Abstract

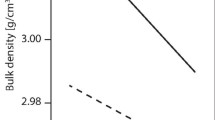

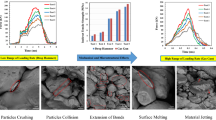

Al 6061100–x–x wt % B4C (x = 0, 5, 10, 20, 30 and 40) composites, prepared by mechanical alloying and compacted at room temperature, have been used for the present investigation. The effects of B4C content and milling time on the powder morphology, powder particle size, and other powder characteristics such as the apparent density, tap density, flow rate, cohesiveness, and hausner ratio are systematically investigated. The steady state of milling process is determined by observing the correlation between apparent densities and milling time explained by the morphological evolution of the powder particles during the milling process. The Hausner ratio (HR), estimated to evaluate friction between the particles, decreases with an increase in milling duration and B4C content due to the changes in morphology and hardness of the powders. The compressibility behavior of post-compacts as a function of compaction pressure and the B4C content was analyzed by using several linear and non-linear powder compaction equations. The linear Panelli and Ambrozio Filho, and non-linear Van Der Zwan and Siskens equations give the highest regression coefficients. The results are explained in terms of the plastic deformation capacity and plastic deformation coefficient of the powders, which are influenced by the hardness and the morphology of the powder. After compaction, the supersolidus liquid phase sintering was performed at various temperatures (585, 610 and 630°C) under high purity nitrogen atmosphere. The results revealed that the sinterability was degraded by increasing the reinforcement content, particularly above 10 wt % B4C. Neutron radiography measurements conducted on the rolled composite sheet have revealed the uniform distribution of B4C particles in the composite.

Similar content being viewed by others

References

Miracle, D.B., Metal matrix composites—from science to technological significance, Compos. Sci. Technol., 2005, vol. 65, pp. 2526–2540.

Smagorinski, M.E., Tsantrizos, P.G., Grenier, S., Cavasin, A., Brzezinski, T., and Kim, G., The properties and microstructure of Al-based composites reinforced with ceramic particles, Mater. Sci. Eng. A, 1988, vol. 244, pp. 86–90.

Harrigan, Jr.W.C., Commercial processing of metal matrix composites, Mater. Sci. Eng. A, 1988, vol. 244, pp. 75–79.

Kaczmar, J.W., Pietrzak, K., and Wlosinski, W., The production and application of metal matrix composite materials, J. Mater. Process. Technol., 2000, vol. 106, pp. 58–67.

Chen, X.-G. and Hark, R., Development of Al–30% B4C metal matrix composites for neutron absorber material, in Proceedings of Aluminium Alloys: Fabrication, Characerization and Applications, Yin, W. and Das S.K., Eds., TMS, (2008), pp. 3–7.

Bonnet, G., Rohr, V., Chen, X.-G., Bernier, J.L., Chiocca, R., and Issard, H., Use of alcan’s Al–B4C metal matrix composites as neutron absorber material in TN international’s transportation and storage casks, Pack. Trans. Stor. Secur. Radioact. Mater., 2009, vol. 20, pp. 98–108.

Zhang, J., Guan, R-G., Tie, D., Wang, X., Guan, X., Chen, B., and Chen, Y., Effects of technical parameters of semi-solid stirring and rheo-rolling on microstructure of A356—5 wt % B4C composite strip, Mater. Manuf. Proc., 2015, vol. 30, pp. 340–345.

Lashgari, H.R., Sufizadeh, A.R., and Emamy, M., The effect of strontium on the microstructure and wear properties of A356—10% B4C cast composites, Mater. Des., 2010, vol. 31, pp. 2187–2195.

Toptan, F., Kilicarslan, A., Karaaslan, A., Cigdem, M., and Kerti, I., Processing and microstructural characterization of AA 1070 and AA 6063 matrix B4Cp reinforced composites, Mater. Des., 2010, vol. 31, pp. S87–S91.

Kalaiselvan, K., Murugan, N., and Parameswaran, S., Production and characterization of AA 6061–B4C stir cast composite, Mater. Des., 2011, vol. 32, pp. 4004–4009.

Khakbiz, M. and Akhlaghi, F., Synthesis and structural characterization of Al–B4C nano-composite powders by mechanical alloying, J. Alloys Compd., 2009, vol. 479, pp. 334–341.

Mohanty, R.M., Balasubramaniana, K., and Seshadri, S.K., Boron carbide-reinforced aluminium 1100 matrix composites: Fabrication and properties, Mater. Sci. Eng. A, 2008, vol. 498, pp. 42–52.

Jeyasimman, D., Sivasankaran, S., Sivaprasad, K., Narayanasamy, R., and Kambali, R.S., An investigation of the synthesis, consolidation and mechanical behaviour of Al 6061 nanocomposites reinforced by TiC via mechanical alloying, Mater. Des., 2014, vol. 57, pp. 394–404.

Sivasankaran, S., Sivaprasad, K., Narayanasamy, R., and Iyer, V.K., Evaluation of compaction equations and prediction using adaptive neuro-fuzzy inference system on compressibility behavior of AA 6061100–x–x wt % TiO2 nanocomposites prepared by mechanical alloying, Powder Technol., 2011, vol. 209, pp. 124–137.

Zhang, Z., Fortin, K., Charette, A., and Chen, X.-G., Effect of titanium on microstructure and fluidity of Al–B4C composites, J. Mater. Sci., 2011, vol. 46, pp. 3176–3185.

Varol, T. and Canakci, A., Effect of particle size and ratio of B4C reinforcement on properties and morphology of nanocrystalline Al2024–B4C composite powders, Powder Technol., 2013, vol. 246, pp. 462–472.

Asghar, Z. and Zahid, G.H., Rafi-ud-din, Ahmad, E., and Mehmood, M., Effect of degassing parameters on the sinterability of Al/B4C composite, Powder Metall., 2015, vol. 58, pp. 36–40.

Sivasankaran, S., Sivaprasad, K., Narayanasamy, R., and Iyer, V.K., An investigation on flowability and compressibility of AA6061 100–x–x wt % TiO2 micro and nanocomposite powder prepared by blending and mechanical alloying, Powder Technol., 2010, vol. 201, pp. 70–82.

Chen, H.S., Wang, W.X., Li, Y.L., Zhang, P., Nie, H.H., and Wu, Q.C., The design, microstructure and tensile properties of B4C particulate reinforced 6061Al neutron absorber composites, J. Alloys Compd., 2015, vol. 632, pp. 23–29.

Gan, K. and Gu, M., The compressibility of Cu/SiCp powder prepared by high-energy ball milling, J. Mater. Process. Sci. Technol., pp. 199,173.

Zhao, N., Nash, P., and Yang, X., The effect of mechanical alloying on SiC distribution and the properties of 6061 aluminum composite, J. Mater. Process. Sci. Technol., 2005, vol. 170, pp. 586–592.

Abenojar, J., Velasco, F., and Mart’inez, M.A., Optimization of processing parameters for the Al + 10% B4C system obtained by mechanical alloying, J. Mater. Process. Sci. Technol., 2007, vol. 184, pp. 441–446.

Alizadeh, A. and Taheri-Nassaj, E., H. Baharvandi, R., Preparation and investigation of Al–4 wt % B4C nanocomposite powders using mechanical milling, Bull. Mater. Sci., 2011, vol. 34, pp. 1039–1048.

Moazami-Goudarzi, M. and Akhlaghi, F., Effect of nanosized SiC particles addition to CP Al and Al–Mg powders on their compaction behavior, Powder Technol., 2013, vol. 245, pp. 126–133.

Joa, B., Fogagnolo, B., Ruiz-Navas, E.M., Robert, M., Jose, H., and Torralba, M., The effects of mechanical alloying on the compressibility of aluminium matrix composite powder, Mater. Sci. Eng. A, 2003, vol. 355, pp. 50–55.

Fogagnolo, J.B., Velasco, F., Robert, M.H., and Torralba, J.M., Effect of mechanical alloying on the morphology, microstructure and properties of aluminium matrix composite powder, Mater. Sci. Eng. A, 2003, vol. 342, pp. 131–143.

Powder metal technologies and applications, ASM Handbook, vol. 7. Materials Park (OH), 1998.

Kawakita, K. and Ludde, K.-H., Some considerations on powder compression equations, Powder Technol., 1971, vol. 4, pp. 61–68.

Elomari, S., Skibo, M.D., Sundarrajan, A., and Richards, H., Thermal expansion behavior of particulate metal-matrix composites, Compos. Sci. Technol., 1998, vol. 58, pp. 369–376.

Hong, S.J. and Kao, P.W., SiC-reinforced aluminum composite made by resistance sintering of mechanically alloyed powders, Mater. Sci. Eng. A, 1989, vol. 119, pp. 153–159.

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

About this article

Cite this article

Din, R.U., Shafqat, Q.A., Asghar, Z. et al. Microstructural Evolution, Powder Characteristics, Compaction Behavior and Sinterability of Al 6061–B4C Composites as a Function of Reinforcement Content and Milling Times. Russ. J. Non-ferrous Metals 59, 207–222 (2018). https://doi.org/10.3103/S1067821218020098

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821218020098