Microalgae as Functional Ingredients in Savory Food Products: Application to Wheat Crackers

Abstract

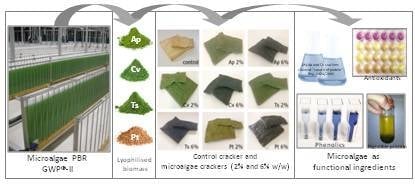

:1. Introduction

2. Materials and Methods

2.1. Microalgae Strains and Biomass Origin

2.2. Cracker Preparation

2.3. Cracker Analyses

2.3.1. Dimensions

2.3.2. Color Analysis

2.3.3. Texture analysis

2.3.4. Microscopy Analysis

2.3.5. Total Water Content and Water Activity (aw) Determination

2.3.6. Proximate Biochemical Composition Determination

2.3.7. Phenolics and Antioxidant Capacity Determination

2.3.8. In Vitro Digestibility Tests

2.3.9. Sensory Analysis

2.4. Statistical Analysis

3. Results and Discussion

3.1. Cracker Colour

3.2. Cracker Dimensions

3.3. Cracker Texture and Microstructure

3.4. Cracker Water Content and Water Activity

3.5. Cracker Proximate Biochemical Composition

3.6. Cracker Phenolic Content and Antioxidant Capacity

3.7. In Vitro Digestibility

3.8. Sensory Evaluation

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mordor Intelligence. Global Snack Food Market—Growth, Trends and Forecasts (2018–2023). 2017. Available online: https://www.mordorintelligence.com/industry-reports/snack-food-market (accessed on 18 January 2019).

- Technavio. Global Crackers Market 2017-SKU: IRTNTR14438. 2017. Available online: https://www.technavio.com/report/global-crackers-market (accessed on 19 April 2019).

- Maneerote, J.; Noomhorm, A.; Takhar, P.S. Optimization of processing conditions to reduce oil uptake and enhance physicochemical properties of deep fried rice crackers. LWT Food Sci. Technol. 2009, 42, 805–812. [Google Scholar] [CrossRef]

- Sedej, I.; Sakač, M.; Mandić, A.; Mišan, A.; Pestorić, M.; Šimurina, O.; Čanadanović-Brunet, J. Quality assessment of gluten-free crackers based on buckwheat flour. LWT Food Sci. Technol. 2011, 44, 694–699. [Google Scholar] [CrossRef]

- Han, J.; Janz, J.A.M.; Gerlat, M. Development of gluten-free cracker snacks using pulse flours and fractions. Food Res. Int. 2010, 43, 627–633. [Google Scholar] [CrossRef]

- Kweon, M.; Slade, L.; Levine, H.; Gannon, D. Cookie-versus Cracker-Baking—What’s the difference? Flour functionality requirements explored by SRC and alveography. Crit. Rev. Food Sci. 2014, 54, 115–138. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Hou, G.G.; Chen, Z. Whole grain saltine crackers: Formulation, processing, and quality improvements. Cereals Food World 2013, 58, 180–185. [Google Scholar] [CrossRef]

- Benjakul, S.; Karnjanapratum, S. Characteristics and nutritional value of whole wheat cracker fortified with tuna bone bio-calcium powder. Food Chem. 2018, 259, 181–187. [Google Scholar] [CrossRef]

- Howard, B.M.; McWatters, K.H.; Saalia, F.; Hashim, I. Formulation and evaluation of snack crackers made with peanut flour. Cereals Food World 2009, 54, 166–171. [Google Scholar]

- Wang, Y.; Zhang, M.; Mujumdar, A.S. Influence of green banana flour substitution for cassava starch on the nutrition, color, texture and sensory quality in two types of snacks. LWT Food Sci. Technol. 2012, 47, 175–182. [Google Scholar] [CrossRef]

- Schmidt, C.; Geweke, I.; Struck, S.; Zahn, S.; Rohm, H. Blackcurrant pomace from juice processing as partial flour substitute in savoury crackers: Dough characteristics and product properties. Int. J. Food Sci. Tech. 2018, 53, 237–245. [Google Scholar] [CrossRef]

- Gouveia, L.; Batista, A.P.; Sousa, I.; Raymundo, A.; Bandarra, N. Food Chemistry Research Developments; Nova Science Publishers, Inc.: Boca Raton, FL, USA, 2008; pp. 75–111. [Google Scholar]

- Batista, A.P.; Gouveia, L.; Bandarra, N.M.; Franco, J.M.; Raymundo, A. Comparison of microalgal biomass profiles as novel functional ingredient for food products. Algal Res. 2013, 2, 164–173. [Google Scholar] [CrossRef]

- Caporgno, M.P.; Mathys, A. Trends in microalgae incorporation into innovative food products with potential health benefits. Front. Nutr. 2018, 5, 58. [Google Scholar] [CrossRef] [PubMed]

- Gouveia, L.; Batista, A.P.; Miranda, A.; Empis, J.; Raymundo, A. Chlorella vulgaris biomass used as coloring source in traditional butter cookies. Innov. Food Sci. Emerg. 2007, 8, 433–436. [Google Scholar] [CrossRef]

- Gouveia, L.; Coutinho, C.; Mendonça, E.; Batista, A.P.; Sousa, I.; Bandarra, N.M.; Raymundo, A. Functional biscuits with PUFA-ω3 from Isochrysis galbana. J. Sci. Food Agric. 2008, 88, 891–896. [Google Scholar] [CrossRef]

- Batista, A.P.; Niccolai, A.; Fradinho, P.; Fragoso, S.; Bursic, I.; Rodolfi, L.; Biondi, N.; Tredici, M.R.; Sousa, I.; Raymundo, A. Microalgae biomass as an alternative ingredient in cookies: Sensory, physical and chemical properties, antioxidant activity and in vitro digestibility. Algal Res. 2017, 26, 161–171. [Google Scholar] [CrossRef]

- García-Segovia, P.; Pagan-Moreno, M.J.; Lara, I.F.; Martinez-Monzo, J. Effect of microalgae incorporation on physicochemical and textural properties in wheat bread formulation. Food Sci. Tech. Int. 2017, 23, 437–447. [Google Scholar] [CrossRef]

- Graça, C.; Fradinho, P.; Sousa, I.; Raymundo, A. Impact of Chlorella vulgaris on the rheology of wheat flour dough and bread texture. LWT Food Sci. Technol. 2018, 89, 466–474. [Google Scholar] [CrossRef]

- Fradique, M.; Batista, A.P.; Nunes, M.C.; Gouveia, L.; Bandarra, N.M.; Raymundo, A. Chlorella vulgaris and Spirulina maxima biomass incorporation in pasta products. J. Sci. Food Agric. 2010, 90, 1656–1664. [Google Scholar] [CrossRef]

- De Marco, E.R.; Steffolani, M.E.; Martínez, C.S.; León, A.E. Effects of Spirulina biomass on the technological and nutritional quality of bread wheat pasta. LWT Food Sci. Technol. 2014, 58, 102–108. [Google Scholar] [CrossRef]

- De Marco, E.R.; Steffolani, M.E.; Martinez, M.; Leon, A.E. The use of Nannochloropsis sp. as a source of omega-3 fatty acids in dry pasta: Chemical, technological and sensory evaluation. Int. J. Food Sci. Technol. 2017, 53, 499–507. [Google Scholar] [CrossRef]

- Lucas, B.F.; de Morais, M.G.; Santos, T.D.; Costa, J.A.V. Spirulina for snack enrichment: Nutritional, physical and sensory evaluations. LWT Food Sci. Technol. 2018, 90, 270–276. [Google Scholar] [CrossRef]

- Matos, J.; Cardoso, C.; Bandarra, N.M.; Afonso, C. Microalgae as healthy ingredients for functional food: A review. Food Funct. 2017, 8, 2672–2685. [Google Scholar] [CrossRef] [PubMed]

- Wells, M.L.; Potin, P.; Craigie, J.S.; Raven, J.A.; Merchant, S.S.; Helliwell, K.E.; Smith, A.G.; Camire, M.E.; Brawley, S.H. Algae as nutritional and functional food sources: Revisiting our understanding. J. Appl. Phycol. 2017, 29, 949–982. [Google Scholar] [CrossRef] [PubMed]

- Becker, E.W. Microalgae as a source of protein. Biotechnol. Adv. 2007, 25, 207–210. [Google Scholar] [CrossRef]

- Del Campo, J.A.; García-González, M.; Guerrero, M.G. Outdoor cultivation of microalgae for carotenoid production: Current state and perspectives. Appl. Microbiol. Biotechnol. 2007, 74, 1163–1174. [Google Scholar] [CrossRef] [PubMed]

- Tredici, M.R.; Biondi, N.; Ponis, E.; Rodolfi, L.; Chini Zittelli, G. New Technologies in Aquaculture: Improving Production Efficiency, Quality and Environmental Management; Woodhead Publishing: Cambridge, UK, 2009; pp. 610–676. [Google Scholar]

- Markets & Markets. Algae Products Market by Type, Application, Source, Form, and Region—Global Forecast to Report ID: 4521311. 2018. Available online: https://www.researchandmarkets.com/publication/me4to4g/ (accessed on 14 January 2019).

- Abdulqader, G.; Barsanti, L.; Tredici, M.R. Harvest of Arthrospira platensis from Lake Kossorom (Chad) and its household usage among the Kanembu. J. Appl. Phycol. 2000, 12, 493–498. [Google Scholar] [CrossRef]

- Carcea, M.; Sorto, M.; Batello, C.; Narducci, V.; Aguzzi, A.; Azzini, E.; Fantauzzi, P.; Finotti, E.; Gabrielli, P.; Galli, V.; et al. Nutritional characterization of traditional and improved dihé, alimentary blue-green algae from the lake Chad region in Africa. LWT Food Sci. Technol. 2015, 62, 753–763. [Google Scholar] [CrossRef]

- Kose, A.; Ozen, M.O.; Elibol, M.; Oncel, S.S. Investigation of in vitro digestibility of dietary microalga Chlorella vulgaris and cyanobacterium Spirulina platensis as a nutritional supplement. 3 Biotech 2017, 7, 170. [Google Scholar] [CrossRef]

- European Union. Regulation (EC) No 258/97 of the European Parliament and of the Council of 27 January 1997 concerning novel foods and novel food ingredients. Off. J. Eur. Union 1997, 43, 1–6. [Google Scholar]

- Kulshreshtha, A.; Jarouliya, U.; Bhadauriya, P.; Prasad, G.B.K.S.; Bisen, P.S. Spirulina in health care management. Curr. Pharm. Biotechnol. 2008, 9, 400–405. [Google Scholar] [CrossRef]

- Niccolai, A.; Shannon, E.; Abu-Ghannam, N.; Biondi, N.; Rodolfi, A.; Tredici, M.R. Lactic acid fermentation of Arthrospira platensis (spirulina) biomass for probiotic-based products. J. Appl. Phycol. 2019, 31, 1077–1083. [Google Scholar] [CrossRef]

- Bigagli, E.; Cinci, L.; Niccolai, A.; Tredici, M.R.; Biondi, N.; Rodolfi, L.; Lodovici, M.; D’ambrosio, M.; Mori, G.; Luceri, C. Safety evaluations and lipid-lowering activity of an Arthrospira platensis enriched diet: A 1-month study in rats. Food Res. Int. 2017, 102, 380–386. [Google Scholar] [CrossRef] [PubMed]

- Tabarsa, M.; Shin, I.S.; Lee, J.H.; Surayot, U.; Park, W.; You, S. An immune-enhancing water-soluble α-glucan from Chlorella vulgaris and structural characteristics. Food Sci. Biotechnol. 2015, 24, 1933–1941. [Google Scholar] [CrossRef]

- European Commission. 2014. Available online: https://ec.europa.eu/food/sites/food/files/safety/docs/novel-food_authorisation_2014_auth-letter_tetraselmis_chuii_en.pdf (accessed on 26 July 2018).

- Pérez-López, P.; González-García, S.; Ulloa, R.G.; Sineiro, J.; Feijoo, G.; Moreira, M.T. Life cycle assessment of the production of bioactive compounds from Tetraselmis suecica at pilot scale. J. Clean. Prod. 2014, 64, 323–331. [Google Scholar] [CrossRef]

- Kim, S.M.; Jung, Y.H.; Kwon, O.; Cha, K.H.; Um, B.H. A potential commercial source of fucoxanthin extracted from the microalga Phaeodactylum tricornutum. Appl. Biochem. Biotech. 2012, 166, 1843–1855. [Google Scholar] [CrossRef] [PubMed]

- Gammone, M.A.; D’Orazio, N. Anti-obesity activity of the marine carotenoid fucoxanthin. Mar. Drugs 2015, 13, 2196–2214. [Google Scholar] [CrossRef]

- European Commission. 2018. Available online: https://ec.europa.eu/food/sites/food/files/safety/docs/novel-food_sum_ongoing-app_epa-rich-oil.pdf (accessed on 11 February 2019).

- Niccolai, A.; Bigagli, E.; Biondi, N.; Rodolfi, L.; Cinci, L.; Luceri, C.; Tredici, M.R. In vitro toxicity of microalgal and cyanobacterial strains of interest as food source. J. Appl. Phycol. 2017, 29, 199–209. [Google Scholar] [CrossRef]

- Tredici, M.R.; Bassi, N.; Prussi, M.; Biondi, N.; Rodolfi, L.; Zittelli, G.C.; Sampietro, G. Energy balance of algal biomass production in a 1-ha “Green Wall Panel” plant: How to produce algal biomass in a closed reactor achieving a high net energy ratio. Appl. Energy. 2015, 154, 1103–1111. [Google Scholar] [CrossRef] [Green Version]

- Guillard, R.R.L.; Ryther, J.H. Studies of marine planktonic diatoms. I. Cyclotella nana Hustedt and Detonula confervacea Cleve. Can. J. Microbiol. 1962, 8, 229–239. [Google Scholar] [CrossRef]

- Zarrouk, C. Contribution à l’étude d’une cyanophycée. Influence de divers facteurs physiques et chimiques sur la croissance et la photosynthèse de Spirulina maxima (Setch et Gardner) Geitler. Ph.D. Thesis, Université de Paris, Paris, France, 1966. [Google Scholar]

- Abiusi, F.; Sampietro, G.; Marturano, G.; Biondi, N.; Rodolfi, L.; D’Ottavio, M.; Tredici, M.R. Growth, photosynthetic efficiency, and biochemical composition of Tetraselmis suecica F&M-M33 grown with LEDs of different colors. Biotechnol. Bioeng. 2014, 111, 956–964. [Google Scholar] [CrossRef]

- AOAC. Protein in Bread; AOAC Official Method 991; AOAC: Rockville, MD, USA, 1950. [Google Scholar]

- NP 4168. Cereais e derivados—Determinação do teor de matéria gorda total; Instituto Português da Qualidade: Lisboa, Portugal, 1991. [Google Scholar]

- AOAC. AOAC. AOAC Official Method 991.Total, Soluble and Insoluble Dietary Fiber in Foods. In Enzymatic-Gravymetric Method, MES-Tris Buffer; AOAC: Rockville, MD, USA, 1996. [Google Scholar]

- European Union. Regulation (EU) No 1169/2011 of the European Parliament and of the Council of 25 October 2011 on the provision of food information to consumers. Off. J. Eur. Union 2011, 54, 18–61. [Google Scholar]

- He, F.J.; Brinsden, H.C.; MacGregor, G.A. Salt reduction in the United Kingdom: A successful experiment in public health. J. Hum. Hypertens. 2014, 28, 345. [Google Scholar] [CrossRef] [PubMed]

- Ganesan, P.; Kumar, C.S.; Bhaskar, N. Antioxidant properties of methanol extract and its solvent fractions obtained from selected Indian red seaweeds. Bioresour. Technol. 2008, 99, 2717–2723. [Google Scholar] [CrossRef] [PubMed]

- Rajauria, G.; Jaiswal, A.K.; Abu-Ghannam, N.; Gupta, S. Antimicrobial, antioxidant and free radical-scavenging capacity of brown seaweed Himanthalia Elongata from western coast of Ireland. J. Food Biochem. 2013, 37, 322–335. [Google Scholar] [CrossRef]

- Niccolai, A.; Zittelli, G.C.; Rodolfi, L.; Biondi, N.; Tredici, M.R. Microalgae of interest as food source: Biochemical composition and digestibility. Algal Res. 2019, 42, 101617. [Google Scholar] [CrossRef]

- Lowry, O.H.; Rosebrough, N.J.; Farr, L.; Randall, R.J. Protein measurement with the folin phenol reagent. J. Biol. Chem. 1951, 193, 265–275. [Google Scholar]

- ISO. EN ISO Sensory Analysis; General Guidance for the Design of Test Rooms: Geneva, Switzerland, 2011. [Google Scholar]

- Davidson, I. Biscuit Baking Technology: Processing and Engineering Manual, 2nd ed.; Academic Press: Cambridge, MA, USA, 2016; pp. 37–96. [Google Scholar] [CrossRef]

- Gilbert-López, B.; Barranco, A.; Herrero, M.; Cifuentes, A.; Ibáñez, E. Development of new green processes for the recovery of bioactives from Phaeodactylum tricornutum. Food Res. Int. 2017, 99, 1056–1065. [Google Scholar] [CrossRef] [Green Version]

- Plaza, M.; Herrero, M.; Cifuentes, A.; Ibáñez, E. Innovative natural functional ingredients from microalgae. J. Agric. Food Chem. 2009, 57, 7159–7170. [Google Scholar] [CrossRef]

- Manohar, R.S.; Rao, P.H. Interrelationship between rheological characteristics of dough and quality of biscuits; use of elastic recovery of dough to predict biscuit quality. Food Res. Int. 2002, 35, 807–813. [Google Scholar] [CrossRef]

- Tunick, M.H.; Onwulata, C.I.; Thomas, A.E.; Phillips, J.G.; Mukhopadhyay, S.; Sheen, S.; Liu, C.K.; Latona, N.; Pimentel, M.R.; Cooke, P.H. Critical Evaluation of Crispy and Crunchy Textures: A Review. Int. J. Food Prop. 2013, 16, 949–963. [Google Scholar] [CrossRef] [Green Version]

- Bourne, M.C. Food Texture and Viscosity: Concept and Measurement, 2nd ed.; Academic Press: London, UK, 2002; pp. 107–291. [Google Scholar]

- Singh, P.; Singh, R.; Jha, A.; Rasane, P.; Gautam, A.K. Optimization of a process for high fibre and high protein biscuit. J. Food Sci. Technol. 2015, 52, 1394–1403. [Google Scholar] [CrossRef] [Green Version]

- Batista, A.P.; Nunes, M.C.; Gouveia, L.; Sousa, I.; Raymundo, A.; Cordobés, F.; Guerrero, A.; Franco, J.M. Microalgae biomass interaction in biopolymer gelled systems. Food Hydrocoll. 2011, 25, 817–825. [Google Scholar] [CrossRef] [Green Version]

- Peleg, M. A mathematical-model of crunchiness/crispness loss in breakfast cereals. J. Texture Stud. 1994, 25, 403–410. [Google Scholar] [CrossRef]

- Arimi, J.M.; Duggan, E.; O’Sullivan, M.; Lyng, J.G.; O’Riordan, E.D. Effect of water activity on the crispiness of a biscuit (Crackerbread): Mechanical and acoustic evaluation. Food Res. Int. 2010, 43, 1650–1655. [Google Scholar] [CrossRef]

- European Commission. Regulation (EC) N° 1924/2006 of the European Parliament and of the Council of 20 December 2006 on nutritions and health claims made on foods. Off. J. Eur. Union 2007, 12, 3–18. [Google Scholar]

- Bolanho, B.C.; Egea, M.B.; Jácome, A.L.M.; Campos, I.; Carvalho, J.C.M.; Danesia, E.D.G. Antioxidant and nutritional potential of cookies enriched with Spirulina platensis and sources of fibre. J. Food Nutr. Res. 2014, 53, 171–179. [Google Scholar]

- Santana-Casiano, J.M.; González-Dávila, M.; González, A.G.; Rico, M.; López, A.; Martel, A. Characterization of phenolic exudates from Phaeodactylum tricornutum and their effects on the chemistry of Fe(II)–Fe(III). Mar. Chem. 2014, 158, 10–16. [Google Scholar] [CrossRef]

- Banskota, A.H.; Sperker, S.; Stefanova, R.; McGinn, P.J.; O’Leary, S.J.B. Antioxidant properties and lipid composition of selected microalgae. J. Appl. Phycol. 2019, 31, 309–318. [Google Scholar] [CrossRef]

- Abraços, L.M.C. Estudo de ingredientes da Salvia sclareoides—Um contributo para o desenvolvimento de um novo suplemento alimentar. Master’s Thesis, Faculdade de Ciências da Universidade de Lisboa, Lisboa, Portugal, 2017. [Google Scholar]

- El-Baky, H.H.A.; El-Baroty, G.S.; Ibrahem, E.A. Functional characters evaluation of biscuits sublimated with pure phycocyanin isolated from Spirulina and Spirulina biomass. Nutr. Hosp. 2015, 32, 231–241. [Google Scholar] [CrossRef]

- Muys, M.; Sui, Y.; Schwaiger, B.; Lesueur, C.; Vandenheuvel, D.; Vermeir, P.; Vlaeminck, S.E. High variability in nutritional value and safety of commercially available Chlorella and Spirulina biomass indicates the need for smart production strategies. Bioresour. Technol. 2019, 275, 247–257. [Google Scholar] [CrossRef]

- Andersen, R.A. Handbook of Microalgal Culture: Applied Phycology and Biotechnology, 2nd ed.; Wiley: Oxford, UK, 2013; pp. 3–20. [Google Scholar]

- Fradique, M.; Batista, A.P.; Nunes, M.C.; Gouveia, L.; Bandarra, N.M.; Raymundo, A. Isochrysis galbana and Diacronema vlkianum biomass incorporation in pasta products as PUFA’s source. LWT Food Sci. Technol. 2013, 50, 312–319. [Google Scholar] [CrossRef] [Green Version]

| Biochemical Component | A. platensis F&M-C256 | C. vulgaris Allma | T. suecica F&M-M33 | P. tricornutum F&M-M40 |

|---|---|---|---|---|

| Protein (%) | 68.9 ± 1.0 | 56.8 ± 2.7 | 40.2 ± 0.5 | 38.8 ± 0.1 |

| Lipid (%) | 10.7 ± 0. 6 | 16.9 ± 2.8 | 28.5 ± 1.2 | 19.3 ± 1.7 |

| Carbohydrate (%) | 12.8 ± 0.2 | 5.9 ± 0.3 | 10.2 ± 0.2 | 11.0 ± 0.7 |

| Ash (%) | 6.1 ± 0.1 | 9.3 ± 1.5 | 15.7 ± 0.2 | 14.8 ± 0.1 |

| Sodium (%) | 0.6 ± 0.1 | 0.3 ± 0.2 | 2.1 ± 0.1 | 1.4 ± 0.2 |

| Product Designation | Brand G | Brand C | Brand I | Brand W | Brand T | Brand F |

|---|---|---|---|---|---|---|

| Product Description | Crackers with olive oil (6.6%) and sea salt | Crackers with extra virgin olive oil (5.4%) | Cracker italiani bio artigianali | Fette croccanti (crunchy slices) | Crackers with wheat flour and caramelized cereals on the surface (rice, wheat, and barley) | Rice crackers |

| Ingredients | Wheat flour, potato flour, olive oil (6.6%), sunflower oil, skimmed milk powder, potato starch, modified corn starch, glucose syrup, milk proteins, sea salt (2%), salt, and raising agent (ammonium hydrogen carbonate) | Wheat flour, extra virgin olive oil (5.4%), salt, brewer’s yeast, malt extract (wheat and barley), barley flour, malted barley flour, and acidity corrector (sodium acid carbonate) | Durum wheat semolina flour, extra virgin olive oil (13.5%), organic tomato extract, organic chili pepper extract, organic garlic extract, organic origan essential oil, and organic basil essential oil | Wholemeal rye flour (111g/100g), salt | Wheat flour (80.4%), palm fat, sugar, leveaning agents (amonium bicarbonate, calcium phosphates, and sodium bicarbonate), puffed rice (1.73%), salt, puffed wheat (0.23%), puffed barley (0.74%), crushed rice grains (0.51%), crushed integral wheat grains (0.23%), rice flour (0.04%), wheat gluten, wheat germen, powdered skimmed milk, wheat starch, and barley malt extract | Rice flour (91%), sugar, sunflower oil, antioxidant E320 (BHA), salt, powdered soy sauce (without gluten) (hydrolyzed grain), flavor enhancer E635 (disodium ribonucleotides), palm oil |

| Average nutritional values (100 g) | ||||||

| Energy | 1822 kJ | 1732 kJ | 1940 kJ | 1405 kJ | 1850 kJ | 1707 kJ |

| 433 kcal | 410 kcal | 461 kcal | 334 kcal | 440 kcal | 408 kcal | |

| Fat | 13.0 g | 6.3 g | 14.8 g | 1.5 g | 18.0 g | 3.8 g |

| (of which: saturated) | 2.3 g | 0.9 g | 1.9 g | 0.3 g | 8.4 g | 1.3 g |

| Carbohydrate | 67.5 g | 76.0 g | 69.0 g | 60.0 g | 60.0 g | 85.0 g |

| (of which: sugars) | 11.0 g | 2.0 g | 1.4 g | 2.0 g | 6.9 g | 4.9 g |

| Fiber | 5.0 g | 2.5 g | 3.6 g | 22.0 g | 3.3 g | - |

| Protein | 9.0 g | 11.0 g | 12.4 g | 9.0 g | 8.6 g | 7.1 g |

| Salt | 2.2 g | 1.8 g | 1.9 g | 1.0 g | 2.2 g | 1.2 g |

| Cracker Formulation | Width (W) (mm) | Thickness (T) (mm) | Spread Ratio (W/T) | Weight (g) | Density (g/cm3) | |

|---|---|---|---|---|---|---|

| Control | 52.9 ± 0.6 de | 4.5 ± 0.5 c | 11.9 ± 1.4 a | 5.8 ± 0.6 e | 0.48 ± 0.06 ab | |

| A. platensis | 2% | 52.5 ± 0.5 cde | 3.7 ± 0.2 ab | 14.2 ± 1.1 abc | 5.3 ± 0.3 de | 0.51 ± 0.05 a |

| 6% | 51.9 ± 0.6 abc | 3.8 ± 0.4 ab | 13.7 ± 1.6 abc | 4.7 ± 0.3 bcd | 0.47 ± 0.05 ab | |

| C. vulgaris | 2% | 52.7 ± 0.7 de | 4.0 ± 0.4 bc | 13.4 ± 1.3 ab | 5.2 ± 0.5 de | 0.48 ± 0.05 ab |

| 6% | 51.3 ± 0.7 a | 3.7 ± 0.3 ab | 13.7 ± 1.1 abc | 4.4 ± 0.4 ab | 0.45 ± 0.04 ab | |

| T. suecica | 2% | 52.5 ± 0.8 de | 3.8 ± 0.5 bc | 13.7 ± 1.7 ab | 5.0 ± 1.0 cde | 0.46 ± 0.05 ab |

| 6% | 51.8 ± 1.1 bcd | 3.6 ± 0.6 ab | 14.4 ± 2.0 bc | 4.3 ± 0.9 abc | 0.45 ± 0.03 b | |

| P. tricornutum | 2% | 53.3 ± 0.5 e | 4.2 ± 0.5 bc | 12.8 ± 1.6 ab | 5.5 ± 0.7 e | 0.47 ± 0.04 ab |

| 6% | 51.5 ± 0.9 ab | 3.5 ± 0.5 a | 15.0 ± 2.3 c | 3.8 ± 0.5 a | 0.43 ± 0.05 b | |

| Water Content (%, w/w) | Water Activity (aw) | ||||||

|---|---|---|---|---|---|---|---|

| Week 0 | Week 4 | Week 8 | Week 0 | Week 4 | Week 8 | ||

| Control | 3.7 ± 0.1 bc,x | 4.7 ± 0.2 c,y | 5.4 ± 0.3 cd,z | 0.128 ± 0.002 b,x | 0.206 ± 0.007 c,y | 0.362 ± 0.005 a,z | |

| A. platensis | 2% | 4.1 ± 0.1 bc,x | 5.1 ± 0.1 c,y | 6.0 ± 0.2 d,z | 0.155 ± 0.005 cd,x | 0.282 ± 0.001 d,y | 0.385 ± 0.004 b,z |

| 6% | 2.9 ± 0.8 abc,x | 3.7 ± 0.1 b,xy | 4.5 ± 0.1 bc,y | 0.081 ± 0.002 a,x | 0.176 ± 0.005 b,y | 0.270 ± 0.005 c,z | |

| C. vulgaris | 2% | 3.4 ± 0.5 abc,x | 4.8 ± 0.1 c,y | 4.5 ± 0.1 bc,y | 0.126 ± 0.001 b,x | 0.207 ± 0.013 c,y | 0.289 ± 0.005 d,z |

| 6% | 2.8 ± 0.2 ab,x | 4.9 ± 0.2 c,y | 5.9 ± 0.2 d,z | 0.081 ± 0.003 a,x | 0.259 ± 0.010 d,y | 0.385 ± 0.003 b,z | |

| T. suecica | 2% | 3.3 ± 0.6 abc,x | 6.2 ± 0.2 d,y | 7.7 ± 0.7 e,y | 0.145 ± 0.003 c,x | 0.385 ± 0.004 e,y | 0.516 ± 0.005 e,z |

| 6% | 2.9 ± 0.1 abc,x | 3.4 ± 0.2 b,x | 3.3 ± 0.3 ab,x | 0.121 ± 0.007 b,x | 0.162 ± 0.004 b,y | 0.171 ± 0.002 f,y | |

| P. tricornutum | 2% | 4.3 ± 0.1 c,x | 3.6 ± 0.1 b,y | 3.3 ± 0.2 ab,y | 0.159 ± 0.005 d,x | 0.127 ± 0.008 a,y | 0.120 ± 0.005 g,y |

| 6% | 2.1 ± 0.2 a,x | 2.6 ± 0.2 a,x | 2.5 ± 0.1 a,x | 0.069 ± 0.003 a,x | 0.106 ± 0.002 a,y | 0.100 ± 0.008 h,y | |

| Total Ash (g/100g dw) | Sodium (g/100g dw) | Crude Fat (g/100g dw) | Crude Protein (g/100g dw) | Total Dietary Fiber (g/100g dw) | Carbohydrates * (g/100g dw) | Energy Value (kcal/100g dw) | ||

|---|---|---|---|---|---|---|---|---|

| Control | 3.3 ± 0.5 a | 0.78 ± 0.07 a | 12.1 ± 0.8 a | 9.8 ± 0.4 a | 5.0 | 69.8 | 437 | |

| A. platensis | 2% | 3.4 ± 0.5 a | 0.73 ± 0.17 a | 12.5 ± 1.1 a | 11.0 ± 0.1 bc | 5.6 | 67.5 | 438 |

| 6% | 4.6 ± 0.5 ab | 0.86 ± 0.12 a | 12.9 ± 0.8 a | 14.3 ± 0.1 e | 6.7 | 61.5 | 433 | |

| C. vulgaris | 2% | 4.4 ± 0.3 ab | 0.80 ± 0.07 a | 11.5 ± 1.4 a | 11.4 ± 0.3 c | 5.1 | 67.6 | 430 |

| 6% | 4.8 ± 1.0 b | 0.82 ± 0.04 a | 12.3 ± 1.4 a | 14.6 ± 0.1 e | 5.7 | 62.6 | 431 | |

| T. suecica | 2% | 3.4 ± 0.1 ab | 0.78 ± 0.06 a | 13.1 ± 0.1 a | 10.4 ± 0.1 ab | 4.7 | 68.5 | 442 |

| 6% | 4.6 ± 0.1 ab | 1.06 ± 0.09 a | 12.6 ± 0.4 a | 12.8 ± 0.4 d | 4.4 | 65.6 | 436 | |

| P. tricornutum | 2% | 3.3 ± 0.1 a | 0.81 ± 0.11 a | 13.2 ± 0.2 a | 10.7 ± 0.1 bc | 5.8 | 67.1 | 441 |

| 6% | 4.3 ± 0.1 ab | 0.89 ± 0.08 a | 12.7 ± 0.4 a | 12.1 ± 0.1 d | 6.3 | 64.6 | 434 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Batista, A.P.; Niccolai, A.; Bursic, I.; Sousa, I.; Raymundo, A.; Rodolfi, L.; Biondi, N.; Tredici, M.R. Microalgae as Functional Ingredients in Savory Food Products: Application to Wheat Crackers. Foods 2019, 8, 611. https://doi.org/10.3390/foods8120611

Batista AP, Niccolai A, Bursic I, Sousa I, Raymundo A, Rodolfi L, Biondi N, Tredici MR. Microalgae as Functional Ingredients in Savory Food Products: Application to Wheat Crackers. Foods. 2019; 8(12):611. https://doi.org/10.3390/foods8120611

Chicago/Turabian StyleBatista, Ana Paula, Alberto Niccolai, Ivana Bursic, Isabel Sousa, Anabela Raymundo, Liliana Rodolfi, Natascia Biondi, and Mario R. Tredici. 2019. "Microalgae as Functional Ingredients in Savory Food Products: Application to Wheat Crackers" Foods 8, no. 12: 611. https://doi.org/10.3390/foods8120611