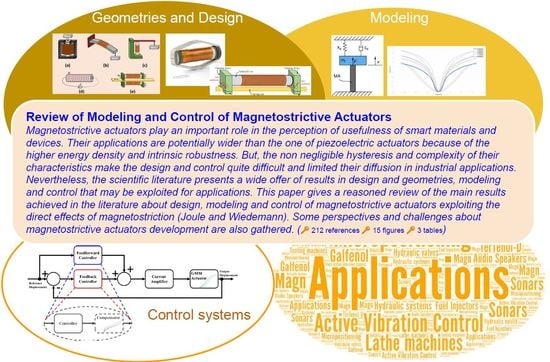

Review of Modeling and Control of Magnetostrictive Actuators

Abstract

:1. Introduction

- Micropositioning. The micrometric strokes of both Terfenol and Galfenol alloys, along with high exerted forces, is exploited for micropositioning task, normally with low or very low working frequencies. Micrometric or sub-micrometric actuations are normally attained. The actuation precision represents the basic performance parameter of such application, which could be compromised by rate-independent memory effects, i.e., hysteresis, mainly shown by rare earth-based ternary compounds [38,39,40,41].

- Motors. The relatively high strokes provided by magnetostrictive materials allows conceiving micro- or inchworm-motors [38,42,43] with promising characteristics in terms of forces/torques and resolution at low speed. Several solution have been proposed in the last decades, such as friction motors, e.g., Flex-M1 by Cedrat Researches [44] or other prototypes invented in different research centers. An interesting and quite exhaustive review was provided by Claeyssen et al. [11]. The availability of Fe-Ga alloys allowed inventing micro-motors where the active material was suitably shaped due to its good mechanical characteristics [45], which demonstrated the applicability of lower-stroke magnetostrictives for actuation purposes.

- Active Vibration Control. This application has seen piezo-actuators as the leading solution in high frequency application of smart materials. However, due to their high strokes and higher energy density (1.4–2.5 J/m), magnetostrictive materials attracted the interests for that kind of high frequency actuation [46,47]. During the early 2000s, EU projects facilitated the rise of research consortiums from industries and research institutions to seek new solutions to the vibration control for aeronautical applications (MESA and MESEMA projects), in which Terfenol-D was widely investigated [48].

- Miscellanea. The framework of application for magnetostrictive materials is not limited to the above issues, but offers specific solutions to specific actuation problems. Among them, the needle actuation for fuel injectors is one of the most interesting applications of MA [10], which were also exploited for micro-pumps [49] or acoustic applications [50].

- The active material, such as Terfenol or Galfenol, is in the shape of cylindrical rods, beams, cymbals, etc.

- The magnetic circuit is necessary to guide the magnetic flux lines and strengthen the field within the active material. Permanent magnets can be added to impart a magnetic bias to the active material.

- The power coil is required to apply the input current and to induce the magnetic field.

- The structural frame has the function of applying a mechanical prestress through the use of springs, to mechanically decouple the active rod from external forces and to make the displacement available outside by using a steel cylinder or a threaded bar.

- Sensor(s) is required to detect displacement, force, strain, current, etc. and is exploited for monitoring purposes or to provide the feedback signal in the feedback control loop.

2. Geometries and Design

2.1. Linear

2.2. Cantilever

2.3. Amplified Configurations

2.4. Inchworm Actuators

2.5. Others Geometries

2.6. Magnetoelectric Coupling in Magnetostrictive Actuators

3. Modeling

- Physics-based models or phenomenological models: In the first category, models relate some basic physical properties of magnetostrictive or magnetic behavior to macroscopic quantities, while, in the second category, the models simply treat the material as a black-box and relate the input and output from a phenomenological point of view.

- Linear, nonlinear or hysteretic models.

- One-input one-output models, two-input one-output models or two-input two-output models: These consider among the two mechanical local variables (strain and stress) and two magnetic ones (field and induction), or among the macroscopic variables (displacement and force, current and magnetic flux).

- Low frequency (rate-independent) or dynamic modeling: This considers whether dynamic phenomena within the active material, the structural frame (inertia or elastic effects) or the magnetic circuit (eddy currents, etc) are neglected.

- Dimension of modeling: The model may be composed by lumped elements or allow a spatial variability of fields in 1D, 2D or 3D.

Characterization

4. Control

Smart Self-Sensing

5. Applications

6. Conclusions

Funding

Conflicts of Interest

Appendix A. Technical Information on the Review

- TITLE ((magnetostrictive OR magnetostrictives) AND (review OR overview OR survey)), to look for other reviews.

- TITLE-ABS-KEY ((magnetostrictive OR magnetostrictives) AND (actuator OR actuators) AND ∗ AND ( model OR modeling OR modeling)), to look for papers on the ∗ type of model.

- TITLE-ABS-KEY ((magnetostrictive OR magnetostrictives) AND (actuator OR actuators) AND (control OR robust OR loop)), to look for papers on control systems.

- TITLE ((actuator OR actuators) AND (magnetostrictives OR magnetostrictive OR magnetostriction)), red line; and

- TITLE ((magnetostrictives OR magnetostrictive OR magnetostriction)), blue line.

References

- Joule, J.P. On the effects of magnetism upon the dimensions of iron and steel bars. Lond. Edinb. Dublin Philos. Mag. 1847, 30, 76–87. [Google Scholar]

- Villari, E. Ueber die Aenderungen des magnetischen Moments, welche der Zug un das Hindurchleiten eines galvanischen Stroms in einem Stabe von Stahl oder Eisen hervorbringen. Annalen der Physik 1865, 202, 87–122. (In German) [Google Scholar] [CrossRef]

- Lee, E.W. Magnetostriction and Magnetomechanical Effects. Rep. Prog. Phys. 1955, 18, 184–229. [Google Scholar] [CrossRef]

- Malyugin, D.V. On the theory of Wiedemann effects. J. Magn. Magn. Mater. 1991, 97, 193–197. [Google Scholar] [CrossRef]

- Vinogradov, S.; Cobb, A.; Light, G. Review of magnetostrictive transducers (MsT) utilizing reversed Wiedemann effect. AIP Conf. Proc. 2017, 1806, 020008. [Google Scholar] [CrossRef]

- Matteucci, C. Recherches expérimentales sur les phénomènes électromagnétiques développés par la torsion. Ann. Chim. Phys. 1858, 53, 385–417. (In French) [Google Scholar]

- Charubin, T.; Nowicki, M.; Szewczyk, R. Influence of torsion on Matteucci effect signal parameters in co-based bistable amorphous wire. Materials 2019, 12, 532. [Google Scholar] [CrossRef] [PubMed]

- Mohri, K.; Humphrey, F.; Panina, L.; Honkura, Y.; Yamasaki, J.; Uchiyama, T.; Hirami, M. Advances of amorphous wire magnetics over 27 years. Phys. Status Solidi A Appl. Mater. Sci. 2009, 206, 601–607. [Google Scholar] [CrossRef]

- Deng, Z.; Dapino, M. Review of magnetostrictive materials for structural vibration control. Smart Mater. Struct. 2018, 27, 113001. [Google Scholar] [CrossRef] [Green Version]

- Xue, G.; Zhang, P.; Li, X.; He, Z.; Wang, H.; Li, Y.; Ce, R.; Zeng, W.; Li, B. A review of giant magnetostrictive injector (GMI). Sens. Actuators A Phys. 2018, 273, 159–181. [Google Scholar] [CrossRef]

- Claeyssen, F.; Lhermet, N.; Le Letty, R.; Bouchilloux, P. Actuators, transducers and motors based on giant magnetostrictive materials. J. Alloys Compd. 1997, 258, 61–73. [Google Scholar] [CrossRef]

- Narita, F.; Fox, M. A review on piezoelectric, magnetostrictive, and magnetoelectric materials and device technologies for energy harvesting applications. Adv. Eng. Mater. 2018, 20, 1700743. [Google Scholar] [CrossRef]

- Bai, Y.; Jantunen, H.; Juuti, J. Energy harvesting research: The road from single source to multisource. Ad. Mater. 2018, 30, 1707271. [Google Scholar] [CrossRef] [PubMed]

- Deng, Z.; Dapino, M. Review of magnetostrictive vibration energy harvesters. Smart Mater. Struct. 2017, 26, 103001. [Google Scholar] [CrossRef]

- Annapureddy, V.; Palneedi, H.; Hwang, G.T.; Peddigari, M.; Jeong, D.Y.; Yoon, W.H.; Kim, K.H.; Ryu, J. Magnetic energy harvesting with magnetoelectrics: An emerging technology for self-powered autonomous systems. Sustain. Energy Fuels 2017, 1, 2039–2052. [Google Scholar] [CrossRef]

- Thoburn, W.; Legvold, S.; Spedding, F. Magnetic properties of terbium metal. Phys. Rev. 1958, 112, 56–58. [Google Scholar] [CrossRef]

- Clark, A.; DeSavage, B.; Bozorth, R. Anomalous thermal expansion and magnetostriction of single-crystal dysprosium. Phys. Rev. 1965, 138, A216–A224. [Google Scholar] [CrossRef]

- Rhyne, J.; Legvold, S. Magnetostriction of Tb single crystals. Phys. Rev. 1965, 138, A507–A514. [Google Scholar] [CrossRef]

- Clark, A.; DeSavage, B.; Callen, E. Magnetostriction of single-crystal dysprosium, gadolinium iron garnet, and dysprosium iron garnet. J. Appl. Phys. 1964, 35, 1028–1029. [Google Scholar] [CrossRef]

- Clark, A.; Belson, H. Giant room-temperature magnetostrictions in TbFe2 and DyFe2. Phys. Rev. B 1972, 5, 3642–3644. [Google Scholar] [CrossRef]

- Clark, A.; Abbundi, R.; Savage, H.; McMasters, O. Magnetostriction of rare earth-Fe2 laves phase compounds. Phys. B+C 1977, 86–88, 73–74. [Google Scholar] [CrossRef]

- Savage, H.; Abbundi, R.; Clark, A.; McMasters, O. Magnetomechanical coupling and magnetostriction in vertically zoned Tb0.27Dy0.73Fe2. J. Magn. Magn. Mater. 1980, 15-18, 609–610. [Google Scholar] [CrossRef]

- Engdahl, G. Handbook of Giant Magnetostrictive Materials; Academic Press–Elsevier Science: Cambridge, MA, USA, 1999. [Google Scholar]

- Hall, R. Single crystal anisotropy and magnetostriction constants of several ferromagnetic materials including alloys of NiFe, SiFe, AlFe, CoNi, and CoFe. J. Appl. Phys. 1959, 30, 816–819. [Google Scholar] [CrossRef]

- Stoelinga, J.; Gersdorf, R.; De Vries, G. Forced magnetostriction and its temperature-dependence of binary alloys between iron, cobalt and nickel. Physica 1965, 31, 349–361. [Google Scholar] [CrossRef]

- Clark, A.; Restorff, J.; Wun-Fogle, M.; Lograsso, T.; Schlagel, D. Magnetostrictive properties of body-centered cubic Fe-Ga and Fe-Ga-Al alloys. IEEE Trans. Magn. 2000, 36, 3238–3240. [Google Scholar] [CrossRef]

- Clark, A.; Wun-Fogle, M.; Restorff, J.; Lograsso, T.; Cullen, J. Effect of Quenching on the Magnetostriction of Fe1−xGax (0.13 < x < 0.21). IEEE Trans. Magn. 2001, 37, 2678–2680. [Google Scholar] [CrossRef]

- Butler, J.L. Application Manual for the Design of ETREMA Terfenol-D Magnetostrictive Transducers; EDGE Technologies Inc.: Ames, IA, USA, 1988. [Google Scholar]

- Ueno, T.; Higuchi, T. Investigation of micro bending actuator using iron-gallium alloy (Galfenol). In Proceedings of the 2007 International Symposium on Micro-NanoMechatronics and Human Science, Nagoya, Japan, 11–14 November 2007; pp. 460–465. [Google Scholar]

- Vranish, J.; Mitchell, E.; Demoyer, R. Outstanding potential shown by magnetoelastic force feedback sensors for robots. Sens. Rev. 1982, 2, 200–205. [Google Scholar] [CrossRef]

- Vranish, J.; Mitchell, E.; Demoyer, R. Magnetoelastic force feedback sensors for robots and machine tools. Proc. SPIE Int. Soc. Opt. Eng. 1983, 360, 253–263. [Google Scholar] [CrossRef]

- Clark, A.; Savage, H.T. Variable Delay line. U.S. Patent 3,949,351, 6 April 1976. [Google Scholar]

- Clark, A. Magnetostrictive Transducer. U.S. Patent 4,158,368, 19 June 1979. [Google Scholar]

- Anjanappa, M.; Bi, J. A theoretical and experimental study of magnetostrictive mini-actuators. Smart Mater. Struct. 1994, 3, 83–91. [Google Scholar] [CrossRef]

- Anjanappa, M.; Bi, J. Magnetostrictive mini actuators for smart structure applications. Smart Mater. Struct. 1994, 3, 383–390. [Google Scholar] [CrossRef]

- Goodfriend, M.; Sewell, J.; Jones, C. Application of a magnetostrictive alloy, terfenol-D to direct control of hydraulic valves. J. Commer. Veh. 1990, 99, 364–369. [Google Scholar]

- Atulasimha, J.; Flatau, A. A review of magnetostrictive iron-gallium alloys. Smart Mater. Struct. 2011, 20, 043001. [Google Scholar] [CrossRef]

- Fukuda, T.; Hosokai, H.; Ohyama, H.; Hashimoto, H.; Arai, F. Giant magnetostrictive alloy (GMA) applications to micro mobile robot as a micro actuator without power supply cables. In Proceedings of the IEEE Micro Electro Mechanical Systems, Nara, Japan, 30 December–2 January 1991; pp. 210–215. [Google Scholar]

- Quandt, E.; Ludwig, A. Magnetostrictive actuation in microsystems. Sens. Actuators A Phys. 2000, 81, 275–280. [Google Scholar] [CrossRef]

- Yang, B.; Bonis, M.; Tao, H.; Prelle, C.; Lamarque, F. A magnetostrictive mini actuator for long-stroke positioning with nanometer resolution. J. Micromech. Microeng. 2006, 16, 1227. [Google Scholar] [CrossRef]

- Cavallo, A.; Natale, C.; Pirozzi, S.; Visone, C.; Formisano, A. Feedback control systems for micropositioning tasks with hysteresis compensation. IEEE Trans. Magn. 2004, 40, 876–879. [Google Scholar] [CrossRef]

- Goldie, J.H.; Gerver, M.J.; Kiley, J.E.; Swenbeck, J.R. Observations and theory of Terfenol-D inchworm motors. In Proceedings of the 5th Annual International Symposium on Smart Structures and Materials, San Diego, CA, USA, 1–5 March 1998; Volume 3329, pp. 780–786. [Google Scholar]

- Vranish, J.; Naik, D.; Restorff, J.; Teter, J. Magnetostrictive direct drive rotary motor development. IEEE Trans. Magn. 1991, 27, 5355–5357. [Google Scholar] [CrossRef]

- Cedrat Technologies. Available online: https://www.cedrat-technologies.com (accessed on 13 March 2019).

- Zhang, Z.; Ueno, T.; Higuchi, T. Development of a magnetostrictive linear motor for microrobots using Fe-Ga (Galfenol) alloys. IEEE Trans. Magn. 2009, 45, 4598–4600. [Google Scholar] [CrossRef]

- Goodfriend, M.; Shoop, K. Adaptive characteristics of the magnetostrictive alloy, terfenol-D, for active vibration control. J. Intell. Mater. Syst. Struct. 1992, 3, 245–254. [Google Scholar] [CrossRef]

- Hiller, M.; Bryant, M.; Umegaki, J. Attenuation and transformation of vibration through active control of magnetostrictive terfenol. J. Sound Vib. 1989, 134, 507–519. [Google Scholar] [CrossRef]

- Boglietti, A.; Cavagnino, A.; Tenconi, A.; Vaschetto, S. The safety critical electric machines and drives in the more electric aircraft: A survey. In Proceedings of the 35th Annual Conference of IEEE Industrial Electronics, Porto, Portugal, 3–5 November 2009; pp. 2587–2594. [Google Scholar] [CrossRef]

- Lhermet, N.; Delas, O.; Claeyssen, F. Magnetostrictive Pump with Piezo Active Valves for More Electrical Aircraft. In Proceedings of the 10th International Conference on New Actuators (ACTUATOR 2006), Bremen, Germany, 14–16 June 2006; Volume 1, pp. 964–967. [Google Scholar]

- Zhou, J.J.; Wang, Y.S.; Wang, X.; Meng, A.H.; Pan, Y.L. Design of a flat-panel loudspeaker with giant magnetostrictive exciters. In Proceedings of the 2008 Symposium on Piezoelectricity, Acoustic Waves, and Device Applications, Nanjing, China, 5–8 December 2008; pp. 528–532. [Google Scholar] [CrossRef]

- Sablik, M.J.; Jiles, D.C. Coupled magnetoelastic theory of magnetic and magnetostrictive hysteresis. IEEE Trans. Magn. 1993, 29, 2113–2123. [Google Scholar] [CrossRef]

- Hughes, D.; Wen, J.T. Preisach modeling of piezoceramic and shape memory alloy hysteresis. Smart Mater. Struct. 1997, 6, 287. [Google Scholar] [CrossRef]

- Visone, C.; Serpico, C. Hysteresis operators for the modeling of magnetostrictive materials. Phys. B Condens. Matter 2001, 306, 78–83. [Google Scholar] [CrossRef]

- Natale, C.; Velardi, F.; Visone, C. Identification and compensation of Preisach hysteresis models for magnetostrictive actuators. Phys. B Condens. Matter 2001, 306, 161–165. [Google Scholar] [CrossRef]

- Tan, X.; Baras, J. Modeling and control of a magnetostrictive actuator. In Proceedings of the 41st IEEE Conference on Decision and Control, Las Vegas, NV, USA, 10–13 December 2002; Volume 1, pp. 866–872. [Google Scholar]

- Kuhnen, K. Modeling, identification and compensation of complex hysteretic nonlinearities: A modified Prandtl-Ishlinskii approach. Eur. J. Control 2003, 9, 407–418. [Google Scholar] [CrossRef]

- Benbouzid, M.E.H.; Reyne, G.; Meunier, G. Nonlinear finite element modelling of giant magnetostriction. IEEE Trans. Magn. 1993, 29, 2467–2469. [Google Scholar] [CrossRef]

- Kannan, K.; Dasgupta, A. A nonlinear Galerkin finite-element theory for modeling magnetostrictive smart structures. Smart Mater. Struct. 1997, 6, 341. [Google Scholar] [CrossRef]

- Gros, L.; Reyne, G.; Body, C.; Meunier, G. Strong coupling magneto mechanical methods applied to model heavy magnetostrictive actuators. IEEE Trans. Magn. 1998, 34, 3150–3153. [Google Scholar] [CrossRef]

- Engdahl, G.; Bergqvist, A. Loss simulations in magnetostrictive actuators. J. Appl. Phys. 1996, 79, 4689–4691. [Google Scholar] [CrossRef]

- Davino, D.; Natale, C.; Pirozzi, S.; Visone, C. Rate-dependent losses modeling for magnetostrictive actuators. J. Magn. Magn. Mater. 2004, 272–276, E1781–E1782. [Google Scholar] [CrossRef]

- Zucca, M.; Roccato, P.E.; Bottauscio, O.; Beatrice, C. Analysis of losses in a magnetostrictive device under dynamic supply conditions. IEEE Trans. Magn. 2010, 46, 183–186. [Google Scholar] [CrossRef]

- Davino, D.; Giustiniani, A.; Visone, C.; Zamboni, W. Stress-induced eddy currents in magnetostrictive energy harvesting devices. IEEE Trans. Magn. 2012, 48, 18–25. [Google Scholar] [CrossRef]

- Smith, R.C. Inverse compensation for hysteresis in magnetostrictive transducers. Math. Comput. Model. 2001, 33, 285–298. [Google Scholar] [CrossRef] [Green Version]

- Schäfer, J.; Janocha, H. Compensation of hysteresis in solid-state actuators. Sens. Actuators A Phys. 1995, 49, 97–102. [Google Scholar] [CrossRef]

- Visone, C.; Sjöström, M. Exact invertible hysteresis models based on play operators. Phys. B Condens. Matter 2004, 343, 148–152. [Google Scholar] [CrossRef]

- Kim, Y.; Kwon, Y. Review of magnetostrictive patch transducers and applications in ultrasonic nondestructive testing of waveguides. Ultrasonics 2015, 62, 3–19. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Calkins, F.; Flatau, A.; Dapino, M. Overview of magnetostrictive sensor technology. J. Intell. Mater. Syst. Struct. 2007, 18, 1057–1066. [Google Scholar] [CrossRef]

- Mitchell, E.E.; Harrison, E. Stroke limit effects on machine tool regulation with a magnetostrictive actuator. Am. Soc. Mech. Eng. 1974, 97, 70. [Google Scholar]

- Zhang, T.; Jiang, C.; Zhang, H.; Xu, H. Giant magnetostrictive actuators for active vibration control. Smart Mater. Struct. 2004, 13, 473–477. [Google Scholar] [CrossRef]

- Kim, W.-j.; Sadighi, A. A novel low-power linear magnetostrictive actuator with local three-phase excitation. IEEE/ASME Trans. Mech. 2010, 15, 299–307. [Google Scholar]

- Braghin, F.; Cinquemani, S.; Resta, F. A model of magnetostrictive actuators for active vibration control. Sens. Actuators A Phys. 2011, 165, 342–350. [Google Scholar] [CrossRef]

- Rong, C.; He, Z.; Li, D.; Yang, Z.; Xue, G. Dynamic modeling and analysis of stack giant magnetostrictive actuator. Sens. Actuators A Phys. 2018, 276, 205–218. [Google Scholar] [CrossRef] [Green Version]

- Ju, X.J.; Lin, M.X.; Fan, W.T.; Bu, Q.Q.; Wu, X.J. Structure design and characteristics analysis of a cylindrical giant magnetostrictive actuator for ball screw preload. J. Cent. South Univ. 2018, 25, 1799–1812. [Google Scholar] [CrossRef]

- Moon, S.J.; Lim, C.W.; Kim, B.H.; Park, Y. Structural vibration control using linear magnetostrictive actuators. J. Sound Vib. 2007, 302, 875–891. [Google Scholar] [CrossRef]

- Chowdhury, H.; Mazlan, S.A.; Olabi, A.G. Implementation of magnetostrictive material Terfenol-D in CNG fuel injection actuation. Adv. Mater. Res. 2008, 47, 630–633. [Google Scholar] [CrossRef]

- Kim, J.; Doo, J. Magnetostrictive self-moving cell linear motor. Mechatronics 2003, 13, 739–753. [Google Scholar] [CrossRef]

- Ueno, T.; Summers, E.; Wun-Fogle, M.; Higuchi, T. Micro-magnetostrictive vibrator using iron–gallium alloy. Sens. Actuators A Phys. 2008, 148, 280–284. [Google Scholar] [CrossRef]

- Tiercelin, N.; Pernod, P.; Preobrazhensky, V.; Le Gall, H.; Youssef, J.B. Non-linear actuation of cantilevers using giant magnetostrictive thin films. Ultrasonics 2000, 38, 64–66. [Google Scholar] [CrossRef]

- Ueno, T.; Higuchi, T. Magnetostrictive bending micro-actuator using iron gallium-alloy. In Proceedings of the SPIE Smart Structures and Materials + Nondestructive Evaluation and Health Monitoring, San Diego, CA, USA, 18–22 March 2007; Volume 6526, p. 65262J. [Google Scholar]

- Quandt, E.; Seemann, K. Fabrication and simulation of magnetostrictive thin-film actuators. Sens. Actuators A Phys. 1995, 50, 105–109. [Google Scholar] [CrossRef]

- Honda, T.; Arai, K.; Yamaguchi, M. Fabrication of actuators using magnetostrictive thin films. In Proceedings of the IEEE Micro Electro Mechanical Systems An Investigation of Micro Structures, Sensors, Actuators, Machines and Robotic Systems, Oiso, Japan, 25–28 January 1994; pp. 51–56. [Google Scholar]

- Ludwig, A.; Quandt, E. Giant magnetostrictive thin films for applications in microelectromechanical systems. J. Appl. Phys. 2000, 87, 4691–4695. [Google Scholar] [CrossRef]

- Basantkumar, R.R.; Stadler, B.H.; Robbins, W.P.; Summers, E.M. Integration of thin-film galfenol with MEMS cantilevers for magnetic actuation. IEEE Trans. Magn. 2006, 42, 3102–3104. [Google Scholar] [CrossRef]

- Zhang, K.; Zhang, L.; Fu, L.; Li, S.; Chen, H.; Cheng, Z.Y. Magnetostrictive resonators as sensors and actuators. Sens. Actuators A Phys. 2013, 200, 2–10. [Google Scholar] [CrossRef]

- Ishiyama, K.; Yokota, C. Cantilevered actuator using magnetostrictive thin film. J. Magn. Magn. Mater. 2008, 320, 2481–2484. [Google Scholar] [CrossRef]

- Karunanidhi, S.; Singaperumal, M. Design, analysis and simulation of magnetostrictive actuator and its application to high dynamic servo valve. Sens. Actuators A Phys. 2010, 157, 185–197. [Google Scholar] [CrossRef]

- Pan, P.S.; Yang, B.T.; Meng, G.; Li, J.Q. Design and simulation of a mini precision positioning magnetostrictive inchworm linear motor. Appl. Mech. Mater. 2012, 130, 2846–2850. [Google Scholar] [CrossRef]

- Zhou, N.; Blatchley, C.C.; Ibeh, C.C. Design and construction of a novel rotary magnetostrictive motor. J. Appl. Phys. 2009, 105, 07F113. [Google Scholar] [CrossRef]

- Yang, Z.; He, Z.; Li, D.; Xue, G.; Cui, X. Hydraulic amplifier design and its application to direct drive valve based on magnetostrictive actuator. Sens. Actuators A Phys. 2014, 216, 52–63. [Google Scholar] [CrossRef]

- Chakrabarti, S.; Dapino, M.J. Design and modeling of a hydraulically amplified magnetostrictive actuator for automotive engine mounts. In Proceedings of the SPIE Smart Structures and Materials + Nondestructive Evaluation and Health Monitoring, San Diego, CA, USA, 7–11 March 2010; Volume 7645, p. 76450G. [Google Scholar]

- Bushko, D.; Goldie, J. High Performance Magnetostrictive Actuators. IEEE Aerosp. Electr. Syst. Mag. 1991, 6, 21–25. [Google Scholar] [CrossRef]

- Lu, Q.; Nie, Q.; Jiang, X.; Cao, Q.; Chen, D. Magnetostrictive actuator with differential displacement amplification mechanism. Mechanics 2016, 22, 273–278. [Google Scholar] [CrossRef]

- Niu, M.; Yang, B.; Yang, Y.; Meng, G. Modeling and optimization of magnetostrictive actuator amplified by compliant mechanism. Smart Mater. Struct. 2017, 26, 095029. [Google Scholar] [CrossRef]

- Bartlett, P.; Eaton, S.; Gore, J.; Metheringham, W.; Jenner, A. High-power, low frequency magnetostrictive actuation for anti-vibration applications. Sens. Actuators A Phys. 2001, 91, 133–136. [Google Scholar] [CrossRef]

- Tanaka, H.; Sato, Y.; Urai, T. Development of a common-rail proportional injector controlled by a tandem arrayed giant-magnetostrictive-actuator. SAE Trans. 2001, 110, 2010–2014. [Google Scholar]

- Sato, Y. Characteristics of a proportional injector for common rail injection system (2nd report, injection characteristics of the injector controlled by a tandem-type gian–magnetostrictive actuator. Trans. Jpn. Soc. Mech. Eng. Part C 2000, 66, 2286–2291. [Google Scholar] [CrossRef]

- Braghin, F.; Cinquemani, S.; Resta, F. A low frequency magnetostrictive inertial actuator for vibration control. Sens. Actuators A Phys. 2012, 180, 67–74. [Google Scholar] [CrossRef]

- Shi-xiang, J. Research on giant magnetostrictive material controller mode. In Proceedings of the 2011 International Conference on Electronics, Communications and Control (ICECC), Ningbo, China, 9–11 September 2011; pp. 4476–4479. [Google Scholar]

- Yang, B.; Yang, D.; Meng, G.; Chen, K.; Qi, Y.; Zhou, H.; Hou, P. Application study on giant-magnetostrictive actuator for driving segmented mirrors of very large astronomical telescope. In Proceedings of the International Conference on Smart Materials and Nanotechnology in Engineering, Harbin, China, 1–4 July 2007; Volume 6423, p. 64230Z. [Google Scholar]

- Miesner, J.E.; Teter, J.P. Piezoelectric/magnetostrictive resonant inchworm motor. In Proceedings of the 1994 North American Conference on Smart Structures and Materials, Orlando, FL, USA, 13–18 February 1994; Volume 2190, pp. 520–528. [Google Scholar]

- Kim, J.; Kim, H.K.; Choi, S.B. A hybrid inchworm linear motor. Mechatronics 2002, 12, 525–542. [Google Scholar] [CrossRef]

- Xu, X.; Sun, F.; Wang, G. The control and optimization design of the fish-like underwater robot with the aid of the giant magnetostrictive material actuator. J. Vib. Control 2009, 15, 1443–1462. [Google Scholar] [CrossRef]

- Park, J.; Oh, O.; Park, Y.; Wereley, N. A novel concept and proof of magnetostrictive motor. IEEE Trans. Magn. 2013, 49, 3379–3382. [Google Scholar] [CrossRef]

- Aksinin, V.; Apollonov, V.; Borodin, V.; Brynskikh, A.; Chetkin, S.; Murav’ev, S.; Ostanin, V.; Vdovin, G. Spring-type magnetostriction actuator based on the Wiedemam effect. Sens. Actuators A Phys. 1990, 21, 236–242. [Google Scholar] [CrossRef]

- Karafi, M.R.; Korivand, S. Design and fabrication of a novel vibration-assisted drilling tool using a torsional magnetostrictive transducer. Int. J. Adv. Manuf. Technol. 2019, 102, 2095–2106. [Google Scholar] [CrossRef]

- Ueno, T.; Higuchi, T.; Saito, C.; Imaizumi, N.; Wun-Fogle, M. Micromagnetostrictive vibrator using a U-shaped core of iron-gallium alloy (Galfenol). J. Appl. Phys. 2008, 103, 07E904. [Google Scholar] [CrossRef]

- Smith, I.; Overshott, K. The Wiedemann effect: a theoretical and experimental comparison. Br. J. Appl. Phys. 1965, 16, 1247. [Google Scholar] [CrossRef]

- Fiebig, M. Revival of the magnetoelectric effect. J. Phys. D Appl. Phys. 2005, 38, R123–R152. [Google Scholar] [CrossRef]

- Nan, C.W.; Bichurin, M.; Dong, S.; Viehland, D.; Srinivasan, G. Multiferroic magnetoelectric composites: Historical perspective, status, and future directions. J. Appl. Phys. 2008, 103, 031101. [Google Scholar] [CrossRef]

- Wang, Y.; Hu, J.; Lin, Y.; Nan, C.W. Multiferroic magnetoelectric composite nanostructures. NPG Asia Mater. 2010, 2, 61–68. [Google Scholar] [CrossRef] [Green Version]

- Nan, C.W. Magnetoelectric effect in composites of piezoelectric and piezomagnetic phases. Phys. Rev. B 1994, 50, 6082–6088. [Google Scholar] [CrossRef] [PubMed]

- Martins, P.; Lanceros-Méndez, S. Polymer-based magnetoelectric materials. Adv. Funct. Mater. 2013, 23, 3371–3385. [Google Scholar] [CrossRef]

- Quandt, E.; Stein, S.; Wuttig, M. Magnetic vector field sensor using magnetoelectric thin-film composites. IEEE Trans. Magn. 2005, 41, 3667–3669. [Google Scholar] [CrossRef]

- Stein, S.; Wuttig, M.; Viehland, D.; Quandt, E. Magnetoelectric effect in sputtered composites. J. Appl. Phys. 2005, 97, 10Q301. [Google Scholar] [CrossRef] [Green Version]

- Jahns, R.; Piorra, A.; Lage, E.; Kirchhof, C.; Meyners, D.; Gugat, J.; Krantz, M.; Gerken, M.; Knöchel, R.; Quandt, E. Giant magnetoelectric effect in thin-film composites. J. Am. Ceram. Soc. 2013, 96, 1673–1681. [Google Scholar] [CrossRef]

- Shindo, Y.; Mori, K.; Narita, F. Electromagneto-mechanical fields of giant magnetostrictive/piezoelectric laminates. Acta Mech. 2010, 212, 253–261. [Google Scholar] [CrossRef]

- Wang, Y.; Or, S.; Chan, H.; Zhao, X.; Luo, H. Giant magnetoelectric effect in mechanically clamped heterostructures of magnetostrictive alloy and piezoelectric crystal-alloy cymbal. Appl. Phys. Lett. 2008, 93, 213504. [Google Scholar] [CrossRef]

- Ryu, J.; Carazo, A.; Uchino, K.; Kim, H.E. Magnetoelectric properties in piezoelectric and magnetostrictive laminate composites. Jpn. J. Appl. Phys. Part 1 Regul. Pap. Short Notes Rev. Pap. 2001, 40, 4948–4951. [Google Scholar] [CrossRef]

- More-Chevalier, J.; Lüders, U.; Cibert, C.; Nosov, A.; Domengès, B.; Bouregba, R.; Poullain, G. Magnetoelectric coupling in Pb(Zr,Ti)O3—Galfenol thin film heterostructures. Appl. Phys. Lett. 2015, 107, 252903. [Google Scholar] [CrossRef]

- Tiercelin, N.; Preobrazhensky, V.; Mortet, V.; Talbi, A.; Soltani, A.; Haenen, K.; Pernod, P. Thin film magnetoelectric composites near spin reorientation transition. J. Magn. Magn. Mater. 2009, 321, 1803–1807. [Google Scholar] [CrossRef] [Green Version]

- Tiercelin, N.; Preobrazhensky, V.; Pernod, P.; Ostaschenko, A. Enhanced magnetoelectric effect in nanostructured magnetostrictive thin film resonant actuator with field induced spin reorientation transition. Appl. Phys. Lett. 2008, 92, 062904. [Google Scholar] [CrossRef]

- Clark, A. Chapter 7: Magnetostrictive rare earth-Fe2 compounds. In Handbook of Ferromagnetic Materials; Elsevier: Amsterdam, The Netherlands, 1980; Volume 1, pp. 531–589. [Google Scholar]

- Davino, D.; Giustiniani, A.; Visone, C. The piezo-magnetic parameters of Terfenol-D: An experimental viewpoint. Phys. B Condens. Matter 2012, 407, 1427–1432. [Google Scholar] [CrossRef]

- Pratt, J.; Flatau, A. Development and Analysis of a Self-Sensing Magnetostrictive Actuator Design. J. Intell. Mater. Syst. Struct. 1995, 6, 639–648. [Google Scholar] [CrossRef]

- Scheidler, J.J.; Asnani, V.M. Validated linear dynamic model of electrically-shunted magnetostrictive transducers with application to structural vibration control. Smart Mater. Struct. 2017, 26, 035057. [Google Scholar] [CrossRef]

- Clemente, C.; Mahgoub, A.; Davino, D.; Visone, C. Multiphysics circuit of a magnetostrictive energy harvesting device. J. Intell. Mater. Syst. Struct. 2017, 28, 2317–2330. [Google Scholar] [CrossRef]

- Gao, X.; Liu, Y. Research of giant magnetostrictive actuator’s nonlinear dynamic behaviours. Nonlinear Dyn. 2018, 92, 793–802. [Google Scholar] [CrossRef]

- Bryant, M. Bond graph models for linear motion magnetostrictive actuators. J. Dyn. Syst. Meas. Control 1996, 118, 161–167. [Google Scholar] [CrossRef]

- Ackerman, A.E.; Liang, C.; Rogers, C.A. Dynamic transduction characterization of magnetostrictive actuators. Smart Mater. Struct. 1996, 5, 115. [Google Scholar] [CrossRef]

- Zhang, T.; Yang, B.T.; Li, H.G.; Meng, G. Dynamic modeling and adaptive vibration control study for giant magnetostrictive actuators. Sens. Actuators A Phys. 2013, 190, 96–105. [Google Scholar] [CrossRef]

- Stillesjo, F.; Engdahl, G.; Wei, Z.; Cedell, T. Dynamic simulation and performance study of magnetostrictive transducers for ultrasonic applications. In Proceedings of the SPIE’s 7th Annual International Symposium on Smart Structures and Materials, Newport Beach, CA, USA, 6–9 March 2000; Volume 3992, pp. 594–603. [Google Scholar]

- Lovisolo, A.; Roccato, P.E.; Zucca, M. Analysis of a magnetostrictive actuator equipped for the electromagnetic and mechanical dynamic characterization. J. Magn. Magn. Mater. 2008, 320, e915–e919. [Google Scholar] [CrossRef]

- Zhou, H.M.; Zheng, X.J.; Zhou, Y.H. Active vibration control of nonlinear giant magnetostrictive actuators. Smart Mater. Struct. 2006, 15, 792. [Google Scholar] [CrossRef]

- Oates, W.; Evans, P.; Smith, R.; Dapino, M. Experimental implementation of a hybrid nonlinear control design for magnetostrictive actuators. J. Dyn. Syst. Meas. Control Trans. 2009, 131, 1–11. [Google Scholar] [CrossRef]

- Yan, R.; Wang, B.; Yang, Q.; Liu, F.; Cao, S.; Huang, W. A numerical model of displacement for giant magnetostrictive actuator. IEEE Trans. Appl. Supercond. 2004, 14, 1914–1917. [Google Scholar] [CrossRef]

- Wenmei, H.; Guiying, S.; Ying, S.; Bowen, W.; Chuang, Z. Numerical dynamic strong coupled model of linear magnetostrictive actuators. IEEE Trans. Magn. 2012, 48, 391–394. [Google Scholar] [CrossRef]

- Idziak, P.; Kowalski, K.; Nowak, L.; Knypiński, L. FE transient analysis of the magnetostrictive actuator. Int. J. Appl. Electromagn. Mech. 2016, 51, S81–S87. [Google Scholar] [CrossRef]

- Smith, R.C. Modeling techniques for magnetostrictive actuators. Proc. SPIE 1997, 3041, 243–254. [Google Scholar] [CrossRef] [Green Version]

- Jiles, D.; Atherton, D. Ferromagnetic hysteresis. IEEE Trans. Magn. 1983, 19, 2183–2185. [Google Scholar] [CrossRef]

- Jiles, D.C.; Atherton, D.L. Theory of ferromagnetic hysteresis. J. Magn. Magn. Mater. 1986, 61, 48–60. [Google Scholar] [CrossRef]

- Zhao, R.; Wang, B. Modified J-A model and parameter identification based on data mining. J. Intell. Fuzzy Syst. 2018, 35, 461–468. [Google Scholar] [CrossRef]

- Jiles, D.C. Frequency dependence of hysteresis curves in conducting magnetic materials. J. Appl. Phys. 1994, 76, 5849–5855. [Google Scholar] [CrossRef] [Green Version]

- Nealis, J.; Smith, R. Nonlinear adaptive parameter estimation algorithms for hysteresis models of magnetostrictive actuators. In Proceedings of the SPIE’s 9th Annual International Symposium on Smart Structures and Materials, San Diego, CA, USA, 17–21 March 2002; Volume 4693, pp. 25–36. [Google Scholar] [CrossRef]

- Dapino, M.J.; Smith, R.C.; Flatau, A.B. Structural magnetic strain model for magnetostrictive transducers. IEEE Trans. Magn. 2000, 36, 545–556. [Google Scholar] [CrossRef] [Green Version]

- Joshi, R.; Kadoli, R. Magneto-mechanical coupled magnetostriction model for Terfenol-D actuator under step input. Procedia Mater. Sci. 2014, 5, 154–163. [Google Scholar] [CrossRef]

- Armstrong, W. An incremental theory of magneto-elastic hysteresis in pseudo-cubic ferro-magnetostrictive alloys. J. Magn. Magn. Mater. 2003, 263, 208–218. [Google Scholar] [CrossRef]

- Xu, H.; Pei, Y.; Fang, D.; Ai, S. An energy-based dynamic loss hysteresis model for giant magnetostrictive materials. Int. J. Solids Struct. 2013, 50, 672–679. [Google Scholar] [CrossRef]

- Smith, R.C.; Dapino, M.J.; Seelecke, S. Free energy model for hysteresis in magnetostrictive transducers. J. Appl. Phys. 2003, 93, 458–466. [Google Scholar] [CrossRef] [Green Version]

- Atulasimha, J.; Flatau, A.; Summers, E. Characterization and energy-based model of the magnetomechanical behavior of polycrystalline iron-gallium alloys. Smart Mater. Struct. 2007, 16, 1265–1276. [Google Scholar] [CrossRef]

- Oates, W.; Smith, R. Nonlinear optimal control techniques for vibration attenuation using magnetostrictive actuators. J. Intell. Mater. Syst. Struct. 2008, 19, 193–209. [Google Scholar] [CrossRef]

- Szewczyk, R. Model of the magnetostrictive hysteresis loop with local maximum. Materials 2018, 12, 105. [Google Scholar] [CrossRef] [PubMed]

- Preisach, F. Über die magnetische Nachwirkung. Zeitschrift für Physik 1935, 94, 277–302. (In German) [Google Scholar] [CrossRef]

- Mayergoyz, I. Mathematical models of hysteresis. IEEE Trans. Magn. 1986, 22, 603–608. [Google Scholar] [CrossRef] [Green Version]

- Hughes, D.C.; Wen, J.T. Preisach modeling and compensation for smart material hysteresis. In Proceedings of the 31st Annual Meeting on Materials and Smart Structures: Society of Engineering Science, College Station, TX, USA, 10–12 October 1994; Volume 2427, pp. 50–65. [Google Scholar]

- Venkataraman, R.; Krishnaprasad, P. Approximate inversion of hysteresis: Theory and numerical results [magnetostrictive actuator]. In Proceedings of the 39th IEEE Conference on Decision and Control, Sydney, NSW, Australia, 12–15 Decembe 2000; Volume 5, pp. 4448–4454. [Google Scholar]

- Iyer, R.; Tan, X.; Krishnaprasad, P. Approximate inversion of the Preisach hysteresis operator with application to control of smart actuators. IEEE Trans. Autom. Control 2005, 50, 798–810. [Google Scholar] [CrossRef]

- Tan, X.; Baras, J. Adaptive identification and control of hysteresis in smart materials. IEEE Trans. Autom. Control 2005, 50, 827–839. [Google Scholar] [CrossRef] [Green Version]

- Valadkhan, S.; Morris, K.; Khajepour, A. Review and comparison of hysteresis models for magnetostrictive materials. J. Intell. Mater. Syst. Struct. 2009, 20, 131–142. [Google Scholar] [CrossRef]

- Li, Z.; Su, C.Y.; Chai, T. Compensation of hysteresis nonlinearity in magnetostrictive actuators with inverse multiplicative structure for preisach model. IEEE Trans. Autom. Sci. Eng. 2014, 11, 613–619. [Google Scholar] [CrossRef]

- Al Janaideh, M.; Rakheja, S.; Su, C.Y. An analytical generalized Prandtl–Ishlinskii model inversion for hysteresis compensation in micropositioning control. IEEE/ASME Trans. Mechatron. 2011, 16, 734–744. [Google Scholar] [CrossRef]

- Al Janaideh, M.; Rakheja, S.; Su, C.Y. A generalized Prandtl–Ishlinskii model for characterizing the hysteresis and saturation nonlinearities of smart actuators. Smart Mater. Struct. 2009, 18, 045001. [Google Scholar] [CrossRef]

- Li, Z.; Su, C.Y.; Chen, X. Modeling and inverse adaptive control of asymmetric hysteresis systems with applications to magnetostrictive actuator. Control Eng. Pract. 2014, 33, 148–160. [Google Scholar] [CrossRef]

- Janaideh, M.A.; Davino, D.; Krejčí, P.; Visone, C. Comparison of Prandtl–Ishlinskii and Preisach modeling for smart devices applications. Phys. B Condens. Matter 2016, 486, 155–159. [Google Scholar] [CrossRef]

- Aljanaideh, O.; AL-Tahat, M.; Al Janaideh, M. Rate-bias-dependent hysteresis modeling of a magnetostrictive transducer. Microsyst. Technol. 2016, 22, 883–892. [Google Scholar] [CrossRef]

- Tan, X.; Baras, J. Modeling and control of hysteresis in magnetostrictive actuators. Automatica 2004, 40, 1469–1480. [Google Scholar] [CrossRef] [Green Version]

- Davino, D.; Natale, C.; Pirozzi, S.; Visone, C. Phenomenological dynamic model of a magnetostrictive actuator. Phys. B Condens. Matter 2004, 343, 112–116. [Google Scholar] [CrossRef]

- Bottauscio, O.; Chiampi, M.; Lovisolo, A.; Roccato, P.E.; Zucca, M. Dynamic modeling and experimental analysis of Terfenol-D rods for magnetostrictive actuators. J. Appl. Phys. 2008, 103, 07F121. [Google Scholar] [CrossRef]

- Bottauscio, O.; Roccato, P.E.; Zucca, M. Modeling the dynamic behavior of magnetostrictive actuators. IEEE Trans. Magn. 2010, 46, 3022–3028. [Google Scholar] [CrossRef]

- Al Janaideh, M.; Aljanaideh, O. Further results on open-loop compensation of rate-dependent hysteresis in a magnetostrictive actuator with the Prandtl-Ishlinskii model. Mech. Syst. Signal Process. 2018, 104, 835–850. [Google Scholar] [CrossRef]

- Adly, A.; Abd-El-Hafiz, S. Simulation of magneto-elastic materials using a novel vector hysteresis model. In Proceedings of the 13th International Conference on Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology (ECTI-CON), Chiang Mai, Thailand, 28 June–1 July 2016. [Google Scholar] [CrossRef]

- Adly, A.A.; Mayergoyz, I.D.; Bergqvist, A. Preisach modeling of magnetostrictive hysteresis. J. Appl. Phys. 1991, 69, 5777–5779. [Google Scholar] [CrossRef]

- Cavallo, A.; Davino, D.; De Maria, G.; Natale, C.; Pirozzi, S.; Visone, C. Hysteresis compensation of smart actuators under variable stress conditions. Phys. B Condens. Matter 2008, 403, 261–265. [Google Scholar] [CrossRef]

- Bergqvist, A.; Engdahl, G. A stress-dependent magnetic Preisach hysteresis model. IEEE Trans. Magn. 1991, 27, 4796–4798. [Google Scholar] [CrossRef]

- Davino, D.; Giustiniani, A.; Visone, C. A magnetostrictive model with stress dependence for real-time applications. IEEE Trans. Magn. 2008, 44, 3193–3196. [Google Scholar] [CrossRef]

- Davino, D.; Giustiniani, A.; Visone, C. Experimental properties of an efficient stress-dependent magnetostriction model. J. Appl. Phys. 2009, 105, 07D512. [Google Scholar] [CrossRef]

- Adly, A.; Abd-El-Hafiz, S. Construction of a magnetostrictive hysteresis operator using a tripod-like primitive hopfield neural network. AIP Adv. 2018, 8, 056802. [Google Scholar] [CrossRef]

- Davino, D.; Krejčí, P.; Visone, C. Fully coupled modeling of magneto-mechanical hysteresis through ‘thermodynamic’ compatibility. Smart Mater. Struct. 2013, 22, 095009. [Google Scholar] [CrossRef]

- Kholmetska, I.; Chleboun, J.; Krejčí, P. Numerical modeling of Galfenol magnetostrictive response. Appl. Math. Comput. 2018, 319, 527–537. [Google Scholar] [CrossRef]

- Xiao, Y.; Gou, X.F.; Zhang, D.G. A one-dimension nonlinear hysteretic constitutive model with elasto-thermo-magnetic coupling for giant magnetostrictive materials. J. Magn. Magn. Mater. 2017, 441, 642–649. [Google Scholar] [CrossRef]

- Bottauscio, O.; Lovisolo, A.; Roccato, P.; Zucca, M.; Sasso, C.; Bonin, R. Modeling and experimental analysis of magnetostrictive devices: From the material characterization to their dynamic behavior. IEEE Trans. Magn. 2008, 44, 3009–3012. [Google Scholar] [CrossRef]

- Moffett, M.; Linberg, J.; McLaughlin, E. Characterization of Terfenol-D for magnetostrictive transducers. J. Acoust. Soc. Am. 1991, 89, 1448–1455. [Google Scholar] [CrossRef]

- Aljanaideh, O.; Rakheja, S.; Su, C.Y. Experimental characterization and modeling of rate-dependent asymmetric hysteresis of magnetostrictive actuators. Smart Mater. Struct. 2014, 23, 035002. [Google Scholar] [CrossRef]

- Apicella, V.; Caponero, M.; Cianfarani, C.; Davino, D.; Polimadei, A.; Visone, C. Demagnetizing Field Effect on the Detection Range of a Galfenol-Based Magnetic Field Sensor. IEEE Trans. Magn. 2017, 53, 2503005. [Google Scholar] [CrossRef]

- Cavallo, A.; Natale, C.; Pirozzi, S.; Visone, C. Effects of hysteresis compensation in feedback control systems. IEEE Trans. Magn. 2003, 39, 1389–1392. [Google Scholar] [CrossRef]

- Skogestad, S.; Postlethwaite, I. Multivariable Feedback Control—Analysis and Design; Wiley: Hoboken, NJ, USA, 2005. [Google Scholar]

- Smith, R. A nonlinear optimal control method for magnetostrictive actuators. J. Intell. Mater. Syst. Struct. 1998, 9, 468–486. [Google Scholar] [CrossRef]

- Davino, D.; Giustiniani, A.; Iannelli, L.; Visone, C. Comparison of real-time control strategies with hysteresis compensation for magnetostrictive actuators. Int. J. Appl. Electromagn. Mech. 2012, 39, 529–534. [Google Scholar] [CrossRef]

- Davino, D.; Natale, C.; Pirozzi, S.; Visone, C. A fast compensation algorithm for real-time control of magnetostrictive actuators. J. Magn. Magn. Mater. 2005, 290–291 Pt 2, 1351–1354. [Google Scholar] [CrossRef]

- Davino, D.; Giustiniani, A.; Vacca, V.; Visone, C. Embedded hysteresis compensation and control on a magnetostrictive actuator. IEEE Trans. Magn. 2006, 42, 3443–3445. [Google Scholar] [CrossRef]

- Nakamura, Y.; Nakayama, M.; Masuda, K.; Tanaka, K.; Yasuda, M.; Fujita, T. Development of active 6-DOF microvibration control system using giant magnetostrictive actuator. In Proceedings of the 1999 Symposium on Smart Structures and Materials, Newport Beach, CA, USA, 1 March 1999; Volume 3671, pp. 229–240. [Google Scholar]

- Nakamura, Y.; Nakayama, M.; Masuda, K.; Tanaka, K.; Yasuda, M.; Fujita, T. Development of active six-degrees-of-freedom microvibration control system using giant magnetostrictive actuators. Smart Mater Struct. 2000, 9, 175–185. [Google Scholar] [CrossRef]

- Shaw, J. Adaptive Vibration Control by Using Magnetostrictive Actuator. J. Intell. Mater. Syst. Struct. 1998, 9, 87–94. [Google Scholar] [CrossRef]

- Nealis, J.; Smith, R. Model-based robust control design for magnetostrictive transducers operating in hysteretic and nonlinear regimes. IEEE Trans. Control Syst. Technol. 2007, 15, 22–39. [Google Scholar] [CrossRef]

- Tong, D.; Veldhuis, S.; Elbestawi, M. Control of a dual stage magnetostrictive actuator and linear motor feed drive system. Int. J. Adv. Manuf. Technol. 2007, 33, 379–388. [Google Scholar] [CrossRef]

- Oates, W.; Zrostlik, R.; Eichhorn, S.; Smith, R. A non-linear optimal control design using narrowband perturbation feedback for magnetostrictive actuators. J. Intell. Mater. Syst. Struct. 2010, 21, 1681–1693. [Google Scholar] [CrossRef]

- Bryant, M.; Fernandez, B.; Ning, W.; Murty, V.; Vadlamani, V.; West, T. Active vibration control in structures using magnetostrictive terfenol with feedback and/or neural network controllers. J. Intell. Mater. Syst. Struct. 1993, 4, 484–489. [Google Scholar] [CrossRef]

- Zhang, C.; Mei, D.; Chen, Z. Active vibration isolation of a micro-manufacturing platform based on a neural network. J. Mater. Process. Technol. 2002, 129, 634–639. [Google Scholar] [CrossRef]

- Mao, J.; Ding, H. Intelligent modeling and control for nonlinear systems with rate-dependent hysteresis. Sci. China Ser. F Inf. Sci. 2009, 52, 656–673. [Google Scholar] [CrossRef]

- Cao, S.; Wang, B.; Zheng, J.; Huang, W.; Weng, L.; Yan, W. Hysteresis compensation for giant magnetostrictive actuators using dynamic recurrent neural network. IEEE Trans. Magn. 2006, 42, 1143–1146. [Google Scholar] [CrossRef]

- Kuhnen, K.; Schommer, M.; Janocha, H. Integral feedback control of a self-sensing magnetostrictive actuator. Smart Mater. Struct. 2007, 16, 1098–1108. [Google Scholar] [CrossRef] [Green Version]

- Duan, H.; Cao, S.; Wang, B.; Hu, M.; Li, J.; An, J. Theory and experiment study of giant magnetostrictive self-sensing actuator. In Proceedings of the 2008 World Automation Congress, Hawaii, HI, USA, 27 September–2 October 2008; pp. 1–5. [Google Scholar]

- Yan, B.P.; Zhang, C.M.; Li, L.Y.; Tang, Z.F.; Lü, F.Z.; Yang, K.J. Modelling self-sensing of a magnetostrictive actuator based on a terfenol-D rod. Chin. Phys. B 2014, 23, 127504. [Google Scholar] [CrossRef]

- Apicella, V.; Clemente, C.S.; Davino, D.; Leone, D.; Visone, C. Self-sensing estimation of mechanical stress in magnetostrictive actuators. IEEE Trans. Magn. 2019, 55, 1–5. [Google Scholar] [CrossRef]

- Clephas, B.; Janocha, H. Simultaneous sensing and actuation of a magnetostrictive transducer. In Proceedings of the 5th Annual International Symposium on Smart Structures and Materials, San Diego, CA, USA, 1–5 March1998; Volume 3329. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, L.; Tan, J.; Zhao, B. Induced voltage linear extraction method using an active Kelvin bridge for disturbing force self-sensing. Sensors 2016, 16, 739. [Google Scholar] [CrossRef]

- Nosouhi, R.; Behbahani, S. Chatter active control in a lathe machine using magnetostrictive actuator. AIP Conf. Proc. 2010, 1315, 1011–1016. [Google Scholar] [CrossRef]

- Bak, C.; Son, H. Magnetostrictive actuator for chatter vibration suppression of boring bar. In Proceedings of the 2018 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Auckland, New Zealand, 9–12 July 2018; Volume 2018, pp. 103–106. [Google Scholar] [CrossRef]

- Wang, Z.; Zou, Q.; Faidley, L.; Kim, G.Y. Dynamics compensation and rapid resonance identification in ultrasonic-vibration-assisted microforming system using magnetostrictive actuator. IEEE/ASME Trans. Mechatron. 2011, 16, 489–497. [Google Scholar] [CrossRef]

- Luo, M.; Li, W.; Wang, J.; Wang, N.; Chen, X.; Song, G. Development of a novel guided wave generation system using a giant magnetostrictive actuator for nondestructive evaluation. Sens. 2018, 18, 779. [Google Scholar] [CrossRef] [PubMed]

- Chaudhuri, A.; Yoo, J.H.; Wereley, N. Design, test and model of a hybrid magnetostrictive hydraulic actuator. Smart Mater. Struct. 2009, 18. [Google Scholar] [CrossRef]

- Sato, E.; Fujita, T. Semi-active seismic isolation system with controllable friction dampers using hydraulic system driven by giant magnetostrictive actuators. Trans. Jpn. Soc. Mech. Eng. Part C 2007, 73, 1723–1730. [Google Scholar] [CrossRef]

| Effect: | Joule (Direct) | Villari (Inverse) | Wiedemann | Matteucci |

|---|---|---|---|---|

| Application: | Actuation | Sensing/Harvesting | Actuation/Torque | Sensing |

| Sketch: |  |  |  |  |

| Reviews: | This review [9,10,11] | [12,13,14,15] | This review [5] | [5,8] |

| Linear | Cantilever | Amplified | Inchworm | Others |

|---|---|---|---|---|

| [36,47,69,70,71,72,73,74,75,76,77,78] | [29,39,79,80,81,82,83,84,85,86] | [50,87,88,89,90,91,92,93,94,95,96,97,98] | [38,40,42,43,88,89,99,100,101,102] | [103,104,105,106] |

|  |  |  |  |

| Linear | Nonlinear | Mechanical Dynamics | Electro-Magnetic Dynamics | Hysteresis | |

|---|---|---|---|---|---|

| 0-D | [23,70,72,75,125,126,129,130] | [10,23,34,51,135,139,140] | [23,132,135] | [10,23,55,75,132,135,138,148,166] | [10,51,52,53,54,55,56,60,61,62,64,65,66,94,128,132,139,140,141,142,143,144,145,146,148,149,151,154,155,156,157,158,159,161,162,163,164,166,167,168,169,170,173,178,179,180] |

| 1-D | [23,70] | [23,57,131,134] | [10,34,64,72,128,129,130,131,139,144,145] | [61] | |

| 2-D | [23] | [23,34,60,137,138,146] | [60,137,151] | [60,136,168] | |

| 3-D | [23] | [58,59] | [94] | [62,169] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Apicella, V.; Clemente, C.S.; Davino, D.; Leone, D.; Visone, C. Review of Modeling and Control of Magnetostrictive Actuators. Actuators 2019, 8, 45. https://doi.org/10.3390/act8020045

Apicella V, Clemente CS, Davino D, Leone D, Visone C. Review of Modeling and Control of Magnetostrictive Actuators. Actuators. 2019; 8(2):45. https://doi.org/10.3390/act8020045

Chicago/Turabian StyleApicella, Valerio, Carmine Stefano Clemente, Daniele Davino, Damiano Leone, and Ciro Visone. 2019. "Review of Modeling and Control of Magnetostrictive Actuators" Actuators 8, no. 2: 45. https://doi.org/10.3390/act8020045