Modular Permanent Magnet Synchronous Machine with Low Space Harmonic Content

Abstract

:1. Introduction

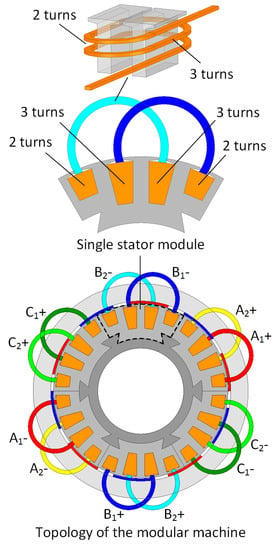

2. Machine Topology

3. Winding MMF and Winding Factors

3.1. MMF of Winding-I

3.2. MMF of Winding-II

3.3. MMF of the Entire Winding

3.4. Winding Factor

3.5. Selection of Coil Side Turns

4. Electromagnetic Characteristics

4.1. No-Load Back EMF

4.2. Cogging Torque

4.3. Armature Reaction Field

4.4. On-Load Torque

4.5. Loss and Efficiency

4.6. Power Factor

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bang, D.J.; Polinder, H.; Shrestha, G.; Abraham Ferreira, J. Promising directdrive generator system for large wind turbines. EPE J. 2008, 18, 7–13. [Google Scholar] [CrossRef]

- Fornasiero, E.; Alberti, L.; Bianchi, N.; Bolognani, S. Considerations on selecting fractional-slot nonoverlapped coil windings. IEEE Trans. Ind. Appl. 2013, 49, 1316–1324. [Google Scholar] [CrossRef]

- EL-Refaie, A.M. Fractional-slot concentrated-windings synchronous permanent magnet machines: Opportunities and challenges. IEEE Trans. Ind. Electron. 2010, 57, 107–121. [Google Scholar] [CrossRef]

- Bianchi, N.; Bolognani, S.; Pre, M.D.; Grezzani, G. Design considerations for fractional-slot winding configurations of synchronous machines. IEEE Trans. Ind. Appl. 2006, 42, 997–1006. [Google Scholar] [CrossRef]

- Jussila, H.; Salminen, P.; Niemela, M.; Pyrhonen, J. Guidelines for designing concentrated winding fractional slot permanent magnet machines. In Proceedings of the IEEE International Conference on Power Engineering, Energy and Electrical Drives, Setubal, Portugal, 12–14 April 2007. [Google Scholar]

- Bianchi, N.; Dai Pre, M. Use of the star of slots in designing fractional-slot single-layer synchronous motors. IEE Electr. Power. Appl. 2006, 153, 459–466. [Google Scholar] [CrossRef]

- Atallah, K.; Howe, D.; Mellor, P.H.; Stone, D.A. Rotor loss in permanent-magnet brushless AC machines. IEEE Trans. Ind. Appl. 2000, 36, 1612–1618. [Google Scholar]

- Bianchi, N.; Bolognani, S.; Fornasiero, E. An overview of rotor losses determination in three-phase fractional-slot PM machines. IEEE Trans. Ind. Appl. 2010, 46, 2338–2345. [Google Scholar] [CrossRef]

- Bianchi, N.; Fornasiero, E. Impact of MMF space harmonic on rotor losses in fractional-slot permanent-magnet machines. IEEE Trans. Energy Convers. 2009, 24, 323–328. [Google Scholar] [CrossRef]

- Fornasiero, E.; Bianchi, N.; Bolognani, S. Slot harmonic impact on rotor losses in fractional-slot permanent-magnet machines. IEEE Trans. Ind. Electron. 2012, 59, 2557–2564. [Google Scholar] [CrossRef]

- Dajaku, G.; Gerling, D. A novel 12-teeth/10-poles PM machine with flux barriers in stator yoke. In Proceedings of the International Conference on Electrical Machines, Marseille, France, 2–5 September 2012. [Google Scholar]

- Dajaku, G.; Xie, W.; Gerling, D. Reduction of low space harmonics for the fractional slot concentrated windings using a novel stator design. IEEE Trans. Magn. 2014, 50, 1–12. [Google Scholar] [CrossRef]

- Dajaku, G.; Gerling, D. Low costs and high-efficiency electric machines. In Proceedings of the International Electric Drives Production Conference, Nuremberg, Germany, 15–18 October 2012. [Google Scholar]

- Wang, Y.; Qu, R.; Wu, L.; Fang, H.; Li, D. Reduction of sub-harmonic effect on the fractional slot concentrated winding interior PM machines by using spoke-type magnets. In Proceedings of the International Electric Machines & Drives Conference, Coeur d’Alene, IL, USA, 10–13 May 2015. [Google Scholar]

- Alberti, L.; Fornasiero, E.; Bianchi, N. Impact of the rotor yoke geometry on rotor losses in permanent-magnet machines. IEEE Trans. Ind. Appl. 2012, 48, 98–105. [Google Scholar] [CrossRef]

- Choi, G.; Jahns, T.M. Reduction of eddy-current losses in fractional-slot concentrated-winding synchronous PM machines. IEEE Trans. Magn. 2016, 52, 1–4. [Google Scholar] [CrossRef]

- Wu, L.; Qu, R.; Li, D. Reduction of rotor eddy-current losses for surface PM machines with fractional slot concentrated windings and retaining sleeve. IEEE Trans. Magn. 2014, 50, 1–4. [Google Scholar] [CrossRef]

- Abdel-Khalik, A.S.; Ahmed, S.; Massoud, A.M. Low space harmonics cancelation in double-layer fractional slot winding using dual multiphase winding. IEEE Trans. Magn. 2015, 51, 1–10. [Google Scholar] [CrossRef]

- Alberti, L.; Bianchi, N. Theory and design of fractional-slot multilayer windings. In Proceedings of the Energy Conversion Congress & Exposition, Phoenix, AZ, USA, 17–22 September 2011. [Google Scholar]

- Cistelecan, M.V.; Ferreira, F.J.T.E.; Popescu, M. Three phase tooth-concentrated multiple-layer fractional windings with low space harmonic content. In Proceedings of the Energy Conversion Congress & Exposition, Atlanta, GA, USA, 12–16 September 2010. [Google Scholar]

- Reddy, P.B.; EL-Refaie, A.M.; Huh, K. Effect of number of layers on performance of fractional-slot concentrated-windings interior permanent magnet machines. IEEE Trans. Power Electron. 2015, 30, 2205–2218. [Google Scholar] [CrossRef]

- Sun, A.; Li, J.; Qu, R.; Li, D. Effect of multilayer windings on rotor losses of interior permanent magnet generator with fractional-slot concentrated-windings. IEEE Trans. Magn. 2014, 50, 1–4. [Google Scholar] [CrossRef]

- Dajaku, G. Elektrische Maschine. German Patent DE 102008 057349 B3, 15 July 2010. [Google Scholar]

- Dajaku, G.; Gerling, D. Eddy current loss minimization in rotor magnets of PM machines using high-efficiency 12-teeth/10-slots winding topology. In Proceedings of the International Conference on Electrical Machines & Systems, Beijing, China, 20–23 August 2011. [Google Scholar]

- Wang, K.; Zhu, Z.Q.; Ombach, G. Synthesis of high performance fractional-slot permanent-magnet machines with coil-pitch of two slot-pitches. IEEE Trans. Energy Convers. 2014, 29, 758–770. [Google Scholar] [CrossRef]

- Yue, Y.; Wu, L.; Jia, S. Comparison of IPM machines with fractional-slot concentrated windings and coil-pitch of two slot-pitches windings for EV application. In Proceedings of the International Conference on Electrical Machines & Systems, Jeju, South Korea, 7–10 October 2018. [Google Scholar]

- Wang, J.; Patel, V.I.; Wang, W. Fractional-slot permanent magnet brushless machines with low space harmonic contents. IEEE Trans. Magn. 2014, 50, 1–9. [Google Scholar] [CrossRef]

- Reddy, P.B.; Huh, K.; EL-Refaie, A.M. Generalized approach of stator shifting in interior permanent-magnet machines equipped with fractional-slot concentrated windings. IEEE Trans. Ind. Electron. 2014, 61, 5035–5046. [Google Scholar] [CrossRef]

- Patel, V.I.; Wang, J.; Wang, W.; Chen, X. Six-phase fractional-slot-per-pole-per-phase permanent-magnet machines with low space harmonics for electric vehicle application. IEEE Trans. Ind. Appl. 2014, 50, 2554–2563. [Google Scholar] [CrossRef] [Green Version]

- Abdel-Khalik, A.S.; Ahmed, S.; Massoud, A.M. A six-phase 24-slot/10-pole permanent-magnet machine with low space harmonics for electric vehicle applications. IEEE Trans. Magn. 2016, 52, 1–10. [Google Scholar] [CrossRef]

- Harke, M. Design of fractional slot windings with coil span of two slots for use in six-phase synchronous machines. J. Eng. 2019, 2019, 4391–4395. [Google Scholar] [CrossRef]

- Dajaku, G.; Gerling, D. A novel 24-slots/10-poles winding topology for electric machines. In Proceedings of the International Electric Machines & Drives Conference, Niagara Falls, ON, Canada, 15–18 May 2011. [Google Scholar]

- Harke, M. Fractional slot windings with a coil span of two slots and less content of low order harmonics. In Proceedings of the International Symposium on Power Electronics, Electrical Drives, Automation and Motion, Amalfi, Italy, 20–22 June 2018. [Google Scholar]

- Sun, H.Y.; Wang, K. Space harmonics elimination for fractional-slot windings with two-slot coil pitch. IEEE Access 2019, 7, 106961–106972. [Google Scholar] [CrossRef]

- Wang, K.; Lin, H. A novel 24-slot/10-pole dual three-phase fractional-slot overlapped winding for low non-working space harmonics and stator modularization. IEEE Access 2020, 8, 85490–85503. [Google Scholar] [CrossRef]

- Tang, N.; Brown, I.P. Framework and solution techniques for suppressing electric machine winding MMF space harmonics by varying slot distribution and coil turns. IEEE Trans. Magn. 2018, 54, 1–12. [Google Scholar] [CrossRef]

- Raziee, S.M.; Misir, O.; Ponick, B. Winding function approach for winding analysis. IEEE Trans. Magn. 2017, 53, 1–9. [Google Scholar] [CrossRef]

| Coil Side MMF Vector | Modulus | Angle | |

|---|---|---|---|

| Phase A1 | V1 | 0 | |

| V13 | |||

| V15 | |||

| V3 | |||

| Phase A2 | V16 | ||

| V4 | |||

| V2 | |||

| V14 |

| Harmonic Order | Proposed Machine | Conventional Machine | ||

|---|---|---|---|---|

| 1 | 0.354 | 0.0114 | 0.259 | 0 |

| 2 | 0 | 0 | 0 | 0 |

| 3 | 0.729 | 0 | 0.707 | 0 |

| 4 | 0 | 0 | 0 | 0 |

| 5 | 0.968 | 0.968 | 0.966 | 0.966 |

| 6 | 0 | 0 | 0 | 0 |

| 7 | 0.968 | 0 | 0.966 | 0.966 |

| 8 | 0 | 0 | 0 | 0 |

| 9 | 0.729 | 0 | 0.707 | 0 |

| 10 | 0 | 0 | 0 | 0 |

| 11 | 0.354 | 0.354 | 0.259 | 0 |

| 12 | 0 | 0 | 0 | 0 |

| 13 | 0.354 | 0.354 | 0.259 | 0 |

| 14 | 0 | 0 | 0 | 0 |

| 15 | 0.729 | 0 | 0.707 | 0 |

| 16 | 0 | 0 | 0 | 0 |

| 17 | 0.968 | 0 | 0.966 | 0.966 |

| 18 | 0 | 0 | 0 | 0 |

| 19 | 0.968 | 0.968 | 0.966 | 0.966 |

| Proposed Machine | Conventional Machine | |

|---|---|---|

| Stator slot number | 24 | 12 |

| Rotor pole number | 10 | |

| Stator outer diameter (mm) | 150 | |

| Stator yoke thickness (mm) | hy1 = 7.755, hy2 = 9 | 9 |

| Stator slot opening width (mm) | 3.5 | 4.8 |

| Air gap length (mm) | 0.5 | |

| PM thickness (mm) | 2 | |

| Pole arc coefficient | 0.694 | |

| Rotor core thickness (mm) | 15 | |

| Active length (mm) | 40 | |

| Number of turns in series per phase | 50 | |

| Number of parallel branches | 1 | |

| PM material | N42SH | |

| Stator core material | 50JNE470 | |

| Rotor core material | Solid steel | |

| Stator frame material | Austenitic stainless steel | |

| Rated speed (rpm) | 2400 | |

| Rated phase current in RMS value (A) | 15 | |

| Proposed Machine | Conventional Machine | |

|---|---|---|

| Average torque (Nm) | 15.50 | 15.18 |

| Torque ripple | 10.70% | 12.39% |

| Proposed Machine | Conventional Machine | |

|---|---|---|

| Stator core loss (W) | 111.51 | 119.1 |

| Stator frame loss (W) | 0.59 | 0.82 |

| Copper loss (W) | 32.38 | 29.03 |

| PM loss (W) | 25 | 31.6 |

| Rotor core loss (W) | 42.37 | 111.33 |

| Total loss (W) | 211.85 | 291.88 |

| Output power (W) | 3895.57 | 3815.15 |

| Efficiency | 94.56% | 92.35% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, K.; Lin, H. Modular Permanent Magnet Synchronous Machine with Low Space Harmonic Content. Energies 2020, 13, 3924. https://doi.org/10.3390/en13153924

Wang K, Lin H. Modular Permanent Magnet Synchronous Machine with Low Space Harmonic Content. Energies. 2020; 13(15):3924. https://doi.org/10.3390/en13153924

Chicago/Turabian StyleWang, Keyi, and Heyun Lin. 2020. "Modular Permanent Magnet Synchronous Machine with Low Space Harmonic Content" Energies 13, no. 15: 3924. https://doi.org/10.3390/en13153924