Abstract

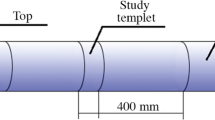

The results of experimental studies on the development of a method for obtaining titanium-containing bar ligature, the study of its structure and modifying ability are presented. The distinctive features of the new technology are the use of titanium sponge and/or titanium shavings as titanium raw materials, the primary alloying of aluminum with titanium, and then boron, the introduction of titanium in two stages: initially, 2/3 of the titanium metal raw materials are dissolved in the aluminum melt, and the remaining amount is introduced after the reduction of potassium tetrafluoroborate. Pre-impregnation of the titanium sponge with halide-containing flux and the use of a briquetted mixture of KBF4 + Al-powder are also provided. The experimental technology for the preparation of the Al–Ti–B melt is described, the extraction of titanium and boron into the ligature is calculated, its microstructure is investigated, and the chemical and molecular compositions of the resulting slags are determined. Deformation treatment for the production of bar ligature was carried out by the method of direct extrolling which made it possible to level the defects of the cast structure. It is established that the use of high-speed crystallization-deformation in the implementation of the combined direct extrolling process makes it possible to obtain alloying bars of a given diameter at minimal energy consumption with the required complex of mechanical and operational properties. A quantitative assessment of the modifying ability of the experimental cast-iron ligature and the deformed cast-iron rod obtained by the direct extrolling method was carried out in comparison with the mass-produced cast-iron ligature produced by KBM Affilips (the Netherlands/Belgium). Based on theoretical and experimental studies, the composition and technology for producing Al–Ti–B modifying ligature using titanium sponge and/or shavings and potassium tetrafluoroborate with a content of 3.0 ± 0.3% titanium and 1.0 ± 0.2% boron as alloying additives have been developed, which meets the requirements for the composition of aluminum ligatures.

Similar content being viewed by others

REFERENCES

Rosenhain, W., Grogan, J., and Schofield, T. Gas removal and grain refinement of aluminum alloys, Foundry Trade J., 1930, vol. 43, pp. 177–180.

Sigworth, G.K., The grain refining of aluminum and phase relationships in the Al-Ti-B system, Metall. Trans. A, 1984, vol. 15, no. 2, pp. 277–282.

Sigworth, G.K. and Kuhn, T.A., Grain refinement of aluminum casting alloys, Int. J. Metalcast., 2007, vol. 1, no. 1, pp. 31–40.

Napalkov, V.I., Bondarev, B.I., Tararyshkin, V.Ch., and Chukhrov, M.V., Ligatury dlya proizvodstva alyuminievykh i magnievykh splavov (Ligatures for the Production of Aluminum and Magnesium Alloys), Moscow: Metallurgiya, 1983.

Amulya, B., Satyabrat, D., Bharat, B., and Nedumbilly, P., Effect of Al-5Ti-1B grain refiner on the microstructure, mechanical properties and acoustic emission characteristics of Al5052 aluminium alloy, J. Mater. Res. Technol., 2015, vol. 4, pp. 171–179.

Birol, Y., An improved practice to manufacture Al–Ti–B master alloys by reacting halide salts with molten aluminium, J. Alloys Compd., 2006, vol. 420, pp. 71–76.

Quested, T.E., Greer, A.L., and Cooper, P.S., The variable potency of TiB2 nucleates particles in the grain refinement of aluminum by Al–Ti–B additions, Mater. Sci. Forum, 2002, vols. 396–402, pp. 53–58.

Venkateswarlu, K., Murty, B.S., and Chakraborty, M., Effect of hot rolling and heat treatment of Al–5Ti–1B master alloy on the grain refining efficiency of aluminum, Mater. Sci. Eng., A, 2001, vol. 301, pp. 180–186.

Quested, T.E., Understanding the mechanisms of grain refinement by inoculation, Mater. Sci. Technol., 2004, vol. 20, pp. 1357–1369.

Wang, X. and Han, Q., Grain refinement mechanism of aluminum by Ai–Ti–B master alloys, in Light Metals, Williams, E., Ed., Cham: Springer, 2016, pp. 187–193.

Birol, Y., Production of Al–Ti–B grain refining master alloys from Na2B4O7 and K2TiF6, J. Alloys Compd., 2007, vol. 458, nos. 1–2, pp. 271–276.

Shu, D., Sun, B.D., Mi, J.W., and Grant, P.S., Refinement of TiB2 in Al–Ti–B grain refiner alloys by ultrasound and the effect on Al grain size, Mater. Sci. Forum, 2010. vols. 654–656, pp. 958–961.

Cheglakov, V.V., Shpakov, V.I., and Mamina, L.I., Influence of Al–Ti–B ligature preparation conditions on the degree of boron transition from its salts, Liteinoe Proizvod., 2001, no. 1, pp. 20–22.

Kostin, I.V., Bezrukikh, A.I., Belyaev, S.V., Frolov, V.F., Gubanov, I.Y., Lesiv, E.M., and Stepanenko, N.A., Study of modification technology for casting flat bars 5XXX series, J. Sib. Fed. Univ., Chem., 2017, vol. 10, no. 1, pp. 90–98.

Nikitin, V.I., Wanqi, J.I.E., Kandalova, E.G., Makarenko, A.G., and Yonk, L., Preparation of Al–Ti–B grain refiner by SHS technology, Scr. Mater., 2000, vol. 42, pp. 561–566.

Dai, W., Wang, X., Zhao, W., and Han, Q., A Comparison of the effects of Al–Ti–B type grain refiners from different makers on pure aluminum, Light Met., 2014, no. 1, pp. 945–949.

Casari, D., Merlin, M., and Garagnani, G., A comparative study on the effects of three commercial Ti-B-based grain refiners on the impact properties of A356 cast aluminium alloy, J. Mater. Sci., 2013, vol. 48, pp. 4365–4377.

Sidel’nikov, S.B., Lopatina, E.S., Dovzhenko, N.N., Drozdova, T.N., Belyaev, S.V., Baranov, V.N., Konstantinov, I.L., Sidel’nikov, A.S., and Berspalov, V.M., Osobennosti strukturoobrazovaniya i svoistva metalla pri vysokoskorostnoi kristallizatsii-deformatsii i modifitsirovanii alyuminievykh splavov (Features of Structure Formation and Properties of Metal During High-Speed Crystallization-Deformation and Modification of Aluminum Alloys), Krasnoyarsk: Siberian Federal Univ., 2015.

Sidelnikov, S.B., Voroshilov, D.S., Startsev, A.A., Kovaleva, A.A., Lopatina, E.S., Galiev, R.I., and Zudin, N.A., Research parameters of combined processing for producing ligature rods from alloy system Al–Ti–B, J. Sib. Fed. Univ., Eng. Technol., 2015, no. 5, pp. 646–654.

Dovzhenko, I.N., Dovzhenko, N.N., Sidelnikov, S.B., and Galiev, R.I., 3D modelling of combined rolling-extrusion of alloying rods of Al–Ti–B, Non-Ferrous Met. (Moscow, Russ. Fed.), 2017, vol. 43, no. 2, pp. 50–55.

Baranov, V.N., Zenkin, E.Yu., Sidel’nikov, S.B., Krohin, A.Y., Dovzhenko, I.N., Voroshilov, D.S., Samchuk, A.P., Yakivyuk, O.V., Belokonova, I.N., and Frolov, V.A., RF Patent 2689460, 2019.

Klimko, A.P., Zagirov, N.N., Biront, V.S., Sidel’nikov, S.B., and Lopatina, E.S., RF Patent 2257419, 2005.

Kirillin, V.A., Sheindlin, A.E., Chekhovskoi, V.Ya., and Tyukaev, V.I., Enthalpy and heat capacity of titanium diboride in the temperature range 273.15–2600 K, Teplofiz. Vys. Temp., 1964, no. 5, pp. 710–715.

Application. Grain Refiner for Aluminium Alloys. The Official Website of the Company KBM with Basic Alloys Based on Aluminum. KBM Affilips B.V., Netherlands. https://www.kbmaffilips.com/aluminium-based//.

Funding

The work was attended by the head of the casting projects department of the Foundry Center LLC RUSAL ITC Krechetov A.B. and graduate student of the Siberian Federal University Medvedev M.Yu.

The research was carried out within the framework of the state assignment of the Ministry of Science and Higher Education of the Russian Federation (scientific theme code FSRZ-2020-0013).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflict of interest.

About this article

Cite this article

Kulikov, B.P., Bezrukikh, A.I., Sidelnikov, S.B. et al. Development of Technology for Obtaining Titanium-Containing Bar Alloy for Modifying Aluminum Alloys. Russ. J. Non-ferrous Metals 62, 265–273 (2021). https://doi.org/10.3103/S106782122103010X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S106782122103010X