Grape Pomace Valorization: A Systematic Review and Meta-Analysis

Abstract

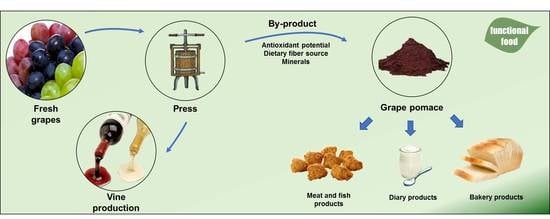

:1. Introduction

2. Search Strategy and Methodology

3. Proximate Composition of Grape Pomace

4. Studies about the Use of Grape Pomace as a Fortifying Agent

4.1. The Fortification of Plant Foodstuffs

4.2. The Fortification of Meat and Fish Products

4.3. The Fortification of Dairy Products

4.4. Meta-Analysis of TDF, TPC, and Color Characteristics of Fortified Products

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- FAOSTAT. Food and Agriculture Organization of the United Nations, 2018. Available online: http://www.fao.org/faostat/en/#data/QC (accessed on 31 July 2020).

- Sousa, E.C.; Uchôa-Thomaz, A.M.A.; Carioca, J.O.B.; Morais, S.M.D.; Lima, A.D.; Martins, C.G.; Alexandrino, C.D.; Ferreira, P.A.T.; Rodrigues, A.L.M.; Rodrigues, S.P.; et al. Chemical composition and bioactive compounds of grape pomace (Vitis vinifera L.), Benitaka variety, grown in the semiarid region of Northeast Brazil. Food Sci. Technol. 2014, 34, 135–142. [Google Scholar] [CrossRef] [Green Version]

- García-Lomillo, J.; González-SanJosé, M.L. Applications of wine pomace in the food industry: Approaches and functions. Compr. Rev. Food Sci. Food Saf. 2017, 16, 3–22. [Google Scholar] [CrossRef]

- Bender, A.B.; Speroni, C.S.; Salvador, P.R.; Loureiro, B.B.; Lovatto, N.M.; Goulart, F.R.; Lovatto, M.T.; Miranda, M.Z.; Silva, L.P.; Penna, N.G. Grape pomace skins and the effects of its inclusion in the technological properties of muffins. J. Culin. Sci. Technol. 2017, 15, 143–157. [Google Scholar] [CrossRef]

- Balbinoti, T.C.V.; Stafussa, A.P.; Haminiuk, C.W.I.; Maciel, G.M.; Sassaki, G.L.; Jorge, L.M.D.M.; Jorge, R.M.M. Addition of grape pomace in the hydration step of parboiling increases the antioxidant properties of rice. Int. J. Food Sci. Technol. 2020, 55, 2370–2380. [Google Scholar] [CrossRef]

- Dwyer, K.; Hosseinian, F.; Rod, M.R. The market potential of grape waste alternatives. J. Food Res. 2014, 3, 91. [Google Scholar] [CrossRef]

- Bustamante, M.A.; Moral, R.; Paredes, C.; Pérez-Espinosa, A.; Moreno-Caselles, J.; Pérez-Murcia, M.D. Agrochemical characterisation of the solid by-products and residues from the winery and distillery industry. Waste Manag. 2008, 28, 372–380. [Google Scholar] [CrossRef] [PubMed]

- Eleonora, N.; Dobrei, A.; Alina, D.; Bampidis, V.; Valeria, C. Grape pomace in sheep and dairy cows feeding. J. Hortic. For. Biotechnol. 2014, 18, 146–150. [Google Scholar]

- Bender, A.B.B.; Speroni, C.S.; Moro, K.I.B.; Morisso, F.D.P.; dos Santos, D.R.; da Silva, L.P.; Penna, N.G. Effects of micronization on dietary fiber composition, physicochemical properties, phenolic compounds, and antioxidant capacity of grape pomace and its dietary fiber concentrate. LWT 2020, 117, 108652. [Google Scholar] [CrossRef]

- Bennato, F.; Di Luca, A.; Martino, C.; Ianni, A.; Marone, E.; Grotta, L.; Ramazzotti, S.; Cichelli, A.; Martino, G. Influence of Grape Pomace Intake on Nutritional Value, Lipid Oxidation and Volatile Profile of Poultry Meat. Foods 2020, 9, 508. [Google Scholar] [CrossRef] [Green Version]

- Acun, S.; Gül, H. Effects of grape pomace and grape seed flours on cookie quality. Qual. Assur. Saf. Crop. Food 2014, 6, 81–88. [Google Scholar] [CrossRef]

- Beres, C.; Costa, G.N.; Cabezudo, I.; da Silva-James, N.K.; Teles, A.S.; Cruz, A.P.; Mellinger-Silva, C.; Tonon, R.V.; Cabral, L.M.; Freitas, S.P. Towards integral utilization of grape pomace from winemaking process: A review. Waste Manag. 2017, 68, 581–594. [Google Scholar] [CrossRef] [PubMed]

- Garrido, M.D.; Auqui, M.; Martí, N.; Linares, M.B. Effect of two different red grape pomace extracts obtained under different extraction systems on meat quality of pork burgers. Lwt-Food Sci. Technol. 2011, 44, 2238–2243. [Google Scholar] [CrossRef]

- Ianni, A.; Di Maio, G.; Pittia, P.; Grotta, L.; Perpetuini, G.; Tofalo, R.; Cichelli, A.; Martino, G. Chemical–nutritional quality and oxidative stability of milk and dairy products obtained from Friesian cows fed with a dietary supplementation of dried grape pomace. J. Sci. Food Agric. 2019, 99, 3635–3643. [Google Scholar] [CrossRef]

- Bekhit, A.E.D.A.; Cheng, V.J.; McConnell, M.; Zhao, J.H.; Sedcole, R.; Harrison, R. Antioxidant activities, sensory and anti-influenza activity of grape skin tea infusion. Food Chem. 2011, 129, 837–845. [Google Scholar] [CrossRef]

- Milinčić, D.D.; Kostić, A.Ž.; Špirović-Trifunović, B.D.; Tešić, Ž.L.; Tosti, T.B.; Dramićanin, A.M.; Barać, M.B.; Pešić, M.B. Grape seed flour of different grape pomaces: Fatty acid profile, soluble sugar profile and nutritional value. J. Serb. Chem. Soc. 2020, 85, 305–319. [Google Scholar] [CrossRef] [Green Version]

- Jin, Q.; O’Hair, J.; Stewart, A.C.; O’Keefe, S.F.; Neilson, A.P.; Kim, Y.-T.; McGuire, M.; Lee, A.; Wilder, G.; Huang, H. Compositional Characterization of Different Industrial White and Red Grape Pomaces in Virginia and the Potential Valorization of the Major Components. Foods 2019, 8, 667. [Google Scholar] [CrossRef] [Green Version]

- Mohamed Ahmed, I.A.; Özcan, M.M.; Al Juhaimi, F.; Babiker, E.F.E.; Ghafoor, K.; Banjanin, T.; Osman, M.A.; Gassem, M.A.; Alqah, H.A. Chemical composition, bioactive compounds, mineral contents, and fatty acid composition of pomace powder of different grape varieties. J. Food Process. Preserv. 2020, 44, e14539. [Google Scholar] [CrossRef]

- Cilli, L.P.; Contini, L.R.F.; Sinnecker, P.; Lopes, P.S.; Andreo, M.A.; Neiva, C.R.P.; Nascimento, M.S.; Yoshida, C.M.; Venturini, A.C. Effects of grape pomace flour on quality parameters of salmon burger. J. Food Process. Preserv. 2019, 44, e14329. [Google Scholar] [CrossRef]

- Theagarajan, R.; Malur Narayanaswamy, L.; Dutta, S.; Moses, J.A.; Chinnaswamy, A. Valorisation of grape pomace (cv. Muscat) for development of functional cookies. Int. J. Food Sci. Technol. 2019, 54, 1299–1305. [Google Scholar] [CrossRef]

- Šporin, M.; Avbelj, M.; Kovač, B.; Možina, S.S. Quality characteristics of wheat flour dough and bread containing grape pomace flour. Food Sci. Technol. Int. 2018, 24, 251–263. [Google Scholar] [CrossRef]

- Tseng, A.; Zhao, Y. Wine grape pomace as antioxidant dietary fibre for enhancing nutritional value and improving storability of yogurt and salad dressing. Food Chem. 2013, 138, 356–365. [Google Scholar] [CrossRef]

- Mildner-Szkudlarz, S.; Bajerska, J.; Zawirska-Wojtasiak, R.; Górecka, D. White grape pomace as a source of dietary fibre and polyphenols and its effect on physical and nutraceutical characteristics of wheat biscuits. J. Sci. Food Agric. 2013, 93, 389–395. [Google Scholar] [CrossRef] [PubMed]

- Nagarajaiah, S.B.; Prakash, J. Chemical composition and bioactivity of pomace from selected fruits. Int. J. Fruit Sci. 2016, 16, 423–443. [Google Scholar] [CrossRef]

- Deng, Q.; Penner, M.H.; Zhao, Y. Chemical composition of dietary fiber and polyphenols of five different varieties of wine grape pomace skins. Food Res. Int. 2011, 44, 2712–2720. [Google Scholar] [CrossRef]

- Llobera, A.; Cañellas, J. Antioxidant activity and dietary fibre of Prensal Blanc white grape (Vitis vinifera) by-products. Int. J. Food Sci. Technol. 2008, 43, 1953–1959. [Google Scholar] [CrossRef]

- Winkler, A.; Weber, F.; Ringseis, R.; Eder, K.; Dusel, G. Determination of polyphenol and crude nutrient content and nutrient digestibility of dried and ensiled white and red grape pomace cultivars. Arch. Anim. Nutr. 2015, 69, 187–200. [Google Scholar] [CrossRef]

- Anđelković, M.; Radovanović, B.; Milenković-Anđelković, A.; Radovanović, V.; Zarubica, A.; Stojković, N.; Nikolić, V. The determination of bioactive ingredients of grape pomace (Vranac variety) for potential use in food and pharmaceutical industries. Adv. Technol. 2015, 4, 32–36. [Google Scholar] [CrossRef] [Green Version]

- Rondeau, P.; Gambier, F.; Jolibert, F.; Brosse, N. Compositions and chemical variability of grape pomaces from French vineyard. Ind. Crop. Prod. 2013, 43, 251–254. [Google Scholar] [CrossRef]

- Javier, H.; Ángel, S.J.; Aida, G.; del Carmen, G.M.; de los Ángeles, M.M. Revalorization of grape marc waste from liqueur wine: Biomethanization. J. Chem. Technol. Biotechnol. 2019, 94, 1499–1508. [Google Scholar] [CrossRef]

- Kammerer, D.; Claus, A.; Carle, R.; Schieber, A. Polyphenol screening of pomace from red and white grape varieties (Vitis vinifera L.) by HPLC-DAD-MS/MS. J. Agric. Food Chem. 2004, 52, 4360–4367. [Google Scholar] [CrossRef]

- Averilla, J.N.; Oh, J.; Kim, H.J.; Kim, J.S.; Kim, J.S. Potential health benefits of phenolic compounds in grape processing by-products. Food Sci. Biotechnol. 2019, 28, 1607–1615. [Google Scholar] [CrossRef]

- Peixoto, C.M.; Dias, M.I.; Alves, M.J.; Calhelha, R.C.; Barros, L.; Pinho, S.P.; Ferreira, I.C. Grape pomace as a source of phenolic compounds and diverse bioactive properties. Food Chem. 2018, 253, 132–138. [Google Scholar] [CrossRef] [Green Version]

- Vital, A.C.P.; Santos, N.W.; Matumoto-Pintro, P.T.; da Silva Scapim, M.R.; Madrona, G.S. Ice cream supplemented with grape juice residue as a source of antioxidants. Int. J. Dairy Technol. 2018, 71, 183–189. [Google Scholar] [CrossRef]

- Antonic, B.; Jancikova, S.; Dordevic, D.; Tremlova, B. Apple pomace as food fortification ingredient: A systematic review and meta-analysis. J. Food Sci. 2020, 85, 2977–2985. [Google Scholar] [CrossRef]

- Zhao, B.; Gong, H.; Li, H.; Zhang, Y.; Lan, T.; Chen, Z. Characterization of Chinese grape seed oil by physicochemical properties, fatty acid composition, triacylglycerol profiles, and sterols and squalene composition. Int. J. Food Eng. 2019, 15, 15. [Google Scholar] [CrossRef]

- Wen, X.; Zhu, M.; Hu, R.; Zhao, J.; Chen, Z.; Li, J.; Ni, Y. Characterisation of seed oils from different grape cultivars grown in China. J. Food Sci. Technol. 2016, 53, 3129–3136. [Google Scholar] [CrossRef]

- Messina, C.M.; Manuguerra, S.; Catalano, G.; Arena, R.; Cocchi, M.; Morghese, M.; Montenegro, L.; Santulli, A. Green biotechnology for valorisation of residual biomasses in nutraceutic sector: Characterization and extraction of bioactive compounds from grape pomace and evaluation of the protective effects in vitro. Nat. Prod. Res. 2019, 1–6. [Google Scholar] [CrossRef]

- Visconti, A.; Perrone, G.; Cozzi, G.; Solfrizzo, M. Managing ochratoxin A risk in the grape-wine food chain. Food Addit. Contam. 2008, 25, 193–202. [Google Scholar] [CrossRef] [Green Version]

- Dachery, B.; Hernandes, K.C.; Veras, F.F.; Schmidt, L.; Augusti, P.R.; Manfroi, V.; Zini, C.A.; Welke, J.E. Effect of Aspergillus carbonarius on ochratoxin a levels, volatile profile and antioxidant activity of the grapes and respective wines. Food Res. Int. 2019, 126, 108687. [Google Scholar] [CrossRef]

- Khan, S.A.; Venancio, E.J.; Fernandes, E.V.; Hirooka, E.Y.; Oba, A.; Flaiban, K.K.; Itano, E.N. Low Doses of Ochratoxin-A Decrease IgY and IgA Production in Broiler Chicks. Toxins 2018, 10, 316. [Google Scholar] [CrossRef] [Green Version]

- Ribeiro, E.; Alves, A. Comparative study of screening methodologies for ochratoxin A detection in winery by-products. Anal. Bioanal. Chem. 2008, 391, 1443–1450. [Google Scholar] [CrossRef]

- Ortega-Heras, M.; Gómez, I.; de Pablos-Alcalde, S.; González-Sanjosé, M.L. Application of the Just-About-Right Scales in the Development of New Healthy Whole-Wheat Muffins by the Addition of a Product Obtained from White and Red Grape Pomace. Foods 2019, 8, 419. [Google Scholar] [CrossRef] [Green Version]

- Walker, R.; Tseng, A.; Cavender, G.; Ross, A.; Zhao, Y. Physicochemical, nutritional, and sensory qualities of wine grape pomace fortified baked goods. J. Food Sci. 2014, 79, S1811–S1822. [Google Scholar] [CrossRef]

- Mildner-Szkudlarz, S.; Zawirska-Wojtasiak, R.; Szwengiel, A.; Pacyński, M. Use of grape by-product as a source of dietary fibre and phenolic compounds in sourdough mixed rye bread. Int. J. Food Sci. Technol. 2011, 46, 1485–1493. [Google Scholar] [CrossRef]

- Hayta, M.; Özuğur, G.; Etgü, H.; Şeker, İ.T. Effect of Grape (Vitis Vinifera L.) Pomace on the Quality, Total Phenolic Content and Anti-Radical Activity of Bread. J. Food Process. Preserv. 2014, 38, 980–986. [Google Scholar] [CrossRef]

- Meral, R.; Doğan, İ.S. Grape seed as a functional food ingredient in bread-making. Int. J. Food Sci. Nutr. 2013, 64, 372–379. [Google Scholar] [CrossRef]

- Smith, I.N.; Yu, J. Nutritional and sensory quality of bread containing different quantities of grape pomace from different grape cultivars. Ec Nutr. 2015, 2, 291–301. [Google Scholar]

- Aksoylu, Z.; Çağindi, Ö.; Köse, E. Effects of blueberry, grape seed powder and poppy seed incorporation on physicochemical and sensory properties of biscuit. J. Food Qual. 2015, 38, 164–174. [Google Scholar] [CrossRef]

- Oliveira, D.M.; Marques, D.R.; Kwiatkowski, A.; Monteiro, A.R.G.; Clemente, E. Sensory analysis and chemical characterization of cereal enriched with grape peel and seed flour. Acta Sci. Technol. 2013, 35, 427–431. [Google Scholar] [CrossRef]

- Rosales Soto, M.U.; Brown, K.; Ross, C.F. Antioxidant activity and consumer acceptance of grape seed flour-containing food products. Int. J. Food Sci. Technol. 2012, 47, 592–602. [Google Scholar] [CrossRef]

- Marinelli, V.; Padalino, L.; Nardiello, D.; Del Nobile, M.A.; Conte, A. New approach to enrich pasta with polyphenols from grape marc. J. Chem. 2015, 2015, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Sant’Anna, V.; Christiano, F.D.P.; Marczak, L.D.F.; Tessaro, I.C.; Thys, R.C.S. The effect of the incorporation of grape marc powder in fettuccini pasta properties. Lwt-Food Sci. Technol. 2014, 58, 497–501. [Google Scholar] [CrossRef] [Green Version]

- Lavelli, V.; Harsha, P.S.; Torri, L.; Zeppa, G. Use of winemaking by-products as an ingredient for tomato puree: The effect of particle size on product quality. Food Chem. 2014, 152, 162–168. [Google Scholar] [CrossRef]

- Gaita, C.; Alexa, E.; Moigradean, D.; Poiana, A. Designing of high value-added pasta formulas by incorporation of grape pomace skins. Rom. Biotechnol. Lett. 2018, 25, 1607–1614. [Google Scholar] [CrossRef]

- Ferreira, V.; Fernandes, F.; Pinto-Carnide, O.; Valentão, P.; Falco, V.; Martín, J.P.; Ortiz, J.M.; Arroyo-García, R.; Andrade, P.B.; Castro, I. Identification of Vitis vinifera L. grape berry skin color mutants and polyphenolic profile. Food Chem. 2016, 194, 117–127. [Google Scholar] [CrossRef] [PubMed]

- Castillo-Muñoz, N.; Gómez-Alonso, S.; García-Romero, E.; Hermosín-Gutiérrez, I. Flavonol profiles of Vitis vinifera white grape cultivars. J. Food Compos. Anal. 2018, 23, 699–705. [Google Scholar] [CrossRef]

- Jung, J.; Cavender, G.; Zhao, Y. Impingement drying for preparing dried apple pomace flour and its fortification in bakery and meat products. J. Food Sci. Technol. 2015, 52, 5568–5578. [Google Scholar] [CrossRef]

- Ross, C.F.; Hoye, C., Jr.; Fernandez-Plotka, V.C. Influence of heating on the polyphenolic content and antioxidant activity of grape seed flour. J. Food Sci. 2011, 76, C884–C890. [Google Scholar] [CrossRef]

- Lee, H.J.; Lee, J.J.; Jung, M.O.; Choi, J.S.; Jung, J.T.; Choi, Y.I.; Lee, J.K. Meat Quality and Storage Characteristics of Pork Loin Marinated in Grape Pomace. Korean J. Food Sci. Anim. Resour. 2017, 37, 726. [Google Scholar] [CrossRef] [Green Version]

- Özvural, E.B.; Vural, H. Grape seed flour is a viable ingredient to improve the nutritional profile and reduce lipid oxidation of frankfurters. Meat Sci. 2011, 88, 179–183. [Google Scholar] [CrossRef]

- Ryu, K.S.; Shim, K.S.; Shin, D. Effect of grape pomace powder addition on TBARS and color of cooked pork sausages during storage. Korean J. Food Sci. Anim. Resour. 2014, 34, 200. [Google Scholar] [CrossRef] [Green Version]

- Selani, M.M.; Contreras-Castillo, C.J.; Shirahigue, L.D.; Gallo, C.R.; Plata-Oviedo, M.; Montes-Villanueva, N.D. Wine industry residues extracts as natural antioxidants in raw and cooked chicken meat during frozen storage. Meat Sci. 2011, 88, 397–403. [Google Scholar] [CrossRef] [PubMed]

- Özalp Özen, B.; Eren, M.; Pala, A.; Özmen, İ.; Soyer, A. Effect of plant extracts on lipid oxidation during frozen storage of minced fish muscle. Int. J. Food Sci. Technol. 2011, 46, 724–731. [Google Scholar] [CrossRef]

- Shirahigue, L.D.; Plata-Oviedo, M.; De Alencar, S.M.; D’Arce, M.A.B.R.; De Souza Vieira, T.M.F.; Oldoni, T.L.C.; Contreras-Castillo, C.J. Wine industry residue as antioxidant in cooked chicken meat. Int. J. Food Sci. Technol. 2010, 45, 863–870. [Google Scholar] [CrossRef]

- Rababah, T.M.; Ereifej, K.I.; Al-Mahasneh, M.A.; Al-Rababah, M.A. Effect of plant extracts on physicochemical properties of chicken breast meat cooked using conventional electric oven or microwave. Poult. Sci. 2006, 85, 148–154. [Google Scholar] [CrossRef]

- Sánchez-Alonso, I.; Jiménez-Escrig, A.; Saura-Calixto, F.; Borderías, A.J. Effect of grape antioxidant dietary fibre on the prevention of lipid oxidation in minced fish: Evaluation by different methodologies. Food Chem. 2007, 101, 372–378. [Google Scholar] [CrossRef]

- Frumento, D.; do Espirito Santo, A.P.; Aliakbarian, B.; Casazza, A.A.; Gallo, M.; Converti, A.; Perego, P. Development of milk fermented with Lactobacillus acidophilus fortified with Vitis vinifera marc flour. Food Technol. Biotechnol. 2013, 51, 370. [Google Scholar]

- Chouchouli, V.; Kalogeropoulos, N.; Konteles, S.J.; Karvela, E.; Makris, D.P.; Karathanos, V.T. Fortification of yoghurts with grape (Vitis vinifera) seed extracts. LWT-Food Sci. Technol. 2013, 53, 522–529. [Google Scholar] [CrossRef]

- Karaaslan, M.; Ozden, M.; Vardin, H.; Turkoglu, H. Phenolic fortification of yogurt using grape and callus extracts. Lwt-Food Sci. Technol. 2011, 44, 1065–1072. [Google Scholar] [CrossRef]

- Marchiani, R.; Bertolino, M.; Belviso, S.; Giordano, M.; Ghirardello, D.; Torri, L.; Piochi, M.; Zeppa, G. Yogurt enrichment with grape pomace: Effect of grape cultivar on physicochemical, microbiological and sensory properties. J. Food Qual. 2016, 39, 77–89. [Google Scholar] [CrossRef]

- Demirkol, M.; Tarakci, Z. Effect of grape (Vitis labrusca L.) pomace dried by different methods on physicochemical, microbiological and bioactive properties of yoghurt. LWT 2018, 97, 770–777. [Google Scholar] [CrossRef]

- Yadav, K.; Bajaj, R.K.; Mandal, S.; Saha, P.; Mann, B. Evaluation of total phenol content and antioxidant properties of encapsulated grape seed extract in yoghurt. Int. J. Dairy Technol. 2018, 71, 96–104. [Google Scholar] [CrossRef]

- Marchiani, R.; Bertolino, M.; Ghirardello, D.; McSweeney, P.L.; Zeppa, G. Physicochemical and nutritional qualities of grape pomace powder-fortified semi-hard cheeses. J. Food Sci. Technol. 2016, 53, 1585–1596. [Google Scholar] [CrossRef] [Green Version]

- Effects of Grape Seed Powder as a Functional Ingredient on Flour Physicochemical Characteristics and Dough Rheological Properties. Available online: http://ir.jkuat.ac.ke/handle/123456789/4234 (accessed on 20 February 2018).

| Compounds | Quantity g/100 g | Compounds | Quantity mg/100 g |

|---|---|---|---|

| Ash | 1.73–9.10 | Na | 87–244 |

| Protein | 3.57–14.17 | K | 1184–2718 |

| Fat | 1.14–13.90 | Mg | 92–644 |

| Total dietary fiber | 17.28–88.70 | Ca | 91–961 |

| Insoluble fiber | 16.44–63.70 | Mn | 6–1356 |

| Soluble fiber | 0.72–12.78 | Fe | 5–5468 |

| Carbohydrates | 12.20–40.53 | Zn | 2–2254 |

| TPC * | 0.28–8.70 | Cu | 39–130 |

| Fructose | 0.38–8.91 | P | 4–3157 |

| Glucose | 0.21–26.34 |

| Product | Conditions | Major Findings |

|---|---|---|

| Muffins, Bender et al. [4] | Replacement of wheat flour with 5, 7.5 and 10% of grape skin flour | ↑ Increased dietary fiber content and well accepted among the consumers ↓ Change in color and textural properties |

| Muffins, Ortega-Heras et al. [43] | Replacement of whole wheat flour with 10 and 20% of grape pomace | ↑ Increase dietary fiber content and good sensory acceptability ↓ Change in color and textural properties |

| Cookies, Theagarajan et al. [20] | Replacement of wheat flour with 2, 4, 6 and 8% of grape pomace | ↑ Increased polyphenolic content and lipid oxidation and textural stability during storage time ↓ Significant change in sensory properties |

| Bread, Sporin et al. [21] | Addition of 6, 10 and 15% of grape pomace based on the wheat flour content | ↑ Increased polyphenolic content and antioxidant activity ↓ Darker color |

| Bread, Walker et al. [44] | Replacement of wheat flour with 5 10 and 15% of grape pomace | ↑ Increased total phenolic content, radical scavenging activity and total dietary fiber ↓ Change in color, texture |

| Muffins, Walker et al. [44] | Replacement of up to 20% of flour with grape pomace | ↑ Increased total phenolic content, radical scavenging activity and total dietary fiber ↓ Change in color, texture |

| Brownie, Walker et al. [44] | Replacement of up to 25% of flour with grape pomace | ↑ Increased total phenolic content, radical scavenging activity and total dietary fiber ↓ Change in color, texture |

| Sourdough rye bread, Mildner-Szkudlarz et al. [45] | Addition of 4, 6, 8 and 10% of grape pomace to the bread mixture | ↑ Increased dietary fiber, total phenolic content and antioxidant activity ↓ Textural changes in the final product |

| Biscuits, Mildner-Szkudlarz et al. [23] | Replacement of wheat flour with 10, 20 and 30% of grape pomace | ↑ Increased dietary fiber, polyphenolic content and antioxidant activity ↓ Decreased hardness and change in color |

| Bread, Hayta et al. [46] | Replacement of flour with 2, 5 and 10% of grape pomace | ↑ Increased total phenolic content and anti-radical activity ↓ Increased hardness and darkness of the product |

| Bread, Meral and Dogan, [47] | Replacement of wheat flour with 2.5%, 5% and 7.5% of grape seed flour | ↑ Increased antioxidant activity and phenolic content. Improved rheological properties ↓ Change in color |

| Bread, Smith and Yu [48] | replacement of 5% and 10% of wheat flour with grape pomace | ↑ Increased antioxidant activity, total phenolic content and dietary fiber content. ↓ Reduced loaf volume, darker color, and harder texture |

| Biscuits, Aksoylu et al. [49] | Incorporation of 5% of grape seed powder into biscuit recipe | ↑ Increase of total phenolic content and antioxidant activity ↓ Darker color |

| Extruded cereals, Oliveira et al. [50] | Replacement of 10%, 15% and 20% of corn grits with grape skin and seed powder | ↑ Increase of total phenolic content and crude fibers ↓ Decrease in hardness |

| Cereal bars, noodles, pancakes, Rosales Soto et al. [51] | Incorporation of 5% to 30% of grape seed flour in product recipe | ↑ Increase of antioxidant activity and polyphenolic content |

| Pasta, Marinelli et al. [52] | Preparation of pasta using the grape pomace water extract | ↑ Increase of antioxidant activity and total phenolic content |

| Pasta, Sant’Anna et al. [53] | Addition of 2.5, 5 and 7.5% of grape pomace powder in fettuccine pasta preparation | ↑ Increase of antioxidant activity and total phenolic content ↓ Change in color |

| Tomato puree, Lavelli et al. [54] | Addition of 3.2% of grape skin powder to the tomato puree | ↑ Increase of antioxidant activity and total phenolic content |

| Tea infusions, Bekhit et al. [15] | Preparation of tea infusion out of grape skins | ↑ Refreshing sensory perception ↓ Weaker antioxidant activity in comparison to the other tea mixtures |

| Rice, Balbinoti et al. [5] | Addition of grape pomace flour in the process of parboiling of the rice, GP rice ratio 1:2 | ↑ Improving the antioxidant activity ↓ Change in color |

| Pasta, Gaita et al. [55] | Replacement of wheat flour with 3, 6 and 9% of grape skins flour | ↑ Increase of antioxidant activity total phenolic content; better sensory evaluation |

| Product | Conditions | Major Findings |

|---|---|---|

| Salmon burger, Cilli et al. [19] | Addition of 1 and 2% of grape pomace flour to the burger recipe | ↑ Increased dietary fiber content and storage stability ↓ Decrease in sensory properties |

| Pork loin marinade, Lee et al. [60] | Soaking of pork loin in 0.5, 1, 2, 20 and 40% grape pomace solution | ↑ Inhibits the lipid oxidation and microorganisms growth |

| Pork burger, Garrido et al. [13] | Addition of 0.06% of grape pomace extract to the product weight | ↑ Inhibition of lipid oxidation and enhanced color stability |

| Frankfurters, Özvural and Vural [61] | Addition of up to 0.5% of grape seed extract to the recipe | ↑ Decreased lipid oxidation ↓ Change in sensory and textural properties |

| Pork sausages, Ryu et al. [62] | Incorporation of 0.5 and 1% of grape pomace into the recipe | ↑ Decreased lipid oxidation ↓ Change in color |

| Chicken meat, Selani et al. [63] | Addition of grape pomace extract to achieve TPC 60 mg/kg in meat | ↑ Decreased lipid oxidation in raw and cooked meat. ↓ Change in color and flavor |

| Minced fish, Ozalp et al. [64] | Addition of 2% of grape seed extract to the minced fish muscle | ↑ Decreased lipid oxidation ↓ Change in color |

| Chicken meat, Shirahigue et al. [65] | Addition of grape pomace extract to achieve 10, 20, 40 and 60 mg/kg TPC in meat | ↑ Decreased lipid oxidation |

| Chicken meat, Rababah et al. [66] | Soaking of chicken breasts in 0.25% grape pomace extract | ↑ Decreased lipid oxidation, improved texture properties |

| Minced fish muscle, Sánchez-Alonso et al. [67] | Addition of 2 and 4% of grape pomace to the minced fish muscle | ↑ Decreased lipid oxidation during storage, increased antioxidant activity |

| Product | Conditions | Major Findings |

|---|---|---|

| Fermented milk, Frumento et al. [68] | Addition of 20 g/L of grape pomace to the milk base | ↑ Increase of antioxidant activity and phenolic content, and accelerated fermentation |

| Yogurt, Chouchouli et al. [69] | Addition of 100mg of dry seed extract in 150 mL of milk | ↑ Increase of antioxidant activity and total phenolic content ↓ Change in color |

| Yogurt, Karaaslan et al. [70] | Addition of 1% of grape pomace extract to yogurt formulation | ↑ Increase of antioxidant activity and total phenolic content |

| Yogurt, Marchiani et al. [71] | Addition of 6% of grape skin flour to yogurt formulation | ↑ Increase of antioxidant activity and total phenolic content ↓ Decreased liking among the consumers |

| Yogurt, Demirkol et al. [72] | Addition of 1, 3 and 5% of grape pomace to the milk before the fermentation | ↑ Increased polyphenolic content and antioxidant activity. Sensory acceptable products. ↓ Decreased viscosity |

| Yogurt, Yadav et al. [73] | Addition of 1% of grape seed extract to the milk before the fermentation | ↑ Increased total phenolic content and antioxidant capacity ↓ Change in color |

| Yogurt and salad dressing, Tseng et al. [22] | Addition of 1, 2 and 3% of grape pomace to the yogurt product | ↑ Increased polyphenolic content and antioxidant activity ↓ Darker product |

| Cheese, Marchiani et al. [74] | Incorporation of 0.8 and 1.6% of grape pomace into cheese formulation | ↑ Increase of antioxidant activity and total phenolic content |

| Ice cream, Vital et al. [34] | Addition of 2.5, 5 and 10% of grape pomace to the ice cream formulation | ↑ Increase of antioxidant activity total phenolic content |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Antonić, B.; Jančíková, S.; Dordević, D.; Tremlová, B. Grape Pomace Valorization: A Systematic Review and Meta-Analysis. Foods 2020, 9, 1627. https://doi.org/10.3390/foods9111627

Antonić B, Jančíková S, Dordević D, Tremlová B. Grape Pomace Valorization: A Systematic Review and Meta-Analysis. Foods. 2020; 9(11):1627. https://doi.org/10.3390/foods9111627

Chicago/Turabian StyleAntonić, Bojan, Simona Jančíková, Dani Dordević, and Bohuslava Tremlová. 2020. "Grape Pomace Valorization: A Systematic Review and Meta-Analysis" Foods 9, no. 11: 1627. https://doi.org/10.3390/foods9111627