Abstract

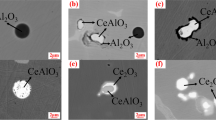

Using a Thermo-Calc software package (TCAl4.0 database), unexplored data concerning the phase composition and crystallization behavior of Al–Mg–Si–Ce alloys have been obtained in the composition range of two-phase cast aluminum-magnesium alloys such as (Al) + Mg2Si. It is shown that phases such as (Al), Al4Ce, Mg2Si, and Al8Mg5 can form in the course of crystallization. At a concentration of Mg amounting to 4% and at a concentration of (Si + Сe) = 1.5%, a simultaneous increase in Ce and decrease in Si from 0.2 and 1.3%, respectively, allow consecutive reactions L + (Al) + Al4Ce and L + (Al) + Al4Ce + Mg2Si to occur. This makes it possible to propose that the Al4Ce phase can hinder the growth of the eutectic Mg2Si phase. Moreover, at a temperature of 20°С, such a change in concentrations decreases the amount of Mg2Si and increases the fraction of the Al8Mg5 phase, which is also accompanied by a decrease in the amount of magnesium silicide. When adding Ce in the Al–4% Ce–0.5% Si alloy, the fraction of Mg2Si is approximately constant throughout the entire crystallization range (1.34%), but each 0.1% of Ce results in a 0.17% increase in the fraction of the Ce-containing intermetallic compound, whereas, at 0.7% of Ce, the fractions of the two phases become equal. In studying the phase composition upon characteristic annealing-temperature values amounting to 400 and 550°С, it has been revealed that, due to the Al8Mg5 phase dissolving, the (Al) solid solution becomes supersaturated. Every 0.1% of Ce leads to a 0.005% increase in the Mg content in (Al) at 400°С and to a 0.01% increase in that at 500°С, which could indicate the potentialities of a positive Ce effect on matrix strengthening. Based on the results, it has been concluded that it is worthwhile to add Ce in an amount of up to 0.7%, which leads to slightly decreasing liquidus temperature (~636–638°С), but results in a 30°С decrease in the nonequilibrium solidus temperature to 421ºС. At the same time, at a constant temperature of the Mg2Si phase formation (581°С), upon adding Ce, the crystallization range of the (Al) + Al4Ce eutectic expands, which can compensate for the deterioration of casting properties. The Al–4% of Ce–0.5% Si–0.7% Ce alloy has the following phase composition: Al4Ce 1.19%; ratio [Mg2Si/Al4Ce] = 0.89; and fraction of Al8Mg5 of 7.92% at 20°С and 3.22 and 3.36% Mg in (Al) at temperatures of 400 and 550°С, respectively. These results can be the basis for further experimental studies to justify the compositions and temperature modes required for obtaining aluminum-magnesium cast alloys containing Ce that exert a modifying effect on the eutectic Mg2Si inclusions.

Similar content being viewed by others

REFERENCES

Belov, N.A., Fazovyi sostav promyshlennykh i perspektivnykh alyuminievykh splavov (Phase Composition of Industrial and Promising Aluminum Alloys), Moscow: National Univ. of Science and Technology MISiS, 2010.

Kim, B.J., Jung, S.S., Hwang, J.H., Park, Y.H., and Lee, Y.C., Effect of eutectic Mg2Si phase modification on the mechanical properties of Al–8Zn–6Si–4Mg–2Cu cast alloy, Metals, 2019, vol. 9, no. 1, article no. 32.

Prusov, E., Deev, V., and Shunqi, M., Thermodynamic assessment of the Al–Mg–Si–Ti phase diagram for metal matrix composites design, Mater. Today: Proc., 2019, vol. 19, pp. 2005–2008.

Merkulova, S.M. and Bochvar, S.G., Influence of complex out-of-furnace modification on the structure of aluminum ingots, Tsvetn. Metall. (Moscow, Russ. Fed.), 2016, no. 8, pp. 80–85.

Eskin, D.G., Tzanakis, I., Wang, F., Lebon, G.S.B., Subroto, T., Pericleous, K., and Mid, J., Fundamental studies of ultrasonic melt processing, Ultrason. Sonochem., 2019, vol. 52, pp. 455–467.

Vdovin, K.N., Dubsky, G.A., Deev, V.B., Egorova, L.G., Nefediev, A.A., and Prusov, E.S., Influence of a magnetic field on structure formation during the crystallization and physicomechanical properties of aluminum alloys, Russ. J. Non-Ferrous Met., 2019, vol. 60, no. 3, pp. 247–252.

Konovalov, S.V., Danilov, V.I., Zuev, L.B., Filip’ev, R.A., and Gromov, V.E., On the influence of the electrical potential on the creep rate of aluminum, Phys. Solid State, 2007, vol. 49, no. 8, pp. 1457–1459.

Wang, H., Song, G., and Tang, G., Evolution of surface mechanical properties and microstructure of Ti–6Al–4V alloy induced by electropulsing-assisted ultrasonic surface rolling process, J. Alloys Compd., 2016, vol. 681, pp. 146–156.

Zuev, L.B., Danilov, V.I., Konovalov, S.V., Filip’ev, R.A., and Gromov, V.E., Influence of contact potential difference and electric potential on the microhardness of metals, Phys. Solid State, 2009, vol. 51, no. 6, pp. 1137–1141.

Rokhlin, L.L., Bochvar, N.R., and Tarytina, I.E., Influence of scandium together with zirconium on the structure and strength properties of alloys based on the Al–Mg2Si, Metally, 2015, no. 5, pp. 60–66.

Emamy, M., Khorshidi, R., and Raouf, A.H., The influence of pure Na on the microstructure and tensile properties of Al–Mg2Si metal matrix composite, Mater. Sci. Eng., A, 2011, no. 13, pp. 4337–4342.

Li, C., Wu, Y., Li, H., Wu, Y., and Liu, X., Effect of Ni on eutectic structural evolution in hypereutectic Al-Mg2Si cast alloys, Mater. Sci. Eng., A, 2010, no. 528, pp. 573–577.

Qin, Q.D., Zhao, Y.G., Zhou, W., and Cong, P.J., Effect of phosphorus on microstructure and growth manner of primary Mg2Si crystal in Mg2Si/Al composite, Mater. Sci. Eng., A, 2007, no. 447, pp. 186–191.

Jiang, W., Xu, X., Zhao, Y., Wang, Z., Wu, C., Pan, D., and Meng, Z., Effect of the addition of Sr modifier in different conditions on microstructure and mechanical properties of T6 treated Al–Mg2Si in-situ composite, Mater. Sci. Eng., A, 2018, no. 721, pp. 263–273.

Li, C., Liua, X., and Zhang, G., Heterogeneous nucleating role of TiB2 or AlP/TiB2 coupled compounds on primary Mg2Si in Al–Mg–Si alloys, Mater. Sci. Eng., A, 2008, no. 497, pp. 432–437.

Tebib, M., Samuel, A.M., Ajersch, F., and Chen, X.G., Effect of P and Sr additions on the microstructure of hypereutectic Al–15Si–14Mg–4Cu alloy, Mater. Charact., 2014, no. 89, pp. 112–123.

Campbell, J. and Tiryakioğlu, M., Review of effect of P and Sr on modification and porosity development in Al–Si alloys, Mater. Sci. Technol., 2010, vol. 26, no. 3, pp. 262–268.

Wang, Y., Liu, Q., Yang, Z., Qiu, C., and Tan, K., Effect of Ce addition and heat treatment on microstructure evolution and tensile properties of industrial A357 cast alloy, Metals, 2020, vol. 10, no. 8, article no. 1100.

Czerwinski, F., Cerium in aluminum alloys, J. Mater. Sci., 2020, no. 55, pp. 24–72.

Jiang, H., Li, S., Zheng, Q., Zhang, L., He, J., Song, Y., Deng, C., and Zhao, J., Effect of minor lanthanum on the microstructures, tensile and electrical properties of Al–Fe alloys, Mater. Des., 2020, vol. 195, article no. 108991.

Zhao, Y.G., Qin, Q.D., Zhou, W., and Liang, Y.H., Microstructure of the Ce-modified in situ Mg2Si/Al–Si–Cu, J. Alloys Compd., 2005, vol. 389, nos. 1–2, pp. L1–L4.

Belov, N.A., Naumova, E.A., and Akopyan, T.K., Evtekticheskie splavy na osnove alyuminiya: novye sistemy legirovaniya (Eutectic Alloys Based on Aluminum: New Alloying Systems), Moscow: Ruda i Metally, 2016.

Gureeva, M.A., Ovchinnikov, V.V., and Manakov, I.N., Metallovedenie: makro- i mikrostruktury liteinykh alyuminievykh splavov (Metal Science: Macro- and Microstructures of Cast Aluminum Alloys), Moscow: Yurait, 2020.

Lu, Z., Li, X., and Zhang, L., Thermodynamic description of Al–Si–Mg–Ce quaternary system in Al-rich corner and its experimental validation, J. Phase Equilib. Diffus., 2018, no. 39, pp. 57–67.

Cui, Z. and Wu, R., Phase diagram and properties of ternary Al–Mg–Ce alloys, Acta Metall. Sin., 1984, vol. 20, no. 6, pp. 323–331.

Grobner, J., Kevorkov, D., and Schmid-Fetzer, R., Thermodynamic modeling of Al–Ce–Mg phase equilibria coupled with key experiments, Intermetallics, 2002, vol. 19, no. 5, pp. 415–422.

Zhang, J., Fan, Z., Wang, Y., and Zhou, B., Microstructural development of Al–15 wt % Mg2Si in situ composite 352 with mischmetal addition, Mater. Sci. Eng., A, 2000, no. 281, pp. 104–112.

Funding

This work was financially supported by the Russian Science Foundation, project no. 20-19-00687.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by O. Polyakov

About this article

Cite this article

Deev, V.B., Prusov, E.S., Shurkin, P.K. et al. Cerium Effect on the Phase Composition and Crystallization Behavior of Aluminum Casting Alloys Based on the Al–Mg–Si System. Russ. J. Non-ferrous Metals 62, 424–430 (2021). https://doi.org/10.3103/S1067821221040064

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821221040064