Abstract

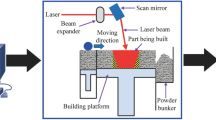

Additive manufacturing (AM) of the nickel–titanium (NiTi) shape memory alloys (SMA) have provided novel component solutions with a variety of design configurations in the industry. Electron beam melting (EBM) is a trending metal additive manufacturing process for industrial applications in the field of biomedical and aerospace engineering. In this study, experimental investigations were conducted to reveal the effect of processing conditions on the microstructure and hardness properties of EBM-fabricated nickel-titanium components. Furthermore, detailed microstructural characterizations were performed with a scanning electron microscope, EDS, and XRD for unveiling of the microscopic structure and phase analysis during the layer by layer solidification. The experimental results were systematically evaluated for the powder and the bulk prismatic components, respectively.

Similar content being viewed by others

REFERENCES

ASTM Committee F42 on Additive Manufacturing Technologies.

Lee, A.Y., An, J., and Chua, C.K., Two-way 4D printing: A review on the reversibility of 3D-printed shape memory materials, Engineering, 2017, vol. 3, no. 5, p. 663.

Shishkovsky, I., Yadroitsev, I., and Smurov, I., Direct selective laser melting of nitinol powder, Phys. Procedia, 2012, vol. 39, p. 447.

Jahadakbar, A., Moghaddam, N.S., Amerinatanzi, A., Dean, D., and Elahinia, M., Mechanical evaluation of the SLM fabricated, stiffness-matched, mandibular bone fixation plates, Proc. SPIE, 2018, vol. 10596, p. 1059610.

Shiva, S., Palani, I.A., Mishra, S.K., Paul, C.P., and Kukreja, L.M., Investigations on the influence of composition in the development of Ni–Ti shape memory alloy using laser based additive manufacturing, Opt. Laser Technol., 2015, vol. 69, p. 44.

Altug-Peduk, G.S., Dilibal, S., Harrysson, O.L.A., Ozbek, S., and West, H., Characterization of N–Ti alloy powders for use in additive manufacturing, Russ. J. Non-Ferrous Met., 2018, vol. 59, p. 433.

Murr, L.E., Metallurgy of additive manufacturing: Examples from electron beam melting, Addit. Manuf., 2015, vol. 5, p. 40.

Frigola, P., Harrysson, O.L.A., and Ramirez, D.A., Fabricating copper components with electron beam melting, Adv. Mater. Processes, 2014, vol. 152, p. 20.

Kumar, S., Marandi, L., Balla, V.K., Bysakh, S., Piorunek, D., Eggeler, G., Das, M., and Sen, I., Microstructure—Property correlations for additively manufactured NiTi based shape memory alloys, Materialia, 2019, vol. 8, p. 15.

Farber, E., Zhu, J., Popovich, A., and Popovich, V., A review of NiTi shape memory alloy as a smart material produced by additive manufacturing, Mater. Today: Proc., 2020, vol. 30, p. 761. https://doi.org/10.1016/j.matpr.2020.01.563

Oliveira, J.P., Cavaleiro, A.J., Schell, N., Stark, Andreas, Miranda, R.M., Ocana, J.L., and Braz Fernandes, F.M., Effects of laser processing on the transformation characteristics of NiTi: A contribute to additive manufacturing, Scr. Mater., 2018, vol. 152, p. 124.

Parvizi, S., Hashemi, S.M., Asgarinia, F., Nematollahi, M., and Elahinia, M., Effective parameters on the final properties of NiTi-based alloys manufactured by powder metallurgy methods: A review, Prog. Mater. Sci., 2020, vol. 117, p. 100739. https://doi.org/10.1016/j.pmatsci.2020.100739

Wang, C., Tan, X.P., Du, Z., Chandra, S., Sun, Z., Lim, C.W.J., Tor, S.B., Lim, C.S., and Wong, C.H., Additive manufacturing of NiTi shape memory alloys using pre-mixed powders, J. Mater. Process. Technol., 2019, vol. 271, p. 153.

Yoder, S., Morgan, S., Kinzy, C., Barnes, E., Kirka, M., Paquit, V., Nandwana, P., Plotkowski, A., Dehoff, R.R., and Babu, S.S., Characterization of topology optimized Ti–6Al–4V components using electron beam powder bed fusion, Addit. Manuf., 2018, vol. 19, pp. 184–196.

Ataee, A., Li, Y., and Wen, C., Metal scaffolds processed by electron beam melting for biomedical applications, in Metallic Foam Bone, Processing, Modification and Characterization and Properties, Elsevier Science, 2017, p. 83.

Vock, S., Klöden, B., Kirchner, A., et al., Powders for powder bed fusion: a review, Prog. Addit. Manuf., 2019, vol. 4, p. 383.

Espiritu, E.R.L., Kumar, A., Nommeots-Nomm, A., et al., Investigation of the rotating drum technique to characterise powder flow in controlled and low pressure environments, Powder Technol., 2020, vol. 366, p. 925.

Chen, H., Chen, Y., Liu, Y., Wei, Q., Shi, Y., and Yan, W., Packing quality of powder layer during counter-rolling-type powder spreading process in additive manufacturing, Int. J. Mach. Tools Manuf., 2020, vol. 153, article no. 103553.

Ashgriz, N., Handbook of Atomization and Sprays: Theory and Applications, Springer, 2011.

Shabalovskaya, S., Anderegg, J., and Van Humbeeck, J., Recent observations of particulates in Nitinol, Mater. Sci. Eng., A, 2008, vol. 481, p. 431.

Massalski, T.B., Okamoto, H., and Subramanian, P.R., Binary Alloy Phase Diagrams, Materials Park, OH: ASM Int., 1990, vol. 3, p. 2874.

Otsuka, K. and Wayman, C.M., Shape Memory Materials, Cambridge: Cambridge Univ. Press, 1988, p. 49.

Khamei, A. and Dehghani, K., Microstructural evolution during the hot deformation of Ti-55Ni (at. pct) intermetallic alloy, Metall. Mater. Trans. A, 2010, vol. 41, p. 2595.

Roy, N., Samuel, A.M., and Samuel, F.H., Porosity formation in Al–9 wt % Si–3 wt % Cu alloy systems: Metallographic observations, Metall. Mater. Trans. A, 1996, vol. 27, p. 415.

Thier, M., Hühner, M., Kobus, E., Drescher, D., and Bourauel, C., Microstructure of As-cast NiTi alloy, Mater. Charact., 1991, vol. 27, p. 133.

Mohd Zaki, H.H., Solid state synthesis of NiTi, MSc Thesis, Univ. of Western Australia, 2011.

Bormann, T., Muller, B., Schinhammer, M., Kessler, A., Thalmann, P., and Wild, M., Microstructure of selective laser melted nickel–titanium, Mater. Charact., 2014, vol. 94, p. 189.

Sames, W.J., List, F.A., Pannala, S., Dehoff, R.R., and Babu, S.S., The metallurgy and processing science of metal additive manufacturing, Int. Mater. Rev., 2016, vol. 61, no. 5, p. 315.

Prokoshkin, S.D., Korotitskiy, A.V., Brailovski, V., Turenne, S., Khmelevskaya, I.Yu., and Trubitsyna, I.B., On the lattice parameters of phases in binary Ti–Ni shape memory alloys, Acta Mater., 2004, vol. 52, no. 15, pp. 4479–4492.

Prokoshkin, S.D., Korotitskiy, A.V., Brailovski, V., Inaekyan, K.E., and Dubinskiy, S.M., Crystal lattice of martensite and the reserve of recoverable strain of thermally and thermomechanically treated Ti–Ni shape-memory alloys, Phys. Met. Metallogr., 2011, vol. 112, no. 2, pp. 170–187.

Adharapurapu, R.R., Jiang, F., and Vecchio, K.S., Aging effects on hardness and dynamic compressive behavior of Ti–55Ni (at %) alloy, Mater. Sci. Eng., A, 2010, vol. 527, p. 1665.

Lucas, F.L.C., Guido, V., Kafer, K.A., Bernardi, H.H., and Otubo, J., ECAE processed NiTi shape memory alloy, Mater. Res., 2014, vol. 17, p. 186.

Saedi, S., Turabi, A.S., Andani, M.T., Moghaddam, N.S., Elahinia, M., and Karaca, H.E., Texture, aging, and superelasticity of selective laser melting fabricated Ni-rich NiTi alloys, Mater. Sci. Eng., A, 2017, vol. 686, p. 8.

Jiang, S.Y., Zhao, Y.N., Zhang, Y.G., Hu, L., and Liang, Y.L., Effect of solution treatment and aging on microstructural evolution and mechanical behavior of NiTi shape memory alloy, Trans. Nonferrous Met. Soc. China, 2013, vol. 23, p. 3658.

Zuback, J.S. and DebRoy, T., The hardness of additively manufactured alloys, Materials (Basel), 2018, vol. 11, p. 28.

Dilibal, S., Hamilton, R.F., and Lanba, A., The effect of employed loading mode on the mechanical cyclic stabilization of NiTi shape memory alloys, Intermetallics, 2017, vol. 89, p. 6.

Moghaddam, N.S., Saedi, S., Amerinatanzi, A., Hinojos, A., Ramazani, A., Kundin, J., Mills, M.J., Karaca, H., and Elahinia, M., Achieving superelasticity in additively manufactured NiTi in compression without post-process heat treatment, Sci. Rep., 2019, vol. 9, p. 7.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors state that they have no conflict of interest.

About this article

Cite this article

Altug-Peduk, G., Dilibal, S., Harrysson, O. et al. Experimental Investigation on the EBM-Based Additively Manufactured Prismatic Nickel–Titanium SMA Components. Russ. J. Non-ferrous Metals 62, 357–367 (2021). https://doi.org/10.3103/S1067821221030020

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821221030020