3.1. Performance of a 10 kW PEMFC Stack under Constant Electrical Load

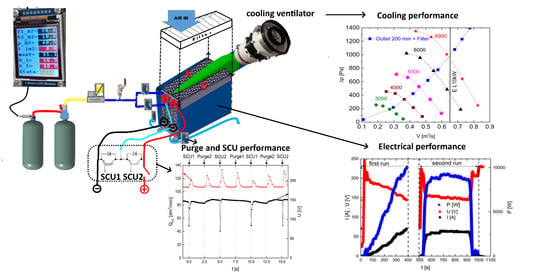

The behaviour of a PEMFC stack under constant and variable electrical load has a great effect on the safety and effectiveness of its operation as a component for a hybrid power source designed to supply a propulsion system. The open-cathode PEMFC stack concept was used to construct a 10 kW V-type PEMFC stack consisting of two series connected to two modules (A) and (B). According to the specifications of the project, ambient air was used for cooling as well as for the provision of oxygen for cathode electrochemical reduction. Air was supplied mainly by two cascade axial fans.

Figure 7a,b presents the distribution of the voltage recorded for single MEA fuel cells in the PEMFC assembled module (A) or (B). The electrical load 10 A was applied.

Based on analysis of

Figure 7b, it can be concluded that all MEA PEMFCs operated randomly in all modules (A) or (B) under applied electrical load I = 10 A.

In the next tests (

Figure 8), the U-I and P-I curves were recorded for module (A) or (B) and for the 10 kW PEMFC stack.

It was also found that no differences in electrical performance were observed for both modules used for construction of the V-type PEMFC stack. The analysis of these curves also indicated that PEMFC stack (A) and (B) exhibited slightly higher power than the assumed 5 kW. This fact allowed for a short-term application of an electrical load that may be slightly higher than 10 kW. Based on these results, the nominal power of PEMFC stack is established for 10 kW for continuous application in the PEMFC-based power source.

The boundary restrictions resulting from the installation of the device in the motor glider platform were also taken into consideration. The V-type PEMFC stack is to be installed in the fuselage in the immediate vicinity of the propeller [

24].

The streamlined air produced by the rotation of the propeller can be also conducted into the area occupied by the stack. The air entering the cathode channels—which, in terms of temperature and humidity, cannot be controlled easily—exerts an impact on the electrical efficiency of the stack. Testing for aeronautical fuel cell applications in the first stage of the experiments was carried out in laboratory environments while taking into account restrictions arising from the installation of the device within the motor glider platform. The representative voltage (U)-current (I) and power (P)-current (I) dependencies, recorded in various ambient conditions, was a crucial element of analysis and provided data concerning the effect of variations in temperature on the performance of the PEMFC stack.

Figure 9a presents the U-I and P-I curves recorded in different measurement conditions. It can be seen from the U-I curve that the open-circuit voltage (OCV) of the PEMFC stack was ~230 V DC. As the current increased, the voltage decreased linearly to approximately 154 V at 67 A. The electrical power of the 10 kW PEMFC stack reached more than 10 kW in all investigated conditions. In all cases, the power output of the PEMFC stack slightly exceeded 10 kW, although the variation in final performance was no more than 5–7% in comparative analysis. At lower temperatures, such as ~4–10 °C, values obtained from the first run of the stack were lower. The application of a slow electrical load with a current of 5–10 A for 5–10 min enabled the attainment of good performance levels in 2 or 3 runs. All of these experimental data indicated that the constructed V-type PEMFC stack was capable of achieving the assumed nominal power of 10 kW in various conditions. The impact of ambient conditions on PEMFC stack performance is important for practical applications of these stacks as power sources for various devices.

The problem of ambient conditions (temperature, humidity) was also analysed using different models for simulation and experimental tests performed on PEMFC stacks with various values of nominal electrical power and types of construction. Rosa et al. [

26], analysing the impact of temperature, air flow rate, hydrogen flow rate, and pressure on the performance of a 300 W PEMFC stack, found that the stack was practically unaffected by operating conditions (temperature, humidity); however, slightly higher power output was achievable with a slight increase in hydrogen pressure up to 150 mbar. Bayrak et al. [

27] also investigated the impact of ambient temperature on the performance of a 200 W PEMFC stack connected to a battery in a hybrid power source. A Li-ion or Ni-MH battery was integrated with a PEMFC stack during experimental tests. It was observed that the hydrogen consumption of fuel cells increased when the ambient temperature was near 40 °C. The range of investigated temperatures varied from 0 to 40 °C. In the case of lower temperatures near 0 °C, some researchers have found that the elaborated procedure for starting the PEMFC stack also had a considerable impact on its final output.

Cano et al. [

28], in a review paper, analysed a free air-breathing PEMFC fuel cell, characterising its thermal behaviour at a near-freezing temperature. In the case of two different ambient temperatures (24 or 3.5 °C), it was found that the relative deviation between models and experimental temperatures was characterised by an error of less than 5%. The deviation observed at near-freezing operating conditions was higher at the beginning of the experiment, i.e., the first run of the PEMFC stack. Analysis of the data contained in [

26,

27,

28] also indicated close agreement with our results concerning the performance of the constructed V-type PEMFC stack (

Figure 9a).

Figure 9b summarises the U-I and P-I curves recorded for a fuel cell stack operating freely in laboratory conditions (A) and in conditions with limited air inlet (B), i.e., with side surfaces from the inlet duct side in the bipolar plates of both PEMFC stack modules covered with foamed polystyrene boards, and the PEMFC stack protected from above with a cassette filter, designed to shield the device against possible solid impurities that may occur at the airport during take-off of a powered sailplane. The proposed test was to reflect the integration of a V-type PEMFC fuel cell stack and simulate additional air intake restrictions in the powered sailplane’s hull. This description is consistent with

Figure 1, the structure of the powered motor glider, and the arrangement of power plant components presented in [

24].

The analysis of U-I and P-I curves recorded in the same laboratory conditions and applied electrical current load in the range 1 to 75 A did not indicate a difference in power output of the PEMFC stack.

The variation in electrical power P produced by the stack vs. time was determined under an applied electrical current load (

Figure 10a,b). The experiments were carried out for 2 h. During PEMFC performance, an elaborated procedure of purging and SCU was applied.

As can be seen in

Figure 10a, a slow increase in electrical power was noted during the applied experiment within the range 2.5–5 kW. Within a range of 6–10 kW, a fairly stable level of power was produced by the stack. In

Figure 7b, the variation in T

min and T

max temperature recorded during this experiment has been added to the graph. T

min or T

max increased when the PEMFC stack reached higher power values. The highest temperature was no higher than 65 °C; however, the difference (ΔT) between T

min and T

max was no greater than 12 °C.

Zhang [

29] suggested that the most favourable operating temperature for a PEMFC stack is usually within the range 55–80 °C. In the case of application in a motor glider platform made from a carbon-based composite, where the assumed temperature was established within the range 60–65 °C, the investigated two-module PEMFC stack operated properly in terms of stability of power and peak temperature attained.

3.2. Analysis of Hydrogen Fuel Consumption during V-Type PEMFC Stack Operation

Analysis of hydrogen fuel consumption during PEMFC stack operation is very important for all transport applications. Efficient control and management strategies of hydrogen fuel consumption are necessary in order to predict the time of operation of a 10 kW PEMFC stack when operating as a part of integrated hybrid power sources. The hydrogen injected into the anode chamber is supposed to be fully consumed in dead-end operation mode. This means that theoretical losses are close to 0%. However, nitrogen and water can easily penetrate a Nafion-based membrane. Excess water and nitrogen that have crossed over in the anode reduce the concentration of hydrogen at the catalyst surface, causing performance losses. Purging the anode with hydrogen removes water and nitrogen and thus restores the performance of the stack. According to Strahl et al. [

30], the optimal purge strategy depends on suitable heat and water management and considerably impacts the durability and performance of the stack.

The ratio of fuel utilisation to electricity production, purification of the stack carried out during the purge process, and the level of humidification implemented by means of the SCU process should all be considered when estimating the time of performance of a V-type PEMFC stack in a propulsion unit.

Manufacturers of PEMFCs recommend the use of the short-circuiting method, aimed at improving performance of these fuel cells over time. In products manufactured by the Ballard or Horizon company, the controller unit includes the option to periodically interrupt the performance of a PEMFC stack via maintenance of water content. One of the main drawbacks of SCU performance is that when ‘voltage dip’ occurs in an operating SCU, voltage values are close to 0. Some electronic devices, in this case certain producers of DC/DC, are sensitive to brief power outages of this type However, there is a lack of data and understanding regarding ways to improve the performance of single MEA cells and to optimise the short-circuiting strategy for fuel cell stacks constructed from smaller modules. The performance of the SCU also has a considerable impact on the integration of other devices, such as DC/DC, into a hybrid power source [

31].

Gupta et al. [

32] elaborated a procedure aimed at the optimisation of SCU performance through maximising cumulative average power density gain and minimising the time required to recover energy losses during short-circuiting. These authors obtained voltage improvements ranging from 10% to 12% in voltage (U)-time (s) curves for different current densities in a 100 W PEMFC stack. They also found that minimum short-circuiting time is a function of double-layer capacitance. Electrochemical impedance spectroscopy is a useful technique which can help to solve double layers in electrochemistry. Kim et al. [

33] used the SCU method to humidify a PEMFC stack for an unmanned aerial vehicle (UAV) application in order to prevent it from drying out. In UAV applications in particular, humidity control becomes more important as the boiling point of water decreases along with increases in flight altitude. A fuel cell controller incorporating a short-circuit unit was developed and a battery hybridised with the PEMFC stack to compensate for lost power when the latter was short-circuited. The performance of the stack was evaluated for the interval (period) and duration of the short circuit. Using this method, the power output was improved by 16% when the short-circuit control was operated in optimal conditions. In the present study, a SCU system was also elaborated and integrated into the fuel cell controller as shown in

Figure 3. Data on modular PEMFC stacks involving SCU units and their impact on performance are limited. In the constructed V-type PEMFC, the SCU process can be implemented in two different ways: the SCU can either occur simultaneously in modules (A) or (B) or be staggered. The use of two SCU systems, 1 and 2 (causing short-term short circuits of the PEMFC stack for purposes of self-healing), enables control of the short circuits so that they occur at maximum intervals relative to each other during the operation of the stack, thus preventing a sudden voltage drop to 0 V in the output of the PEMFC module, which might be unfavourable for all devices in the propulsion system. In addition, purification of the anode space via periodic (every 10 s) opening of the H

2-out solenoid ‘purge’ valve for each of the module piles should be shifted in terms of time so as to avoid excessive pressure drop in the hydrogen supply line due to the high intensity of flow in the motor glider installation. An analysis of hydrogen consumption involving the purge and SCU performance of the PEMFC stack under variable electrical load was also carried out in situ. Special emphasis was placed on analysis based on the variation of pressure, monitored online by pressure sensors installed in composite bottles. This procedure of measuring online variation in hydrogen pressure should also be considered in predictions of operating time for a PEMFC stack in a propeller system along with transmission of information on the expected time of operation of the fuel cells and the amount of stored hydrogen as a fuel to an on-board computer.

In this study, the minimal hydrogen value and the highest level of fuel consumption vs. electrical power produced by a V-type PEMFC stack was determined during operation under constant as well as dynamic loads.

Figure 11a presents the total analysis of hydrogen consumption during electrical power production. In addition, performance during purification (purge operation) or the humidification process realised via the SCU mode was also measured for the V-type PEMFC stack.

Figure 11b presents the variation in hydrogen flow Q

H2 as well as voltage U vs. time during SCU operation of the 10 kW PEMFC stack under electrical load. In the voltage vs. time dependence, a reduction in voltage by half is visible every 5 s. These reductions were related to the operation of the SCU system, which shorted one of the two modules every 10 s (shorting one SCU module and, 5 s later, the other) for purposes of auto-humidification, which was accomplished during the short-circuit current flow. At the time of the occurrence of a short circuit in the SCU, an increase in hydrogen flow rate Q

H2 (dm

3/min), associated with increased consumption during short-circuit current flow, can also be seen in the diagram in

Figure 11b.

Increases can also be observed in hydrogen flow rate between short circuits, associated with the opening of the solenoid valves at the hydrogen outlet from the anode spaces of fuel cell modules A and B, described as Purge 1 and Purge 2. Hydrogen flow during the operation of the electricity generator with the fuel cell stack equalled 123 Ndm3 H2/min; during the operation of the SCU1 and SCU2 systems and the opening of the Purge 1 and Purge 2 flushing solenoids, this value temporarily increased to 140–150 Ndm3 H2/min. It was estimated that hydrogen consumption increases by 4–8% during SCU and purge operation.

Figure 11c presents the representative hydrogen dependence of intensity of hydrogen flow measured during the operation of a PEMFC stack on declared electrical power. The highest flow rate of hydrogen was estimated at ~140 m

3/min for V-type PEMFC stack operation at electrical power of 10 kW.

It was found that the intensity of hydrogen volume flow increased nearly linearly with increases in the electrical power produced by the PEMFC stack. It was also observed that minimal consumption of fuel might directly correspond to utilisation of production of electrical power by the investigated power source. In the case of a PEMFC operating with 10 kW of power, the consumption of hydrogen was established at ~114 dm3/min (without purge and SCU processes). The consumption of hydrogen during purification of the PEMFC stack via the purge process as well as under humidification implemented via the SCU module during operation of this device was also measured and considered.

Gaseous hydrogen is stored in two composite cylinders and supplied directly to the PEMFC stack. The efficiency

ε of the electrical V-type PEMFC stack can be calculated according to Formula (1),

as the ratio of the electricity measured at the terminals of the stack to the chemical energy of hydrogen consumed during stack operation.

Figure 7a presents the variation of electrical efficiency vs. the power produced by the constructed V-type PEMFC stack. As can be seen, electrical efficiency close to 50% is observed within a power range of 1–7 kW; following attainment of 8 kW, a small decrease was observed. At 10 kW, electrical efficiency was close to 45%. This value is close to that indicated in all data existing in the literature regarding an air-cooled PEMFC stack.

According to paper [

31], the hydrogen utilisation coefficient was calculated according to the following formula

where: U (the PEMFC stack’s open-circuit voltage) is 0.97 V/cell and the ideal open-circuit voltage is 1.48 V/cell.

The dependence of hydrogen utilisation during production of electrical power by the stack is also presented in

Figure 12. As can be seen, a coefficient of fuel utilisation close to 80% was recorded over a wide range of power, from 1 to 7 kW. An increase in electric power produced by the V-type stack above 7 kW caused a reduction in this value to about 70%. In this construction, the recovery of hydrogen from purging processes was not considered.

The effect of power output of the PEMFC stack on the dynamic variation of electrical load generated by the propulsion energy system is necessary for practical applications in transport. The dynamic response of the hydrogen-oxygen fuel cell is required in order for it to quickly adapt to changes in electrical load in the course of different missions. A PEMFC stack is composed of main subsystems involving reagents such as air or hydrogen, cooling devices, and other devices used to control the stack’s performance. The operation of each exerts a considerable impact on the performance and durability of the stack as a complete electrochemical power source. The impact of these subsystems on the dynamic response of fuel cells was taken into consideration in simulations, modelling, and experimental studies [

34,

35,

36,

37].

In this study, detailed investigations were conducted involving variations in electrical power and temperature vs. time of applied variable electrical load.

Figure 10a presents an example of a test examining the variation in electrical parameters such as voltage (U), current (I), and electrical power (P) vs. time.

The first run of the constructed V-type PEMFC stack was conducted immediately after supplying hydrogen to two modules. After 750 s, when the PEMFC stack was initiating operation, the current load increased with a ramp of 1 A per 30 s to achieve electrical power of 2.5 kW (one-fourth of nominal power) in conditions characterised by current (I) = 13.5 A and voltage (U) = 183 V; the PEMFC stack operated in these conditions for no longer than 1000 s. Subsequently, the investigated power source was turned off. When turned on a second time, the assumed electrical load of the PEMFC stack rose to 5 kW. After the power source was turned on again for 3200 s, the current (I) load increased with a ramp of 1 A/30 s until it reached 13.5 A and P = 2.5 kW. At t = 3800 s, an increase in the current to 5.5 kW (164 V, 34 A) was reached. This load was continued up to 4100 s. Subsequently, the PEMFC stack was turned off again. In the third test, at t = 4800 s, the electrical current load also increased with a ramp of 1 A/30 s, to 2.5 kW, and again at 5300 s to 5.5 kW (164 V, 34 A). At t = 5600 s, the power source reached the nominal power of 10 kW (130 V, 75 A).

Analysis of temperature distribution is also necessary to ensure the performance and durability of a PEMFC stack designed for transport and avionic applications. The distribution of temperature T measured in the stack in module (A) or (B) is presented in

Figure 13b,c. The installation locations of temperature sensors T1–T14 correspond to

Figure 2. The temperature sensors measuring the temperature in module (A) are marked T1–T7 in module (B) T8–T14. T15 denotes a reference temperature measured in the outlet channel. All collected data refer to the electrical performance of the PEMFC stack in the conditions shown in

Figure 13a.

As can be seen from

Figure 13b,c, the temperature increased when the stack operated with higher electrical power. The maximum temperature of the stack with 10 kW of power was ~60 °C. Increases in temperature were observed for sensors T1, T5, T10, and T14, i.e., the points farthest from the air outlet channel of the constructed stack. The lowest temperatures were recorded by T3 and T8, the points near the outlet channel. The temperature difference ΔT between the minimum and maximum recorded temperatures increased with increasing loads, reaching values of approximately 12–13 °C in the measurement conditions corresponding to

Figure 13a.

Stabilisation of the partial pressure of the hydrogen (pH

2) introduced directly into the anode chambers of the PEMFC stack should also be analysed under variable electrical load. The variation of pH

2 vs. time under applied experimental conditions (from

Figure 13a) is presented in

Figure 13d.

As can be seen in the graph in

Figure 13d, the experimental data show the average value of hydrogen stabilisation pressure established by an automatic electronic pressure regulator at the hydrogen input of the 10 kW PEMFC stack. The hydrogen inlet pressure changed due to the operation of the anode flushing system (periodic opening of the purge flush valve every 10 s). It can be seen that over the entire tested load range of the 10 kW PEMFC stack, adequate hydrogen flow capacity is ensured, maintained by the pressure regulator an average level of P = 500 mbar depending on the degree of electrical load of the device. The increase in electrical power results in a higher level of hydrogen consumption and a lower average value of pressure stabilisation; however, the use of an active pressure regulator (with stabilisation pressure set at 500 mbar) enabled the pressure to be maintained at the required level. The most stable pressure values (P

H2) occurred during the third start-up when the stack was fed with hydrogen from composite cylinders, as the supply line was then shortest and no pressure drops caused by increased flow in the course of flushing of the anode space (opening the ‘purge’ valve) occurred.

In the case of the constructed V-type 10 kW PEMFC stack, hydrogen consumption under variable dynamic load operation during the humidification process as well as purification carried out by means of the short-circuit unit (SCU) were also analysed. The purification of the MEA during the purging process has a great impact on stack performance. There is no description in the literature concerning the response of hydrogen consumption under variable electrical load. For practical applications involving the constructed V-type PEMFC stack and variation in dynamic hydrogen consumption occurring during the purge via the SCU process should be discussed. These data are necessary to elaborate real-time control of the operation of the fuel cell power system. The PEMFC stack suffers from reversible performance loss during operation caused by oxidation of the Pt catalyst which, in turn, reduces the electrochemically active surface area. An improvement in PEMFC performance (a small gain of potentials) due to purging processes is expected based on the removal of the Pt hydroxide and oxide layers formed on the Pt catalyst, thus resulting in a larger effective surface area of Pt available for the electrochemical reaction [

38,

39].

Figure 14a presents the variation of electrical parameters such as voltage (U), current (I), and electrical power (P) during the operation of the V-type constructed PEMFC stack under variable electrical load, involving a procedure in which the device is first turned on, then turned off, and finally turned on again. The variation in partial pressure, the volume of hydrogen storage in composite cylinders, and the amount of fuel consumed during electrical operation of the PEMFC stack vs. time during this experiment are presented in

Figure 14b.

The experimental conditions are given in

Figure 14a. In the first part of the experiment (from 0 to 400 s), the hydrogen pressure varied between 120 and 80 bar due to the utilisation of hydrogen in the fuel cell stack. In these conditions, the electrical load of the stack was increased from 0 to 10 kW and the stack was turned off. During the second part of the experiment (450–1000 s), hydrogen pressure varied between 80 and 20 bar due to the utilisation of hydrogen for performance of the stack with 8 kW of power. Analysis of variation in the hydrogen volume, which was stored in two composite cylinders and then utilised during the operation of the stack within the period of time under consideration, was also carried out. In the case of operation of the stack under 9–9.5 kW, which took place over a period ranging from 9 to 14 min, the consumption of total hydrogen was calculated about 145 dm

3 H

2/min. This estimated value is in close agreement with the consumption measured directly by F-202AV-M20-RAD-44-V mass flow controller. This device was also used during the measurement of intensity of hydrogen flow presented in

Figure 11.

3.3. Investigations of an Air-Cooling Performance System for the 10 kW V-Type PEMFC Stack

One of the key functions of an air-cooling system integrated with a PEMFC stack applied in a hybrid power source supplying a propulsion system is to ensure proper humidity and thermal management during operation under variable electric dynamic load. Ensuring adequate air flow while removing heat from the stack is a crucial factor in determining the performance and durability of this power source. Waste heat production from a PEMFC stack depends on operating conditions under different electrical loads. Intensification of air flow within a V-type PEMFC stack eliminates local overheating, thus significantly prolonging its trouble-free operation. However, it is important to maintain proper humidity in the membrane as the excessive flow of non-humidified air can lead to its drying out, thus increasing the internal electrical resistance of the stack and, as a consequence, significantly impairing its performance [

16,

40,

41].

A cooling system managed by effective control algorithms plays the main role in maintaining proper stack operation parameters. Achievement of a high level of control efficiency is understood as the use of follow-up control in accordance with the electrical load state of the PEMFC stack while maintaining the high level of internal efficiency of the flow-inducing fans. An additional criterion for the designed cooling system is its intended use in a powered glider, which necessitates reductions in its size and weight. In the elaboration of an air-cooling system for a 10 kW V-type PEMFC stack, the first thing to be considered is an air-flow installation for air volume flow, as energy loss may occur due to fluid viscosity and channel geometry changes, due to which a drop in partial pressure may occur. In the elaborated system, with air flowing from two cascade axial fans into the inlet of the stack, losses in air volume flow occurred along with partial pressure drops. The high level of efficiency of a cooling system operating with two axial fans is highly recommended.

Figure 15a presents the dependence of total pressure losses (Δp) vs. volumetric flow rate (V) determined for the cooling system (whose experimental setup is presented and explained in

Figure 6). Two diameters for the outlet (D

1 = 150 mm, D

2 = 200 mm) to the V-channel were considered in the design of this system. At the nominal electrical power of a 10 kW PEMFC stack, it was found that the required air volumetric flow rate is about 0.65 m

3/s. In these conditions, the maximum temperature was close to 65 °C; however, the observed gradient of temperature was no higher than 12 °C. The experimentally measured losses of partial pressure (Δp) vs. air flow rate corresponding to electrical power of 10 kW were estimated at approximately 1200 Pa. In order to reduce the pressure losses, the diameter was increased from 150 to 200 mm. This modification led to a reduction in total pressure losses by more than half, i.e., to ca. 550 Pa. It is also known that in order to overcome air flow resistance, electrical power consumption increases nearly linearly relative to pressure losses. In the course of these investigations, the application of protective dust filters in the air-cooling system to cover the V-type PEMFC stack was also considered. Application of protective filters is necessary in aviation implementations due to the solid airborne contaminants which are caught on this surface during take-offs and landings. It was found that the geometry with the applied filter caused an increase in partial losses by 100 Pa for the nominal power of 10 kW.

Figure 15b presents the dependence of pressure losses vs. air volumetric flow rate. Data obtained from a numerical simulation as well as from the experimental tests are presented; close agreement was obtained. The data presented in

Figure 15b show that in a 10 kW V-type PEMFC stack operated at nominal power, the rotor speed required to ensure adequate cooling is 6900 rpm.

Figure 16a presents the dependence of the predicted consumption of power required for supplying two cascade axial fans vs. volumetric air flow;

Figure 16b presents the dependence of electrical power consumed during operation of a V-type PEMFC stack on cooling system performance. The data were obtained during measurements of consumed power N

el vs. electrical power produced by a PEMFC stack with an elaborated cooling system.

Figure 16a presents the estimated power consumption needed for the operation of two cascade axial fans with different rotation speeds (

n). As can be seen, during operation of a PEMFC stack at nominal power of 10 kW, 1.2–1.3 kW is required to run cooling fans at a rotation speed of 6900 rpm.

Figure 16b presents the electrical power required to supply the fans during the cooling of a PEMFC stack operating at different levels of nominal power. The experimental results agree closely with those from the elaborated numerical model of two cascade axial fans.