Model Predictive Control of Internal Combustion Engines: A Review and Future Directions

Abstract

:1. Introduction

1.1. Progress in Engine Control

1.2. Rationale for Using Model Predictive Control (MPC) in ICE

1.3. MPC Background

1.3.1. A Short History of MPC

1.3.2. Terminology

1.3.3. Methods

1.4. Scope of the Paper

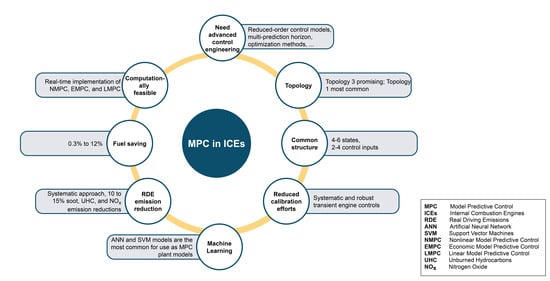

2. MPC Applications in ICEs

3. MPC Designs for ICEs

3.1. Topology/Structure

- Level 1 (L1A): Optimizer/supervisory controller.

- Level 2 (L2A): Feedback optimal tracking controllers.

- Level 3 (L3A): Actuator controllers.

- Level 1 (L1B): Combined supervisory and feedback controller.

- Level 2 (L2B): Actuator controllers.

3.1.1. Methods of MPC in ICEs

3.1.2. Dynamic Models for MPC

4. Real-Time Implementation of MPC

4.1. MPC Optimization Methods

4.2. Non Linear Programming (NLP)

4.3. MPC Implementation

5. AI and MPC Integration

6. Recommendation and Future Directions

6.1. MPC in ICEs

6.2. Optimization of MPC in ICEs

6.3. Integration of AI and MPC

7. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Verbruggen, F.J.R.; Silvas, E.; Hofman, T. Electric powertrain topology analysis and design for heavy-duty trucks. Energies 2020, 13, 2434. [Google Scholar] [CrossRef]

- Ma, X.; Chigan, T.; Shahbakhti, M. Connected vehicle based distributed meta-learning for online adaptive engine/powertrain fuel consumption modeling. IEEE Trans. Veh. Technol. 2020, 69, 9553–9565. [Google Scholar] [CrossRef]

- Solouk, A.; Shahbakhti, M. Energy optimization and fuel economy investigation of a series hybrid electric vehicle integrated with diesel/RCCI engines. Energies 2016, 9, 1020. [Google Scholar] [CrossRef] [Green Version]

- Aliramezani, M.; Norouzi, A.; Koch, C.R.; Hayes, R.E. A control oriented diesel engine NOx emission model for on board diagnostics and engine control with sensor feedback. In Proceedings of the Combustion Institute-Canadian Section (CICS 2019), Kelowna, BC, Canada, 13 May 2019. [Google Scholar]

- Norouzi, A.; Ebrahimi, K.; Koch, C.R. Integral discrete-time sliding mode control of homogeneous charge compression ignition (HCCI) engine load and combustion timing. IFAC-PapersOnLine 2019, 52, 153–158. [Google Scholar] [CrossRef]

- Planakis, N.; Karystinos, V.; Papalambrou, G.; Kyrtatos, N. A predictive energy management system for a hybrid diesel-electric marine propulsion plant. In Proceedings of the 2020 European Control Conference (ECC), St. Petersburg, Russia, 12–15 May 2020; pp. 693–698. [Google Scholar] [CrossRef]

- Gordon, D.; Wouters, C.; Wick, M.; Xia, F.; Lehrheuer, B.; Andert, J.; Koch, C.R.; Pischinger, S. Development and experimental validation of a real-time capable field programmable gate array–based gas exchange model for negative valve overlap. Int. J. Engine Res. 2020, 21, 421–436. [Google Scholar] [CrossRef]

- Nishio, Y.; Shen, T. Model predictive control with traffic information-based driver’s torque demand prediction for diesel engines. Int. J. Engine Res. 2021, 22, 674–684. [Google Scholar] [CrossRef]

- Vu, T.V.; Chen, C.K.; Hung, C.W. A model predictive control approach for fuel economy improvement of a series hydraulic hybrid vehicle. Energies 2014, 7, 7017–7040. [Google Scholar] [CrossRef] [Green Version]

- Cepowski, T.; Chorab, P. The use of artificial neural networks to determine the engine power and fuel consumption of modern bulk carriers, tankers and container ships. Energies 2021, 14, 4827. [Google Scholar] [CrossRef]

- Dewangan, A.; Mallick, A.; Yadav, A.K.; Kumar, R. Combustion-generated pollutions and strategy for its control in CI engines: A review. Mater. Today Proc. 2020, 21, 1728–1733. [Google Scholar] [CrossRef]

- Ashok, B.; Denis Ashok, S.; Ramesh Kumar, C. A review on control system architecture of a SI engine management system. Annu. Rev. Control 2016, 41, 94–118. [Google Scholar] [CrossRef]

- Cervantes-Bobadilla, M.; Escobar-Jiménez, R.F.; Gómez-Aguilar, J.F.; García-Morales, J.; Olivares-Peregrino, V.H. Experimental study on the performance of controllers for the hydrogen gas production demanded by an internal combustion engine. Energies 2018, 11, 2157. [Google Scholar] [CrossRef] [Green Version]

- Ekberg, K.; Eriksson, L.; Sundström, C. Electrification of a heavy-duty CI truck—Comparison of electric turbocharger and crank shaft motor. Energies 2021, 14, 1402. [Google Scholar] [CrossRef]

- Guzzella, L.; Onder, C. Introduction to Modeling and Control of Internal Combustion Engine Systems; Springer Science & Business Media: Berlin, Germany, 2009. [Google Scholar] [CrossRef]

- Isermann, R. Engine Modeling and Control; Springer: Berlin/Heidelberg, Germany, 2014; Volume 1017. [Google Scholar] [CrossRef]

- López, J.D.; Espinosa, J.J.; Agudelo, J.R. LQR control for speed and torque of internal combustion engines. IFAC Proc. Vol. 2011, 44, 2230–2235. [Google Scholar] [CrossRef] [Green Version]

- Pfeiffer, R.; Haraldsson, G.; Olsson, J.O.; TunestAl, P.; Johansson, R.; Johansson, B. System identification and LQG control of variable-compression HCCI engine dynamics. In Proceedings of the 2004 IEEE International Conference on Control Applications, Taipei, Taiwan, 2–4 September 2004; Volume 2, pp. 1442–1447. [Google Scholar] [CrossRef] [Green Version]

- Amini, M.R.; Shahbakhti, M.; Pan, S.; Hedrick, J.K. Discrete adaptive second order sliding mode controller design with application to automotive control systems with model uncertainties. In Proceedings of the 2017 American Control Conference (ACC 2017), Seattle, WA, USA, 24–26 May 2017; pp. 4766–4771. [Google Scholar] [CrossRef] [Green Version]

- Souder, J.S.; Hedrick, J.K. Adaptive sliding mode control of air–fuel ratio in internal combustion engines. Int. J. Robust Nonlinear Control IFAC-Aff. J. 2004, 14, 525–541. [Google Scholar] [CrossRef]

- Irdmousa, B.K.; Rizvi, S.Z.; Velni, J.M.; Naber, J.; Shahbakhti, M. Data-driven modeling and predictive control of combustion phasing for RCCI Engines. In Proceedings of the American Control Conference (ACC 2019), Philadelphia, PA, USA, 10–12 July 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Basina, L.A.; Irdmousa, B.K.; Velni, J.M.; Borhan, H.; Naber, J.D.; Shahbakhti, M. Data-driven modeling and predictive control of maximum pressure rise rate in RCCI engines. In Proceedings of the IEEE Conference on Control Technology and Applications (CCTA 2020), Montreal, QC, Canada, 24–26 August 2020; pp. 94–99. [Google Scholar] [CrossRef]

- Powell, J. A review of IC engine models for control system design. IFAC Proc. Vol. 1987, 20, 235–240. [Google Scholar] [CrossRef]

- Lennox, B.; Montaguet, G.A.; Frith, A.M.; Beaumont, A.J. Non-linear model-based predictive control of gasoline engine air-fuel ratio. Trans. Inst. Meas. Control 1998, 20, 103–112. [Google Scholar] [CrossRef]

- Bromnick, P. Development of a Model Predictive Controller for Engine Idle Speed Using CPower; SAE Technical Paper 1999-01-1171; SAE International: Warrendale, PA, USA, 1999. [Google Scholar] [CrossRef]

- Liao-McPherson, D.; Huang, M.; Kim, S.; Shimada, M.; Butts, K.; Kolmanovsky, I. Model predictive emissions control of a diesel engine airpath: Design and experimental evaluation. Int. J. Robust Nonlinear Control 2020, 30, 7446–7477. [Google Scholar] [CrossRef]

- Raut, A.; Irdmousa, B.; Shahbakhti, M. Dynamic modeling and model predictive control of an RCCI engine. Control Eng. Pract. 2018, 81, 129–144. [Google Scholar] [CrossRef]

- Karlsson, M.; Ekholm, K.; Strandh, P.; Johansson, R.; Tunestål, P. Multiple-input multiple-output model predictive control of a diesel engine. IFAC Proc. Vol. 2010, 43, 131–136. [Google Scholar] [CrossRef] [Green Version]

- Dahl, J.; Wassén, H.; Santin, O.; Herceg, M.; Lansky, L.; Pekar, J.; Pachner, D. Model Predictive Control of a Diesel Engine with Turbo Compound and Exhaust After-Treatment Constraints. IFAC-PapersOnLine 2018, 51, 349–354. [Google Scholar] [CrossRef]

- Zhao, D.; Liu, C.; Stobart, R.; Deng, J.; Winward, E.; Dong, G. An explicit model predictive control framework for turbocharged diesel engines. IEEE Trans. Ind. Electron. 2014, 61, 3540–3552. [Google Scholar] [CrossRef] [Green Version]

- Yashiro, Y.; Jiwariyavej, V.; Yamashita, Y.; Hoshi, T.; Terakado, K.; Ibaraki, S. High-speed Model Predictive Control for Next-Generation Turbocharging System. Mitsubishi Heavy Ind. Tech. Rev. 2017, 54, 77–81. [Google Scholar]

- Huang, M.; Liao-McPherson, D.; Kim, S.; Butts, K.; Kolmanovsky, I. Toward real-time automotive model predictive control: A perspective from a diesel air path control development. In Proceedings of the American Control Conference (ACC 2018), Milwaukee, WI, USA, 27–29 June 2018; pp. 2425–2430. [Google Scholar] [CrossRef]

- Bemporad, A.; Bernardini, D.; Long, R.; Verdejo, J. Model Predictive Control of Turbocharged Gasoline Engines for Mass Production; WCX World Congress Experience; SAE International: Warrendale, PA, USA, 2018. [Google Scholar] [CrossRef]

- Saerens, B.; Diehl, M.; Swevers, J.; Van den Bulck, E. Model predictive control of automotive powertrains-first experimental results. In Proceedings of the 2008 47th IEEE Conference on Decision and Control, Cancun, Mexico, 9–11 December 2008; pp. 5692–5697. [Google Scholar] [CrossRef] [Green Version]

- Broomhead, T.; Manzie, C.; Hield, P.; Shekhar, R.; Brear, M. Economic model predictive control and applications for diesel generators. IEEE Trans. Control Syst. Technol. 2016, 25, 388–400. [Google Scholar] [CrossRef]

- Di Cairano, S.; Yanakiev, D.; Bemporad, A.; Kolmanovsky, I.V.; Hrovat, D. Model predictive idle speed control: Design, analysis, and experimental evaluation. IEEE Trans. Control Syst. Technol. 2011, 20, 84–97. [Google Scholar] [CrossRef]

- Ebrahimi, K.; Koch, C.B. Real-time control of HCCI engine using model predictive control. In Proceedings of the American Control Conference (ACC 2018), Milwaukee, WI, USA, 27–29 June 2018; pp. 1622–1628. [Google Scholar] [CrossRef]

- Widd, A.; Liao, H.H.; Gerdes, J.C.; Tunestål, P.; Johansson, R. Control of exhaust recompression HCCI using hybrid model predictive control. In Proceedings of the American Control Conference (ACC 2011), San Francisco, CA, USA, 29 June–1 July 2011; pp. 420–425. [Google Scholar] [CrossRef] [Green Version]

- Ravi, N.; Liao, H.H.; Jungkunz, A.F.; Widd, A.; Gerdes, J.C. Model predictive control of HCCI using variable valve actuation and fuel injection. Control Eng. Pract. 2012, 20, 421–430. [Google Scholar] [CrossRef]

- Yin, L.; Turesson, G.; Tunestål, P.; Johansson, R. Model predictive control of an advanced multiple cylinder engine with partially premixed combustion concept. IEEE/ASME Trans. Mechatron. 2020, 25, 804–814. [Google Scholar] [CrossRef]

- Ferreau, H.; Lorini, G.; Diehl, M. Fast nonlinear model predictive control of gasoline engines. In Proceedings of the 2006 IEEE Conference on Computer Aided Control System Design, 2006 IEEE International Conference on Control Applications, 2006 IEEE International Symposium on Intelligent Control, Munich, Germany, 4–6 October 2006; pp. 2754–2759. [Google Scholar] [CrossRef]

- Majecki, P.; van der Molen, G.M.; Grimble, M.J.; Haskara, I.; Hu, Y.; Chang, C.F. Real-Time Predictive Control for SI Engines Using Linear Parameter-Varying Models. IFAC-PapersOnLine 2015, 48, 94–101. [Google Scholar] [CrossRef] [Green Version]

- Di Cairano, S.; Yanakiev, D.; Bemporad, A.; Kolmanovsky, I.V.; Hrovat, D. An MPC design flow for automotive control and applications to idle speed regulation. In Proceedings of the 2008 47th IEEE Conference on Decision and Control, Cancun, Mexico, 9–11 December 2008; pp. 5686–5691. [Google Scholar] [CrossRef]

- Rajaei, N.; Han, X.; Chen, X.; Zheng, M. Model Predictive Control of Exhaust Gas Recirculation Valve; SAE 2010 World Congress & Exhibition; SAE International: Warrendale, PA, USA, 2010. [Google Scholar] [CrossRef]

- Stewart, G.; Borrelli, F. A model predictive control framework for industrial turbodiesel engine control. In Proceedings of the 2008 47th IEEE Conference on Decision and Control, Cancun, Mexico, 9–11 December 2008; pp. 5704–5711. [Google Scholar] [CrossRef]

- Borhan, H.; Kothandaraman, G.; Pattel, B. Air handling control of a diesel engine with a complex dual-loop EGR and VGT air system using MPC. In Proceedings of the American Control Conference (ACC 2015), Chicago, IL, USA, 1–3 July 2015; pp. 4509–4516. [Google Scholar] [CrossRef]

- Ortner, P.; Del Re, L. Predictive control of a diesel engine air path. IEEE Trans. Control Syst. Technol. 2007, 15, 449–456. [Google Scholar] [CrossRef]

- Ferreau, H.J.; Ortner, P.; Langthaler, P.; Del Re, L.; Diehl, M. Predictive control of a real-world diesel engine using an extended online active set strategy. Annu. Rev. Control 2007, 31, 293–301. [Google Scholar] [CrossRef]

- Drews, P.; Hoffmann, K.; Beck, R.; Gasper, R.; Vanegas, A.; Felsch, C.; Peters, N.; Abel, D. Fast model predictive control for the air path of a turbocharged diesel engine. In Proceedings of the 2009 European Control Conference (ECC), Budapest, Hungary, 23–26 August 2009; pp. 3377–3382. [Google Scholar] [CrossRef]

- Emekli, M.E.; Güvenç, B.A. Explicit MIMO model predictive boost pressure control of a two-stage turbocharged diesel engine. IEEE Trans. Control Syst. Technol. 2016, 25, 521–534. [Google Scholar] [CrossRef]

- Sudhakar, S.; Hansen, A.; Hedrick, J.K. Algorithmic performance of receding horizon sliding control for engine emission reduction. In Proceedings of the 2016 IEEE Conference on Control Applications (CCA), Buenos Aires, Argentina, 19–22 September 2016; pp. 1398–1403. [Google Scholar] [CrossRef]

- Zhu, Q.; Onori, S.; Prucka, R. An economic nonlinear model predictive control strategy for SI engines: Model-based design and real-time experimental validation. IEEE Trans. Control Syst. Technol. 2017, 27, 296–310. [Google Scholar] [CrossRef]

- Shin, B.; Chi, Y.; Kim, M.; Dickinson, P.; Pekar, J.; Ko, M. Model Predictive Control of an Air Path System for Multi-Mode Operation in a Diesel Engine; WCX SAE World Congress Experience; SAE International: Warrendale, PA, USA, 2020. [Google Scholar] [CrossRef]

- Zhu, Q.; Prucka, R.; Prucka, M.; Dourra, H. A nonlinear model predictive control strategy with a disturbance observer for spark ignition engines with external EGR. SAE Int. J. Commer. Veh. 2017, 10, 360–372. [Google Scholar] [CrossRef]

- Kwon, W.H.; Han, S.H. Receding Horizon Control: Model Predictive Control for State Models; Springer Science & Business Media: Berlin, Germany, 2006. [Google Scholar] [CrossRef] [Green Version]

- Matschek, J.; Bäthge, T.; Faulwasser, T.; Findeisen, R. Nonlinear predictive control for trajectory tracking and path following: An introduction and perspective. In Handbook of Model Predictive Control; Springer: Berlin/Heidelberg, Germany, 2019; pp. 169–198. [Google Scholar] [CrossRef]

- Thomsen, S.; Hoffmann, N.; Fuchs, F.W. PI control, PI-based state space control, and model-based predictive control for drive systems with elastically coupled loads—A comparative study. IEEE Trans. Ind. Electron. 2010, 58, 3647–3657. [Google Scholar] [CrossRef]

- Lee, E.; Markus, L. Foundations of Optimal Control Theory; Wiley: New York, NY, USA, 1967. [Google Scholar]

- Rault, J.; Richalet, A.; Testud, J.; Papon, J. Model predictive heuristic control: Application to industrial processes. Automatica 1978, 14, 413–428. [Google Scholar] [CrossRef]

- Qin, S.J.; Badgwell, T.A. An Overview of Industrial Model Predictive Control Technology; AIche Symposium Series; American Institute of Chemical Engineers: New York, NY, USA, 1997; Volume 93, pp. 232–256. [Google Scholar]

- Lee, J.H. Model predictive control: Review of the three decades of development. Int. J. Control Autom. Syst. 2011, 9, 415. [Google Scholar] [CrossRef]

- Bemporad, A.; Borrelli, F.; Morari, M. Piecewise linear optimal controllers for hybrid systems. In Proceedings of the American Control Conference (ACC 2000), Chicago, IL, USA, 28–30 June 2000; Volume 2, pp. 1190–1194. [Google Scholar] [CrossRef]

- Bemporad, A.; Morari, M.; Dua, V.; Pistikopoulos, E.N. The explicit linear quadratic regulator for constrained systems. Automatica 2002, 38, 3–20. [Google Scholar] [CrossRef]

- Hovgaard, T.G.; Boyd, S.; Larsen, L.F.; Jørgensen, J.B. Nonconvex model predictive control for commercial refrigeration. Int. J. Control 2013, 86, 1349–1366. [Google Scholar] [CrossRef] [Green Version]

- Alrifaee, B.; Abel, D.; Ament, C. Networked Model Predictive Control for Vehicle Collision Avoidance; Technical Report; Lehrstuhl und Institut für Regelungstechnik RWTH Publications: Aachen, Germany, 2017; Available online: http://publications.rwth-aachen.de/record/689037 (accessed on 23 September 2021).

- Ellis, M.; Liu, J.; Christofides, P.D. Economic Model Predictive Control; Springer: Berlin/Heidelberg, Germany, 2017; Volume 2. [Google Scholar] [CrossRef]

- Adeodu, O.; Chmielewski, D.J. Control of electric power transmission networks with massive energy storage using economic MPC. In Proceedings of the American Control Conference (ACC 2013), Washington, DC, USA, 17–19 June 2013; pp. 5839–5844. [Google Scholar] [CrossRef]

- Halvgaard, R.; Poulsen, N.K.; Madsen, H.; Jørgensen, J.B. Economic model predictive control for building climate control in a smart grid. In Proceedings of the 2012 IEEE PES iNnovative Smart Grid Technologies (ISGT), Washington, DC, USA, 16–20 January 2012; pp. 1–6. [Google Scholar] [CrossRef]

- Anderson, T.L.; Ellis, M.; Christofides, P.D. Distributed economic model predictive control of a catalytic reactor: Evaluation of sequential and iterative architectures. IFAC-PapersOnLine 2015, 48, 26–31. [Google Scholar] [CrossRef] [Green Version]

- Touretzky, C.R.; Baldea, M. Integrating scheduling and control for economic MPC of buildings with energy storage. J. Process Control 2014, 24, 1292–1300. [Google Scholar] [CrossRef]

- Drgoňa, J.; Arroyo, J.; Cupeiro Figueroa, I.; Blum, D.; Arendt, K.; Kim, D.; Ollé, E.P.; Oravec, J.; Wetter, M.; Vrabie, D.L.; et al. All you need to know about model predictive control for buildings. Annu. Rev. Control 2020, 50, 190–232. [Google Scholar] [CrossRef]

- Serale, G.; Fiorentini, M.; Capozzoli, A.; Bernardini, D.; Bemporad, A. Model predictive control (MPC) for enhancing building and HVAC system energy efficiency: Problem formulation, applications and opportunities. Energies 2018, 11, 631. [Google Scholar] [CrossRef] [Green Version]

- Bemporad, A.; Morari, M. Control of systems integrating logic, dynamics, and constraints. Automatica 1999, 35, 407–427. [Google Scholar] [CrossRef]

- Axehill, D.; Hansson, A. Towards Parallel Implementation of Hybrid MPC—A Survey and Directions for Future Research. In Distributed Decision Making and Control; Springer: Berlin/Heidelberg, Germany, 2012; pp. 313–338. [Google Scholar] [CrossRef]

- Mayne, D. Robust and stochastic MPC: Are we going in the right direction? IFAC-PapersOnLine 2015, 48, 1–8. [Google Scholar] [CrossRef]

- Villanueva, M.E.; Quirynen, R.; Diehl, M.; Chachuat, B.; Houska, B. Robust MPC via min–max differential inequalities. Automatica 2017, 77, 311–321. [Google Scholar] [CrossRef]

- Farina, M.; Giulioni, L.; Scattolini, R. Stochastic linear Model Predictive Control with chance constraints—A review. J. Process Control 2016, 44, 53–67. [Google Scholar] [CrossRef]

- Heirung, T.A.N.; Paulson, J.A.; O’Leary, J.; Mesbah, A. Stochastic model predictive control—How does it work? Comput. Chem. Eng. 2018, 114, 158–170. [Google Scholar] [CrossRef]

- Maeder, U.; Borrelli, F.; Morari, M. Linear offset-free Model Predictive Control. Automatica 2009, 45, 2214–2222. [Google Scholar] [CrossRef]

- Adetola, V.; Guay, M. Robust adaptive MPC for constrained uncertain nonlinear systems. Int. J. Adapt. Control Signal Process. 2011, 25, 155–167. [Google Scholar] [CrossRef]

- Tabatabaei, S.M.; Kamali, S.; Jahed-Motlagh, M.R.; Yazdi, M.B. Practical explicit model predictive control for a class of noise-embedded chaotic hybrid systems. Int. J. Control Autom. Syst. 2019, 17, 857–866. [Google Scholar] [CrossRef]

- Ortner, P.; Langthaler, P.; Ortiz, J.V.G.; Del Re, L. MPC for a diesel engine air path using an explicit approach for constraint systems. In Proceedings of the 2006 IEEE Conference on Computer Aided Control System Design, 2006 IEEE International Conference on Control Applications, 2006 IEEE International Symposium on Intelligent Control, Munich, Germany, 4–6 October 2006; pp. 2760–2765. [Google Scholar] [CrossRef]

- Papadimitriou, A.; Andrikopoulos, G.; Nikolakopoulos, G. Experimental evaluation of an explicit model predictive controller for an adhesion vortex actuated climbing robot. In Proceedings of the American Control Conference (ACC 2020), Denver, CO, USA, 1–3 July 2020; pp. 2137–2142. [Google Scholar] [CrossRef]

- Lindqvist, B.; Mansouri, S.S.; Agha-mohammadi, A.A.; Nikolakopoulos, G. Nonlinear MPC for collision avoidance and control of UAVs with dynamic obstacles. IEEE Robot. Autom. Lett. 2020, 5, 6001–6008. [Google Scholar] [CrossRef]

- Faroni, M.; Beschi, M.; Pedrocchi, N. An MPC framework for online motion planning in human-robot collaborative tasks. In Proceedings of the 24th IEEE International Conference on Emerging Technologies and Factory Automation (ETFA 2019), Zaragoza, Spain, 10–13 September 2019; pp. 1555–1558. [Google Scholar] [CrossRef]

- Villarreal, O.; Barasuol, V.; Wensing, P.M.; Caldwell, D.G.; Semini, C. MPC-based controller with terrain insight for dynamic legged locomotion. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA 2020), Paris, France, 31 May–31 August 2020; pp. 2436–2442. [Google Scholar] [CrossRef]

- Di Cairano, S.; Kolmanovsky, I.V. Real-time optimization and model predictive control for aerospace and automotive applications. In Proceedings of the American Control Conference (ACC 2018), Milwaukee, WI, USA, 27–29 June 2018; pp. 2392–2409. [Google Scholar] [CrossRef]

- Eren, U.; Prach, A.; Koçer, B.B.; Raković, S.V.; Kayacan, E.; Açıkmeşe, B. Model predictive control in aerospace systems: Current state and opportunities. J. Guid. Control Dyn. 2017, 40, 1541–1566. [Google Scholar] [CrossRef]

- Wang, Y.; Boyd, S. Fast model predictive control using online optimization. IEEE Trans. Control Syst. Technol. 2009, 18, 267–278. [Google Scholar] [CrossRef] [Green Version]

- Rawlings, J.B.; Angeli, D.; Bates, C.N. Fundamentals of economic model predictive control. In Proceedings of the IEEE 51st IEEE Conference on Decision and Control (CDC 2012), Maui, HI, USA, 10–13 December 2012; pp. 3851–3861. [Google Scholar] [CrossRef]

- Ellis, M.; Christofides, P.D. Economic model predictive control with time-varying objective function for nonlinear process systems. AIChE J. 2014, 60, 507–519. [Google Scholar] [CrossRef]

- Bemporad, A.; Borrelli, F.; Morari, M. Model predictive control based on linear programming—The explicit solution. IEEE Trans. Autom. Control 2002, 47, 1974–1985. [Google Scholar] [CrossRef]

- Kvasnica, M. Implicit vs explicit MPC—Similarities, differences, and a path owards a unified method. In Proceedings of the European Control Conference (ECC 2016), Aalborg, Denmark, 29 June–1 July 2016; p. 603. [Google Scholar] [CrossRef]

- González, E.; Sanchis, J.; García-Nieto, S.; Salcedo, J. A comparative study of stochastic model predictive controllers. Electronics 2020, 9, 2078. [Google Scholar] [CrossRef]

- Alessio, A.; Barcelli, D.; Bemporad, A. Decentralized model predictive control of dynamically coupled linear systems. J. Process Control 2011, 21, 705–714. [Google Scholar] [CrossRef]

- Cranmer, A.; Shahbakhti, M.; Hedrick, J. Grey-box modeling architectures for rotational dynamic control in automotive engines. In Proceedings of the American Control Conference (ACC 2012), Montreal, QC, Canada, 27–29 June 2012; pp. 1278–1283. [Google Scholar] [CrossRef]

- Bidarvatan, M.; Shahbakhti, M. Gray-box modeling for performance control of an HCCI engine with blended fuels. J. Eng. Gas Turbines Power 2014, 136, 101510. [Google Scholar] [CrossRef]

- Bidarvatan, M.; Thakkar, V.; Shahbakhti, M. Grey-box modeling and control of HCCI engine emissions. In Proceedings of the American Control Conference (ACC 2014), Portland, OR, USA, 4–6 June 2014; pp. 837–842. [Google Scholar] [CrossRef]

- Ghazimirsaied, A.; Shahbakhti, M.; Koch, C. HCCI engine combustion phasing prediction using a symbolic-statistics approach. J. Eng. Gas Turbines Power 2010, 132, 082805. [Google Scholar] [CrossRef]

- Shahbakhti, M.; Bidarvatan, M.; Jazayeri, S.A. Model-based control of combustion phasing in an HCCI engine. SAE Int. J. Engines 2012, 5, 1163–1176. [Google Scholar] [CrossRef]

- Bidarvatan, M.; Shahbakhti, M. Grey-box modeling for HCCI engine control. In Proceedings of the ASME 2013 Internal Combustion Engine Division Fall Technical Conference, Dearborn, MI, USA, 13–16 October 2013. ASME Paper No. ICEF2013-19097. [Google Scholar] [CrossRef]

- Bahri, B.; Aziz, A.A.; Shahbakhti, M.; Muhamad Said, M.F. Understanding and detecting misfire in an HCCI engine fuelled with ethanol. Appl. Energy 2013, 108, 24–33. [Google Scholar] [CrossRef]

- Bahri, B.; Aziz, A.; Shahbakhti, M.; Muhamad Said, M. Analysis and modeling of exhaust gas temperature in an ethanol fuelled HCCI engine. J. Mech. Sci. Technol. 2013, 27, 3531–3539. [Google Scholar] [CrossRef]

- Fathi, M.; Jahanian, O.; Shahbakhti, M. Modeling and controller design architecture for cycle-by-cycle combustion control of homogeneous charge compression ignition (HCCI) engines—A comprehensive review. Energy Convers. Manag. 2017, 139, 1–19. [Google Scholar] [CrossRef]

- Bidarvatan, M.; Shahbakhti, M. Two-Input Two-Output Control of Blended Fuel HCCI Engines; SAE 2013 World Congress & Exhibition; SAE International: Warrendale, PA, USA, 2013. [Google Scholar] [CrossRef]

- Bidarvatan, M.; Shahbakhti, M.; Jazayeri, S.; Koch, C. Cycle-to-cycle modeling and sliding mode control of blended-fuel HCCI engine. Control Eng. Pract. 2014, 24, 79–91. [Google Scholar] [CrossRef]

- Bidarvatan, M.; Thakkar, V.; Shahbakhti, M.; Bahri, B.; Abdul Aziz, A. Grey-box modeling of HCCI engines. Appl. Therm. Eng. 2014, 70, 397–409. [Google Scholar] [CrossRef]

- Ebrahimi, K.; Koch, C. Model Predictive Control for Combustion Timing and Load Control in HCCI Engines; SAE 2015 World Congress & Exhibition; SAE International: Warrendale, PA, USA, 2015. [Google Scholar] [CrossRef]

- Rezaei, J.; Shahbakhti, M.; Bahri, B.; Aziz, A.A. Performance prediction of HCCI engines with oxygenated fuels using artificial neural networks. Appl. Energy 2015, 138, 460–473. [Google Scholar] [CrossRef]

- Bahri, B.; Shahbakhti, M.; Kannan, K.; Aziz, A.A. Identification of ringing operation for low temperature combustion engines. Appl. Energy 2016, 171, 142–152. [Google Scholar] [CrossRef]

- Bahri, B.; Shahbakhti, M.; Aziz, A. Real-time modeling of ringing in HCCI engines using artificial neural networks. Energy 2017, 125, 509–518. [Google Scholar] [CrossRef]

- Bao, Y.; Velni, J.M.; Basina, A.; Shahbakhti, M. Identification of State-space Linear Parameter-varying Models Using Artificial Neural Networks. IFAC-PapersOnLine 2020, 53, 5286–5291. [Google Scholar] [CrossRef]

- Norouzi, A.; Masoumi, M.; Barari, A.; Farrokhpour Sani, S. Lateral control of an autonomous vehicle using integrated backstepping and sliding mode controller. Proc. Inst. Mech. Eng. Part K J. Multi-Body Dyn. 2019, 233, 141–151. [Google Scholar] [CrossRef]

- Norouzi, A.; Gordon, D.; Aliramezani, M.; Koch, C.R. Machine learning-based diesel engine-Out NOx reduction using a plug-in PD-type iterative learning control. In Proceedings of the IEEE Conference on Control Technology and Applications (CCTA 2020), Montreal, QC, Canada, 24–26 August 2020; pp. 450–455. [Google Scholar] [CrossRef]

- Norouzi, A.; Aliramezani, M.; Koch, C.R. A correlation-based model order reduction approach for a diesel engine NOx and brake mean effective pressure dynamic model using machine learning. Int. J. Engine Res. 2021, 22, 2654–2672. [Google Scholar] [CrossRef]

- Norouzi, A.; Aliramezani, M.; Koch, C.R. Diesel engine NOx reduction using a PD-type fuzzy iterative learning control with a fast response NOx sensor. In Proceedings of the Combustion Institute-Canadian Section (CICS 2019), Kelowna, BC, Canada, 13 May 2019. [Google Scholar]

- Aliramezani, M.; Norouzi, A.; Koch, C.R. Support vector machine for a diesel engine performance and NOx emission control-oriented model. IFAC-PapersOnLine 2020, 53, 13976–13981. [Google Scholar] [CrossRef]

- Aliramezani, M.; Norouzi, A.; Koch, C.R. A grey-box machine learning based model of an electrochemical gas sensor. Sens. Actuators B Chem. 2020, 321, 128414. [Google Scholar] [CrossRef]

- Norouzi, A.; Adibi-Asl, H.; Kazemi, R.; Hafshejani, P.F. Adaptive sliding mode control of a four-wheel-steering autonomous vehicle with uncertainty using parallel orientation and position control. Int. J. Heavy Veh. Syst. 2020, 27, 499–518. [Google Scholar] [CrossRef]

- Shahpouri, S.; Norouzi, A.; Hayduk, C.; Rezaei, R.; Shahbakhti, M.; Koch, C.R. Soot emission modeling of a compression ignition engine using machine learning. IFAC-PapersOnLine 2021, in press. [Google Scholar]

- Gordon, D.; Wouters, C.; Ottenwälder, T.; Lehrheuer, B.; Pischinger, S.; Wick, M.; Andert, J. Evaluation of the Potential of Direct Water Injection in HCCI Combustion; 2019 JSAE/SAE Powertrains, Fuels and Lubricants; SAE International: Warrendale, PA, USA, 2019. [Google Scholar] [CrossRef]

- Gordon, D.; Wouters, C.; Kinoshita, S.; Wick, M.; Lehrheuer, B.; Andert, J.; Pischinger, S.; Koch, C.R. Homogeneous charge compression ignition combustion stability improvement using a rapid ignition system. Int. J. Engine Res. 2020, 21, 1846–1856. [Google Scholar] [CrossRef]

- Gordon, D.; Wouters, C.; Wick, M.; Lehrheuer, B.; Andert, J.; Koch, C.; Pischinger, S. Development and experimental validation of a field programmable gate array–based in-cycle direct water injection control strategy for homogeneous charge compression ignition combustion stability. Int. J. Engine Res. 2019, 20, 1101–1113. [Google Scholar] [CrossRef]

- Ebrahimi, K.; Gordon, D.; Canteenwalla, P.; Koch, C.R. Evaluation of ASTM D6424 standard for knock analysis using unleaded fuel candidates on a six cylinder aircraft engine. Int. J. Engine Res. 2021. [Google Scholar] [CrossRef]

- Raut, A.; Bidarvatan, M.; Borhan, H.; Shahbakhti, M. Model predictive control of an RCCI engine. In Proceedings of the American Control Conference (ACC 2018), Milwaukee, WI, USA, 27–29 June 2018; pp. 1604–1609. [Google Scholar] [CrossRef]

- Borhan, H.; Desai, A.S.; Hodzen, E.P.; Tulpule, P.J.; Pattel, B.N. System and Method for Predictive Engine and Aftertreatment System Control. U.S. Patent 10,576,978, 6 June 2019. [Google Scholar]

- Khameneian, A.; Wang, X.; Dice, P.; Shahbakhti, M.; Naber, J.D.; Archer, C.; Moilanen, P.; Glugla, C.; Huberts, G. Model-based dynamic in-cylinder air charge, residual gas and temperature estimation for a GDI spark ignition engine using cylinder, intake and exhaust pressures. In Dynamic Systems and Control Conference; American Society of Mechanical Engineers: New York, NY, USA, 2020; Volume 84287, p. V002T26A002. [Google Scholar] [CrossRef]

- Polat, S.; Yücesu, H.S.; Uyumaz, A.; Kannan, K.; Shahbakhti, M. An experimental investigation on combustion and performance characteristics of supercharged HCCI operation in low compression ratio engine setting. Appl. Therm. Eng. 2020, 180, 115858. [Google Scholar] [CrossRef]

- Khoshbakht Irdmousa, B.; Naber, J.; Mohammadpour Velni, J.; Borhan, H.; Shahbakhti, M. Input–output Data-driven Modeling and MIMO Predictive Control of an RCCI Engine Combustion. IFAC-PapersOnLine 2021, in press. [Google Scholar]

- Batool, S.; Naber, J.; Shahbakhti, M. Data-Driven Modeling and Control of Cyclic Variability of an Engine Operating in Low Temperature Combustion Modes. IFAC-PapersOnLine 2021, in press. [Google Scholar]

- Rosolia, U.; Zhang, X.; Borrelli, F. Data-Driven Predictive Control for Autonomous Systems. Annu. Rev. Control Robot. Auton. Syst. 2018, 1, 259–286. [Google Scholar] [CrossRef]

- Di Cairano, S.; Kolmanovsky, I.V. Automotive applications of model predictive control. In Handbook of Model Predictive Control; Springer: Berlin/Heidelberg, Germany, 2019; pp. 493–527. [Google Scholar]

- Liu, H.; Wen, M.; Yang, H.; Yue, Z.; Yao, M. A Review of Thermal Management System and Control Strategy for Automotive Engines. J. Energy Eng. 2021, 147, 03121001. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, H.; Khajepour, A.; He, H.; Ji, J. Model predictive control power management strategies for HEVs: A review. J. Power Sources 2017, 341, 91–106. [Google Scholar] [CrossRef]

- Asprion, J.; Chinellato, O.; Guzzella, L. Optimal control of diesel engines: Numerical methods, applications, and experimental validation. Math. Probl. Eng. 2014, 2014, 286538. [Google Scholar] [CrossRef]

- Zhu, Q.; Onori, S.; Prucka, R. Nonlinear economic model predictive control for SI engines based on sequential quadratic programming. In Proceedings of the American Control Conference (ACC 2016), Boston, MA, USA, 6–8 July 2016; pp. 1802–1807. [Google Scholar] [CrossRef]

- Liu, Z.; Dizqah, A.M.; Herreros, J.M.; Schaub, J.; Haas, O. Simultaneous control of NOx, soot and fuel economy of a diesel engine with dual-loop EGR and VNT using economic MPC. Control Eng. Pract. 2021, 108, 104701. [Google Scholar] [CrossRef]

- Nuss, E.; Wick, M.; Andert, J.; De Schutter, J.; Diehl, M.; Abel, D.; Albin, T. Nonlinear model predictive control of a discrete-cycle gasoline-controlled auto ignition engine model: Simulative analysis. Int. J. Engine Res. 2019, 20, 1025–1036. [Google Scholar] [CrossRef]

- Xu, F.; Chen, H.; Gong, X.; Hu, Y. Engine idle speed control using nonlinear model predictive control. IFAC Proc. Vol. 2013, 46, 171–176. [Google Scholar] [CrossRef]

- Shamekhi, A.M.; Taghavipour, A.; Shamekhi, A.H. Engine idle speed control using nonlinear multiparametric model predictive control. Optim. Control Appl. Methods 2020, 41, 960–979. [Google Scholar] [CrossRef]

- Herceg, M.; Raff, T.; Findeisen, R.; Allgowe, F. Nonlinear model predictive control of a turbocharged diesel engine. In Proceedings of the 2006 IEEE Conference on Computer Aided Control System Design, 2006 IEEE International Conference on Control Applications, 2006 IEEE International Symposium on Intelligent Control, Munich, Germany, 4–6 October 2006; pp. 2766–2771. [Google Scholar] [CrossRef]

- Iwadare, M.; Ueno, M. Multi-Variable Air-Path Management for a Clean Diesel Engine Using Model Predictive Control. SAE Int. J. Engines 2009, 2, 764–773. [Google Scholar] [CrossRef]

- García-Nieto, S.; Martínez, M.; Blasco, X.; Sanchis, J. Nonlinear predictive control based on local model networks for air management in diesel engines. Control Eng. Pract. 2008, 16, 1399–1413. [Google Scholar] [CrossRef]

- El Hadef, J.; Olaru, S.; Rodriguez-Ayerbe, P.; Colin, G.; Chamaillard, Y.; Talon, V. Explicit nonlinear model predictive control of the air path of a turbocharged spark-ignited engine. In Proceedings of the IEEE International Conference on Control Applications (CCA 2013), Hyderabad, India, 28–30 August 2013; pp. 71–77. [Google Scholar] [CrossRef] [Green Version]

- Chiang, C.J.; Kuo, C.L.; Huang, C.C.; Lee, J.Y. Model predictive control of SCR aftertreatment system. In Proceedings of the 2010 5th IEEE Conference on Industrial Electronics and Applications, Taichung, Taiwan, 15–17 June 2010; pp. 2058–2063. [Google Scholar] [CrossRef]

- Kim, Y.; Park, T.; Jung, C.; Kim, C.H.; Kim, Y.W.; Lee, J.M. Hybrid nonlinear model predictive control of LNT and urealess SCR aftertreatment system. IEEE Trans. Control Syst. Technol. 2018, 27, 2305–2313. [Google Scholar] [CrossRef]

- Feru, E.; Willems, F.; de Jager, B.; Steinbuch, M. Model predictive control of a waste heat recovery system for automotive diesel engines. In Proceedings of the 18th International Conference on System Theory, Control and Computing, Sinaia, Romania, 17–19 October 2014; pp. 658–663. [Google Scholar] [CrossRef]

- Yebi, A.; Xu, B.; Liu, X.; Shutty, J.; Anschel, P.; Onori, S.; Filipi, Z.; Hoffman, M. Nonlinear model predictive control strategies for a parallel evaporator diesel engine waste heat recovery system. In Proceedings of the ASME 2016 Dynamic Systems and Control Conference, Minneapolis, MN, USA, 12–14 October 2016. [Google Scholar] [CrossRef]

- Feru, E.; Willems, F.; De Jager, B.; Steinbuch, M. Modeling and control of a parallel waste heat recovery system for euro-VI heavy-duty diesel engines. Energies 2014, 7, 6571–6592. [Google Scholar] [CrossRef] [Green Version]

- Koli, R.; Egan, D.; Zhu, Q.; Prucka, R. Quantification of Linear Approximation Error for Model Predictive Control of Spark-Ignited Turbocharged Engines. In Proceedings of the 14th International Conference on Engines & Vehicles, Capri, Italy, 15–19 September 2019; SAE International: Warrendale, PA, USA, 2019. [Google Scholar] [CrossRef]

- Šika, Z.; Valášek, M.; Florián, M.; Macek, J.; Polášek, M. Multilevel Predictive Models of IC Engine for Model Predictive Control Implementation; SAE World Congress & Exhibition; SAE International: Warrendale, PA, USA, 2008. [Google Scholar] [CrossRef]

- Shahbakhti, M.; Ghazimirsaied, A.; Koch, C.R. Modeling Ranges of Cyclic Variability for Ignition Timing Control of HCCI Engines. In Proceedings of the ASME 2011 Dynamic Systems and Control Conference 2011, Arlington, VA, USA, 31 October–2 November 2011; Volume 2, pp. 693–700. [Google Scholar] [CrossRef]

- Frommater, S.; Neumann, J.; Hasse, C. A phenomenological modelling framework for particle emission simulation in a direct-injection gasoline engine. Int. J. Engine Res. 2021, 22, 1166–1179. [Google Scholar] [CrossRef]

- Babajimopoulos, A.; Assanis, D.N.; Flowers, D.L.; Aceves, S.M.; Hessel, R.P. A fully coupled computational fluid dynamics and multi-zone model with detailed chemical kinetics for the simulation of premixed charge compression ignition engines. Int. J. Engine Res. 2005, 6, 497–512. [Google Scholar] [CrossRef]

- Eckert, P.; Kong, S.C.; Reitz, R.D. Modeling autoignition and engine knock under spark ignition conditions. J. Engines 2003, 112, 100–111. [Google Scholar] [CrossRef]

- Korkmaz, M.; Lakshmanan, R.; Falkenstein, T.; Beeckmann, J.; Pitsch, H. Experimental and numerical investigation of the maximum pressure rise rate for an LTC concept in a single cylinder CI engine. In 14th International Conference on Engines & Vehicles; SAE International: Warrendale, PA, USA, 2019. [Google Scholar] [CrossRef]

- Li, R.C.; Zhu, G.G.; Men, Y. A two-zone reaction-based combustion model for a spark-ignition engine. Int. J. Engine Res. 2021, 22, 109–124. [Google Scholar] [CrossRef]

- Dal Bianco, N.; Bertolazzi, E.; Biral, F.; Massaro, M. Comparison of direct and indirect methods for minimum lap time optimal control problems. Veh. Syst. Dyn. 2019, 57, 665–696. [Google Scholar] [CrossRef]

- Biral, F.; Bertolazzi, E.; Bosetti, P. Notes on numerical methods for solving optimal control problems. IEEJ J. Ind. Appl. 2016, 5, 154–166. [Google Scholar] [CrossRef] [Green Version]

- Nocedal, J.; Wright, S. Numerical Optimization; Springer Science & Business Media: Berlin, Germany, 2006. [Google Scholar]

- Rawlings, J.B.; Mayne, D.Q.; Diehl, M. Model Predictive Control: Theory, Computation, and Design; Nob Hill Publishing: Madison, WI, USA, 2017; Volume 2. [Google Scholar]

- Stein, O. How to solve a semi-infinite optimization problem. Eur. J. Oper. Res. 2012, 223, 312–320. [Google Scholar] [CrossRef]

- Alizadeh, F.; Goldfarb, D. Second-order cone programming. Math. Program. 2003, 95, 3–51. [Google Scholar] [CrossRef]

- Beck, A. First-Order Methods in Optimization; SIAM: Philadelphia, PA, USA, 2017. [Google Scholar]

- Lee, J.; Leyffer, S. Mixed Integer Nonlinear Programming; Springer Science & Business Media: Berlin, Germany, 2011; Volume 154. [Google Scholar]

- Arnström, D.; Axehill, D. Exact complexity certification of a standard primal active-set method for quadratic programming. In Proceedings of the IEEE 58th Conference on Decision and Control (CDC 2019), Nice, France, 11–13 December 2019; pp. 4317–4324. [Google Scholar] [CrossRef]

- Cimini, G.; Bemporad, A. Exact complexity certification of active-set methods for quadratic programming. IEEE Trans. Autom. Control 2017, 62, 6094–6109. [Google Scholar] [CrossRef]

- Cimini, G.; Bernardini, D.; Levijoki, S.; Bemporad, A. Embedded model predictive control with certified real-time optimization for synchronous motors. IEEE Trans. Control Syst. Technol. 2021, 29, 893–900. [Google Scholar] [CrossRef]

- Zanelli, A.; Domahidi, A.; Jerez, J.; Morari, M. FORCES NLP: An efficient implementation of interior-point methods for multistage nonlinear nonconvex programs. Int. J. Control 2020, 93, 13–29. [Google Scholar] [CrossRef]

- Mittelmann, H.D.; Spellucci, P. Decision Tree for Optimization Software. 2005. Available online: http://plato.asu.edu/guide.html (accessed on 4 September 2021).

- Wächter, A.; Biegler, L.T. On the implementation of an interior-point filter line-search algorithm for large-scale nonlinear programming. Math. Program. 2006, 106, 25–57. [Google Scholar] [CrossRef]

- Tawarmalani, M.; Sahinidis, N.V. A polyhedral branch-and-cut approach to global optimization. Math. Program. 2005, 103, 225–249. [Google Scholar] [CrossRef]

- Gurobi Optimization Team. Gurobi Optimizer Reference Manual. 2021. Available online: http://www.gurobi.com (accessed on 4 September 2021).

- Domahidi, A.; Jerez, J. FORCES Professional. Embotech AG. 2014–2019. Available online: https://embotech.com/FORCES-Pro (accessed on 4 September 2021).

- Gill, P.E.; Murray, W.; Saunders, M.A. SNOPT: An SQP algorithm for large-scale constrained optimization. SIAM Rev. 2005, 47, 99–131. [Google Scholar] [CrossRef]

- Gertz, E.M.; Wright, S.J. Object-oriented software for quadratic programming. ACM Trans. Math. Softw. (TOMS) 2003, 29, 58–81. [Google Scholar] [CrossRef] [Green Version]

- Necoara, I.; Kvamme, S. DuQuad: A toolbox for solving convex quadratic programs using dual (augmented) first order algorithms. In Proceedings of the 54th IEEE Conference on Decision and Control (CDC 2015), Osaka, Japan, 15–18 December 2015; pp. 2043–2048. [Google Scholar] [CrossRef]

- Frison, G.; Diehl, M. HPIPM: A high-performance quadratic programming framework for model predictive control. IFAC-PapersOnLine 2020, 53, 6563–6569. [Google Scholar] [CrossRef]

- Sopasakis, P.; Fresk, E.; Patrinos, P. OpEn: Code Generation for Embedded Nonconvex Optimization. IFAC-PapersOnLine 2020, 53, 6548–6554. [Google Scholar] [CrossRef]

- Büskens, C.; Wassel, D. The ESA NLP Solver WORHP. In Modeling and Optimization in Space Engineering; Springer: New York, NY, USA, 2013; pp. 85–110. [Google Scholar] [CrossRef]

- Cplex, I.I. V12. 1: User’s Manual for CPLEX. Int. Bus. Mach. Corp. 2009, 46, 157. [Google Scholar]

- Steven, D.; Stephen, B. CVXPY: A Python-embedded modeling language for convex optimization. J. Mach. Learn. Res. 2016, 17, 2909–2913. [Google Scholar]

- Byrd, R.H.; Nocedal, J.; Waltz, R.A. KNITRO: An integrated package for nonlinear optimization. In Large-Scale Nonlinear Optimization; Springer US: Boston, MA, USA, 2006; pp. 35–59. [Google Scholar] [CrossRef]

- Bemporad, A.; Morari, M.; Ricker, N.L. Model Predictive Control Toolbox™ Getting Started Guide. 2005. Available online: https://instruct.uwo.ca/engin-sc/391b/downloads/mpc_gsg.pdf (accessed on 4 September 2021).

- Ullmann, F. FiOrdOs: A MATLAB Toolbox for C-Code Generation for First Order Methods. Master’s Thesis, ETH, Zurich, Switzerland, 2011. [Google Scholar]

- Hedengren, J.; Mojica, J.; Cole, W.; Edgar, T. APOPT: MINLP solver for differential and algebraic systems with benchmark testing. In Proceedings of the INFORMS National Meeting, Phoenix, AZ, USA, 14 October 2012; Volume 1417, p. 47. [Google Scholar]

- Vanderbei, R.J. LOQO: An interior point code for quadratic programming. Optim. Methods Softw. 1999, 11, 451–484. [Google Scholar] [CrossRef]

- Lofberg, J. YALMIP: A toolbox for modeling and optimization in MATLAB. In Proceedings of the 2004 IEEE International Conference on Robotics and Automation (IEEE Cat. No. 04CH37508), Taipei, Taiwan, 2–4 September 2004; pp. 284–289. [Google Scholar] [CrossRef]

- Houska, B.; Ferreau, H.J.; Diehl, M. ACADO toolkit—An open-source framework for automatic control and dynamic optimization. Optim. Control Appl. Methods 2011, 32, 298–312. [Google Scholar] [CrossRef]

- Andersson, J.A.E.; Gillis, J.; Horn, G.; Rawlings, J.B.; Diehl, M. CasADi – A software framework for nonlinear optimization and optimal control. Math. Program. Comput. 2019, 11, 1–36. [Google Scholar] [CrossRef]

- Grant, M.; Boyd, S.; Ye, Y. CVX: MATLAB Software for Disciplined Convex Programming. 2008. Available online: http://cvxr.com/cvx/ (accessed on 4 September 2021).

- Chen, Y.; Tong, Z.; Zheng, Y.; Samuelson, H.; Norford, L. Transfer learning with deep neural networks for model predictive control of HVAC and natural ventilation in smart buildings. J. Clean. Prod. 2020, 254, 119866. [Google Scholar] [CrossRef]

- Kuo, C.Y.; Cui, Y.; Matsubara, T. Sample-and-computation-efficient Probabilistic Model Predictive Control with Random Features. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA 2020), Paris, France, 31 May–31 August 2020; pp. 307–313. [Google Scholar] [CrossRef]

- Hewing, L.; Wabersich, K.P.; Menner, M.; Zeilinger, M.N. Learning-based model predictive control: Toward safe learning in control. Annu. Rev. Control Robot. Auton. Syst. 2020, 3, 269–296. [Google Scholar] [CrossRef]

- Drgoňa, J.; Picard, D.; Kvasnica, M.; Helsen, L. Approximate model predictive building control via machine learning. Appl. Energy 2018, 218, 199–216. [Google Scholar] [CrossRef]

- Klaučo, M.; Kalúz, M.; Kvasnica, M. Machine learning-based warm starting of active set methods in embedded model predictive control. Eng. Appl. Artif. Intell. 2019, 77, 1–8. [Google Scholar] [CrossRef]

- Bao, Y.; Mohammadpour Velni, J.; Shahbakhti, M. An Online Transfer Learning Approach for Identification and Predictive Control Design With Application to RCCI Engines. In Dynamic Systems and Control Conference; American Society of Mechanical Engineers: New York, NY, USA, 2020; Volume 84270, p. V001T21A003. [Google Scholar] [CrossRef]

- Vaughan, A.; Bohac, S. Real-time, adaptive machine learning for non-stationary, near chaotic gasoline engine combustion time series. Neural Netw. 2015, 70, 18–26. [Google Scholar] [CrossRef] [Green Version]

- Yang, S.; Wan, M.P.; Chen, W.; Ng, B.F.; Dubey, S. Model predictive control with adaptive machine-learning-based model for building energy efficiency and comfort optimization. Appl. Energy 2020, 271, 115147. [Google Scholar] [CrossRef]

- Smarra, F.; Jain, A.; de Rubeis, T.; Ambrosini, D.; D’Innocenzo, A.; Mangharam, R. Data-driven model predictive control using random forests for building energy optimization and climate control. Appl. Energy 2018, 226, 1252–1272. [Google Scholar] [CrossRef] [Green Version]

- Wu, Z.; Tran, A.; Ren, Y.M.; Barnes, C.S.; Chen, S.; Christofides, P.D. Model predictive control of phthalic anhydride synthesis in a fixed-bed catalytic reactor via machine learning modeling. Chem. Eng. Res. Des. 2019, 145, 173–183. [Google Scholar] [CrossRef]

- Wang, J.; Li, S.; Chen, H.; Yuan, Y.; Huang, Y. Data-driven model predictive control for building climate control: Three case studies on different buildings. Build. Environ. 2019, 160, 106204. [Google Scholar] [CrossRef]

- Wang, S.; Yu, D.; Gomm, J.; Page, G.; Douglas, S. Adaptive neural network model based predictive control for air–fuel ratio of SI engines. Eng. Appl. Artif. Intell. 2006, 19, 189–200. [Google Scholar] [CrossRef]

- Janakiraman, V.M.; Nguyen, X.; Assanis, D. An ELM based predictive control method for HCCI engines. Eng. Appl. Artif. Intell. 2016, 48, 106–118. [Google Scholar] [CrossRef] [Green Version]

- Bao, Y.; Velni, J.M.; Shahbakhti, M. Epistemic Uncertainty Quantification in State-Space LPV Model Identification Using Bayesian Neural Networks. IEEE Control Syst. Lett. 2020, 5, 719–724. [Google Scholar] [CrossRef]

- Macek, J.; Polášek, M.; Šika, Z.; Valášek, M.; Florián, M.; Vítek, O. Transient Engine Model as a Tool for Predictive Control; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2006. [Google Scholar] [CrossRef]

- Ira, A.S.; Shames, I.; Manzie, C.; Chin, R.; Nešić, D.; Nakada, H.; Sano, T. A Machine Learning Approach for Tuning Model Predictive Controllers. In Proceedings of the 15th International Conference on Control, Automation, Robotics and Vision (ICARCV 2018), Singapore, 18–21 November 2018; pp. 2003–2008. [Google Scholar]

- Hu, Y.; Chen, H.; Wang, P.; Chen, H.; Ren, L. Nonlinear model predictive controller design based on learning model for turbocharged gasoline engine of passenger vehicle. Mech. Syst. Signal Process. 2018, 109, 74–88. [Google Scholar] [CrossRef]

- Billings, S.A. Nonlinear System Identification: NARMAX Methods in the Time, Frequency, and Spatio-Temporal Domains; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- ŁAwryńCzuk, M.; Tatjewski, P. Nonlinear predictive control based on neural multi-models. Int. J. Appl. Math. Comput. Sci. 2010, 20, 7–21. [Google Scholar] [CrossRef] [Green Version]

- Huang, G.B.; Zhu, Q.Y.; Siew, C.K. Extreme learning machine: Theory and applications. Neurocomputing 2006, 70, 489–501. [Google Scholar] [CrossRef]

- Cortes, C.; Vapnik, V. Support-vector networks. Mach. Learn. 1995, 20, 273–297. [Google Scholar] [CrossRef]

- Jospin, L.V.; Buntine, W.; Boussaid, F.; Laga, H.; Bennamoun, M. Hands-on Bayesian Neural Networks—A Tutorial for Deep Learning Users. arXiv 2020, arXiv:2007.06823. [Google Scholar]

- Carron, A.; Arcari, E.; Wermelinger, M.; Hewing, L.; Hutter, M.; Zeilinger, M.N. Data-driven model predictive control for trajectory tracking with a robotic arm. IEEE Robot. Autom. Lett. 2019, 4, 3758–3765. [Google Scholar] [CrossRef] [Green Version]

- Yoo, J.; Molin, A.; Jafarian, M.; Esen, H.; Dimarogonas, D.V.; Johansson, K.H. Event-triggered model predictive control with machine learning for compensation of model uncertainties. In Proceedings of the IEEE 56th Annual Conference on Decision and Control (CDC 2017), Melbourne, Australia, 12–15 December 2017; pp. 5463–5468. [Google Scholar] [CrossRef]

- Yoo, J.; Johansson, K.H. Event-Triggered Model Predictive Control With a Statistical Learning. IEEE Trans. Syst. Man Cybern. Syst. 2019, 51, 2571–2581. [Google Scholar] [CrossRef]

- Cui, Y.; Osaki, S.; Matsubara, T. Reinforcement Learning Boat Autopilot: A Sample-efficient and Model Predictive Control based Approach. In Proceedings of the 2019 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Macau, China, 3–8 November 2019; pp. 2868–2875. [Google Scholar] [CrossRef]

- Cui, Y.; Osaki, S.; Matsubara, T. Autonomous boat driving system using sample-efficient model predictive control-based reinforcement learning approach. J. Field Robot. 2020, 38, 331–354. [Google Scholar] [CrossRef]

- Fehér, Á.; Aradi, S.; Bécsi, T. Hierarchical evasive path planning using reinforcement learning and model predictive control. IEEE Access 2020, 8, 187470–187482. [Google Scholar] [CrossRef]

- Gardezi, M.S.M.; Hasan, A. Machine learning based adaptive prediction horizon in finite control set model predictive control. IEEE Access 2018, 6, 32392–32400. [Google Scholar] [CrossRef]

- Negenborn, R.R.; De Schutter, B.; Wiering, M.A.; Hellendoorn, H. Learning-based model predictive control for Markov decision processes. IFAC Proc. Vol. 2005, 38, 354–359. [Google Scholar] [CrossRef] [Green Version]

- Gurriet, T.; Mote, M.; Ames, A.D.; Feron, E. An Online Approach to Active Set Invariance. In Proceedings of the IEEE Conference on Decision and Control (CDC 2018), Miami, FL, USA, 17–19 December 2018; pp. 3592–3599. [Google Scholar] [CrossRef]

- Wabersich, K.P.; Zeilinger, M.N. Linear Model Predictive Safety Certification for Learning-Based Control. In Proceedings of the 2018 IEEE Conference on Decision and Control (CDC), Miami, FL, USA, 17–19 December 2018; pp. 7130–7135. [Google Scholar] [CrossRef] [Green Version]

| MPC Types | Experimental | Simulation | Processor-In-Loop (PIL) | |

|---|---|---|---|---|

| Linear | Explicit | [30,38,39,40,43,45,47,50] | – | – |

| Single | [24,28,36,37,40,49] | [108,142,145,151] | – | |

| Switching | [27,29,33,46,53] | [147,149] | – | |

| LPV | [21,29,42,48] | [22,129,143,150] | – | |

| Economic | Linear | [35] | – | – |

| Nonlinear | [52,54,136] | [137] | – | |

| Nonlinear | – | [26,32,34,41,51] | [130,138,139,140,141,144,148,150] | [135] |

| Problems | Control Applications |

|---|---|

| Multi linear | Waste heat recovery [147,149] |

| Burn rate/combustion phasing [21,22,27,28,37,38,39,108,129] | |

| Torque and IMEP [22,27,28,33,35,37,38,39,40,42,108] | |

| Idle speed [25,36,43,140] | |

| Convex or convexifiable | NOx emission [26,28,30,137] |

| Exhaust aftertreatment system [145] | |

| Combustion mode transition [53] | |

| Airpath of turbocharged engines [32,34,52,141,144] | |

| Non-Convex | Cyclic Variability [54,152] |

| Soot and uHC emissions [153,154] | |

| Knock and MPRR [155,156,157] |

| Optimization Solver | MPC Problem Type | Optimization | Commercial/Free |

|---|---|---|---|

| IPOPT * [171] | LMPC, Convex NMPC, Nonconvex NMPC | IP | F |

| BARON [172] | LMPC, Convex NMPC, Nonconvex NMPC | IP, SQP | C |

| Gurobi [173] | LMPC, Convex NMPC, Nonconvex NMPC | IP | C |

| ForcesPro [169,174] | LMPC, Convex NMPC, Nonconvex NMPC | IP, SQP, FOM | C |

| SNOPT * [175] | LMPC, Convex NMPC, Nonconvex NMPC | IP, SQP | C |

| OOQP [176] | LMPC | IP | F |

| duQuad [177] | LMPC, Convex NMPC | FOM | F |

| HPIPM [178] | LMPC, Convex NMPC | IP | F |

| qpOASES * [179] | LMPC, Convex NMPC, Nonconvex NMPC | SQP | F |

| OpEn [179] | LMPC, Convex NMPC, Nonconvex NMPC | AGD | F |

| WORHP * [180] | LMPC, NMPC | SQP, IP | C |

| CPLEX [181] | LMPC, Convex NMPC | C | |

| CVXOPT [182] | LMPC, Convex NMPC | IP | F |

| KNITRO * [183] | LMPC, Convex NMPC, Nonconvex NMPC | IP, SQP | C |

| Mathworks MPC Toolbox * [184] | LMPC, NMPC | C | |

| FiOrdOs [185] | LMPC | FOM | F |

| APOPT [186] | LMPC, Convex NMPC | SQP | F |

| LOQO [187] | LMPC, Convex NMPC, Nonconvex NMPC | IP, SQP | C |

| OnRAMP (Honeywell) * | LMPC, Convex NMPC, Nonconvex NMPC | C | |

| YALMIP * [188] | LMPC, Convex NMPC, Nonconvex NMPC | IP, SQP | F |

| ACADO * [189] | LMPC, Convex NMPC, Nonconvex NMPC | IP, SQP | F |

| Supervisory SMPC | NMPC Feedforward | NMPC Feedback | |

|---|---|---|---|

| Average execution time [s] | 530 | 31 | 127 |

| Maximum execution time [s] | 550 | 32 | 133 |

| Maximum estimated ECU execution time [ms] | 5.6 | 0.33 | 1.5 |

| Number of decision variables | 17 | 18 | 18 |

| Number of hard constraints | 41 | 0 | 0 |

| Achievements | References |

|---|---|

| Fuel Saving (0.3 to 12%) | [26,28,29,34,35,36,47,52,54,135,136,137] |

| NOx reduction (up to 15%) | [26,28,30,41,45,47,135,137,145] |

| PM reduction (up to 11%) | [29,47,137] |

| HC reduction (10 to 15%) | [26] |

| Calibration effort reduction | [36,46,52,53] |

| Tracking improvement (up to 40%) | [21,22,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,108,136,137,138,139,140,141,142,143,144,147,148,149,150,151] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Norouzi, A.; Heidarifar, H.; Shahbakhti, M.; Koch, C.R.; Borhan, H. Model Predictive Control of Internal Combustion Engines: A Review and Future Directions. Energies 2021, 14, 6251. https://doi.org/10.3390/en14196251

Norouzi A, Heidarifar H, Shahbakhti M, Koch CR, Borhan H. Model Predictive Control of Internal Combustion Engines: A Review and Future Directions. Energies. 2021; 14(19):6251. https://doi.org/10.3390/en14196251

Chicago/Turabian StyleNorouzi, Armin, Hamed Heidarifar, Mahdi Shahbakhti, Charles Robert Koch, and Hoseinali Borhan. 2021. "Model Predictive Control of Internal Combustion Engines: A Review and Future Directions" Energies 14, no. 19: 6251. https://doi.org/10.3390/en14196251