Review of Flow-Control Devices for Wind-Turbine Performance Enhancement

Abstract

:1. Introduction

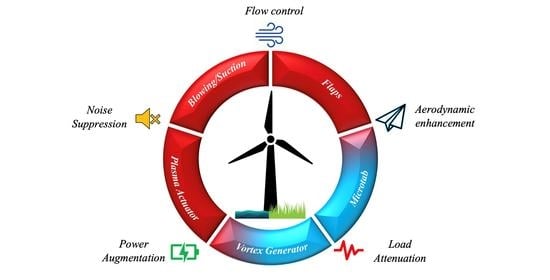

2. Performance Enhancement Devices

2.1. Flaps

2.1.1. Adaptive Trailing Edge Geometry (ATEG)

2.1.2. Gurney Flaps

2.2. Microtabs

2.3. Vortex Generators

2.3.1. Smart Vortex Generators (VGs)

2.3.2. Miniature Vortex Generators (MVGs)

2.3.3. High-Frequency Micro Vortex Generators (HiMVGs)

2.4. Plasma Actuators

2.5. Blowing-Suction Control

2.5.1. Circulation Control

2.5.2. Vortex Generator Jet (VGJ)

3. Discussion

3.1. Prospects

3.2. Challenges

3.3. Outlook

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| AEP | Annual Energy Production |

| AOA | Angle of Attack |

| ATEG | Adaptive Trailing-edge Geometry |

| CC | Circulation Control |

| COE | Cost of Energy |

| DBD | Dielectric Barrier Discharge |

| GW | Gigawatts |

| HiMVG | High-Frequency Micro Vortex Generator |

| MiTE | Mini Trailing-edge Effectors |

| MVG | Micro Vortex Generator |

| MW | Megawatts |

| NREL | National Renewable Energy Laboratory |

| TRL | Technology Readiness Level |

| VG | Vortex Generator |

| VGJ | Vortex Generator Jet |

References

- IRENA. Renewable Energy Statistics 2020; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2020. [Google Scholar]

- GWEC. Global Wind Report 2019; Global Wind Energy Council: Brussels, Belgium, 2020. [Google Scholar]

- Offshore Wind Turbine SG 14-222 DD I Siemens Gamesa. Available online: https://www.siemensgamesa.com/en-int/products-and-services/offshore/wind-turbine-sg-14-222-dd (accessed on 13 July 2020).

- Gad-el-Hak, M. Overview of Turbulence Control Research in U.S.A. In Proceedings of the Symposium on Smart Control of Turbulence, Tokyo, Japan, 2–3 December 1999; pp. 1–20. [Google Scholar]

- Kral, L.D. Active Flow Control Technology. In ASME Fluids Engineering Technical Brief; Washington University: St. Louis, MO, USA, 1998. [Google Scholar]

- Chopra, I. Review of State of Art of Smart Structures and Integrated Systems. AIAA J. 2002, 40, 2145–2187. [Google Scholar] [CrossRef]

- Abbott, I.H.; von Doenhoff, A.E. Theory of Wing Sections; Courier Corporation: New York, NY, USA, 1959. [Google Scholar]

- Berg, D.E.; Zayas, J.R.; Lobitz, D.W.; van Dam, C.P.; Chow, R.; Baker, J.P. Active Aerodynamic Load Control of Wind Turbine Blades; American Society of Mechanical Engineers Digital Collection; American Society of Mechanical Engineers: New York, NY, USA, 2009; pp. 1119–1127. [Google Scholar] [CrossRef] [Green Version]

- Migliore, P.G.; Miller, L.S.; Quandt, G.A. Wind Turbine Trailing Edge Aerodynamic Brakes; National Renewable Energy Laboratory: Golden, CO, USA, 1995.

- Miller, S.; Migliore, P.G.; Quandt, G.A. An Evaluation of Several Wind Turbine Trailing-Edge Aerodynamic Brakes. J. Sol. Energy Eng. 1996, 118, 198–203. [Google Scholar] [CrossRef]

- Miller, L.S. Experimental Investigation of Aerodynamic Devices for wind Turbine Rotational Speed Control: Phase, I.I.; National Renewable Energy Laboratory: Golden, CO, USA, 1996. [CrossRef] [Green Version]

- Somers, D.M. Effect of Flap Deflection on Section Characteristics of S813 Airfoil; Period of Performance: 1993–1994; National Renewable Energy Laboratory: Golden, CO, USA, 2005. [CrossRef] [Green Version]

- Ramsay, R.; Janiszewska, J.; Gregorek, G. Wind tunnel testing of an S809 spoiler flap model. In Proceedings of the 35th Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 6–9 January 1997; American Institute of Aeronautics and Astronautics: Reston, VA, USA. [Google Scholar] [CrossRef]

- Stuart, J.G.; Wright, A.D.; Butterfield, C.P. Considerations for an Integrated Wind Turbine Controls Capability at the National Wind Technology Center: An Aileron Control Case Study for Power Regulation and Load Mitigation; National Renewable Energy Laboratory: Golden, CO, USA, 1996. [CrossRef] [Green Version]

- Stuart, J.; Wright, A.; Butterfield, C. Wind turbine control systems—Dynamic model development using system identification and the FAST structural dynamics code. In Proceedings of the 35th Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 6–9 January 1997; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 1997. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.-W.; Han, J.-H.; Shin, H.-K.; Bang, H.-J. Active load control of wind turbine blade section with trailing edge flap: Wind tunnel testing. J. Intell. Mater. Syst. Struct. 2014, 25, 2246–2255. [Google Scholar] [CrossRef]

- Castaignet, D.; Barlas, T.; Buhl, T.; Poulsen, N.K.; Wedel-Heinen, J.J.; Olesen, N.A.; Bak, C.; Kim, T. Full-scale test of trailing edge flaps on a Vestas V27 wind turbine: Active load reduction and system identification. Wind Energy 2014, 17, 549–564. [Google Scholar] [CrossRef]

- Fischer, J.; Eisele, O.; Pechlivanoglou, S.; Vey, S.; Nayeri, C.N.; Paschereit, C.O. Development of a medium scale research hawt for inflow and aerodynamics research in the large wind tunnel of TU berlin wind tunnel. In Proceedings of the 12th German Wind Energy Conference (DEWEK), Bremen, Germany, 19–20 May 2015. [Google Scholar]

- Vey, S.; Marten, D.; Pechlivanoglou, G.; Nayeri, C.; Paschereit, C.O. Experimental and Numerical Investigations of a Small Research Wind Turbine. In Proceedings of the 33rd AIAA Applied Aerodynamics Conference, Dallas, TX, USA, 22–26 June 2015; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2015. [Google Scholar] [CrossRef]

- Plumley, C.; Leithead, W.; Jamieson, P.; Bossanyi, E.; Graham, M. Comparison of individual pitch and smart rotor control strategies for load reduction. J. Phys. Conf. Ser. 2014, 524, 012054. [Google Scholar] [CrossRef] [Green Version]

- Ng, B.F.; Hesse, H.; Kerrigan, E.C.; Palacios, R.; Graham, J.M.R. Efficient aeroservoelastic modeling and control using trailing-edge flaps of wind turbines. In Proceedings of the 2014 UKACC International Conference on Control (CONTROL), Loughborough, UK, 9–11 July 2014; pp. 1–6. [Google Scholar] [CrossRef]

- Ng, B.F.; Palacios, R.; Kerrigan, E.C.; Graham, J.M.R.; Hesse, H. Aerodynamic load control in horizontal axis wind turbines with combined aeroelastic tailoring and trailing-edge flaps. Wind Energy 2016, 19, 243–263. [Google Scholar] [CrossRef]

- Lackner, M.A.; van Kuik, G. A comparison of smart rotor control approaches using trailing edge flaps and individual pitch control. Wind Energy 2010, 13, 117–134. [Google Scholar] [CrossRef] [Green Version]

- Ungurán, R.; Kühn, M. Combined individual pitch and trailing edge flap control for structural load alleviation of wind turbines. In Proceedings of the 2016 American Control Conference (ACC), Boston, MA, USA, 6–8 July 2016; pp. 2307–2313. [Google Scholar] [CrossRef]

- Fischer, A.; Madsen, H.A. Investigation of the theoretical load alleviation potential using trailing edge flaps controlled by inflow data. Wind Energy 2016, 19, 1567–1583. [Google Scholar] [CrossRef]

- Oltmann, N.-C.; Sobotta, D.; Hoffmann, A. Load reduction of wind turbines using trailing edge flaps. Energy Procedia 2017, 136, 176–181. [Google Scholar] [CrossRef]

- Smit, J.; Bernhammer, L.O.; Navalkar, S.T.; Bergami, L.; Gaunaa, M. Sizing and control of trailing edge flaps on a smart rotor for maximum power generation in low fatigue wind regimes. Wind Energy 2016, 19, 607–624. [Google Scholar] [CrossRef]

- Chen, Z.J.; Stol, K.A.; Mace, B.R. Wind turbine blade optimisation with individual pitch and trailing edge flap control. Renew. Energy 2017, 103, 750–765. [Google Scholar] [CrossRef]

- Zhang, W.; Bai, X.; Wang, Y.; Han, Y.; Hu, Y. Optimization of sizing parameters and multi-objective control of trailing edge flaps on a smart rotor. Renew. Energy 2018, 129, 75–91. [Google Scholar] [CrossRef]

- Montinari, P.; Gualdoni, F.; Croce, A.; Bottasso, C.L. Ultimate and fatigue load mitigation by an inertial-driven passive flap, using a geometrically exact multibody formulation. J. Wind Eng. Ind. Aerodyn. 2018, 175, 169–178. [Google Scholar] [CrossRef]

- Wei, X.; Ng, B.F.; Zhao, X. Aeroelastic load control of large and flexible wind turbines through mechanically driven flaps. J. Frankl. Inst. 2019, 356, 7810–7835. [Google Scholar] [CrossRef]

- Basualdo, S. Load Alleviation on Wind Turbine Blades Using Variable Airfoil Geometry. Wind Eng. 2005, 29, 169–182. [Google Scholar] [CrossRef]

- Jacob, J.D. On the Fluid Dynamics of Adaptive Airfoils. In Proceedings of the 1998 ASME International Mechanical Engineering Congress and Exposition Anaheim, Anaheim, CA, USA, 15–20 November 1988. [Google Scholar]

- Monner, H.P. Realization of an optimized wing camber by using formvariable flap structures. Aerosp. Sci. Technol. 2001, 5, 445–455. [Google Scholar] [CrossRef]

- Kota, S.; Hetrick, J.A. Adaptive Compliant Wing and Rotor System. CA2518080C, 5 February 2014. [Google Scholar]

- Campanile, L.F.; Anders, S. Aerodynamic and aeroelastic amplification in adaptive belt-rib airfoils. Aerosp. Sci. Technol. 2005, 9, 55–63. [Google Scholar] [CrossRef]

- Berry, P. Segmented Flap with Variable Camber for Aircraft Wing. WO1997044238A1, 27 November 1997. [Google Scholar]

- Brown, S.T. Variable Camber Flap End Seal. US4427169A, 24 January 1984. [Google Scholar]

- Kudva, J.; Appa, K.; Martin, C.; Jardine, A.; Sendeckyj, G.; Harris, T.; McGowan, A.; Lake, R. Design, fabrication, and testing of the DARPA/Wright Lab “smart wing” wind tunnel model. In Proceedings of the 38th Structures, Structural Dynamics, and Materials Conference, Kissimmee, FL, USA, 7–10 April 1997; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 1997. [Google Scholar]

- Bartley-Cho, J.D.; Wang, D.P.; Martin, C.A.; Kudva, J.N.; West, M.N. Development of High-rate, Adaptive Trailing Edge Control Surface for the Smart Wing Phase 2 Wind Tunnel Model. J. Intell. Mater. Syst. Struct. 2014, 15, 279–291. [Google Scholar] [CrossRef]

- Straub, F.K.; Ngo, H.T.; Anand, V.; Domzalski, D.B. Development of a piezoelectric actuator for trailing edge flap control of full scale rotor blades. Smart Mater. Struct. 2001, 10, 25–34. [Google Scholar] [CrossRef]

- Straub, F.K.; Merkley, D.J. Design of a servo-flap rotor for reduced control loads. Smart Mater. Struct. 1996, 5, 68–75. [Google Scholar] [CrossRef]

- Troldborg, N. Computational Study of the Risø-B1-18 Airfoil with a Hinged Flap Providing Variable Trailing Edge Geometry. Wind Eng. 2005, 29, 89–113. [Google Scholar] [CrossRef]

- Bak, C.; Gaunaa, M.; Andersen, P.B.; Buhl, T.; Hansen, P.; Clemmensen, K.; Moeller, R. Wind Tunnel Test on Wind Turbine Airfoil with Adaptive Trailing Edge Geometry. In Proceedings of the 45th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 8–11 January 2007. [Google Scholar]

- Theodorsen, T. General Theory of Aerodynamic Instability and the Mechanism of Flutter; National Advisory Committee for Aeronautics: Washington DC, USA, 1949.

- Leishman, J.G. Unsteady lift of a flapped airfoil by indicial concepts. J. Aircr. 1994, 31, 288–297. [Google Scholar] [CrossRef]

- Gaunaa, M. Unsteady 2D Potential-Flow Forces and a Thin Variable Geometry Airfoil Undergoing Arbitrary Motion; Risoe National Laboratory Wind Energy Department: Roskilde, Denmark, 2006.

- Buhl, T.; Gaunaa, M.; Bak, C. Potential Load Reduction Using Airfoils with Variable Trailing Edge Geometry. J. Sol. Energy Eng. 2005, 127, 503–516. [Google Scholar] [CrossRef]

- Andersen, P.B.; Gaunaa, M.; Buhl, T. Load Alleviation on Wind Turbine Blades using Variable Airfoil Geometry. In Proceedings of the 2006 European Wind Energy Conference & Exhibition, Athens, Greece, 27 February–2 March 2006. [Google Scholar]

- Hulskamp, A.W.; Beukers, A.; Bersee, H.E.N.; van Wingerden, J.W.; Barlas, T. Design of a wind tunnel scale model of an adaptive wind turbine blade for active aerodynamic load control experiments. In Proceedings of the ICCM 16: 16th International Conference on Composite Materials, Kyoto, Japan, 8–13 July 2007. [Google Scholar]

- Barlas, T.; van Wingerden, J.W.; Hulskamp, A.; van Kuik, G. Closed-Loop Control Wind Tunnel Tests on an Adaptive Wind Turbine Blade for Load Reduction. In Proceedings of the 46th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 7–10 January 2008; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2008. [Google Scholar] [CrossRef] [Green Version]

- Barlas, T.K.; van Kuik, G.A.M. State of the art and prospectives of smart rotor control for wind turbines. J. Phys. Conf. Ser. 2007, 75, 012080. [Google Scholar] [CrossRef]

- van Wingerden, J.W.; Hulskamp, A.W.; Barlas, T.K.; Marrant, B.; van Kuik, G.A.M.; Molenaar, D.P.; Verhaegen, M. On the proof of concept of a ‘Smart’ wind turbine rotor blade for load alleviation. Wind Energy 2008, 11, 265–280. [Google Scholar] [CrossRef]

- Cairns, D.S.; Blockey, J.C.; Ehresman, J. Design and Feasibility of Active Control Surfaces on Wind Turbine Blade Systems. In Proceedings of the 46th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 7–10 January 2008; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2008. [Google Scholar] [CrossRef]

- Pechlivanoglou, G.; Wagner, J.; Nayeri, C.; Paschereit, C. Active Aerodynamic Control of Wind Turbine Blades with High Deflection Flexible Flaps. In Proceedings of the 48th AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition, Orlando, USA, 4–7 January 2010; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2010. [Google Scholar] [CrossRef]

- Andersen, P.B. Advanced Load Alleviation for Wind Turbines Using Adaptive Trailing Edge Flaps: Sensoring and Control. Ph.D. Thesis, National Laboratory for Sustainable Energy Risø, D.T.U., Roskilde, Denmark, 2010. [Google Scholar]

- Andersen, P.B.; Henriksen, L.; Gaunaa, M.; Bak, C.; Buhl, T. Deformable trailing edge flaps for modern megawatt wind turbine controllers using strain gauge sensors. Wind Energy 2010, 13, 193–206. [Google Scholar] [CrossRef]

- Barlas, T.K.; van Wingerden, J.W.; Hulskamp, A.W.; van Kuik, G.A.M.; Bersee, H.E.N. Smart dynamic rotor control using active flaps on a small-scale wind turbine: Aeroelastic modeling and comparison with wind tunnel measurements. Wind Energy 2013, 16, 1287–1301. [Google Scholar] [CrossRef]

- Daynes, S.; Weaver, P.M. A morphing trailing edge device for a wind turbine. J. Intell. Mater. Syst. Struct. 2012, 23, 691–701. [Google Scholar] [CrossRef]

- Daynes, S.; Weaver, P.M. Design and testing of a deformable wind turbine blade control surface. Smart Mater. Struct. 2012, 21, 105019. [Google Scholar] [CrossRef]

- Wolff, T.; Ernst, B.; Seume, J.R. Aerodynamic behavior of an airfoil with morphing trailing edge for wind turbine applications. J. Phys. Conf. Ser. 2014, 524, 012018. [Google Scholar] [CrossRef] [Green Version]

- Zhang, M.; Tan, B.; Xu, J. Parameter study of sizing and placement of deformable trailing edge flap on blade fatigue load reduction. Renew. Energy 2015, 77, 217–226. [Google Scholar] [CrossRef]

- Bergami, L.; Poulsen, N.K. A smart rotor configuration with linear quadratic control of adaptive trailing edge flaps for active load alleviation. Wind Energy 2015, 18, 625–641. [Google Scholar] [CrossRef] [Green Version]

- Bernhammer, L.O.; van Kuik, G.A.M.; De Breuker, R. Fatigue and extreme load reduction of wind turbine components using smart rotors. J. Wind Eng. Ind. Aerodyn. 2016, 154, 84–95. [Google Scholar] [CrossRef]

- Jost, E.; Lutz, T.; Krämer, E. A Parametric CFD Study of Morphing Trailing Edge Flaps Applied on a 10 MW Offshore Wind Turbine. Energy Procedia 2016, 94, 53–60. [Google Scholar] [CrossRef] [Green Version]

- Zhang, M.; Li, X.; Xu, J. Smart control of fatigue loads on a floating wind turbine with a tension-leg-platform. Renew. Energy 2019, 134, 745–756. [Google Scholar] [CrossRef]

- Zhuang, C.; Yang, G.; Zhu, Y.; Hu, D. Effect of morphed trailing-edge flap on aerodynamic load control for a wind turbine blade section. Renew. Energy 2020, 148, 964–974. [Google Scholar] [CrossRef]

- Liebeck, R.H. Design of Subsonic Airfoils for High Lift. J. Aircr. 1978, 15, 547–561. [Google Scholar] [CrossRef]

- Liu, T.; Montefort, J. Thin-Airfoil Theoretical Interpretation for Gurney Flap Lift Enhancement. J. Aircr. 2007, 44, 667–671. [Google Scholar] [CrossRef]

- Liebeck, R. On the design of subsonic airfoils for high lift. In Proceedings of the 9th Fluid and PlasmaDynamics Conference, San Diego, CA, USA, 14–16 July 1976; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 1976. [Google Scholar] [CrossRef]

- Greenblatt, D.; Vey, S.; Paschereit, O.C.; Meyer, R. Flap Vortex Management Using Active Gurney Flaps. AIAA J. 2009, 47, 2845–2856. [Google Scholar] [CrossRef]

- Storms, B.L.; Jang, C.S. Lift enhancement of an airfoil using a Gurney flap and vortex generators. J. Aircr. 1994, 31, 542–547. [Google Scholar] [CrossRef] [Green Version]

- Myose, R.; Papadakis, M.; Heron, I. Gurney Flap Experiments on Airfoils, Wings, and Reflection Plane Model. J. Aircr. 1998, 35, 206–211. [Google Scholar] [CrossRef]

- Li, Y.; Wang, J.; Zhang, P. Effects of Gurney Flaps on a NACA0012 Airfoil. Flow Turbul. Combust. 2002, 68, 27. [Google Scholar] [CrossRef]

- Timmer, W.A.; van Rooij, R.P.J.O.M. Summary of the Delft University Wind Turbine Dedicated Airfoils. J. Sol. Energy Eng. 2003, 125, 488–496. [Google Scholar] [CrossRef]

- Tongchitpakdee, C.; Benjanirat, S.; Sankar, L.N. Numerical Studies of the Effects of Active and Passive Circulation Enhancement Concepts on Wind Turbine Performance. J. Sol. Energy Eng. 2006, 128, 432–444. [Google Scholar] [CrossRef]

- Troolin, D.R.; Longmire, E.K.; Lai, W.T. Time resolved PIV analysis of flow over a NACA 0015 airfoil with Gurney flap. Exp. Fluids 2006, 41, 241–254. [Google Scholar] [CrossRef]

- Fuglsang, P.; Bak, C. Development of the Risø wind turbine airfoils. Wind Energy 2004, 7, 145–162. [Google Scholar] [CrossRef]

- Tang, D.; Dowell, E.H. Aerodynamic Loading for an Airfoil with an Oscillating Gurney Flap. J. Aircr. 2007, 44, 1245–1257. [Google Scholar] [CrossRef]

- Maughmer, M.D.; Bramesfeld, G. Experimental Investigation of Gurney Flaps. J. Aircr. 2008, 45, 2062–2067. [Google Scholar] [CrossRef]

- Jain, S.; Sitaram, N.; Krishnaswamy, S. Computational Investigations on the Effects of Gurney Flap on Airfoil Aerodynamics. Int. Sch. Res. Not. 2015, 2015, e402358. [Google Scholar] [CrossRef] [Green Version]

- Cole, J.A.; Vieira, B.A.O.; Coder, J.G.; Premi, A.; Maughmer, M.D. Experimental Investigation into the Effect of Gurney Flaps on Various Airfoils. J. Aircr. 2013, 50, 1287–1294. [Google Scholar] [CrossRef]

- Bechert, D.; Meyer, R.; Hage, W. Drag reduction of airfoils with miniflaps—Can we learn from dragonflies? In Proceedings of the Fluids 2000 Conference and Exhibit, Denver, CO, USA, 19–22 June 2000; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2000. [Google Scholar] [CrossRef] [Green Version]

- Van Dam, C.P.; Chow, R.; Zayas, J.R.; Berg, D.E. Computational Investigations of Small Deploying Tabs and Flaps for Aerodynamic Load Control. J. Phys. Conf. Ser. 2007, 75, 012027. [Google Scholar] [CrossRef] [Green Version]

- Van Dam, C.P.; Berg, D.E.; Johnson, S.J. Active Load Control Techniques for Wind Turbines; Sandia National Laboratories: Albuquerque, NM, USA, 2008. [CrossRef] [Green Version]

- Lee, T. Aerodynamic Characteristics of Airfoil with Perforated Gurney-Type Flaps. J. Aircr. 2009, 46, 542–548. [Google Scholar] [CrossRef]

- Eisele, O.; Pechlivanoglou, G.; Nayeri, C.N.; Paschereit, C.O. Experimental investigation of dynamic load control strategies using active microflaps on wind turbine blades. In Proceedings of the EWEA 2011, Brussels, Belgium, 14–17 March 2011. [Google Scholar]

- Weinzierl, G.; Pechlivanoglou, G.; Nayeri, C.N.; Paschereit, C.O. Performance Optimization of Wind Turbine Rotors With Active Flow Control: Part 2—Active Aeroelastic Simulations; American Society of Mechanical Engineers Digital Collection; American Society of Mechanical Engineers: Copenhagen, Denmark, 2013; pp. 915–927. [Google Scholar] [CrossRef]

- Bach, A.B.; Pechlivanoglou, G.; Nayeri, C.; Paschereit, C.O. Wake Vortex Field of an Airfoil Equipped with an Active Finite Gurney Flap; American Institute of Aeronautics and Astronautics: Kissimmee, FL, USA, 2015. [Google Scholar] [CrossRef]

- Holst, D.; Bach, A.B.; Nayeri, C.N.; Paschereit, C.O.; Pechlivanoglou, G. Wake Analysis of a Finite Width Gurney Flap. J. Eng. Gas Turbines Power 2016, 138. [Google Scholar] [CrossRef]

- Xie, Y.H.; Jiang, W.; Lu, K.; Zhang, D. Numerical investigation into energy extraction of flapping airfoil with Gurney flaps. Energy 2016, 109, 694–702. [Google Scholar] [CrossRef]

- Dighe, V.V.; Avallone, F.; Tang, J.; van Bussel, G. Effects of Gurney Flaps on the Performance of Diffuser Augmented Wind Turbine. In Proceedings of the 35th Wind Energy Symposium, Grapevine, TX, USA, 9–13 January 2017; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2017. [Google Scholar] [CrossRef]

- Fernandez-Gamiz, U.; Zulueta, E.; Boyano, A.; Ansoategui, I.; Uriarte, I. Five Megawatt Wind Turbine Power Output Improvements by Passive Flow Control Devices. Energies 2017, 10, 742. [Google Scholar] [CrossRef] [Green Version]

- Fernandez-Gamiz, U.; Gomez-Mármol, M.; Chacón-Rebollo, T. Computational Modeling of Gurney Flaps and Microtabs by POD Method. Energies 2018, 11, 2091. [Google Scholar] [CrossRef] [Green Version]

- Aramendia, I.; Fernandez-Gamiz, U.; Zulueta, E.; Saenz-Aguirre, A.; Teso-Fz-Betoño, D. Parametric Study of a Gurney Flap Implementation in a DU91W(2)250 Airfoil. Energies 2019, 12, 294. [Google Scholar] [CrossRef] [Green Version]

- Saenz-Aguirre, A.; Fernandez-Gamiz, U.; Zulueta, E.; Ulazia, A.; Martinez-Rico, J. Optimal Wind Turbine Operation by Artificial Neural Network-Based Active Gurney Flap Flow Control. Sustainability 2019, 11, 2809. [Google Scholar] [CrossRef] [Green Version]

- Baker, J.P.; Standish, K.J.; van Dam, C.P. Two-Dimensional Wind Tunnel and Computational Investigation of a Microtab Modified Airfoil. J. Aircr. 2007, 44, 563–572. [Google Scholar] [CrossRef]

- Yen, D.; van Dam, C.; Braeuchle, F.; Smith, R.; Collins, S. Active load control and lift enhancement using MEM translational tabs. In Proceedings of the Fluids 2000 Conference and Exhibit, Denver, CO, USA, 9–20 June 2000; American Institute of Aeronautics and Astronautics: Reston, VA, USA. [Google Scholar]

- Yen, D.; van Dam, C.; Smith, R.; Collins, S. Active load control for wind turbine blades using MEM translational tabs. In Proceedings of the 20th 2001 ASME Wind Energy Symposium, Reno, NV, USA,, 11–14 January 2001; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2001. [Google Scholar] [CrossRef]

- Nakafuji, D.T.Y.; van Dam, C.P.; Smith, R.L.; Collins, S.D. Active Load Control for Airfoils using Microtabs. J. Sol. Energy Eng. 2001, 123, 282–289. [Google Scholar] [CrossRef]

- Yen Nakafuji, D.T.; van Dam, C.P.; Michel, J.; Morrison, P. Load Control for Turbine Blades: A Non-Traditional Microtab Approach; American Society of Mechanical Engineers Digital Collection; American Society of Mechanical Engineers: New York, NY, USA, 2002; pp. 321–330. [Google Scholar] [CrossRef]

- Standish, K.J.; van Dam, C.P. Computational Analysis of a Microtab-Based Aerodynamic Load Control System for Rotor Blades. J. Am. Helicopter Soc. 2005, 50, 249–258. [Google Scholar] [CrossRef]

- Somers, D.M. Design and Experimental Results for the S809 Airfoil; National Renewable Energy Laboratory: Golden, CO, USA, 1997. [CrossRef] [Green Version]

- Mayda, E.A.; van Dam, C.P.; Nakafuji, D. Computational Investigation of Finite Width Microtabs for Aerodynamic Load Control. In Proceedings of the 43rd AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 10–13 January 2005; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2005. [Google Scholar] [CrossRef]

- Chow, R.; van Dam, C.P. Unsteady Computational Investigations of Deploying Load Control Microtabs. J. Aircr. 2006, 43, 1458–1469. [Google Scholar] [CrossRef] [Green Version]

- Chow, R.; van Dam, C. Computational Investigations of Deploying Load Control Microtabs on a Wind Turbine Airfoil. In Proceedings of the 45th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 8–11 January 2007; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2007. [Google Scholar] [CrossRef]

- Chow, R.; van Dam, C.P. On the temporal response of active load control devices. Wind Energy 2010, 13, 135–149. [Google Scholar] [CrossRef]

- Bæk, P.; Gaunaa, M.; Sørensen, N.N.; Fuglsang, P. A Comparison of Two Devices for Distributed Active Load Control of Wind Turbine Blades. In Torque 2010: The Science of Making Torque from Wind; European Wind Energy Association (EWEA): Brussels, Belgium, 2010; pp. 611–617. [Google Scholar]

- Baek, P.; Gaunaa, M. Modeling the Temporal Response of a Microtab in an Aeroelastic Model of a Wind Turbine. In Proceedings of the 49th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 4–7 January 2001; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2011. [Google Scholar] [CrossRef]

- Zayas, J.R.; van Dam, C.P.; Chow, R.; Baker, J.P.; Mayda, E.A. Active Aerodynamic Load Control of Wind Turbine Blades. In Proceedings of the Fluids Engineering Division Summer Meeting, Athens, Greece, 30 July–2 August 2006. [Google Scholar]

- Wilson, D.G.; Berg, D.E.; Lobitz, D.W.; Zayas, J.R. Optimized Active Aerodynamic Blade Control for Load Alleviation on Large Wind Turbines. In Proceedings of the American Wind Energy Association (AWEA) Windpower 2008 Conference & Exhibition, Houston, TX, USA, 1–4 June 2008; p. 7. [Google Scholar]

- Macquart, T.; Maheri, A.; Busawon, K. Microtab dynamic modelling for wind turbine blade load rejection. Renew. Energy 2014, 64, 144–152. [Google Scholar] [CrossRef] [Green Version]

- Macquart, T.; Maheri, A. Integrated aeroelastic and control analysis of wind turbine blades equipped with microtabs. Renew. Energy 2015, 75, 102–114. [Google Scholar] [CrossRef] [Green Version]

- Migliore, P.; Oerlemans, S. Wind Tunnel Aeroacoustics Tests of Six Airfoils for Use on Small Wind Turbines. J. Sol. Energy Eng. 2004, 126, 974–985. [Google Scholar] [CrossRef]

- Qiu, S.; Song, W.; Liu, H. Multi-objective Optimization of Airfoil Trailing Edge Noise with Three Different Measures. In Proceedings of the 18th AIAA/CEAS aeroacoustics conference (33rd AIAA Aeroacousticss Conference), Colorado Springs, CO, USA, 4–6 June 2012; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2012. [Google Scholar] [CrossRef]

- Kinzel, M.P.; Maughmer, M.D.; Duque, E.P.N. Numerical Investigation on the Aerodynamics of Oscillating Airfoils with Deployable Gurney Flaps. AIAA J. 2010, 48, 1457–1469. [Google Scholar] [CrossRef]

- Cooperman, A.; Chow, R.; Johnson, S.; van Dam, C. Experimental and Computational Analysis of a Wind Turbine Airfoil with Active Microtabs. In Proceedings of the 49th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 4–7 January 2011; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2011. [Google Scholar] [CrossRef]

- Cooperman, A.; Brunner, M.; Van Dam, C. Wind Tunnel Testing of Jets and Tabs for Active Load Control of Wind Turbine Blades. In Proceedings of the 50th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Nashville, TN, USA, 9–12 January 2012; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2012. [Google Scholar] [CrossRef]

- Cooperman, A.M.; Chow, R.; van Dam, C.P. Active Load Control of a Wind Turbine Airfoil Using Microtabs. J. Aircr. 2013, 50, 1150–1158. [Google Scholar] [CrossRef]

- Li, N.; Balas, M.J. Flutter Suppression of Rotating Wind Turbine Blade Based on Beddoes-Leishman model using Microtabs. In Proceedings of the AIAA Modeling and Simulation Technologies (MST) Conference, Boston, MA, USA, 19–22 August 2013; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2013. [Google Scholar] [CrossRef]

- Li, N.; Balas, M.J. Aeroelastic Control of a Wind Turbine Blade Using Microtabs Based on UA97W300-10 Airfoil. Wind Eng. 2013, 37, 501–516. [Google Scholar] [CrossRef]

- Li, N.; Balas, M.J. Direct Periodic Adaptive Control of the aerodynamic loads of a rotating wind turbine blade using microtabs. In Proceedings of the 2014 American Control Conference, Portland, OR, USA, 4–6 June 2014; pp. 4428–4433. [Google Scholar] [CrossRef]

- Li, N.; Balas, M.J.; Yang, H.; Jiang, W.; Magar, K.T. Numerical Investigation of Flapwise-Torsional Vibration Model of a Smart Section Blade with Microtab. Shock Vib. 2015, 2015, 136026. [Google Scholar] [CrossRef] [Green Version]

- Li, N.; Balas, M.J.; Nikoueeyan, P.; Yang, H.; Naughton, J.W. Stall Flutter Control of a Smart Blade Section Undergoing Asymmetric Limit Oscillations. Shock Vib. 2016, 2016, 5096128. [Google Scholar] [CrossRef] [Green Version]

- Lennie, M.; Bach, A.; Pechlivanoglou, G.; Nayeri, C.; Paschereit, C.O. The Unsteady Aerodynamic Response of an Airfoil with Microtabs and it’s Implications for Aerodynamic Damping. In Proceedings of the 34th Wind Energy Symposium, San Diego, CA, USA, 4–8 January 2016; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2016. [Google Scholar] [CrossRef]

- Holst, D.; Bach, A.B.; Nayeri, C.N.; Paschereit, C.O. Influence of a Finite Width Micro-Tab on the Spanwise Lift Distribution. In ASME Turbo Expo 2013: Turbine Technical Conference and Exposition; American Society of Mechanical Engineers Digital Collection; American Society of Mechanical Engineers: New York, NY, USA, 2013. [Google Scholar] [CrossRef]

- Bach, A.B.; Holst, D.; Nayeri, C.N.; Paschereit, C.O. Transitional Effects of Active Micro-Tabs for Wind Turbine Load Control. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers Digital Collection; American Society of Mechanical Engineers: New York, NY, USA, 2013. [Google Scholar] [CrossRef]

- Bach, A.B.; Lennie, M.; Pechlivanoglou, G.; Nayeri, C.N.; Paschereit, C.O. Finite micro-tab system for load control on a wind turbine. J. Phys. Conf. Ser. 2014, 524, 012082. [Google Scholar] [CrossRef]

- Tsai, K.-C.; Pan, C.-T.; Cooperman, A.M.; Johnson, S.J.; Van Dam, C.P. An Innovative Design of a Microtab Deployment Mechanism for Active Aerodynamic Load Control. Energies 2015, 8, 5885–5897. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Yang, Z. Numerical study on transonic shock oscillation suppression and buffet load alleviation for a supercritical airfoil using a microtab. Eng. Appl. Comput. Fluid Mech. 2016, 10, 529–544. [Google Scholar] [CrossRef] [Green Version]

- Heathcote, D.J.; Gursul, I.; Cleaver, D.J. Aerodynamic Load Alleviation Using Minitabs. J. Aircr. 2018, 55, 2068–2077. [Google Scholar] [CrossRef]

- Fernandez-Gamiz, U.; Zulueta, E.; Boyano, A.; Ramos-Hernanz, J.A.; Lopez-Guede, J.M. Microtab Design and Implementation on a 5 MW Wind Turbine. Appl. Sci. 2017, 7, 536. [Google Scholar] [CrossRef]

- Ebrahimi, A.; Movahhedi, M. Wind turbine power improvement utilizing passive flow control with microtab. Energy 2018, 150, 575–582. [Google Scholar] [CrossRef]

- Zhang, Y.; Ramdoss, V.; Saleem, Z.; Wang, X.; Schepers, G.; Ferreira, C. Effects of root Gurney flaps on the aerodynamic performance of a horizontal axis wind turbine. Energy 2019, 187, 115955. [Google Scholar] [CrossRef]

- Kroo, I. Aerodynamic concepts for future aircraft. In Proceedings of the 30th Fluid Dynamics Conference, Norfolk, VA, USA, 28 June–1 July 1999; American Institute of Aeronautics and Astronautics: Reston, VA, USA. [Google Scholar] [CrossRef]

- Lee, H.-T.; Bieniawski, S.R.; Kroo, I.M. Miniature Trailing Edge Effector for Aerodynamic Control. US7410133B2, 12 August 2008. [Google Scholar]

- Lee, H.-T.; Kroo, I.; Bieniawski, S. Flutter Suppression for High Aspect Ratio Flexible Wings Using Microflaps. In Proceedings of the 43rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Denver, CO, USA, 22–25 April 2002; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2002. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.-T.; Kroo, I. Computational Investigation of Wings with Miniature Trailing Edge Control Surfaces. In Proceedings of the 2nd AIAA Flow Control Conference, Portland, OR, USA, 28 June–1 July 2004; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2004. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.-T.; Kroo, I. Computational Investigation of Airfoils with Miniature Trailing Edge Control Surfaces. In Proceedings of the 42nd AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 5–8 January 2004; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2004. [Google Scholar]

- Lee, H.-T.; Kroo, I. Two Dimensional Unsteady Aerodynamics of Miniature Trailing Edge Effectors. In Proceedings of the 44th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 9–12 January 2006; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2006. [Google Scholar]

- Matalanis, C.G.; Eaton, J.K. Wake Vortex Control Using Static Segmented Gurney Flaps. AIAA J. 2007, 45, 321–328. [Google Scholar] [CrossRef]

- Vieira, B.O.; Kinzel, M.; Maughmer, M. Unsteady Aerodynamics of Miniature Trailing-Edge Effectors Based on Indicial Methods. In Proceedings of the 49th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 4–7 January 2011; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2011. [Google Scholar] [CrossRef]

- Richter, K.; Rosemann, H. Steady Aerodynamics of Miniature Trailing-Edge Devices in Transonic Flows. J. Aircr. 2012, 49, 898–910. [Google Scholar] [CrossRef]

- Gunasekaran, S.; Curry, D. On the Wake Properties of Segmented Trailing Edge Extensions. Aerospace 2018, 5, 89. [Google Scholar] [CrossRef] [Green Version]

- Lin, J.C. Review of research on low-profile vortex generators to control boundary-layer separation. Prog. Aerosp. Sci. 2002, 38, 389–420. [Google Scholar] [CrossRef]

- Velte, C.M.; Hansen, M.O.L.; Okulov, V.L. Helical structure of longitudinal vortices embedded in turbulent wall-bounded flow. J. Fluid Mech. 2009, 619, 167–177. [Google Scholar] [CrossRef] [Green Version]

- Godard, G.; Stanislas, M. Control of a decelerating boundary layer. Part 1: Optimization of passive vortex generators. Aerosp. Sci. Technol. 2006, 10, 181–191. [Google Scholar] [CrossRef]

- Taylor, H.D. The Elimination of Diffuser Separation by Vortex Generators; United Aircraft Corporation: Hartford, CT, USA, 1947. [Google Scholar]

- Taylor, H.D. Summary Report on Vortex Generators; United Aircraft Corporation: Hartford, CT, USA, 1950. [Google Scholar]

- Miller, G.E. Comparative Performance Tests on the Mod-2, 2.5-mW Wind Turbine with and without Vortex Generators; DASCON Engineering: Cleveland, OH, USA, 1995. [Google Scholar]

- Sullivan, T.L. Effect of Vortex Generators on the Power Conversion Performance and Structural Dynamic Loads of the Mod-2 Wind Turbine; National Aeronautics and Space Administration: Cleveland, OH, USA, 1984.

- Corrigan, R.D.S. Vortex Generators as a Means for Increasing Rotor Performance; National Aeronautics and Space Administration: Cleveland, OH, USA, 1985.

- Oye, S. The Effect of Vortex Generators on the Performance of the Elkraft 1000 kW Turbine. 9th Symposium on Aerodynamics of Wind Turbines, Stockholm, Sweden, 11–12 December 1995. [Google Scholar]

- Lin, J.; Howard, F.; Selby, G. Turbulent flow separation control through passive techniques. In Proceedings of the 2nd Shear Flow Conference, Tempe, AZ, USA, 13–16 March 1989; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 1989. [Google Scholar] [CrossRef]

- Lin, J.; Howard, F.; Bushnell, D.; Selby, G. Investigation of several passive and active methods for turbulent flow separation control. In Proceedings of the 21st Fluid Dynamics, Plasma Dynamics and Lasers Conference, Seattle, WA, USA, 18–20 June 1990; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 1990. [Google Scholar] [CrossRef]

- Lin, J.; Howard, F.; Selby, G. Exploratory study of vortex-generating devices for turbulent flow separation control. In Proceedings of the 29th Aerospace Sciences Meeting, Reno, NV, USA, 7–10 January 1991; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 1991. [Google Scholar] [CrossRef]

- Lin, J. Control of turbulent boundary-layer separation using micro-vortex generators. In Proceedings of the 30th Fluid Dynamics Conference, Norfolk, VA, USA, 28 June–1 July 1999; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 1999. [Google Scholar] [CrossRef]

- Bragg, M.B.; Gregorek, G.M. Experimental study of airfoil performance with vortex generators. J. Aircr. 1987, 24, 305–309. [Google Scholar] [CrossRef]

- Mai, H.; Dietz, G.; Geißler, W.; Richter, K.; Bosbach, J.; Richard, H.; de Groot, K. Dynamic Stall Control by Leading Edge Vortex Generators. J. Am. Helicopter Soc. 2008, 53, 26–36. [Google Scholar] [CrossRef]

- Bender, E.E.; Anderson, B.H.; Yagle, P.J. Vortex Generator Modeling for Navier-Stokes Codes; American Society of Mechanical Engineers: San Francisco, CA, USA, 1999. [Google Scholar]

- Jirasek, A. Vortex-Generator Model and Its Application to Flow Control. J. Aircr. 2005, 42, 1486–1491. [Google Scholar] [CrossRef]

- Velte, C.M.; Okulov, V.L.; Hansen, M.O.L. Alteration of helical vortex core without change in flow topology. Phys. Fluids 2011, 23, 051707. [Google Scholar] [CrossRef] [Green Version]

- Fernández, U.; Rethore, P.E.; Sorensen, N.N.; Velte, C.M.; Zahle, F.; Egusquiza, E. Comparison of four different models of vortex generators. In Proceedings of the EWEA 2012—European Wind Energy Conference & Exhibition, Copenhagen, Denmark, 16–19 April 2012. [Google Scholar]

- Johansen, J.; Sørensen, N.; Reck, M.; Hansen, M.O.L.; Stuermer, A.; Ramboer, J.; Hirsch, C.; Ekaterinaris, J.; Voutsinas, S.; Perivolaris, Y. Rotor Blade Computations with 3D Vortex Generators; Risø National Laboratories: Roskilde, Denmark, 2005.

- Mueller-Vahl, H.; Pechlivanoglou, G.; Nayeri, C.N.; Paschereit, C.O. Vortex Generators for Wind Turbine Blades: A Combined Wind Tunnel and Wind Turbine Parametric Study. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers Digital Collection; American Society of Mechanical Engineers: New York, NY, USA, 2013; pp. 899–914. [Google Scholar] [CrossRef]

- Gao, L.; Zhang, H.; Liu, Y.; Han, S. Effects of vortex generators on a blunt trailing-edge airfoil for wind turbines. Renew. Energy 2015, 76, 303–311. [Google Scholar] [CrossRef]

- Zhang, L.; Li, X.; Yang, K.; Xue, D. Effects of vortex generators on aerodynamic performance of thick wind turbine airfoils. J. Wind Eng. Ind. Aerodyn. 2016, 156, 84–92. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, B.; Qiu, Q.; Xu, X. Flow control on the NREL S809 wind turbine airfoil using vortex generators. Energy 2017, 118, 1210–1221. [Google Scholar] [CrossRef]

- Skrzypiński, W.; Gaunaa, M.; Bak, C. The Effect of Mounting Vortex Generators on the DTU 10MW Reference Wind Turbine Blade. J. Phys. Conf. Ser. 2014, 524, 012034. [Google Scholar] [CrossRef]

- Troldborg, N.; Sørensen, N.N.; Zahle, F.; Réthoré, P.-E. Simulation of a MW rotor equipped with vortex generators using CFD and an actuator shape model. In Proceedings of the 53rd AIAA Aerospace Sciences Meeting, Kissimmee, FL, USA, 5–9 January 2015; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2015. [Google Scholar] [CrossRef] [Green Version]

- Troldborg, N.; Zahle, F.; Sørensen, N.N. Simulations of wind turbine rotor with vortex generators. J. Phys. Conf. Ser. 2016, 753, 022057. [Google Scholar] [CrossRef] [Green Version]

- Tian, Q.Q.; Corson, D.; Baker, J.P. Application of Vortex Generators to Wind Turbine Blades. In Proceedings of the 34th Wind Energy Symposium, San Diego, CA, USA, 4–8 January 2016; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2016. [Google Scholar] [CrossRef]

- Hwangbo, H.; Ding, Y.; Eisele, O.; Weinzierl, G.; Lang, U.; Pechlivanoglou, G. Quantifying the effect of vortex generator installation on wind power production: An academia-industry case study. Renew. Energy 2017, 113, 1589–1597. [Google Scholar] [CrossRef]

- Velte, C.M.; Hansen, M.O.L.; Cavar, D. Flow analysis of vortex generators on wing sections by stereoscopic particle image velocimetry measurements. Environ. Res. Lett. 2008, 3, 015006. [Google Scholar] [CrossRef]

- Velte, C.M.; Hansen, M.O.L. Investigation of flow behind vortex generators by stereo particle image velocimetry on a thick airfoil near stall. Wind Energy 2013, 16, 775–785. [Google Scholar] [CrossRef]

- Rey, G.Z.; Garro, B.; Gamiz, U.F.; Guerrero, E.Z. A Computational Study of the Variation of the Incidence Angle in a Vortex Generator. DYNA New Technol. 2015, 2. [Google Scholar] [CrossRef]

- Fernández-Gámiz, U.; Marika Velte, C.; Réthoré, P.-E.; Sørensen, N.N.; Egusquiza, E. Testing of self-similarity and helical symmetry in vortex generator flow simulations. Wind Energy 2016, 19, 1043–1052. [Google Scholar] [CrossRef]

- Martínez-Filgueira, P.; Fernandez-Gamiz, U.; Zulueta, E.; Errasti, I.; Fernandez-Gauna, B. Parametric study of low-profile vortex generators. Int. J. Hydrogen Energy 2017, 42, 17700–17712. [Google Scholar] [CrossRef]

- Fernandez-Gamiz, U.; Errasti, I.; Gutierrez-Amo, R.; Boyano, A.; Barambones, O. Computational Modelling of Rectangular Sub-Boundary-Layer Vortex Generators. Appl. Sci. 2018, 8, 138. [Google Scholar] [CrossRef] [Green Version]

- Manolesos, M.; Voutsinas, S.G. Experimental investigation of the flow past passive vortex generators on an airfoil experiencing three-dimensional separation. J. Wind Eng. Ind. Aerodyn. 2015, 142, 130–148. [Google Scholar] [CrossRef] [Green Version]

- Zhu, C.; Chen, J.; Wu, J.; Wang, T. Dynamic stall control of the wind turbine airfoil via single-row and double-row passive vortex generators. Energy 2019, 189, 116272. [Google Scholar] [CrossRef]

- Zhu, C.; Wang, T.; Wu, J. Numerical Investigation of Passive Vortex Generators on a Wind Turbine Airfoil Undergoing Pitch Oscillations. Energies 2019, 12, 654. [Google Scholar] [CrossRef] [Green Version]

- Suarez, J.M.; Flaszyński, P.; Doerffer, P. Streamwise vortex generator for separation reduction on wind turbine profile. J. Phys. Conf. Ser. 2016, 760, 012018. [Google Scholar] [CrossRef] [Green Version]

- Suarez, J.M.; Flaszyński, P.; Doerffer, P. Application of rod vortex generators for flow separation reduction on wind turbine rotor. Wind Energy 2018, 21, 1202–1215. [Google Scholar] [CrossRef]

- Hansen, M.O.L.; Velte, C.M.; Øye, S.; Hansen, R.; Sørensen, N.N.; Madsen, J.; Mikkelsen, R. Aerodynamically shaped vortex generators. Wind Energy 2016, 19, 563–567. [Google Scholar] [CrossRef]

- Barrett, R.; Farokhi, S. Subsonic aerodynamics and performance of a smart vortex generator system. J. Aircr. 1996, 33, 393–398. [Google Scholar] [CrossRef]

- Lin, J.C.; Robinson, S.K.; McGhee, R.J.; Valarezo, W.O. Separation control on high-lift airfoils via micro-vortex generators. J. Aircr. 1994, 31, 1317–1323. [Google Scholar] [CrossRef]

- Kerho, M.; Hutcherson, S.; Blackwelder, R.F.; Liebeck, R.H. Vortex generators used to control laminar separation bubbles. J. Aircr. 1993, 30, 315–319. [Google Scholar] [CrossRef]

- Lisy, F.; Schmidt, R. Large Throw, Imbedded Microactuators for Drag Reduction; Wright-Patterson, A.F.B., Ed.; U.S. Air Force Research Laboratory: Dayton, OH, USA, 1995. [Google Scholar]

- Osborn, R.F.; Kota, S.; Hetrick, J.A.; Geister, D.E.; Tilmann, C.P.; Joo, J. Active Flow Control Using High-Frequency Compliant Structures. J. Aircr. 2001, 41, 603–609. [Google Scholar] [CrossRef]

- Moreau, E. Airflow control by non-thermal plasma actuators. J. Phys. Appl. Phys. 2007, 40, 605–636. [Google Scholar] [CrossRef]

- Nelson, R.; Corke, T.; Othman, H.; Patel, M.; Vasudevan, S.; Ng, T. A Smart Wind Turbine Blade Using Distributed Plasma Actuators for Improved Performance. In Proceedings of the 46th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 7–10 January 2008; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2008. [Google Scholar] [CrossRef] [Green Version]

- Enloe, C.L.; McLaughlin, T.E.; VanDyken, R.D.; Kachner, K.D.; Jumper, E.J.; Corke, T.C. Mechanisms and Responses of a Single Dielectric Barrier Plasma Actuator: Plasma Morphology. AIAA J. 2004, 42, 589–594. [Google Scholar] [CrossRef]

- Corke, T.C.; Post, M.L.; Orlov, D.M. SDBD plasma enhanced aerodynamics: Concepts, optimization and applications. Prog. Aerosp. Sci. 2007, 43, 193–217. [Google Scholar] [CrossRef]

- Simms, D.; Schreck, S.; Hand, M.; Fingersh, L.J. NREL Unsteady Aerodynamics Experiment in the NASA-Ames Wind Tunnel: A Comparison of Predictions to Measurements; National Renewable Energy Laboratory: Golden, CO, USA, 2001.

- Fingersh, L.; Simms, D.; Hand, M.; Jager, D.; Cotrell, J.; Robinson, M.; Schreck, S.; Larwood, S.M. Wind tunnel testing of NREL’s unsteady aerodynamics experiment. In Proceedings of the 20th 2001 ASME Wind Energy Symposium, Reno, NV, USA, 11–14 January 2001; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2001. [Google Scholar] [CrossRef]

- Moreau, E.; Artana, G.; Touchard, G. Surface corona discharge along an insulating flat plate in air applied to electrohydrodynamically airflow control: Electrical properties. In Electrostatics 2003; Conference Series-Institute of Physics; Institute of Physics: Philadelphia, PA, USA, 2008. [Google Scholar] [CrossRef]

- Orlov, D.M.; Font, G.I.; Edelstein, D. Characterization of Discharge Modes of Plasma Actuators. AIAA J. 2008, 46, 3142–3148. [Google Scholar] [CrossRef]

- Velkoff, H.R.; Ketcham, J. Effect of an electrostatic field on boundary-layer transition. AIAA J. 1968, 6, 1381–1383. [Google Scholar] [CrossRef]

- Jukes, T.; Choi, K.-S.; Johnson, G.; Scott, S. Turbulent Boundary-Layer Control for Drag Reduction Using Surface Plasma. In Proceedings of the 2nd AIAA Flow Control Conference, Portland, OR, USA, 28 June – 1 July 2004; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2004. [Google Scholar] [CrossRef]

- El-Khabiry, S.; Colver, G.M. Drag reduction by dc corona discharge along an electrically conductive flat plate for small Reynolds number flow. Phys. Fluids 1997, 9, 587–599. [Google Scholar] [CrossRef]

- Mendes, R.V.; Dente, J.A. Boundary-layer control by electric fields: A feasibility study. arXiv 1997, arXiv:physics/9705020. [Google Scholar]

- Corke, T.; Jumper, E.; Post, M.; Orlov, D.; McLaughlin, T. Application of weakly-ionized plasmas as wing flow-control devices. In Proceedings of the 40th AIAA Aerospace Sciences Meeting & Exhibit, Reno, NV, USA, 14–17 January 2002; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2002. [Google Scholar] [CrossRef]

- Post, M.L.; Corke, T.C. Separation Control on High Angle of Attack Airfoil Using Plasma Actuators. AIAA J. 2004, 42, 2177–2184. [Google Scholar] [CrossRef]

- Post, M.; Corke, T. Separation Control using Plasma Actuators—Stationary & Oscillating Airfoils. In Proceedings of the 42nd AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 5–8 January 2004; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2004. [Google Scholar] [CrossRef]

- Post, M.L.; Corke, T.C. Separation Control Using Plasma Actuators: Dynamic Stall Vortex Control on Oscillating Airfoil. AIAA J. 2006, 44, 3125–3135. [Google Scholar] [CrossRef]

- Corke, T.; Post, M. Overview of Plasma Flow Control: Concepts, Optimization, and Applications. In Proceedings of the 43rd AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 10–13 January 2005; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2005. [Google Scholar] [CrossRef]

- Corke, T.; Mertz, B.; Patel, M. Plasma Flow Control Optimized Airfoil. In Proceedings of the 44th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 9–12 January 2006; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2006. [Google Scholar] [CrossRef]

- He, C.; Corke, T.C.; Patel, M.P. Plasma Flaps and Slats: An Application of Weakly Ionized Plasma Actuators. J. Aircr. 2009, 46, 864–873. [Google Scholar] [CrossRef]

- Jukes, T.N.; Segawa, T.; Furutani, H. Flow Control on a NACA 4418 Using Dielectric-Barrier-Discharge Vortex Generators. AIAA J. 2013, 51, 452–464. [Google Scholar] [CrossRef]

- Aono, H.; Yamakawa, S.; Iwamura, K.; Honami, S.; Ishikawa, H. Straight and curved type micro dielectric barrier discharge plasma actuators for active flow control. Exp. Therm. Fluid Sci. 2017, 88, 16–23. [Google Scholar] [CrossRef]

- Kotsonis, M.; Pul, R.; Veldhuis, L. Influence of circulation on a rounded-trailing-edge airfoil using plasma actuators. Exp. Fluids 2014, 55, 1772. [Google Scholar] [CrossRef]

- Fukumoto, H.; Aono, H.; Watanabe, T.; Tanaka, M.; Matsuda, H.; Osako, T.; Nonomura, T.; Oyama, A.; Fujii, K. Control of dynamic flowfield around a pitching NACA633−618 airfoil by a DBD plasma actuator. Int. J. Heat Fluid. Flow 2016, 62, 10–23. [Google Scholar] [CrossRef]

- Guoqiang, L.; Weiguo, Z.; Yubiao, J.; Pengyu, Y. Experimental investigation of dynamic stall flow control for wind turbine airfoils using a plasma actuator. Energy 2019, 185, 90–101. [Google Scholar] [CrossRef]

- Kelley, C.L.; Bowles, P.O.; Cooney, J.; He, C.; Corke, T.C.; Osborne, B.A.; Silkey, J.S.; Zehnle, J. Leading-Edge Separation Control Using Alternating-Current and Nanosecond-Pulse Plasma Actuators. AIAA J. 2014, 52, 1871–1884. [Google Scholar] [CrossRef]

- Sekimoto, S.; Nonomura, T.; Fujii, K. Burst-Mode Frequency Effects of Dielectric Barrier Discharge Plasma Actuator for Separation Control. AIAA J. 2017, 55, 1385–1392. [Google Scholar] [CrossRef]

- Batlle, E.C.; Pereira, R.; Kotsonis, M. Airfoil Stall Hysteresis Control with DBD Plasma actuation. In Proceedings of the 55th AIAA Aerospace Sciences Meeting, Grapevine, TX, USA, 9–13 January 2017; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2017. [Google Scholar] [CrossRef]

- Ebrahimi, A.; Hajipour, M. Flow separation control over an airfoil using dual excitation of DBD plasma actuators. Aerosp. Sci. Technol. 2018, 79, 658–668. [Google Scholar] [CrossRef]

- Mitsuo, K.; Watanabe, S.; Atobe, T.; Kato, H.; Tanaka, M.; Uchida, T. Lift Enhancement of a Pitching Airfoil in Dynamic Stall by DBD Plasma Actuators. In Proceedings of the 51st AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Grapevine, TX, USA, 7–10 January 2013; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2013. [Google Scholar] [CrossRef]

- Moreau, E.; Benard, N.; Jolibois, M.; Touchard, G. Airflow Control by Plasma Actuators: Last Significant Results at the University of Poitiers. In Proceedings of the European Conference for Aerospace Sciences (EUCASS), Brussels, Belgium, 1–6 July 2007. [Google Scholar]

- Jolibois, J.; Forte, M.; Moreau, E. Separation Control along a NACA 0015 Airfoil Using a Dielectric Barrier Discharge Actuator. In IUTAM Symposium on Flow Control and MEMS; Morrison, J.F., Birch, D.M., Lavoie, P., Eds.; Springer: Dordrecht, The Netherlands, 2008; pp. 175–181. [Google Scholar] [CrossRef]

- Asada, K.; Nonomura, T.; Aono, H.; Sato, M.; Okada, K.; Fujii, K. LES of transient flows controlled by DBD plasma actuator over a stalled airfoil. Int. J. Comput. Fluid. Dyn. 2015, 29, 215–229. [Google Scholar] [CrossRef]

- Roupassov, D.V.; Nikipelov, A.A.; Nudnova, M.M.; Starikovskii, A.Y. Flow Separation Control by Plasma Actuator with Nanosecond Pulsed-Periodic Discharge. AIAA J. 2009, 47, 168–185. [Google Scholar] [CrossRef]

- Little, J.; Takashima, K.; Nishihara, M.; Adamovich, I.; Samimy, M. Separation Control with Nanosecond-Pulse-Driven Dielectric Barrier Discharge Plasma Actuators. AIAA J. 2012, 50, 350–365. [Google Scholar] [CrossRef]

- Hua, L.; Shangen, C.; Shengzhi, Z.; Junxing, B. Experimental Investigation of Airfoil Suction Side Flow Separation Control by Spanwise Nanosecond Actuation. In Proceedings of the 2011 Third International Conference on Measuring Technology and Mechatronics Automation, Shanghai, China, 6–7 January 2011; Volume 2, pp. 108–111. [Google Scholar] [CrossRef]

- Singhal, A.; Castañeda, D.; Webb, N.; Samimy, M. Control of Dynamic Stall over a NACA 0015 Airfoil Using Plasma Actuators. AIAA J. 2018, 56, 78–89. [Google Scholar] [CrossRef]

- Meijerink, J.; Hoeijmakers, H. Plasma Actuators for Active Flow Control on Wind Turbine Blades. In Proceedings of the 29th AIAA Applied Aerodynamics Conference, Honolulu, HI, USA, 27–30 June 2011; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2011. [Google Scholar] [CrossRef]

- Baleriola, S.; Leroy, A.; Loyer, S.; Devinant, P.; Aubrun, S. Circulation control on a rounded trailing-edge wind turbine airfoil using plasma actuators. J. Phys. Conf. Ser. 2016, 753, 052001. [Google Scholar] [CrossRef]

- De Giorgi, M.G.; Motta, V.; Suma, A. Influence of actuation parameters of multi-DBD plasma actuators on the static and dynamic behaviour of an airfoil in unsteady flow. Aerosp. Sci. Technol. 2020, 96, 105587. [Google Scholar] [CrossRef]

- Nati, G.; Kotsonis, M.; Ghaemi, S.; Scarano, F. Control of vortex shedding from a blunt trailing edge using plasma actuators. Exp. Therm. Fluid. Sci. 2013, 46, 199–210. [Google Scholar] [CrossRef]

- Jukes, T.N.; Choi, K.-S. On the formation of streamwise vortices by plasma vortex generators. J. Fluid. Mech. 2013, 733, 370–393. [Google Scholar] [CrossRef] [Green Version]

- Cai, J.; Tian, Y.; Meng, X.; Han, X.; Zhang, D.; Hu, H. An experimental study of icing control using DBD plasma actuator. Exp. Fluids 2017, 58, 102. [Google Scholar] [CrossRef]

- Aono, H.; Abe, Y.; Sato, M.; Yakeno, A.; Okada, K.; Nonomura, T.; Fujii, K. Flow control using a DBD plasma actuator for horizontal-axis wind turbine blades of simple experimental model. In Proceedings of the 11th World Congress on Computational Mechanics (WCCM) 2014, 5th European Conference Computational Mechanics (ECCM) 2014, 6th European Conference on Computational Fluid Dynamics (ECFD) 2014, Barcelona, Spain, 20–25 July; International Center for Numerical Methods in Engineering: Barcelona, Spain, 2014; pp. 5193–5204. [Google Scholar]

- Jukes, T.N. Smart control of a horizontal axis wind turbine using dielectric barrier discharge plasma actuators. Renew. Energy 2015, 80, 644–654. [Google Scholar] [CrossRef]

- Matsuda, H.; Tanaka, M.; Osako, T.; Yamazaki, K.; Shimura, N.; Asayama, M.; Oryu, Y. Plasma Actuation Effect on a MW class Wind Turbine. Int. J. Gas Turbine Propuls. Power Syst. 2017, 9, 6. [Google Scholar]

- Ebrahimi, A.; Movahhedi, M. Power improvement of NREL 5-MW wind turbine using multi-DBD plasma actuators. Energy Convers Manag. 2017, 146, 96–106. [Google Scholar] [CrossRef]

- Udalov, S.N.; Achitaev, A.A.; Tarbill, R.D. Increasing the regulating ability of lift force in the power-limited mode of wind turbines based on plasma technology. Wind Eng. 2017, 41, 91–100. [Google Scholar] [CrossRef]

- Greenblatt, D.; Wygnanski, I.J. The control of flow separation by periodic excitation. Prog. Aerosp. Sci. 2000, 36, 487–545. [Google Scholar] [CrossRef]

- Schlichting, H.; Gersten, K. Boundary-Layer Theory, 9th ed.; Springer: Berlin, Germany, 2016. [Google Scholar]

- Houghton, E.L.; Carpenter, P.W. Aerodynamics for Engineering Students, 5th ed.; Elsevier: Amsterdam, The Netherlands, 2003. [Google Scholar]

- Mises, R.V. Theory of Flight; Dover Publications: New York, NY, USA, 1959. [Google Scholar]

- Prandtl, L. Ueber Fluessigkeitsbewegungen bei Sehr Kleiner Reibung; Springer: Heidelberg, Germany, 1904; pp. 3–7. [Google Scholar]

- Hinton, S.H. Application of Boundary Layer Control to Rotor Blades. J. Am. Helicopter Soc. 1957, 2, 36–64. [Google Scholar] [CrossRef]

- Huang, L.; Huang, P.G.; LeBeau, R.P.; Hauser, T. Numerical Study of Blowing and Suction Control Mechanism on NACA0012 Airfoil. J. Aircr. 2004, 41, 1005–1013. [Google Scholar] [CrossRef]

- Sorenson, J. Influence of boundary layer blowing on the low-speed aerodynamic performance of a 45 degree swept-wing airplane. In Proceedings of the 10th Annual Meeting and Technical Display, Washington, DC, USA, 28–30 January 1974; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 1974. [Google Scholar] [CrossRef]

- Braslow, A.L. A History of Suction-type Laminar-flow Control with Emphasis on Flight Research; NASA History Division, Office of Policy and Plans, NASA Headquarters: Washington, DC, USA, 1999.

- Raghu, S. Fluidic oscillators for flow control. Exp. Fluids 2013, 54, 1455. [Google Scholar] [CrossRef]

- Ostermann, F.; Woszidlo, R.; Nayeri, C.N.; Paschereit, C.O. Phase-Averaging Methods for the Natural Flowfield of a Fluidic Oscillator. AIAA J. 2015, 53, 2359–2368. [Google Scholar] [CrossRef] [Green Version]

- Woszidlo, R.; Ostermann, F.; Nayeri, C.N.; Paschereit, C.O. The time-resolved natural flow field of a fluidic oscillator. Exp. Fluids 2015, 56, 125. [Google Scholar] [CrossRef] [Green Version]

- Seifert, A.; Bachar, T.; Koss, D.; Shepshelovich, M.; Wygnanski, I. Oscillatory Blowing: A Tool to Delay Boundary-Layer Separation. AIAA J. 1993, 31, 2052–2060. [Google Scholar] [CrossRef]

- Seifert, A.; Pack, L. Active control of separated flows on generic configurations at high Reynolds numbers. In Proceedings of the 30th Fluid Dynamics Conference, Norfolk, VA, USA, 28 June–1 July 1999; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 1999. [Google Scholar] [CrossRef]

- Seifert, A.; Greenblatt, D.; Wygnanski, I.J. Active separation control: An overview of Reynolds and Mach numbers effects. Aerosp. Sci. Technol. 2004, 8, 569–582. [Google Scholar] [CrossRef]

- Weaver, D.; McAlister, K.; Tso, J. Suppression of dynamic stall by steady and pulsed upper-surface blowing. In Proceedings of the 16th AIAA Applied Aerodynamics Conference, Albuquerque, MX, USA, 15–18 June 1998; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 1998. [Google Scholar] [CrossRef] [Green Version]

- Koklu, M.; Owens, L.R. Flow Separation Control Over a Ramp Using Sweeping Jet Actuators. In Proceedings of the 7th AIAA Flow Control Conference, Atlanta, GA, USA, 16–20 June 2014; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2014. [Google Scholar] [CrossRef]

- Ekaterinaris, J.A. Prediction of active flow control performance on airfoils and wings. Aerosp. Sci. Technol. 2004, 8, 401–410. [Google Scholar] [CrossRef]

- Cerretelli, C.; Wuerz, W.; Gharaibah, E. Unsteady Separation Control on Wind Turbine Blades using Fluidic Oscillators. AIAA J. 2010, 48, 1302–1311. [Google Scholar] [CrossRef]

- Blaylock, M.; Chow, R.; van Dam, C.P. Comparison of Microjets with Microtabs for Active Aerodynamic Load Control. In Proceedings of the 5th Flow Control Conference, Chicago, MA, USA, 28 June–1 July 2010; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2010. [Google Scholar] [CrossRef]

- Yousefi, K.; Saleh, S.R.; Zahedi, P. Numerical Investigation of Suction and Length of Suction Jet on Aerodynamic Characteristics of the NACA 0012 Airfoil. Int. J. Mater. Mech. Manuf. 2013, 1, 136–142. [Google Scholar] [CrossRef] [Green Version]

- Yousefi, K.; Saleh, R. Three-dimensional suction flow control and suction jet length optimization of NACA 0012 wing. Meccanica 2015, 50, 1481–1494. [Google Scholar] [CrossRef]

- Chawla, J.S.; Suryanarayanan, S.; Puranik, B.; Sheridan, J.; Falzon, B.G. Efficiency improvement study for small wind turbines through flow control. Sustain Energy Technol. Assess 2014, 7, 195–208. [Google Scholar] [CrossRef]

- Koop, L.; Ehrenfried, K.; Dillmann, A. Reduction of Flap Side-Edge Noise: Passive and Active Flow Control. In Proceedings of the 10th AIAA/CEAS Aeroacoustics Conference, Manchester, UK, 10–12 May 2004; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2004. [Google Scholar] [CrossRef]

- Wolf, A.; Lutz, T.; Würz, W.; Krämer, E.; Stalnov, O.; Seifert, A. Trailing edge noise reduction of wind turbine blades by active flow control. Wind Energy 2015, 18, 909–923. [Google Scholar] [CrossRef]

- Arnold, B.; Lutz, T.; Krämer, E. Design of a boundary-layer suction system for turbulent trailing-edge noise reduction of wind turbines. Renew. Energy 2018, 123, 249–262. [Google Scholar] [CrossRef]

- Arnold, B.; Lutz, T.; Krämer, E.; Rautmann, C. Wind-Turbine Trailing-Edge Noise Reduction by Means of Boundary-Layer Suction. AIAA J. 2018, 56, 1843–1854. [Google Scholar] [CrossRef]

- Wang, G.; Lewalle, J.; Glauser, M.; Walczak, J. Investigation of the benefits of unsteady blowing actuation on a 2D wind turbine blade. J. Turbul. 2013, 14, 165–189. [Google Scholar] [CrossRef]

- Schatzman, D.; Wilson, J.; Arad, E.; Seifert, A.; Shtendel, T. Drag-Reduction Mechanisms of Suction-and-Oscillatory-Blowing Flow Control. AIAA J. 2014, 52, 2491–2505. [Google Scholar] [CrossRef]

- Mueller-Vahl, H.; Nayeri, C.; Paschereit, C.O.; Greenblatt, D. Control of Unsteady Aerodynamic Loads Using Adaptive Blowing. In Proceedings of the 32nd AIAA Applied Aerodynamics Conference, Atlanta, GA, USA, 16–20 June 2014; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2014. [Google Scholar] [CrossRef]

- Müller-Vahl, H.F.; Nayeri, C.N.; Paschereit, C.O.; Greenblatt, D. Dynamic stall control via adaptive blowing. Renew. Energy 2016, 97, 47–64. [Google Scholar] [CrossRef]

- Niether, S.; Bobusch, B.; Marten, D.; Pechlivanoglou, G.; Navid Nayeri, C.; Oliver Paschereit, C. Development of a Fluidic Actuator for Adaptive Flow Control on a Thick Wind Turbine Airfoil. J. Turbomach. 2015, 137. [Google Scholar] [CrossRef]

- Wake, B.; Tillman, G.; Ochs, S.; Kearney, J. Control of High-Reynolds-Number Turbulent Boundary Layer Separation Using Counter-Flow Fluid Injection. In Proceedings of the 3rd AIAA Flow Control Conference, San Francisco, CA, USA, 5–8 June 2006; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2006. [Google Scholar] [CrossRef]

- Hong, L.; Fupeng, H.; Zuoyi, C. Analysing and Optimizing the Aerodynamic Performance of Wind Turbine Blades Using Injected-Air Jets at Variable Frequency and Amplitude for Flow Control. Wind Eng. 2005, 29, 331–339. [Google Scholar] [CrossRef]

- Chng, T.L.; Rachman, A.; Tsai, H.M.; Zha, G.-C. Flow Control of an Airfoil via Injection and Suction. J. Aircr. 2009, 46, 291–300. [Google Scholar] [CrossRef]

- Xu, H.; Xing, S.; Ye, Z. Numerical Simulation of the Effect of a Co-flow Jet on the Wind Turbine Airfoil Aerodynamic Characteristics. Procedia Eng. 2015, 126, 706–710. [Google Scholar] [CrossRef] [Green Version]

- Metral, A.R. On the Phenomenon of Fluid Veins and their Application, the Coanda Effect, AF Translation, F-TS-786-RE. 1939.

- Djojodihardjo, H. Progress and Development of Coandă Jet and Vortex Cell for Aerodynamic Surface Circulation Control—An Overview. SIJ Trans. Adv. Space Res. Earth Explor. 2013, 1, 14–24. [Google Scholar] [CrossRef]

- Englar, R.J.; Smith, M.J.; Kelley, S.M.; Rover, R.C. Application of circulation control to advanced subsonic transport aircraft. Part II—Transport application. J. Aircr. 1994, 31, 1169–1177. [Google Scholar] [CrossRef]

- Shrewsbury, G.; Sankar, L. Dynamic stall of circulation control airfoils. In Proceedings of the 28th Aerospace Sciences Meeting, Reno, NV, USA, 8–11 January 1990; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 1990. [Google Scholar] [CrossRef]

- Liu, Y.; Sankar, L.; Englar, R.; Ahuja, K. Numerical simulations of the steady and unsteady aerodynamic characteristics of a circulation control wing airfoil. In Proceedings of the 39th Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 8–11 January 2001; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2001. [Google Scholar] [CrossRef]

- Liu, Y.I.; Sankar, L.; Englar, R.; Ahuja, K.; Gaeta, R. Computational Evaluation of the Steady and Pulsed Jet Effects on the Performance of a Circulation Control Wing Section. In Proceedings of the 42nd AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 5–8 January 2004; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2004. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y. Numerical Simulations of the Aerodynamic Characteristics of Circulation Control Wing Sections. Ph.D. Thesis, Georgia Institute of Technology, Atlanta, GA, USA, 2003. [Google Scholar]

- Englar, R.J.; Huson, G.G. Development of advanced circulation control wing high-lift airfoils. J. Aircr. 1984, 21, 476–483. [Google Scholar] [CrossRef]

- Englar, R. Circulation control pneumatic aerodynamics: Blown force and moment augmentation and modification—Past, present and future. In Proceedings of the Fluids 2000 Conference and Exhibit, Denver, CO, USA, 19–22 June 2000; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2000. [Google Scholar] [CrossRef]

- Englar, R.; Smith, M.; Kelley, S.; Richard Rover, I. Development of circulation control technology for application to advanced subsonic transport aircraft. In Proceedings of the 31st Aerospace Sciences Meeting, Reno, NV, USA, 11–14 January 1993; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 1993. [Google Scholar] [CrossRef]

- Djojodihardjo, H.; Hamid, M.F.A.; Basri, S.; Rmli, F.I.; Majid, D.L.A. Numerical Simulation And Analysis Of Coanda Effect Circulation Control For Wind-Turbine Application Considerations. IIUM Eng. J. 2011, 12. [Google Scholar] [CrossRef]

- Djojodihardjo, H.; Abdul Hamid, M.F.; Jaafar, A.A.; Basri, S.; Romli, F.I.; Mustapha, F.; Mohd Rafie, A.S.; Abdul Majid, D.L.A. Computational Study on the Aerodynamic Performance of Wind Turbine Airfoil Fitted with Coandă Jet. J. Renew. Energy 2013, 2013, e839319. [Google Scholar] [CrossRef] [Green Version]

- Xu, H.-Y.; Qiao, C.-L.; Yang, H.-Q.; Ye, Z.-Y. Active Circulation Control on the Blunt Trailing Edge Wind Turbine Airfoil. AIAA J. 2018, 56, 554–570. [Google Scholar] [CrossRef]

- Xu, H.-Y.; Dong, Q.-L.; Qiao, C.-L.; Ye, Z.-Y. Flow Control over the Blunt Trailing Edge of Wind Turbine Airfoils Using Circulation Control. Energies 2018, 11, 619. [Google Scholar] [CrossRef] [Green Version]

- Koklu, M. Effect of a Coanda Extension on the Performance of a Sweeping-Jet Actuator. AIAA J. 2016, 54, 1131–1134. [Google Scholar] [CrossRef]

- Leroy, A.; Braud, C.; Baleriola, S.; Loyer, S.; Devinant, P.; Aubrun, S. Comparison of flow modification induced by plasma and fluidic jet actuators dedicated to circulation control around wind turbine airfoils. J. Phys. Conf. Ser. 2016, 753, 022012. [Google Scholar] [CrossRef] [Green Version]

- Selby, G.V.; Lin, J.C.; Howard, F.G. Control of low-speed turbulent separated flow using jet vortex generators. Exp. Fluids 1992, 12, 394–400. [Google Scholar] [CrossRef]

- Johnston, J.P. Pitched and Skewed Vortex Generator Jets for Control of Turbulent Boundary Layer Separation: A Review. In Proceedings of the 3rd ASME/JSME Joint Fluids Engineering Conference, San Francisco, CA, USA, 18–23 July 1999. [Google Scholar]

- Wallis, R.A. A Preliminary Note on a Modified Type of Air Jet for Boundary Layer Control; Aeronautical Research Council: London, UK, 1960. [Google Scholar]

- Johnston, J.P.; Nishi, M. Vortex generator jets—Means for flow separation control. AIAA J. 1990, 28, 989–994. [Google Scholar] [CrossRef]

- Compton, D.A.; Johnston, J.P. Streamwise vortex production by pitched and skewed jets in a turbulent boundary layer. AIAA J. 1992, 30, 640–647. [Google Scholar] [CrossRef]

- McManus, K.; Legner, H.; Davis, S. Pulsed vortex generator jets for active control of flow separation. In Proceedings of the Fluid Dynamics Conference, Colorado Springs, CO, USA, 20–23 June 1994; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 1994. [Google Scholar] [CrossRef]

- Wygnanski, I.; Seifert, A. The control of separation by periodic oscillations. In Proceedings of the 25th Plasmadynamics Lasers Conference, Colorado Springs, CO, USA, 20–23 June 1994; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 1994. [Google Scholar] [CrossRef]

- Johari, H.; McManus, K. Visualization of pulsed vortex generator jets for active control of boundary layer separation. In Proceedings of the 28th Fluid Dynamics Conference, Snowmass Village, CO, USA, 29 June–2 July 1997; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 1997. [Google Scholar] [CrossRef]

- Tensi, J.; Bourgois, S.; Bonnet, J.P.; Siauw, W.L.; Breux, J.M. Airfoil Performance enhancement using fluidic actuators. In Proceedings of the 2nd European Conference for Aero-Space Sciences, Laboratoire d’Etudes Aérodynamiques, Brussels, Belgium, 1–7 July 2007. [Google Scholar]

- Prince, S.A.; Khodagolian, V.; Singh, C.; Kokkalis, T. Aerodynamic Stall Suppression on Aerofoil Sections Using Passive Air-Jet Vortex Generators. AIAA J. 2009, 47, 2232–2242. [Google Scholar] [CrossRef] [Green Version]

- Volino, R.J.; Ibrahim, M.B. Separation control on high lift low-pressure turbine airfoils using pulsed vortex generator jets. Appl. Therm. Eng. 2012, 49, 31–40. [Google Scholar] [CrossRef] [Green Version]

- Tejero, F.; Doerffer, P.; Szulc, O. Shock Wave Induced Flow Separation Control by Air-Jet and Rod Vortex Generators. Task Q 2015, 19, 167–180. [Google Scholar]

- Prince, S.A.; Badalamenti, C.; Regas, C. The application of passive air jet vortex-generators to stall suppression on wind turbine blades. Wind Energy 2017, 20, 109–123. [Google Scholar] [CrossRef]

- Wang, J.J.; Li, Y.C.; Choi, K.-S. Gurney flap—Lift enhancement, mechanisms and applications. Prog. Aerosp. Sci. 2008, 44, 22–47. [Google Scholar] [CrossRef]

- Baker, J.P.; Mayda, E.A.; van Dam, C.P. Experimental Analysis of Thick Blunt Trailing-Edge Wind Turbine Airfoils. J. Sol. Energy Eng. 2006, 128, 422–431. [Google Scholar] [CrossRef]

- Eisele, O.; Pechlivanoglou, G.; Nayeri, C.N.; Paschereit, C.O. Flow Control Using Plasma Actuators at the Root Region of Wind Turbine Blades. In Proceedings of the 10th German Wind Energy Conference DEWEK 2010, Bremen, Germany, 17–18 November 2010. [Google Scholar]

- Fu, X.; Li, Y.; Li, B.; Kwok, D.Y. Drag force reduction on an airfoil via glow discharge plasma-based control. Eur. Phys. J. Spec. Top. 2009, 171, 195–204. [Google Scholar] [CrossRef]

- Pechlivanoglou, G. Passive and Active Flow Control Solutions for Wind Turbine Blades; Technical University of Berlin: Berlin, Germany, 2013. [Google Scholar] [CrossRef]

- Siemens Gamesa. Energy Thrust—Energy Output Upgrade. 2014. Available online: https://www.siemensgamesa.com/ (accessed on 15 July 2020).

- Vestas. PowerPlus—Pure Performance. 2015. Available online: https://www.vestas.com/powerplus#! (accessed on 15 July 2020).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akhter, M.Z.; Omar, F.K. Review of Flow-Control Devices for Wind-Turbine Performance Enhancement. Energies 2021, 14, 1268. https://doi.org/10.3390/en14051268

Akhter MZ, Omar FK. Review of Flow-Control Devices for Wind-Turbine Performance Enhancement. Energies. 2021; 14(5):1268. https://doi.org/10.3390/en14051268

Chicago/Turabian StyleAkhter, Md Zishan, and Farag Khalifa Omar. 2021. "Review of Flow-Control Devices for Wind-Turbine Performance Enhancement" Energies 14, no. 5: 1268. https://doi.org/10.3390/en14051268