Prognostics and Health Management in Nuclear Power Plants: An Updated Method-Centric Review With Special Focus on Data-Driven Methods

- 1Nuclear Energy and Fuel Cycle Division, Oak Ridge National Laboratory, Oak Ridge, TN, United States

- 2Department of Mechanical, Aerospace and Nuclear Engineering, Rensselaer Polytechnic Institute, Troy, NY, United States

- 3Department of Nuclear Science and Engineering, Massachusetts Institute of Technology, Cambridge, MA, United States

In a carbon-constrained world, future uses of nuclear power technologies can contribute to climate change mitigation as the installed electricity generating capacity and range of applications could be much greater and more diverse than with the current plants. To preserve the nuclear industry competitiveness in the global energy market, prognostics and health management (PHM) of plant assets is expected to be important for supporting and sustaining improvements in the economics associated with operating nuclear power plants (NPPs) while maintaining their high availability. Of interest are long-term operation of the legacy fleet to 80 years through subsequent license renewals and economic operation of new builds of either light water reactors or advanced reactor designs. Recent advances in data-driven analysis methods—largely represented by those in artificial intelligence and machine learning—have enhanced applications ranging from robust anomaly detection to automated control and autonomous operation of complex systems. The NPP equipment PHM is one area where the application of these algorithmic advances can significantly improve the ability to perform asset management. This paper provides an updated method-centric review of the full PHM suite in NPPs focusing on data-driven methods and advances since the last major survey article was published in 2015. The main approaches and the state of practice are described, including those for the tasks of data acquisition, condition monitoring, diagnostics, prognostics, and planning and decision-making. Research advances in non-nuclear power applications are also included to assess findings that may be applicable to the nuclear industry, along with the opportunities and challenges when adapting these developments to NPPs. Finally, this paper identifies key research needs in regard to data availability and quality, verification and validation, and uncertainty quantification.

Introduction

Reducing anthropogenic greenhouse gas (GHG) emissions for climate change mitigation while expanding energy access to billions of people is a central global challenge of this century. As the world’s second-largest low-carbon power source (second only to hydropower), nuclear power makes up more than one-quarter of annual low-carbon electricity supply worldwide and has avoided about 60 gigatons of GHG emissions over the past 50 years (IEA, 2019). At present, approximately 10% of global electricity generation is produced by nuclear power each year (IAEA, 2021). To achieve deep decarbonization targets, including the one limiting average global warming to 2°C in 2050 (Gao et al., 2017), it is imperative to maintain the existing nuclear share of electricity production (MIT, 2018).

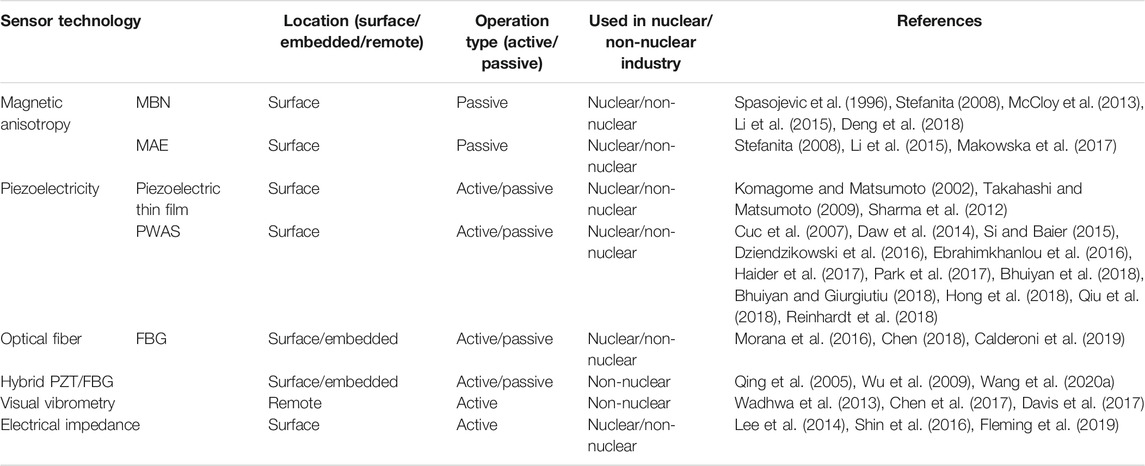

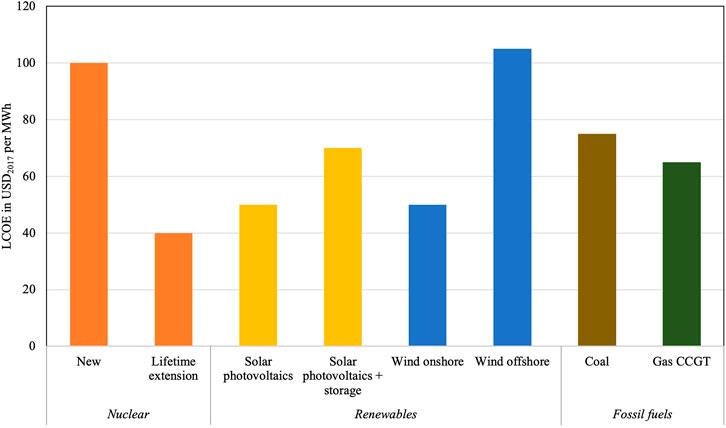

Despite its important role in energy transitions to meet climate goals, the nuclear industry is facing an uncertain future in many countries, not only due to the March 2011 Fukushima accident in Japan but also more fundamentally for economic reasons. In advanced economies such as the United States, unfavorable market conditions—including weak growth in electricity demand, low natural gas prices, and increasing competition from renewables-based power supply—are putting pressure on the financial performance of existing nuclear power plants (NPPs), which may lead to their early retirements. One of the first thrusts being pursued to support economical nuclear power has been focused on life extensions of the legacy fleet, from the initial license period of 40 years (in most cases) to 50–60 years and possibly beyond. Life extensions are considerably cheaper than new construction and will be cost-competitive with any other electricity generation technology, as illustrated in Figure 1 for the projected US levelized cost of electricity associated with different technologies in 2040. A new joint report (IEA and NEA, 2020) by the International Energy Agency (IEA) and the Nuclear Energy Agency (NEA) also concludes that prolonging the operation of existing nuclear assets, known as long-term operation (LTO), is the most affordable low-carbon solution. Unfortunately, the LTO of current NPPs alone—mostly light water reactors (LWRs)—can only provide temporary support for the transition to clean energy systems. New builds are necessary, and near-term interests are rising in LWR-based small modular reactors (SMRs) and mature Generation-IV concepts.

FIGURE 1. Projected US LCOE by technology in 2040 [modified from IEA (2019)]. Note for Figure 1: LCOE = levelized cost of electricity, average cost to build and operate a power plant over its lifetime divided by the total electricity output of the plant over the same period; it represents the break-even price of electricity generation at a power production facility. CCGT = combined-cycle gas turbines. Estimates of nuclear lifetime extension are based on a 500 million USD investment to extend operations for 20 years. Other cost assumptions can be found in IEA (2019).

To achieve safe, reliable, and economical operation of NPPs, attention is turning to enhanced plant asset management methods within the activities of both legacy fleet LTO and new construction. Decades of global operational experience have shown that greater situational awareness of the condition of key structures, systems, and components (SSCs) is essential for managing and mitigating plant equipment degradation, particularly the aging-related degradation due to exposure to a harsh operating environment. While the traditional approaches to maintenance and aging management complied with the defense-in-depth policy (IAEA, 1996) and proved to be adequate for maintaining safety margins in the past, they were not optimized in terms of effort, time, or cost (Coble et al., 2012). Historically, corrective find-and-fix maintenance policies prevailed in the early days of the nuclear industry, which would incur overly long facility downtime and excessively high cost (Ayo-Imoru and Cilliers, 2018). The time-based periodic maintenance scheduling became widely employed since the 1970s. However, this strategy is generally conservative and often yields unnecessary planned inspection and maintenance that challenge the economics of nuclear generation. Meanwhile, it does not prevent plant downtime caused by unanticipated equipment failure, which leads to a significant amount of lost revenue: at least $1.2 million per day of plant shutdown for an average NPP in the United States and France (NEI, 2011; Power Engineering International, 2017). Therefore, it is necessary to move from uneconomic find-and-fix or periodic maintenance strategies to the more cost-effective just-in-time repair policies.

The just-in-time repair is a predictive maintenance strategy that relies on continuous monitoring and full awareness of the equipment health condition throughout its life cycle, or in other words, the use of prognostics and health management (PHM) principles. The full PHM suite includes five modules: data acquisition, monitoring and anomaly detection, fault diagnostics, prognostics, and planning and decision-making. Through appropriate detection, diagnosis and prognosis, and mitigation actions, a robust PHM system will allow early warning of degradation in NPPs and will potentially preclude serious consequences due to faults and failures while helping alleviate the burden of unnecessary maintenance activities.

This paper provides an updated method-centric review of the full PHM suite in NPPs since the last major survey article by Coble et al. (2015) was published in 2015. The results of that survey are augmented with new progress made in the intervening years. In particular, recent advances in data-driven analysis methods—largely represented by those in artificial intelligence (AI) and machine learning (ML)—have enhanced applications ranging from robust anomaly detection to automated control and autonomous operation of complex systems. PHM in NPPs is one area where the application of those algorithmic advances can significantly improve the ability to perform enhanced asset management. Therefore, special attention is dedicated to the advances in data-driven diagnostic and prognostic methods. PHM technologies in non-nuclear power applications are also included to assess findings that may be applicable to the nuclear industry, along with the opportunities and challenges when adapting these developments to NPPs. “US NPP Monitoring and Maintenance: Historical Approach and Motivations for Prognostics and Health Management” Section summarizes the historical approach to monitoring and maintenance in US NPPs and outlines the PHM needs for improving the safety and economy of both LTO and new builds. “Prognostics and Health Management Framework and Modeling Approaches” Section describes the PHM framework, followed by the state of practice for each of its five modules with a focus on data-driven methods. “Research Needs for Deployment of Prognostics and Health Management in Nuclear Power Plants” Section identifies the overarching research needs to support the development and deployment of PHM in NPPs. “Summary” Section summarizes the key findings of this paper.

US NPP Monitoring and Maintenance: Historical Approach and Motivations for Prognostics and Health Management

The United States has the largest number of commercial nuclear reactors in the world. Its operating fleet [94 LWRs in 56 NPPs (IAEA, 2021) as of January 2021] has steadily generated about 20% of the nation’s electricity since the mid-1990s (NEI, 2021a) at by far the highest capacity factor [93.4% in 2019 (US DOE, 2019)] of any energy source. Despite this performance and the fact that nuclear makes up more than half of the nation’s clean energy (NEI, 2021b), nine reactors have been shut down in the United States before their licenses expired since 2012 due to unfavorable market conditions, and an additional five units are scheduled to retire in 2021 (US DOE, 2020a; US EIA, 2021a). The average age of US operating reactors is almost 40 years. The youngest unit, Tennessee’s Watts Bar Nuclear Plant Unit 2, began operation in 2016 and was the nation’s first new reactor in 20 years (US EIA, 2021b). Meanwhile, only two commercial reactors—2 AP1000 units at Georgia’s Vogtle plant—are currently under construction (IAEA, 2021) in the country. To keep America’s nuclear capacity from sharply declining and to enable clean energy transition, the current LWR fleet is undergoing 20-years life extensions from the original 40-years licenses; 85 reactors1 have been approved by the US Nuclear Regulatory Commission (NRC) to operate 60 years through the initial license renewal applications (NEI, 2021c). To date, 53 reactors have already entered extended operation or LTO (US NRC, 2021a). Additionally, utilities are intending to operate up to 80 years through second 20-years extensions or subsequent license renewals; four reactors have been issued a second renewed license for extended LTO and six additional applications are under review (US NRC, 2021b).

To comply with the NRC’s license renewal rule [Title 10, Part 54 of the Code of Federal Regulations, or 10 CFR 54 (US NRC, 1995)] and to continue to provide secure nuclear power generation, it is imperative to understand and manage the effects of SSC aging in NPPs. As described in Coble et al. (2012), the NRC monitoring and maintenance programs usually draw a distinction between active and passive SSCs.2 The active SSCs—such as control rod drives, generators, sensors, motors, pumps, and valves—must move to perform their intended functions. Their performance monitoring and aging management have been historically covered by the Maintenance Rule (10 CFR 50.65) (US NRC, 2021c). The Maintenance Rule provides a performance-based approach to monitoring and improving the overall effectiveness of active component maintenance. However, it does not directly improve the economics of performing maintenance (Coble et al., 2012). Under the Maintenance Rule, a large majority of maintenance activities remain periodically scheduled. The passive SSCs—such as reactor pressure vessels (RPVs), heat exchangers, transformers, cables, support structures, and piping—do not move during normal functions. Their degradation and maintenance are managed through periodic in-service inspection as dictated by the plant’s aging management program. As codified in 10 CFR 50.55a (US NRC, 2021d), nondestructive inspection requirements are specified for the in-service inspection of passive components.

As plants enter LTO, aging becomes a more challenging problem. Because it is of paramount importance to be warned of impending SSC faults and failures, the frequency of periodic inspection and maintenance will need to increase to compensate for potentially growing failure rates over time due to wear-out failures in active SSCs and for reduced safety margins toward the lowest allowable level due to degraded material characteristics in passive SSCs. The increased inspection frequency would cause extended (and sometimes unnecessary) downtime of plant safety-critical systems and eventually affect the industry’s competitiveness. Transitioning from periodic maintenance scheduling to a more continuous, just-in-time health management approach is essential to ensure that the intended functions of NPP assets are maintained for the period of extended operation. Advanced monitoring techniques will provide the necessary support to this transition, along with advances in diagnostic and prognostic methods.

Currently, there is a growing interest in applying condition-based (rather than time-based) maintenance for active components and automated online monitoring (instead of periodic inspection) for passive components through the use of PHM. In fact, well-applied PHM technologies will benefit not only aging LWRs but also new builds, especially LWR-based SMRs [such as the pressurized water NuScale720 (US DOE, 2020b) and the boiling water GEH BWRX-300 (US DOE, 2020c)] and mature advanced reactor designs as part of the Generation-IV initiative [such as TerraPower’s Natrium and X-energy’s Xe-100 under the US Department of Energy [DOE]’s Advanced Reactor Demonstration Program (US DOE, 2020d)], into which inherent and passive safety features are extensively incorporated. These reactors have additional monitoring and surveillance needs over currently operating LWRs due to extended fuel cycles, exposure to harsher operating environments, use of innovative materials, and remote siting with reduced maintenance staffing levels (Coble et al., 2015). Traditional inspection techniques and maintenance policies will not meet such needs.

In addition to improving plant safety and reliability, PHM is also economically attractive for reducing operations & maintenance (O&M) costs compared to time-based and even traditional condition-based (i.e., without the use of PHM)3 policies. The O&M costs represent a crucial disadvantage for the nuclear industry and comprise about two thirds of total generating costs in NPPs (Coble et al., 2015; Al Rashdan et al., 2018). As discussed in “Introduction” Section, periodic inspection and maintenance could lead to unnecessary and unanticipated repair or replacement of SSCs, incurring significant additional downtime and costs. Besides, compared to the traditional concept of condition-based maintenance (CBM), PHM-enabled CBM provides capabilities to achieve more proactivity in O&M, places stronger emphasis on the operation stage than the design stage, and rely on condition-based, facility-specific status identification rather than population statistics. While detailed cost-benefit analyses of using PHM in specific NPPs are yet to be conducted, Bond et al. (2011) suggest that applying PHM technologies to all key SSCs in the nation’s legacy plants could result in an annual fleet-wide savings of more than $1 billion.4 Furthermore, proper application of the complete PHM suite—especially with automated planning and decision-making capabilities—can effectively reduce labor reliance and frequency of O&M activities because labor costs account for approximately 80% of O&M costs in US plants.

Prognostics and Health Management Framework and Modeling Approaches

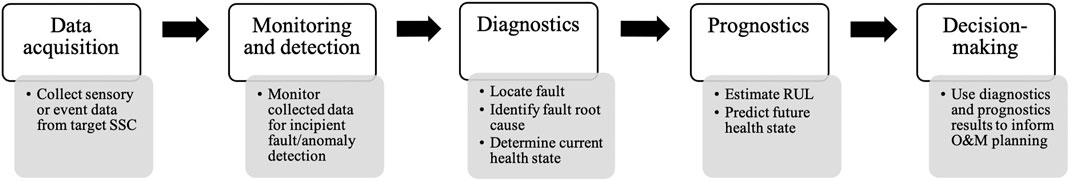

This paper reviews the full PHM suite, which utilizes sensor technologies and data analytics to monitor health conditions, detect anomalies, diagnose faults, predict the remaining useful life (RUL), and proactively manage failures (Droguett, 2020) in complex engineering systems such as NPP assets. The five modules/steps of a full PHM system are depicted in Figure 2, and each module will be elaborated on in the following subsections. To date, there has been no universally well-defined categorization of PHM systems partly due to lack of unifying PHM standards, which are needed for harmonized terminology, consistency of PHM methods, and compatibility/interoperability of PHM technology. A number of disparate industrial standards—mostly developed by the International Organization for Standardization (ISO) and the Institute of Electrical and Electronics Engineers (IEEE)—exist which pertain to different modules of a PHM system, such as ISO 13374 series for condition monitoring (CM) of industrial machines, ISO 13379 for diagnostics, ISO 13381 for prognostics, and IEEE P1856 for PHM of electronic systems. Vogl et al. (2014) surveyed existing PHM-related standards and identified areas for development of future standards.

FIGURE 2. Five modules/steps of PHM [adapted and extended from Coble et al., 2015)].

In a PHM system, sensory data collected from a target SSC are continuously monitored for deviations from normal behavior, which are indicators of incipient faults or anomalies.5 Once an anomaly is detected, it is important to diagnose the fault, or in other words, to locate the fault to a specific component or area of a structure (i.e., fault isolation) and to determine the root cause of the fault (i.e., fault identification). Depending on how the SSC will degrade, an appropriate prognostic model is then applied to estimate its RUL. Finally, O&M planning is informed by integrating prognostic calculations and risk assessment of proposed mitigation actions based on the current and postulated future health states of the target SSC to achieve optimal (and ultimately autonomous) control and decision-making.

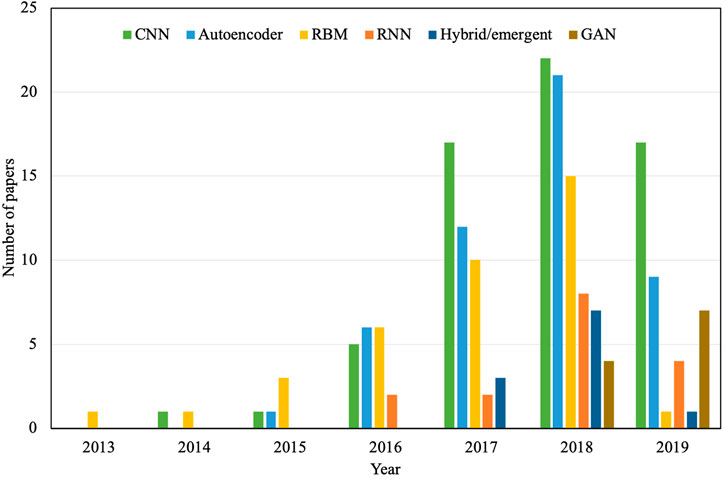

Besides traditional modeling tools, the recent advancements in AI and ML technologies provide opportunities for leveraging emerging data-driven algorithms to effectively address PHM problems, especially those of diagnostics and prognostics. Details will be provided in the corresponding subsections. Figure 3 illustrates the growing research interest in the application of one such algorithmic example for PHM: deep learning (DL), a quickly developing subfield of ML. Through a systematic review of state-of-the-art DL-based PHM frameworks, Rezaeianjouybari and Shang (2020) recently presented the benefits and potentials of DL technologies in the PHM paradigm, especially in the presence of high-volume and multidimensional data streams that contain real-time information about the degradation and health condition of the system of interest.

FIGURE 3. Breakdown of published papers on DL in PHM between 2013 and September 2019 (modified from Rezaeianjouybari and Shang (2020)) Note for Figure 3: DL architecture–share of total publications as follows: CNN (convolutional neural network)—32.1%; autoencoder—26.8%; RBM (restricted Boltzmann machine)—19.6%; RNN (recurrent neural network)—9.2%; hybrid/emergent—6.7%; GAN (generative adversarial network)—5.6%.

Data Acquisition: Emerging Sensor Technologies

Traditional reliability analyses rely on population statistics rather than condition-based status identification. Thus, they do not provide any useful insight regarding a specific SSC’s current or future state. The process of data acquisition from the target equipment is necessary to make an accurate, reliable prediction of individual SSC health. Collected data can be either event or sensory data (Atamuradov et al., 2017). Event data are O&M logs containing actions taken by the operator or maintenance staff in response to events that occurred to the physical asset and are not the focus of this paper. Sensory data are measurements tracked via sensors installed on the target equipment. Various types of sensors are needed to monitor key health related parameters in nuclear SSCs. Examples of such parameters include vibration, electrical signatures (current/voltage) and position measures in active SSCs, localized change in material properties (mechanical, magnetic, optical, thermal, or electrical) in passive SSCs, as well as general measurands of process conditions (such as temperature, flow, pressure) that may be associated with equipment degradation.

Due to the harsh operating environments (such as radiation, high pressure, high temperature) encountered in some parts of the NPP systems, many of the existing sensors that are widely used in other industries for abovementioned measurands may not survive. This section surveys recent research efforts to improve sensor survivability and measurement sensitivity for nuclear instrumentation. Some of the emerging sensing techniques, including those in use for nuclear applications and those which are deemed useful in the near future for CM inside NPPs, are briefly described in the following six subsections and compared in Table 1.

Magnetic Anisotropy

Magnetic properties of ferromagnetic materials depend on the direction in which they are measured. This phenomenon is known as magnetic anisotropy (Stefanita, 2008). Magnetic Barkhausen noise (MBN)—the electromagnetic waves emitted during a ferromagnetic material’s magnetization process—allows one to characterize magnetic anisotropy without regard to its origin (Spasojevic et al., 1996). Several studies have utilized MBN to continuously or periodically monitor material structure degradation, such as in structural steels of nuclear reactors (McCloy et al., 2013). Another effect produced by the movement of magnetic domain walls is the magneto acoustic emission (MAE). Acoustic signals are generated by the sudden and discontinuous changes in magnetization, which involve localized deformations (Stefanita, 2008). Simply put, the magnetic signal from a sensing coil corresponds to MBN (Deng et al., 2018), whereas the acoustic signal from a piezoelectric (PZT) sensor corresponds to MAE (Makowska et al., 2017). Li et al. (2015) investigated magnetic anisotropy of α-iron containing nonmagnetic particles for checking integrity of a nuclear RPV and suggested the possibility of using magnetic technologies for nondestructive evaluation of RPV embrittlement.

Piezoelectricity

Progress in sensor technology development has enabled the use of PZT transducers, which can be mounted on the surface or embedded inside host structural materials. Once they are integrated with the host structure, PZT elements are utilized as sensors to deliver signals in real-time. Simultaneously, they can also serve as actuators to generate diagnostic stress waves into the structure to detect, localize, and quantify damage in the materials. Various studies have proposed techniques using piezoelectric thin films attached to a material surface (Komagome and Matsumoto, 2002; Takahashi and Matsumoto, 2009; Sharma et al., 2012). By measuring the electric potential distribution on the piezoelectric film, the location, the aperture shape, and the defect’s depth can be estimated. The piezoelectric wafer active sensor (PWAS), another type of PZT sensor, has emerged as one of the major sensing techniques. PWASs were developed as convenient enablers for generating and receiving Lamb waves—a type of ultrasonic guided waves propagating between two parallel surfaces without much energy loss—for structural health monitoring in space applications (Cuc et al., 2007). Radiation influence on their sensing capability and survivability has been investigated to determine the reliability of PWAS-based methods for PHM in extreme nuclear environments (Haider et al., 2017). Additionally, research of PZT sensors using Lamb waves has been ongoing, and their capabilities for impact localization (Si and Baier, 2015; Park et al., 2017; Qiu et al., 2018), acoustic emission detection (Bhuiyan et al., 2018; Bhuiyan and Giurgiutiu, 2018), and damage detection in isotropic and composite plates (Dziendzikowski et al., 2016; Ebrahimkhanlou et al., 2016; Hong et al., 2018) have been explored. In-pile instrumentation development activities using PZT sensors have also been conducted recently—such as under several DOE Nuclear Energy programs investigating the use of new fuels and materials for advanced and existing reactors—to address crosscutting needs for irradiation testing by providing higher-fidelity, real-time data with increased accuracy and resolution from smaller, compact sensors that are less intrusive (Daw et al., 2014; Reinhardt et al., 2018).

Optical Fiber

Measurement techniques based on optical fibers have demonstrated the capability to provide multi-sensing (measuring different operational parameters within a single sensor configuration, such as temperature, pressure, and strain) and multiplexing (communicating data collected at multiple locations through the single line) instrumentation. They are intrinsically immune to electromagnetic interference, electrically passive, and widely available at a reasonable cost. Beyond the use as a light guide, several optical sensors and related measurement techniques have been considered for nuclear applications. Fiber Bragg grating (FBG) sensors have been the focus of many research efforts due to their demonstrated potential for high-temperature operation in a radioactive environment and their multiplexing capability. An FBG is achieved by creating a periodic modulation of the refractive index of the fiber core, which generates a distributed reflector characterized by its period and modulation depth. Several recent studies (Morana et al., 2016; Chen, 2018; Calderoni et al., 2019) have shown the effectiveness of certain radiation-resistant FBG sensor types—such as femtosecond-etched FBGs and germanosilicate singlemode FBGs—in monitoring diverse physical parameters for in-reactor instrumentation.

Piezoelectric-Fiber Hybrid Sensor System

A hybrid PZT/FBG system offers the best decoupling of actuator and sensor signals because the two devices apply different mechanisms for signal transmission. The PZT transducers rely on electrical channels to actuate or detect dynamic responses, whereas the FBG sensors rely on optical means to measure quasi-static or relatively low frequency responses (Wu et al., 2009). In other words, such a hybrid system uses piezoelectric actuators to input a controlled excitation to the structure and uses fiber optic sensors to capture the corresponding structural response (Qing et al., 2005). More generally, the accuracy and stability of SSC health monitoring can be potentially improved by constructing a hybrid sensor network and integrating multi-source sensor information (Wang et al., 2020a). Such hybrid sensor systems have not seen applications in NPPs but should not face hurdles given the respective success of PZT and FBG sensors.

Visual Vibrometry

Visual testing has played a prominent role in inspecting civil infrastructures. Recently, researchers have been able to use computer vision techniques to analyze small motions in videos. Those techniques amplify imperceptibly small motions in specified frequency bands, effectively producing a visualization of an object’s operational deflection shapes (Wadhwa et al., 2013). Video cameras provide the benefit of long-range measurements and enable the collection of a large amount of data at once since each pixel can be considered as a sensor. Objects tend to vibrate in a set of preferred modes, and the shapes and frequencies of the modes depend on the structure and material properties of an object. Focusing on the case where geometry is known or fixed, information about an object’s vibration modes can be extracted from video and used to make inferences about that object’s material properties (Davis et al., 2017). A camera-based vibration measurement methodology was also recently demonstrated for civil infrastructure by measuring an antenna tower’s ambient vibration response (Chen et al., 2017). Future research is needed to investigate the application of visual vibrometry inside NPPs with radiation exposure, such as for nuclear containment systems.

Electrical Impedance

Electrical impedance–based sensing is a relatively mature measurement field with broad nuclear applications, including passive structure, standby component, and in-pile monitoring. Lee et al. (2014) proposed laser-based mechanical impedance (LMI) measurement, utilizing a fiber-guided laser ultrasound system to generate and measure LMI response for damage detection in NPP pipes. Shin et al. (2016) suggested an online monitoring technique for standstill motors based on an impedance analysis method. More recently, Fleming et al. (2019) developed an impedance-based diameter gauge consisting of an electrically conductive concentric ring around fuel cladding, such that the electrical impedance between the ring and cladding could be measured.

Condition Monitoring and Fault Detection

Condition monitoring describes a suite of activities for providing state estimation and early warning of anomalous behavior. It is a crucial step of the PHM framework, and the effectiveness of PHM largely depends on the accuracy of the CM process (Ayo-Imoru and Cilliers, 2018). The process of fault detection attempts to recognize incipient faults and failures6 from CM data and quantification of the inconsistencies between the actual and the expected behavior of the monitored SSC in nominal conditions (Atamuradov et al., 2017).

The instrumentation and control (I&C) systems in NPPs receive large amounts of sensory data from various components to enable and support safe and reliable power generation by controlling the system variables. However, most raw data collected by sensors are not ready to be used directly, and appropriate data manipulation is required. The multidimensionality of high-volume data and redundancy among data attributes are examples of challenges faced by CM and fault detection. Therefore, the feature selection process—including choosing high-quality attributes, removing collinear features, and selecting an optimal subset from the original data set—is usually needed (Chandrashekar and Sahin, 2014). The objective of feature selection is to find a subset of variables from the full array of raw sensor data that can efficiently describe the input data stream while reducing effects from error/noise or irrelevant information (Guyon and Elisseeff, 2003).

Feature Selection Methods

Feature selection methods can be divided into three categories: filters, wrappers, and embedded methods. Filter methods pick up the intrinsic properties of the features measured by univariate statistics. In general, filter methods use variable ranking techniques as the principal criteria for variable selection. A suitable ranking criterion is used to score the input variables, and thresholds are applied to filter out the less relevant features. Several studies (John et al., 1994; Blum and Langley, 1997; Kohavi and John, 1997) have presented various definitions and measurements for the relevance of a variable. The widely used metrics such as mutual information, Fisher score, relief, separability, and correlation are all under the umbrella of the filter methods. The primary advantage of filter methods is their speed and ability to scale to large data sets. They are computationally light and are not prone to overfitting (Lazar et al., 2012). They also do not rely on the learning algorithm. One of the drawbacks of filter methods is that the selected subset might not be optimal because a redundant subset might be obtained. Besides, essential features that are less informative on their own but are informative when combined with other features could be discarded in error (Xu et al., 2010). Bommert et al. (2020) recently published a comprehensive survey analyzing 22 filter methods concerning runtime and accuracy in high-dimensional classification data.

Wrapper methods use the predictor as a black box and the predictor performance as the objective function to evaluate the variable subset. They search through the space of feature subsets using a learning algorithm and calculate the estimated accuracy of the learning algorithm for each feature that can be added to or removed from the feature subset. Also, they depend on a classification algorithm used to evaluate the candidate solutions (i.e., subsets of features) generated by a search algorithm and thus are more computationally expensive. Wrapper methods often provide more accurate results than filter methods (Pudil and Somol, 2008), although one needs to take extra care to prevent overfitting and wrappers usually scale poorly to large data sets (Das, 2001). The selection process is based on a specific learning algorithm trying to fit on a given data set. In general, it follows a greedy search approach by evaluating all the possible combinations of features against the evaluation criterion. For instance, the branch and bound algorithm (Narendra and Fukunaga, 1977), genetic algorithm (Goldberg, 1989), particle swarm optimization (Kennedy and Eberhart, 1995), adaptive floating search (Somol et al., 1999), recursive feature elimination (Guyon et al., 2002), and similarity measure (Chen and Chen, 2015) are all under the category of the wrapper methods.

Embedded methods complete the feature selection process within the construction of the ML algorithm itself. This method category combines the qualities of both filters and wrappers. The search for an optimal subset of features is embedded into the classifier construction and can be seen as a search in the combined space of feature subsets and hypotheses. The embedded methods use an independent measure to decide the best subsets for a given cardinality and use the learning algorithm to select the optimal subset among the best subsets across different cardinalities. Therefore, they are specific to a given learning algorithm and have the advantage of taking into consideration the interaction of features with the classification model (like wrapper methods) while being far less computationally intensive (like filter methods) (Saeys et al., 2007). Regularization and tree-based models are some common methods that use embedded feature selection. The weights of a classifier can also be used to rank the features for their removal, and the features can be selected by conducting sensitivity analysis on the corresponding weights. Several methods (Archibald and Fann, 2007; Mundra and Rajapakse, 2010; Zhang et al., 2015a) used support vector machines (SVMs)7 as classifiers, optimizing the SVM equation and assigning weights to each feature. In some other studies (Setiono and Liu, 1997; Verikas and Bacauskiene, 2002; Romero and Sopena, 2008; Yang and Ong, 2011), an artificial neural network (ANN) was applied for the same purpose.

As examples in the nuclear field, Deleplace et al. (2020) recently used a separability-based feature selection metric (i.e., filter method) to enhance accuracy of fault detection in NPP water screen cleaners; Peng et al. (2018a) applied correlation analysis (i.e., filter method) for dimensionality reduction of NPP transient data simulated from their personal computer transient analyzer; Zio et al. (2006) selected features for early transient detection by means of genetic algorithms (i.e., wrapper method); Moshkbar-Bakhshayesh (2021) investigated six different feature selection techniques for parameter estimation in an NPP, among which the ANN with Bayesian regularization (i.e., embedded method) gave the most accurate results.

Anomaly Detection Methods

One can attempt to derive first principles–based analytical models to describe the expected nominal or faulty SSC behavior if its underlying physical mechanisms/relationships are well understood. In an engineering system, physics-based models are attractive for three reasons: first, they consider mechanical, material, and operational characteristics explicitly; second, they can be developed and evaluated even before the system has been built and operated; and third, they can be used to understand behavior over a broad range of operational and material conditions (Coble et al., 2012). Unfortunately, it is challenging, time-consuming, and often impossible to model a complex, nonlinear system with first principles and mathematical functions alone (Mirnaghi and Haghighat, 2020). Furthermore, the physical foundation in such models is inevitably diluted by the use of simplifying (sometimes unjustified) assumptions to make up for runtime performance or incomplete domain knowledge (Coble et al., 2012; Zhao et al., 2020a). In contrast, data-driven approaches have shown the potential to characterize system operations and develop system models due to their independence in modeling and sole reliance on system data (Yang and Rizzoni, 2016).

With the development of sensor technologies—which enable routine collection of online data for numerous system variables—various anomaly detection approaches based on multivariate statistics have gained attention. Principal component analysis (PCA) and partial least squares (PLS) are two basic multivariate statistical techniques (Severson et al., 2016), and many applications based on those techniques have been considered for detecting faults (Harrou et al., 2013; Liu et al., 2013; Rato and Reis, 2013; Mnassri et al., 2015; Jia and Zhang, 2016; Li et al., 2016; Jiao et al., 2017; Jiang and Yan, 2018). Once the detection method is selected, a metric for identifying faults is needed. In PCA- and PLS-based methods, Hotelling’s t-squared statistic (Hotelling, 1933)—a generalization of Student’s t-statistic in multivariate hypothesis testing—is widely used to detect anomalies with specific thresholds. The sum of squared prediction error (Box, 1954), also known as the Q statistic, is another metric that denotes the change of the events that are not explained by the model of principal components (Mujica et al., 2011). In the nuclear field, Li et al. (2019a) recently applied an improved PCA method using data pre-processing and false alarm reducing techniques for NPP sensor fault detection, which reduced the false alarms of both t-squared and Q statistics.

Traditional multivariate statistical-based methods have inherent limitations. Calculating monitoring statistics and thresholds of the PCA- or PLS-based methods is made under the assumptions that data from sensors are Gaussian-distributed and linearly correlated and that the process is operated under a single stationary condition (Ge et al., 2013). In practice, most of these assumptions may be violated. Various research efforts using data-driven methods have been developed to relax assumptions in the traditional statistical-based methods. Independent component analysis (ICA), finding both statistically independent and non-Gaussian components, is a reliable alternative for fault detection (Li and Wang, 2002). Stefatos and Ben Hamza (2010) further introduced the dynamic ICA technique, extending the advantages behind ICA to detect faults in a time-correlated environment. Cai and Tian (2014) developed a non-Gaussian process based on robust ICA to alleviate the effect of outliers. Ajami and Daneshvar (2012) showed the validity and effectiveness of ICA for fault detection of a typical turbine system, which are found in an NPP.

The Gaussian mixture model (GMM) is another commonly used technique for non-Gaussian data processing. Yu (2012) proposed a nonlinear kernel GMM-based inferential monitoring approach for fault detection, which projected data from a raw measurement space into a high-dimensional kernel space so that the GMM could be estimated in the feature space satisfying multivariate Gaussianity. Karami and Wang (2018) proposed an adaptive GMM for automatic fault detection in nonlinear systems. Ma et al. (2019) presented a nuclear application by using a GMM-based early fault detection method on 30 sets of real data from reciprocating compressors containing three fault types.

More recently, SVM variants—which do not require the data to be Gaussian—have emerged. Liu and Zio (2018) developed a k-nearest neighbors–based fuzzy SVM to reduce the computational burden and tackle the issue of data imbalance and outliers. Several applications exist for fault detection in NPP assets using SVM-based models (Jamil et al., 2018; Lin and Wu, 2019; Meng et al., 2020).

Fault Diagnostics

Within the overarching area of PHM, fault diagnostics begins after a fault has been detected during the CM process. Diagnostics is further divided into fault isolation, which seeks to identify the piece of equipment or component from which the fault originates, and fault identification, which determines the cause of the fault. Logically, these two subtasks of fault diagnostics are often performed as a single analysis. The analysis is based upon fault symptoms, which primarily take the form of available features or signatures of the fault, obtained in the form of sensed data and measurements. A common classification scheme for diagnostics problems is by modeling method, in which the problem is approached using either a model-based or a data-driven method. This is not a completely clear distinction, though, as some overlap can exist between the two approaches, and various hybrid approaches can be developed. One specific area of overlap is in the use of rule-based expert systems for fault diagnosis. These expert systems rely on “if-then” rules to diagnose a system’s state given its fault symptoms. It will be seen that the development of “if-then” rules can be done by either model-based or data-driven methods.

This review places emphasis on developments in data-driven methods for PHM. However, a brief review of advances in model-based methods is still deemed beneficial to the reader interested in fault diagnostics or PHM in general. As such, the following subsections will survey model-based methods first; then rule-based expert systems, namely those which rely on fuzzy rule bases; and finally, data-driven methods. Additionally, the interested reader can refer to Li et al. (2020) for a second review of diagnostic methods.

Model-Based Methods

According to Yang (2004), who presented a review of both model-based and data-driven methods, common model-based methods include the use of observers or statistical filters, checks of the parity between plant models and sensor outputs, generation of residuals in the frequency domain, use of causal graphical models (such as signed directed graphs and fault trees), and approaches based on qualitative physics (such as qualitative simulation and qualitative process theory). A common classification scheme for these methods is that filtering, parity, and frequency approaches are grouped as quantitative methods, and that graphical models and qualitative physics are considered qualitative methods.

In the area of filtering-based methods, Gautam et al. (2019) used an extended Kalman filter for fault identification and performed fault isolation for single and simultaneous multiple-sensor faults in an NPP with a recursive least squares estimate. An advancement to the parity space method was performed by Cho and Jiang (2018) for nuclear applications, in which Fisher discriminant analysis (FDA) was used to address the issue where the number of fault classes exceeds the total independent residual signatures. Lee and Shin (2018) proposed a method using time-frequency domain reflectometry and k-means clustering to determine the fault location and faulty line in a multi-core I&C cable system to assure the safety and reliability of NPP operation. Advances in qualitative causal graphs for NPP asset fault diagnosis include those on signed directed graphs (Liu et al., 2016) and dynamic uncertain causality graphs (Zhao et al., 2017a).

Rule-Based Methods

Rule-based methods operate by firing specific “if-then” rules to determine the consequence associated with a measured/detected fault symptom. Rule bases have traditionally been developed using expert judgment and prior knowledge about the system. Although a system based on engineering knowledge may be attractive, issues in classical rule-based systems can include rule bases growing to unmanageable size to describe an increasing number of scenarios and the potential for a rule-based system to fail when it encounters a situation for which there is currently no rule (Coble et al., 2012). Another large difficulty encountered by the standard rule-based method is how to operate when there is not complete certainty as to which rule should be activated given the measured symptoms. This situation typically arises when the symptom cannot be simply classified into a single qualitative category, such as “low” or “high.” The most common means of handling this uncertainty is by using a fuzzy rule–based system. Similar methods have also received some attention, such as the use of confidence degrees (Deng et al., 2017) or the development of a belief rule-based expert system (Xu et al., 2017). However, fuzzy rule–based fault diagnostic tools are still the most prominently used method in the literature to deal with uncertainty.

Fuzzy rule bases, and the fuzzy logic in general on which they operate, act as a nonlinear mapping between inputs and outputs by means of determining the degree of membership to which “crisp” inputs belong to “fuzzy” qualitative states and using the fuzzy states to determine the consequence of the given inputs. Fuzzy rule bases have found application for fault diagnosis in various disciplines and numerous components—many of which are found in NPPs—including induction motors (Shetgaonkar, 2017), other standard rotating machinery (Da Silva et al., 2017), spur gears (Krishnakumari et al., 2017), bearings (Berredjem and Benidir, 2018), power transformers (Husain, 2018), diesel generators (Nain and Varde, 2013), distributed sensor networks (Bhajantri, 2018), and high-power lithium-ion batteries (Wu et al., 2017).

Despite their advantages over traditional rule-based fault diagnosis, fuzzy rule–based systems are the subject of ongoing research to improve their performance. Work by Yan et al. (2019) and Rodríguez Ramos et al. (2019) both addressed identifying multiple faults using fuzzy rule–based systems. Du et al. (2020) proposed a self-organizing fuzzy logic classifier based on the harmonic mean difference for application in bearing fault diagnosis. That approach in particular is an example of a rule-based method also potentially being classed as a data-driven method because measured fault features were used to train a fuzzy classifier. As a means of further characterizing the uncertainty present in signals and measurements, Wang et al. (2019a) introduced an interval-valued fuzzy spiking neural P system,8 also demonstrated on an example case with the presence of multiple faults.

Data-Driven Methods

Data-driven methods generally rely on a large amount of process data, typically historical, to develop models and reasoning methods (Yang, 2004). Methods traditionally classed as data-driven methods comprise ANNs–discriminative methods (for traditional neural networks), models based on Bayesian statistics or utilizing Bayesian networks (BNs)—generative methods, SVMs–discriminative, and PCA–generative (if unsupervised) or discriminative (supervised). Often, combinations of these methods are used. In addition, many more methods considered as data-driven exist, which have seen less applications in the nuclear field than those presented in this section.

The ANNs constitute a large subject area in data-driven methods for fault diagnostics, and research of ANNs is an extensive field unto itself due to the vast number of techniques and types of neural networks in use. Lin et al. (2021) developed a nearly autonomous management and control (NAMAC) system for advanced reactors and proposed to apply a feed-forward neural network (FFNN) model for NAMAC’s diagnostic digital twin (DT) layer; Gomes and Canedo Medeiros (2015) used a network of Gaussian radial basis functions (RBFs) to identify accidents in an NPP; Banerjee et al. (2020) demonstrated use of an ANN to identify nuclear reactor sensor and actuator faults in the presence of a proportional–integral–derivative controller; Ayo-Imoru and Cilliers (2018) implemented an ANN while using a plant simulator as a dynamic reference. A common theme in the literature sees ANNs working in tandem with some other technique to transform sensory data into a form usable by the ANN. As examples, Messai et al. (2015) and Tagaris et al. (2019) both used data from wavelet transformations; Lee et al. (2021) transformed the number of plant state variables into a 2D image and used a convolutional neural network (CNN) to process the image as a means of diagnosing abnormal states; Saeed et al. (2020) implemented a long short-term memory (LSTM) network and CNN after performing PCA; and Ayodeji et al. (2018) tested the effectiveness of an RBF network and an Elman neural network (ENN) after using PCA to perform noise filtering for NPP fault diagnosis. Another common trend, both in the literature surrounding ANNs for diagnostics and AI as a whole, is the increased interest in utilizing DL methods. In application to NPP fault diagnostics, DL architectures have been applied by Ahmed et al. (2017), Mandal et al. (2017), Peng et al. (2018a), and Kim et al. (2019). Outside of the nuclear industry, Yu et al. (2018) applied DL for fault diagnosis in wind turbines, and Ren et al. (2019) developed a DL diagnoser in autonomous vehicles.

In the current state of the industry, the application of BNs to diagnostics is sparser than those of ANNs. Unlike black-box data-driven methods such as ANNs, the BN approach offers transparent model interpretability, reasoning under uncertainty, and graphical representation capability to emulate the target SSC’s physical behavior (Zhao and Golay, 2020). However, constructing the BN knowledge base is a cumbersome and time-consuming process, and problems using BNs can become intractable for complex scenarios. Wu et al. (2018a) developed a BN framework for fault diagnosis in NPPs with multi-source sensor nodes, and Zhao et al. (2020b) proposed a method to diagnose operational and on-demand failures using dynamic BNs (DBNs). A large body of work on using BNs as fault diagnosers also exists outside the nuclear field. Cai et al. (2017) provided a detailed review of BNs for application in fault diagnosis. Wang et al. (2018) proposed an improved BN method by determining the network structure with a hybrid technique of process knowledge and data-driven correlation, which was validated with the Tennessee Eastman Process open-source benchmark (Downs and Vogel, 1993). Areas where BNs have seen application, in addition to those discussed in Cai et al. (2017), include the general case of industrial processes (Yu and Zhao, 2019), hydroelectric generation systems (Xu et al., 2019), and ground-source heat pumps (Cai et al., 2014). Lastly, as a method used in combination with ANNs, Bayesian statistics was used in Tolo et al. (2019) as a means of connecting a set of neural network architectures for early accident detection in NPPs.

Research efforts directed toward SVMs have been primarily focused on improving the optimization of SVM parameters and then applying the SVM to the problem of fault diagnostics. In the nuclear field, Wang et al. (2019b) developed an improved particle swarm optimization, and Zhang et al. (2015b) used a hybrid of the bare bones particle swarm optimization and differential evolution. Beyond simply developing a better means of parameter optimization, Wang et al. (2021) introduced a hybrid least squares SVM method for fault diagnosis in NPPs. Another approach beyond optimization was to separately train an ensemble of SVMs and combine them after training (Ayodeji and Liu, 2018).

Developments involving PCA are mostly fault diagnosers that utilize PCA combined with another tool, as was observed during the discussion of ANNs. An example of using PCA for fault diagnosis without combination with another major method is that of Li et al. (2018a), which presented an optimized PCA method for fault identification and reconstruction of NPP sensors. An approach fundamental to PCA, however, was the development of statistical methods to reduce the number of false alarms raised by PCA (Li et al., 2018b). Approaches having seen fusion with PCA for fault diagnosis in NPPs include FDA (Jamil et al., 2016), conditional Gaussian networks (Atoui et al., 2015), multilevel flow modeling (Peng et al., 2018b), ENNs (Liu et al., 2017), and SVMs (Xin et al., 2019). Additionally, Wang et al. (2017) used a semiparametric PCA in combination with a BN.

Prognostics

Prognostics is one of the major tasks in PHM as its results are directly used to support proactive decision-making for maintenance practices. The prognostics module is typically defined as the process of predicting the remaining time before the equipment can no longer perform a particular function (i.e., RUL) (Atamuradov et al., 2017). Prognostic calculations cannot be done in isolation and depend largely on the stages of monitoring, detection, and diagnostics: the accuracy of these stages will all affect RUL estimation. It is desirable to develop generalizable prognostic methods that can accurately predict the future equipment state given a set of measurements correlated to the equipment’s current state (Ramuhalli et al., 2020). An appropriate estimate of the equipment’s RUL can improve overall plant performance and reduce costs by optimizing O&M activities. Therefore, prognostics is seen as one of the most beneficial aspects of PHM (Hess, 2002).

Paradoxically, prognostics is an underdeveloped element of PHM systems (Vogl et al., 2019), especially in the nuclear industry (Coble et al., 2015; Ayo-Imoru and Cilliers, 2018). Unlike fault detection and diagnostics, the prognostic technology is just emerging and often is deemed immature due to lack of uncertainty calculations, method verification and validation, and risk assessment for PHM system development (Saxena et al., 2010). Although many approaches to prognostics have been proposed in the literature, the state of practice is mainly at the research level and much of the published work has been exploratory. There is no universally accepted methodology for all prognostic problems (Lee et al., 2011; Coble et al., 2012). A variety of models have been developed for application to specific situations or specific classes of components. As such, prognostic algorithms can be categorized according to different criteria. Based on the recent publications (Atamuradov et al., 2017; Lei et al., 2018; Taheri et al., 2019; Vogl et al., 2019; Baur et al., 2020; Bektas et al., 2020; Ramuhalli et al., 2020) that contain a comprehensive review of prognostics, these algorithms can be loosely divided into four categories according to their basic techniques or methodologies: physics-based methods, knowledge-based methods, data-driven methods, and hybrid methods.

Physics-Based Methods

Physics-based prognostic methods attempt to describe the evolving SSC degradation process based on a comprehensive mathematical model—usually in the form of a series of ordinary or partial differential equations—that represents the underlying physics of failure and encodes the first-principles input-output relationship. The derived mathematical model is combined with CM data to identify model parameters, which are then used to predict the future evolution of SSC health state. A commonly illustrated physics-based method example in the literature is a crack growth model for which Paris’ law (also known as the Paris–Erdogan equation) (Paris and Erdogan, 1963) or the Forman equation (Forman, 1972) is used to relate the growth rate of a fatigue crack to the stress intensity factor and the number of fatigue cycles. Some other examples include prediction of bearing deterioration, turbine creep evolution, pipeline tube degradation, battery life, and gearbox failure (Qiu et al., 2002; Liao and Kottig, 2014; Hu et al., 2016).

When the failure mechanism is well known and correctly captured, a physics-based prognostic model should yield highly robust and accurate RUL prediction for a specific type of component and require less data for tuning (Baur et al., 2020). Unfortunately, the underlying physical processes leading to failure are often not completely understood or cannot be explicitly modeled. In this case, simplifying assumptions and estimations must be made to facilitate model development, raising skepticism about the model’s applicability to real-world engineering systems (An et al., 2015; Coble et al., 2015). Due to their nature of being component-specific, physics-based methods can hardly be reconfigured to fit alternative domains, and most of them are only applicable at the component or subsystem level (Baur et al., 2020; Bektas et al., 2020). When applied to system-level prognostic problems or when multiple failure modes need to be represented (which is the case for a typical SSC in a nuclear facility), the model complexity and associated computational cost may become prohibitive for online analysis and decision-making. For these reasons, Coble et al. (2015) concluded that physics-based methods would be preferable for high-cost, high-risk equipment, such as electronic components in which failure data needed to develop empirical methods might not exist.

Knowledge-Based Methods

Knowledge-based (also known as experience-based or rule-based) prognostic methods are solely built upon expert knowledge. Such methods do not rely on a physical model of the system. Their implementation is relatively simple; however, they are applicable only in cases where expert knowledge exists to mimic human-like representation and reasoning with algorithm families that employ expert systems or fuzzy logics.

Analogous to rule-based diagnostic methods (see “Rule-Based Methods” Section), expert systems for prognostics aim to translate explicit knowledge from experts into human-coded “if-then” rules that closely resemble the way a domain specialist solves the same problem (Liao and Kottig, 2014). They do not perform well when a huge number of rules are needed and cannot handle new situations that are not explicitly coded. Compared with expert systems, fuzzy logic–based prognostic methods are more robust and can handle the uncertainty intrinsic to expert knowledge (Jardine et al., 2006). For complex systems and in the presence of high-volume data, fuzzy logics are typically used in conjunction with data-driven approaches—such as ANN to create a hybrid neuro-fuzzy (NF) model (Lei et al., 2018)—for systematized dimensionality reduction and membership function optimization. The stand-alone knowledge-based methods have been much less studied or recommended by recent publications than the other method categories (Atamuradov et al., 2017) due to their inherent limitations.

The similarity-based prognostics is an alternative knowledge-based approach—such as the one proposed by Liu et al. (2019) for the RUL prediction of a gas turbine—that removes the requirements to model qualitative knowledge from domain experts. Although this approach is sometimes classified under data-driven methods, it actually follows the rule-based modeling philosophy of similarity evaluation between a monitored case and a library of previously known failures (Taheri et al., 2019; Bektas et al., 2020), which does not give enough insight into the current or future condition of the specific SSC in question.

Data-Driven Methods

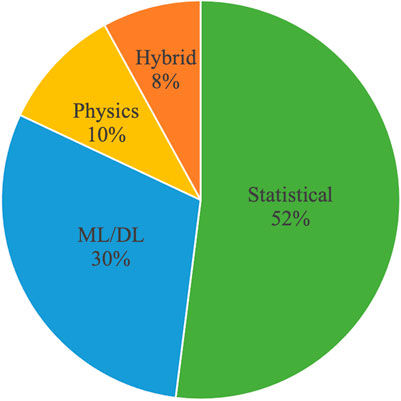

Data-driven prognostic methods directly use CM data for the target SSC and do not incorporate first-principles information or expert knowledge. They rely on trends within the observed data to construct mathematical models to estimate future states of the monitored equipment. As will be further elaborated in this section, the mathematical approaches range from conventional statistical methods to advanced ML and DL techniques. In data-driven methods, no mechanism or input-output relationship needs to be known a priori to produce acceptable results, and the method development/implementation cost is relatively low (Diez-Olivan et al., 2019). Therefore, these methods are highly flexible and can be deployed at any level (component, subsystem, or system level) of the physical asset, which is of particular interest to large, complex systems (Ramuhalli et al., 2020; Sun et al., 2010). As shown in Figure 4, statistical-based and ML/DL-based data-driven methods have attracted most of the research attention in machinery prognostics. However, prognostic models that use a data-driven approach usually require large amounts of data covering a broad range of conditions, including run-to-failure data for degradation models. Availability of run-to-failure data for a particular SSC can be a key challenge (Sutharssan et al., 2015), which is the case of safety-critical systems in NPPs (Coble et al., 2015). The performance and confidence level of RUL predictions are bound to the quantity and quality of available data that are used to infer model parameters and to determine failure thresholds. Furthermore, data-driven methods cannot extrapolate beyond the domain spanned by the training data (Ramuhalli et al., 2020).

FIGURE 4. Distribution of method categories in 274 recently published papers on machinery health prognostics [modified from Lei et al. (2018)].

Statistical-Based Prognostics

Statistical-based prognostic methods, also known as empirical prognostic methods, are a grey-box approach that treats asset degradation as a stochastic process subject to different sources of variability and uncertainty (Baur et al., 2020). In statistical methods, RUL is a random variable whose probability density function is determined based on empirical data. Distinguished by its data-driven nature and ability to incorporate the uncertainty of the degradation process, this method category has been heavily focused upon in the literature, as illustrated in Figure 4 for the field of machinery prognostics. Multiple review papers (Si et al., 2011; Ye and Xie, 2015; Lei et al., 2018; Taheri et al., 2019; Baur et al., 2020; Bektas et al., 2020) have surveyed statistical-based models systematically and have included their advancements in recent years. To unify apparently confusing terminologies used by different authors while minimizing repetition, a summary is provided in this section.

Statistical-based prognostics can be generally classified into two subcategories. Models in the first subcategory are based upon time-series CM data that directly describe the underlying degradation process of the monitored SSC. Both regression- and Markovian-based models fall into this subcategory. In regression-based models, forecasting of time-series data is achieved by using auto-regressive moving average processes, which assume that the future state of the target SSC is linearly dependent of both past observations and normally distributed random noise. These models are easy to implement with low computational cost, but their performance is heavily affected by the trend information of historical observations, which may be unreliable during incipient failure stage and for long-term forecasts (Baur et al., 2020). Recent examples of using regression-based prognostic models include Qian et al. (2014) for bearing wear-out, Barraza-Barraza et al. (2017) for crack growth in aluminum plates, Nguyen et al. (2018) for NPP steam generator degradation, and Mei et al. (2020) for shear building structural damage. In Markovian-based models, the degradation process is assumed to transform within a finite state space that satisfies the Markov (or memoryless) property. With a well-established theoretical basis to support these models, the Markovian approach was first introduced into the field of prognostics by Kharoufeh (2003). It was later refined by Kharoufeh and Cox (2005) and Kharoufeh et al. (2010). This version of Markovian models was not widely adopted by the PHM community because all the health states would need to be observed directly. Moreover, the memoryless assumption may not be valid for some real degradation processes, and a large volume of data or empirical knowledge is typically required for constructing the state transition probability matrix.

Models in the second subcategory rely on partially observed state processes and indirect CM data (i.e., data that can only indirectly indicate the underlying health state of the monitored SSC, such as vibration data). Stochastic filtering-based methods, which are based on the Bayes’ theorem, fall into this subcategory. Built upon DBNs, Kalman filter and particle filter are two of the most common types of filtering algorithms. The basic Kalman filter algorithm is designed for linear Gaussian problems, and some of its enhanced versions have been proposed; the particle filter algorithm is a sequential Monte Carlo method and is a better choice in nonlinear, non-Gaussian systems. Due to their ability to characterize the future uncertainty of degradation processes by updating the probabilistic state estimation from online measurements, both filtering methods have seen many applications in machinery RUL prediction (Lei et al., 2018) and were introduced by Ramuhalli et al. (2010) for prognostics of NPP components. Similar to, yet simpler than the filtering-based models, hidden Markov models (Ghahramani, 2001) are extensions of the standard Markovian approach to incorporate unobservable health states. The hidden Markov models and their variants [e.g., hidden semi-Markov models (Yu, 2010)] have been applied to the PHM framework since the beginning of this century (Baur et al., 2020). However, their capabilities are still limited by the memoryless assumption.

Machine Learning–Based Prognostics

ML-based prognostic methods attempt to learn degradation patterns and predict RUL directly from available observations (or extracted features) using ML or DL techniques. Numerous opportunities have arisen from the continuously fast-growing trends of AI and ML to effectively address the problems of prognostics, especially those in complex multidimensional, nonlinear systems with large amounts of training data representative of true data range and variability. No prior physical understanding of the analyzed SSC is required in ML-based methods. However, as a black-box approach, the results are hard to interpret due to their lack of transparency. The ML-based methods generally provide point estimates of RUL instead of a probabilistic treatment unless additional uncertainty quantification—usually with Bayesian inference methods—is performed. A more fundamental comparison of statistical- and ML-based methods can be found in Bzdok et al. (2018). A variety of ML algorithms have been used for prognostics, which can be loosely grouped into variants of ANN, Gaussian process regression (GPR), and SVM.

The ANNs are the most common modeling techniques in data-driven methods for prognostics (Bektas et al., 2020), just like for fault diagnostics (see “Data-Driven Methods” Section). Comprehensive surveys of ANN architectures—in the context of DL—and their recent applications in machinery prognostics have been presented by Rezaeianjouybari and Shang (2020), Khan and Yairi (2018), and Wang et al. (2020b). Among the multiple types of ANNs in use, FFNNs and recurrent neural networks (RNNs) are the most popular. The FFNNs are the simplest form of ANN and have been mainly used to learn the relationship between the health index9 and RUL (Lei et al., 2018). Lin et al. (2021) recently implemented FFNNs into the prognostic DT of their NAMAC system for advanced reactors. The RNNs, descendants of FFNN, are distinguished by their ability to handle time-series data explicitly. Standard RNNs suffer from vanishing and exploding gradients when learning long-term temporal dependencies; the gated recurrent unit (GRU) and LSTM networks are RNN variants to remedy that problem. Generally, GRUs are computationally less expensive and better suited for smaller data sets, whereas LSTMs work better with large data sets (Rezaeianjouybari and Shang, 2020). A limited number of studies in the literature have applied GRU for prognostic tasks, such as Zhao et al. (2018) for milling machine cutter tool wear prediction, Li et al. (2019b) for rolling bearing RUL, and Chen et al. (2019) for a nonlinear degradation process using the US National Aeronautics and Space Administration’s commercial modular aero-propulsion system simulation (C-MAPSS) turbofan engine data. LSTM-based networks have gained greater attention in applications of RUL prediction. Some recent studies include Ramuhalli et al. (2020) using NPP asset data from the feedwater and condensate system (FWCS) of a boiling water reactor (BWR); Zhao et al. (2017b) using a convolutional bidirectional LSTM and raw sensory data from high-speed milling machine cutters for a real-life tool wear test; Zhang et al. (2018), Wu et al. (2018b), and Elsheikh et al. (2019) using different variants of LSTM on the C-MAPSS data set; Shi and Chehade (2021) using a novel dual-LSTM framework for both change point detection and RUL prediction on the same C-MAPSS data; and Bampoula et al. (2021) using LSTM autoencoders to estimate RUL in a cyber-physical production system. Besides the above two commonly used ANNs, several other variants—such as wavelet neural network (Javed et al., 2014), CNN variants (Wang et al., 2019c; Zhu et al., 2019), generative adversarial network (Khan et al., 2018), and reinforcement learning (Kozjek et al., 2020)—can be found in the literature of prognostics.

The GPR models build upon Gaussian processes—cumulative damage processes of random variables with joint multivariate Gaussian distributions—to predict future health states. In contrast to ANNs, this approach is adaptable to both small- and large-size data sets, although it often suffers from high complexity in terms of computation and storage (Rasmussen, 2004). As elaborated in the modules of fault detection (“Condition Monitoring and Fault Detection” Section) and diagnostics (“Data-Driven Methods” Section), SVMs are well-established supervised learning tools based on the core concept of support vectors. Different SVM variants have been applied to the machinery RUL prediction (Lei et al., 2018). In the nuclear domain, Liu et al. (2015) proposed a dynamic-weighted probabilistic SVM model to evaluate fault scenarios in the reactor coolant pump of a typical pressurized water reactor, and Ramuhalli et al. (2020) applied SVM with both a linear kernel and an optimized Gaussian kernel on a BWR FWCS data source. Compared with ANNs, SVM-based models usually perform better on small data sets and can guarantee a unique solution (i.e., global minimum) to a given problem. However, their performance is strongly correlated with the selected kernel functions.

Hybrid Methods

The physics-based, knowledge-based, and data-driven prognostic methods each have their own strengths and limitations. While appropriate method selection depends on knowledge of the system behavior and available data, a hybrid or fusion approach attempts to integrate the advantages of different method types for improved RUL prediction results. Additionally, in the real world, no single method is deemed adequate to account for all the possible faults and failure modes of an analyzed system (Baur et al., 2020; Venkatasubramanian, 2005). As shown in Figure 4, this area of research is still at its early development stage. The hybrid methods can consist of any combination of the previously described approaches. Of special interest is the ensemble of physics- and ML/DL-based techniques where both physics-of-failure knowledge and experimental data can be properly leveraged (Dourado and Viana, 2020). In this way, the combined approach fosters a physical interpretation of the input-output relationship instead of a black-box treatment while not requiring as accurate physical understanding or large-size data as stand-alone counterparts would do (Zhao et al., 2020a). Another popular direction is to develop hybrid prognostic tools under the Bayesian framework (e.g., Kalman filter and particle filter) because of their robustness and ability to reason under uncertainty. This direction has been the subject of several research studies and has been applied to various applications like rotating machinery, batteries, and electrolytic capacitors (Taheri et al., 2019).

Some hybrid models use one method to predict health state and another one to estimate RUL, while other models attempt to apply both method types to RUL forecasting (Ramuhalli et al., 2020). The selection of the actual model and method is usually driven by the problem and specific to the application. As an example in nuclear systems, Gurgen et al. (2020) recently proposed a physics-guided RNN (with LSTM blocks) prognostic model within the NAMAC system to predict the evolution of fuel centerline temperature in loss of flow transient conditions and demonstrated its superior performance over pure data-driven prognosis. In other fields, research related to the hybrid approach has been much more active (Liao and Kottig, 2014; Atamuradov et al., 2017). Goebel et al. (2006) combined a physics-based model of fault initiation and an empirical model of condition-based fault propagation rate to estimate RUL of avionic roller bearings. Liu et al. (2012) developed a hybrid method to improve the accuracy and transparency of long-horizon lithium-ion battery health state forecasting by leveraging particle filter and ANN predictors (FFNN, NF and recurrent NF). Eker et al. (2019) presented a unified approach integrating the short-term prediction of a physics-based model with the longer-term projection of a data-driven model and validated with run-to-failure observations for crack growth and filter clogging. Yucesan and Viana (2020) proposed a physics-informed neural network model that merged physics- and data-driven layers within a deep neural network to predict main bearing failure in wind turbines.

Decision-Making

Once the current and postulated future health states of a monitored SSC are determined based on CM data and diagnostic/prognostic modeling, it is of crucial importance to be able to act in a timely and correct fashion on possible (incipient) faults/failures before they progress to becoming emergencies. Therefore, decision-making is deemed an indispensable module in the full PHM suite. In this context, the process of decision-making refers to using outputs from the previous modules—failure analysis and probability of failure (POF) estimate from diagnostics, RUL prediction from prognostics—to inform O&M planning and the selection of optimal maintenance action among several alternative options to be executed for the most beneficial operational performance. This process can be conducted by human labors with different operator decision support levels, or ultimately through autonomy-enabled technologies. If properly implemented, this module will play an impactful and beneficial role in asset integrity management as well as planning for O&M activities and staffing levels.

While the study of decision theories has a rich history, autonomy—i.e., operation without relying on human intervention—is in large part an advancement that appeared with the invention of computers and programmable devices that could perform fairly complex computations. Significant technological advances in controls and autonomy have been demonstrated in robotics, aerospace, unmanned aerial vehicles, and self-driving automobiles. However, autonomous control has not been extensively studied for any operating NPP or any new reactor concept (Wood et al., 2017). The nuclear industry lags far behind some other industries (such as avionics and electronics) in transferring the current human-based roles and responsibilities to cutting-edge machines, systems, and controls. To date, NPP equipment surveillance, diagnostics, and prognostics have been mostly used for offline asset management and modest decision support, but those technologies are not being fully leveraged for intelligent, optimal O&M planning and control. To achieve the desired operational efficiency with a reduced staffing burden, autonomous decision-making capabilities must be developed and demonstrated in the nuclear power context.

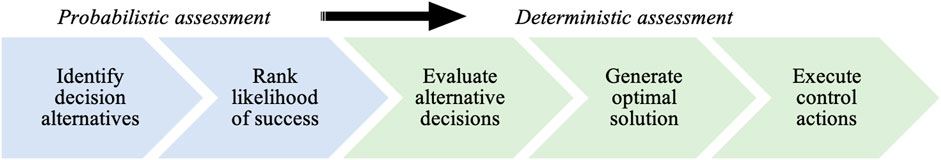

Given the current status and apparent gaps for NPPs, this section first provides a summary of general approaches used in decision-making, all of which are driven by data to a certain extent. [See Cetiner et al. (2014) and Cetiner and Ramuhalli (2019) for more detailed surveys]. A pioneering study in the nuclear domain by Ramuhalli et al. (2017) is then briefly presented to showcase the ability to integrate diagnostics and prognostics results with supervisory control systems for making risk-informed autonomous decisions that utilize real-time information on component conditions.

Decision-Making Methods

Statistical Decision Theory