struct 49:3341–3367

Lindgård J, Thomas MDA, Sellevold EJ, Pedersen B, Andiç-Çakır Ö, Justnes H, Rønning TF (2013) Alkali–silica reaction (ASR)—performance testing Influence of specimen pre-treatment, exposure conditions and prism size on alkali leaching and prism expansion. Cem Concr Res 53:68–90

Yamada K, Kawabata Y, Ogawa S, Haga K, Sagawa Y, Ochiai T (2017) Importance of alkali-wrapping for CPT. In: Sellier A, Grimal E, Multon S, Bourdarot E (eds) Swelling concrete in dams and hydraulic structures. Wiley, New York, pp 68–79

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This recommendation has been prepared by a working group within RILEM TC 258-AAA. The recommendation has been reviewed and approved by all members of the TC.

Chair: Børge Johannes WIGUM; Deputy Chair: Jan LINDGÅRD

TC Members: Mark G. ALEXANDER, Mario BERRA, Ingmar BORCHERS, Maarten BROEKMANS, Rene BRUECKNER, João CUSTÓDIO, Vinh DAO, Mario DE ROOIJ, Klaartje DE WEERDT, Josée DUCHESNE, Rui Miguel FERREIRA, Benoît FOURNIER, Sue FREITAG, Ricardo GARCIA-ROVES LOZA, Eric GIANNINI, Colin GIEBSON, Michal A. GLINICKI, R. Doug HOOTON, Jason H. IDEKER, Patricija KARA DE MAEIJER, Yuichiro KAWABATA, Stefan KRISPEL, Selmo C. KUPERMAN, Andreas LEEMANN, Lech LEWCZUK, Jan LINDGÅRD, Tung Chai LING, Qing-Feng LIU, Renaud-Pierre MARTIN, Esperanza MENENDEZ MENDEZ, Birgit MENG, Urs MÜLLER, Christoph MÜLLER, Bård M. PEDERSEN, Gilles PLUSQUELLEC, Terje F. RØNNING, Leandro SANCHEZ, Antonio SANTOS SILVA, Ignacio SEGURA, Katrin SEYFARTH, Gintautas SKRIPKIUNAS, Zhenguo SHI, Ian SIMS, Suvimol SUJJAVANICH, Michael D. A. THOMAS, Børge Johannes WIGUM, (late) Jonathan WOOD, Kazuo YAMADA.

Appendices

Appendix A

Determining the alkali concentration of solution for wrapping material

In this Appendix A, the scientific background of the alkali concentration of the solution is given.

It is well known that the main role of SCMs to inhibit ASR expansion is to reduce the alkalinity of the pore solution [4]. Also, a recent study in Norway has shown that only up to 60% of the alkalis from OPC will be soluble, and approximately 40% for a system with 30% fly ash [5]. The uptake of alkalis by C–A–S–H is attributed to the reaction of SCMs, leading to formation of C–A–S–H with lower Ca/(Al + Si) ratio. This reaction depends on the chemical composition and degree of hydration of the SCMs. The hydration of SCMs in concrete prism tests at higher temperature in the laboratory will be faster compared to concrete used in the field. At the same time, the effect of alkali binding in the laboratory resulting in ASR suppression could be higher compared to binding in the field. If the alkalis from SCMs are not taken into account for the total alkali calculation, the calculated alkali concentration in the pore solution might in some cases be underestimated when concrete is placed in cold climates and the pozzolanic reaction is limited. Therefore, to work from a worst-case scenario, all alkalis from SCMs are counted as a part of the total alkalis present in concrete. It should be noted that an example for estimating the alkali concentration of pore solution for a system with SCMs is presented in the paper [2], to consider the positive effect of SCMs.

Alkalis from other materials such as from chemical admixtures should also be counted in the calculation for the total alkali concentration. If known release sources, e.g. sea-dredged sand is included as aggregate, it also should be counted as a part of the total alkalis in concrete. On the other hand, any potentially releasable alkalis from minerals in aggregates are at the moment not counted as part of the total alkalis in concrete because of the lack of knowledge regarding alkali release rate and/or amount and their contribution to pH in the pore solution.

In addition to the amount of alkalis released from sources as discussed above, the alkali concentration of the pore solution is also affected by the amount of free water in the concrete. This effect is included in the calculation through the unit mass of water (W) in the concrete.

There are many ways to estimate the alkali concentration of the pore solution in concrete, normally expressed in mol/l. Helmuth [6] formulated equation (A1) to show the relationship between the alkali content of cement and OH− concentration in pore solution based on experiments:

where [OH−] is the hydroxide ion concentration in the pore solution, Na2Oeq,cem is the equivalent alkali content of the cement, and W/C is the water-to-cement ratio.

Thomas et al. [7] formulated an equation based on review of pore solution data. Kawabata and Yamada [4] calculated the hydroxide ion concentrations of cement with various SCMs, taking the interaction of alkali metal ion (Na, K) between C–S–H gel and pore solution into consideration. As a result, a simple relationship between the alkali content of Portland cement and the hydroxide ion concentration for a water-to-cement ratio of 0.50 was determined.

The comparison of these relationships, with some experimental results, are summarized in Fig.

Alkali content of ordinary Portland cement and hydroxide ion concentration in pore solution. (Modified from [2])

3. As expected, there are large variations in the hydroxide ion concentration [8].

In order to calculate [OH−] in the pore solution from the equivalent alkali content of the cement, Kawabata and Yamada reviewed the previous studies and the representative and simple relationship was obtained as follows (A2) [4]:

This equation was developed for Portland cement paste with water-to-cement ratio of 0.50.

Finally, Eq. (A3) is proposed in order to apply this calculation to various mixture proportions, especially for calibrating the effect of water-to-cement ratios with reference to Eq. (A1).

Equation (A3) was established based on the experiments of cement paste or mortar with water-to-cement ratios higher than 0.45. Therefore, care should be taken when applying this calculation to concrete with a very low water-to-cement ratio (e.g. 0.35). Also, Eq. (A3) can provide an estimation for the alkali concentration of pore solution of cement paste but is not a perfect solution for the alkali concentration of the pore solution in concrete since it strongly depends on various concrete properties such as characteristics of aggregate (especially alkali absorption) and exposed environments. However, it is difficult to include the influence of aggregate and environments in the estimation of the alkali concentration of the pore solution in concrete. Therefore, it is assumed that the alkali concentration of the pore solution in concrete is assumed equivalent to that in cement paste.

In order to extend Eq. (A3) from cement paste to the estimation of alkali concentration of concrete with SCMs, the equivalent alkali content of the total binder, which is calculated from all the binder as well as alkaline solution for boosting, is to used:

where Na2Oeq,binder is the equivalent alkali content of the total binder (%), Na2Oeq,cem is the equivalent alkali content of the Portland cement (%), Na2Oeq,scm1 is the equivalent alkali content of the supplementary cementitious material 1 (SCM1, %), Na2Oeq,scm2 is the equivalent alkali content of the supplementary cementitious material 2 (SCM2, %), and so on. B is the total unit content of the binder (kg/m3), C is the unit content of the Portland cement, S1 is the unit content of SCM1 (kg/m3), S2 is the unit content of SCM2 (kg/m3), NaOH is the unit content of NaOH (kg/m3), and so on.

Finally, replacing Na2Oeq,cem and C by Na2Oeq,binder and B, respectively, Eq. (A5) is obtained. Note that this equation might give a conservative value since the uptake of alkalis by C-A-S–H is not taken into account.

Examples of calculated results by Eq. (A5) are shown in Fig.

Examples of calculation with Eq. (A5) a Influence of water-binder ratio b Influence of equivalent alkali content of the total binder

4. In this estimation, alkali uptake by C(–A)–S–H with lower Ca/(Al + Si) ratio is not considered because of lack of experimental data. A specific example considering the effect of alkali uptake is shown in a reference [2].

As alkali concentration of the pore solution of concrete changes with time, it is quite difficult to quantify the concentration accurately. The following factors affect the alkali concentration:

-

(1)

Alkali concentration of cement and SCMs.

-

(2)

Degree of hydration of alkali bearing phases of cement and SCMs.

-

(3)

Alkali absorption by, or release from aggregate depending on the nature of aggregate.

-

(4)

Alkali adsorption by C–A–S–H with low Ca/(Si + Al) ratio.

-

(5)

Alkali consumption by alkali-silica reaction products.

-

(6)

Water suction from solution-holding wrapping material by water consumption due to cement hydration and ASR.

-

(7)

Age and curing condition depending on factors above.

Therefore, it is necessary to make an assumption on how the alkali concentration of the pore solution of concrete is determined. The highest alkali concentration of pore solution is obtained for the case considering only 1) and assuming all other effects to be negligible. As a test method, AAR-13 assumes the worst case. Furthermore, if all the alkalis originally present in the wrapping material are absorbed by a concrete prism, the total increase of total alkalis is limited to as much as 20% of the originally present alkali level in the pore solution of the concrete prism [2]. The important point of AAR-13 is in controlling the total alkali content in the concrete prism without leaching alkalis (e.g. 10–40% [9]) while maintaining sufficient supply of water.

According to the most recent research results [10], alkalis in wrapping material may move from the wrapping material to the concrete prism even in the case of equilibrium in alkali concentration between the wrapping material and the pore solution of the concrete prism. Even in the case of non-reactive aggregate, carbonation of cement paste, and moisture imbibition affect the movement of alkalis. Through carbonation of cement paste, alumino-silica gel is formed, and a significant amount of alkalis are absorbed. Alkali-silica reaction products formed inside the concrete consume alkalis and reduce the alkali concentration in the pore solution, resulting in ingress of alkalis from the wrapping material by diffusion. An even more complicated issue is that for certain aggregates, significant amounts of alkali-silica reaction products can exude or leak from prisms and this changes the reactivity of the aggregate and the acceleration conditions. Higher reactivity and more severe conditions thus can result in more exudations and less final expansion.

Rights and permissions

About this article

Cite this article

Yamada, K., Kawabata, Y., de Rooij, M.R. et al. Recommendation of RILEM TC 258-AAA: RILEM AAR-13: application of alkali-wrapping for concrete prism testing to assess the expansion potential of alkali-silica reaction. Mater Struct 54, 201 (2021). https://doi.org/10.1617/s11527-021-01684-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-021-01684-z