Online Remaining Useful Life Prediction for Lithium-Ion Batteries Using Partial Discharge Data Features

Abstract

:1. Introduction

2. Remaining Useful Life (RUL)

3. Classification and Regression Using Support Vector Machine

3.1. Support Vector Machine

3.2. Extraction of Features from Battery Discharge Data

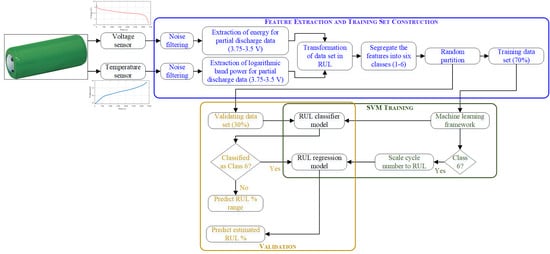

3.3. Classification and Regression Model for RUL Prediction

4. Results and Analysis

4.1. Remaining Useful Life Prediction Using Full Discharge Data

4.2. Remaining Useful Life Prediction Using Partial Discharge Data

5. Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Umair Ali, M.; Hussain Nengroo, S.; Adil Khan, M.; Zeb, K.; Ahmad Kamran, M.; Kim, H.J. A real-time simulink interfaced fast-charging methodology of lithium-ion batteries under temperature feedback with fuzzy logic control. Energies 2018, 11, 1122. [Google Scholar] [CrossRef]

- Tanaka, N. Technology Roadmap: Electric and Plug-in Hybrid Electric Vehicles; Technical Report; International Energy Agency: Paris, France, 2011.

- Ali, M.U.; Zafar, A.; Nengroo, S.H.; Hussain, S.; Alvi, M.J.; Kim, H.J. Towards a Smarter Battery Management System for Electric Vehicle Applications: A Critical Review of Lithium-Ion Battery State of Charge Estimation. Energies 2019, 12, 446. [Google Scholar] [CrossRef]

- Hussain Nengroo, S.; Umair Ali, M.; Zafar, A.; Hussain, S.; Murtaza, T.; Junaid Alvi, M.; Raghavendra, K.; Jee Kim, H. An Optimized Methodology for a Hybrid Photo-Voltaic and Energy Storage System Connected to a Low-Voltage Grid. Electronics 2019, 8, 176. [Google Scholar] [CrossRef]

- Nengroo, S.; Kamran, M.; Ali, M.; Kim, D.H.; Kim, M.S.; Hussain, A.; Kim, H. Dual battery storage system: An optimized strategy for the utilization of renewable photovoltaic energy in the United Kingdom. Electronics 2018, 7, 177. [Google Scholar] [CrossRef]

- Hussain, S.; Ali, M.U.; Nengroo, S.H.; Khan, I.; Ishfaq, M.; Kim, H.J. Semiactive Hybrid Energy Management System: A Solution for Electric Wheelchairs. Electronics 2019, 8, 345. [Google Scholar] [CrossRef]

- Khan, M.; Zeb, K.; Sathishkumar, P.; Ali, M.; Uddin, W.; Hussain, S.; Ishfaq, M.; Khan, I.; Cho, H.G.; Kim, H.J. A novel supercapacitor/lithium-ion hybrid energy system with a fuzzy logic-controlled fast charging and intelligent energy management system. Electronics 2018, 7, 63. [Google Scholar] [CrossRef]

- Hu, C.; Jain, G.; Zhang, P.; Schmidt, C.; Gomadam, P.; Gorka, T. Data-driven method based on particle swarm optimization and k-nearest neighbor regression for estimating capacity of lithium-ion battery. Appl. Energy 2014, 129, 49–55. [Google Scholar] [CrossRef]

- Zhao, Q.; Qin, X.; Zhao, H.; Feng, W. A novel prediction method based on the support vector regression for the remaining useful life of lithium-ion batteries. Microelectron. Reliab. 2018, 85, 99–108. [Google Scholar] [CrossRef]

- Ali, M.U.; Zafar, A.; Nengroo, S.H.; Hussain, S.; Kim, H.J. Effect of Sensors Sensitivity on Lithium-Ion Battery Modeled Parameters and State of Charge: A Comparative Study. Electronics 2019, 8, 709. [Google Scholar] [CrossRef]

- Ali, M.; Kamran, M.; Kumar, P.; Nengroo, S.; Khan, M.; Hussain, A.; Kim, H.J. An online data-driven model identification and adaptive state of charge estimation approach for lithium-ion-batteries using the lagrange multiplier method. Energies 2018, 11, 2940. [Google Scholar] [CrossRef]

- How, D.N.; Hannan, M.; Lipu, M.H.; Ker, P.J. State of Charge Estimation for Lithium-Ion Batteries Using Model-Based and Data-Driven Methods: A Review. IEEE Access 2019, 7, 136116–136136. [Google Scholar] [CrossRef]

- Hannan, M.A.; Lipu, M.H.; Hussain, A.; Mohamed, A. A review of lithium-ion battery state of charge estimation and management system in electric vehicle applications: Challenges and recommendations. Renew. Sustain. Energy Rev. 2017, 78, 834–854. [Google Scholar] [CrossRef]

- Barré, A.; Deguilhem, B.; Grolleau, S.; Gérard, M.; Suard, F.; Riu, D. A review on lithium-ion battery ageing mechanisms and estimations for automotive applications. J. Power Sources 2013, 241, 680–689. [Google Scholar] [CrossRef]

- Chiang, Y.H.; Sean, W.Y.; Ke, J.C. Online estimation of internal resistance and open-circuit voltage of lithium-ion batteries in electric vehicles. J. Power Sources 2011, 196, 3921–3932. [Google Scholar] [CrossRef]

- Remmlinger, J.; Buchholz, M.; Meiler, M.; Bernreuter, P.; Dietmayer, K. State-of-health monitoring of lithium-ion batteries in electric vehicles by on-board internal resistance estimation. J. Power Sources 2011, 196, 5357–5363. [Google Scholar] [CrossRef]

- Tsang, K.M.; Chan, W.L. State of health detection for Lithium ion batteries in photovoltaic system. Energy Convers. Manag. 2013, 65, 7–12. [Google Scholar] [CrossRef]

- Rezvanizaniani, S.M.; Liu, Z.; Chen, Y.; Lee, J. Review and recent advances in battery health monitoring and prognostics technologies for electric vehicle (EV) safety and mobility. J. Power Sources 2014, 256, 110–124. [Google Scholar] [CrossRef]

- Plett, G.L. Extended Kalman filtering for battery management systems of LiPB-based HEV battery packs: Part 3. State and parameter estimation. J. Power Sources 2004, 134, 277–292. [Google Scholar] [CrossRef]

- Saha, B.; Goebel, K.; Poll, S.; Christophersen, J. Prognostics Methods for Battery Health Monitoring Using a Bayesian Framework. IEEE Trans. Instrum. Meas. 2009, 58, 291–296. [Google Scholar] [CrossRef]

- Liu, D.; Luo, Y.; Liu, J.; Peng, Y.; Guo, L.; Pecht, M. Lithium-ion battery remaining useful life estimation based on fusion nonlinear degradation AR model and RPF algorithm. Neural Comput. Appl. 2014, 25, 557–572. [Google Scholar] [CrossRef]

- Andre, D.; Appel, C.; Soczka-Guth, T.; Sauer, D.U. Advanced mathematical methods of SOC and SOH estimation for lithium-ion batteries. J. Power Sources 2013, 224, 20–27. [Google Scholar] [CrossRef]

- Mosallam, A.; Medjaher, K.; Zerhouni, N. Data-driven prognostic method based on Bayesian approaches for direct remaining useful life prediction. J. Intell. Manuf. 2016, 27, 1037–1048. [Google Scholar] [CrossRef]

- Kim, I.S. A technique for estimating the state of health of lithium batteries through a dual-sliding-mode observer. IEEE Trans. Power Electron. 2010, 25, 1013–1022. [Google Scholar] [CrossRef]

- Eddahech, A.; Briat, O.; Bertrand, N.; Delétage, J.Y.; Vinassa, J.M. Behavior and state-of-health monitoring of Li-ion batteries using impedance spectroscopy and recurrent neural networks. Int. J. Electr. Power Energy Syst. 2012, 42, 487–494. [Google Scholar] [CrossRef]

- Ng, S.S.Y.; Xing, Y.; Tsui, K.L. A naive Bayes model for robust remaining useful life prediction of lithium-ion battery. Appl. Energy 2014, 118, 114–123. [Google Scholar] [CrossRef]

- Liu, D.; Pang, J.; Zhou, J.; Peng, Y.; Pecht, M. Prognostics for state of health estimation of lithium-ion batteries based on combination Gaussian process functional regression. Microelectron. Reliab. 2013, 53, 832–839. [Google Scholar] [CrossRef]

- Wu, W.; Hu, J.; Zhang, J. Prognostics of machine health condition using an improved ARIMA-based prediction method. In Proceedings of the 2007 2nd IEEE Conference on Industrial Electronics and Applications, Harbin, China, 23–25 May 2007; pp. 1062–1067. [Google Scholar]

- Tang, S.; Yu, C.; Wang, X.; Guo, X.; Si, X. Remaining Useful Life Prediction of Lithium-Ion Batteries Based on the Wiener Process with Measurement Error. Energies 2014, 7, 520–547. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, M.; Xi, X.; Zhou, D. Remaining Useful Life Prediction for Degradation Processes With Long-Range Dependence. IEEE Trans. Reliab. 2017, 66, 1368–1379. [Google Scholar] [CrossRef]

- Wu, J.; Wang, Y.; Zhang, X.; Chen, Z. A novel state of health estimation method of Li-ion battery using group method of data handling. J. Power Sources 2016, 327, 457–464. [Google Scholar] [CrossRef]

- Klass, V.; Behm, M.; Lindbergh, G. A support vector machine-based state-of-health estimation method for lithium-ion batteries under electric vehicle operation. J. Power Sources 2014, 270, 262–272. [Google Scholar] [CrossRef]

- Chen, Z.; Sun, M.; Shu, X.; Xiao, R.; Shen, J. Online State of Health Estimation for Lithium-Ion Batteries Based on Support Vector Machine. Appl. Sci. 2018, 8, 925. [Google Scholar] [CrossRef] [Green Version]

- Patil, M.A.; Tagade, P.; Hariharan, K.S.; Kolake, S.M.; Song, T.; Yeo, T.; Doo, S. A novel multistage Support Vector Machine based approach for Li ion battery remaining useful life estimation. Appl. Energy 2015, 159, 285–297. [Google Scholar] [CrossRef]

- Saha, B.; Goebel, K. Battery data set. In NASA AMES Prognostics Data Repository; NASA: Washington, DC, USA, 2007. Available online: https://ti.arc.nasa.gov/tech/dash/groups/pcoe/prognostic-data-repository/ (accessed on 1 November 2019).

- Herbrich, R. Learning Kernel Classifiers: Theory and Algorithms; MIT Press: Cambridge, MA, USA, 2002. [Google Scholar]

- Cristianini, N.; Shawe-Taylor, J. An Introduction to Support Vector Machines and Other Kernel-Based Learning Methods; Cambridge University Press: Cambridge, UK, 2000. [Google Scholar]

- Smola, A.J.; Schölkopf, B. A tutorial on support vector regression. Stat. Comput. 2004, 14, 199–222. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Liu, P.; Hicks-Garner, J.; Sherman, E.; Soukiazian, S.; Verbrugge, M.; Tataria, H.; Musser, J.; Finamore, P. Cycle-life model for graphite-LiFePO4 cells. J. Power Sources 2011, 196, 3942–3948. [Google Scholar] [CrossRef]

- Hong, K.S.; Khan, M.J.; Hong, M.J. Feature extraction and classification methods for hybrid fNIRS-EEG brain-computer interfaces. Front. Hum. Neurosci. 2018, 12, 246. [Google Scholar] [CrossRef] [PubMed]

| Battery Type | Battery Positive Electrode Material | Battery Number | Battery Capacity (mAh) | Battery Discharge Ending Voltage (V) | Battery Discharge Current (A) | Operating Temperature (°C) | No. of Cycles |

|---|---|---|---|---|---|---|---|

| 18,650 Lithium-ion battery | LiNi0.8Co0.15 Al0.05O2 | B0005 | 2000 | 2.7 | 2 | 24 | 168 |

| B0006 | 2.5 | 2 | 24 | 168 | |||

| B0036 | 2.7 | 2 | 24 | 197 | |||

| B0056 | 2.7 | 2 | 4 | 102 |

| Classified as | ||||||

|---|---|---|---|---|---|---|

| Class No. | Class 1 | Class 2 | Class 3 | Class 4 | Class 5 | Class 6 |

| Class 1 | 7 | - | 1 | - | - | - |

| Class 2 | 1 | 6 | - | - | - | - |

| Class 3 | - | - | 9 | 1 | - | - |

| Class 4 | - | - | - | 7 | - | - |

| Class 5 | - | - | - | - | 9 | - |

| Class 6 | - | - | - | - | - | 10 |

| Range of Discharge Data (V) | Classification | Regression Model | ||

|---|---|---|---|---|

| Training Accuracy | Root Mean Square Error (RMSE) | Mean Average Error (MAE) | Mean Square Error (MSE) | |

| 4.2–3.9 | 71.40% | 0.19607 | 0.14638 | 0.039031 |

| 4.2–3.7 | 81.50% | 0.21118 | 0.16373 | 0.042453 |

| 4.0–3.5 | 91.10% | 0.16607 | 0.14091 | 0.034821 |

| 4.0–3.75 | 87.50% | 0.1789 | 0.14123 | 0.034012 |

| 3.75–3.5 | 93.50% | 0.14195 | 0.10699 | 0.02145 |

| 3.6–3.5 | 86.30% | 0.16218 | 0.12876 | 0.028954 |

| 3.6–3.3 | 87.50% | 0.17678 | 0.13085 | 0.031245 |

| 3.5–3.3 | 77.40% | 0.16191 | 0.12016 | 0.027865 |

| 3.4–3.2 | 85.70% | 0.16867 | 0.13084 | 0.029756 |

| 3.3–3.1 | 82.10% | 0.21805 | 0.16672 | 0.046891 |

| 3.2–3.0 | 85.70% | 0.20317 | 0.14746 | 0.039856 |

| 3.1–2.9 | 81.50% | 0.17385 | 0.14947 | 0.034958 |

| 3–2.6 | 76.80% | 0.15124 | 0.11542 | 0.024658 |

| Class No. | Classified as | |||||

|---|---|---|---|---|---|---|

| Class 1 | Class 2 | Class 3 | Class 4 | Class 5 | Class 6 | |

| Class 1 | 6 | - | - | - | - | - |

| Class 2 | 1 | 8 | - | - | - | - |

| Class 3 | - | - | 8 | - | - | - |

| Class 4 | - | - | 1 | 7 | 1 | - |

| Class 5 | - | - | - | - | 8 | - |

| Class 6 | - | - | - | - | 1 | 9 |

| Battery Number | Classification | Regression | ||

|---|---|---|---|---|

| Accurately Classified Samples | Total Number of Samples | Accuracy (%) | RMSE (%) | |

| B0005 | 46 | 50 | 92.0 | 0.2159 |

| B0006 | 47 | 50 | 94.0 | 0.3108 |

| B0036 | 55 | 60 | 91.6 | 0.2250 |

| B0056 | 36 | 40 | 90.0 | 0.4267 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, M.U.; Zafar, A.; Nengroo, S.H.; Hussain, S.; Park, G.-S.; Kim, H.-J. Online Remaining Useful Life Prediction for Lithium-Ion Batteries Using Partial Discharge Data Features. Energies 2019, 12, 4366. https://doi.org/10.3390/en12224366

Ali MU, Zafar A, Nengroo SH, Hussain S, Park G-S, Kim H-J. Online Remaining Useful Life Prediction for Lithium-Ion Batteries Using Partial Discharge Data Features. Energies. 2019; 12(22):4366. https://doi.org/10.3390/en12224366

Chicago/Turabian StyleAli, Muhammad Umair, Amad Zafar, Sarvar Hussain Nengroo, Sadam Hussain, Gwan-Soo Park, and Hee-Je Kim. 2019. "Online Remaining Useful Life Prediction for Lithium-Ion Batteries Using Partial Discharge Data Features" Energies 12, no. 22: 4366. https://doi.org/10.3390/en12224366