Cryostructuring of Polymeric Systems. 55. Retrospective View on the More than 40 Years of Studies Performed in the A.N.Nesmeyanov Institute of Organoelement Compounds with Respect of the Cryostructuring Processes in Polymeric Systems

Abstract

:1. Introduction

2. Short Historical Remarks

3. The Main Effects and Trends Characteristic of the Cryostructuring Processes

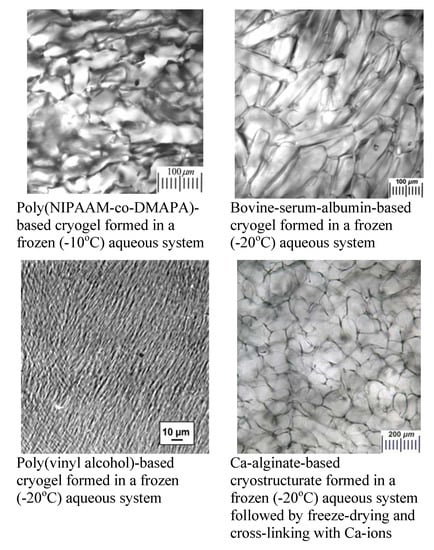

3.1. Specifics of the Macroporous Morphology of Polymeric Cryogels and Cryostructurates

3.2. Some Peculiarities of the Mechanisms of the Cryostructuring Processes in Different Polymeric Systems and the Influence of These Peculiarities on the Physico-Chemical Properties of the Resulting Cryogels and Cryostructurates

3.3. Filled (Composite) Cryogels and Cryostructurates

4. Applied Potential of Some Cryogenically-Structured Polymeric Materials Developed in the IOEC

4.1. Food-Related Systems

4.2. Cryogenically-Structured Materials of Biotechnological Purposes

4.3. Polymeric Cryogels and Cryostructurates of Biomedical Interests

4.4. Polymeric Cryogels and Cryostructurates as Technical Materials

5. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Available online: https://apps.webofknowledge.com/Search.do?product=UA&SID=E43ITX9UlkSonrz2QrP&search_mode=GeneralSearch&prID=45dc4303-5728-41fc-8784-2d027837d63c (accessed on 7 September 2020).

- Lozinsky, V.I. Cryostructuring of polymer systems. 50. Cryogels and cryotropic gel-formation: Terms and definitions. Gels 2018, 4, 77. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rogers, Z.J.; Bencherif, S.A. Cryogelation and Cryogels. Gels 2019, 5, 46. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lawrence, R.; Consolacion, F.; Jelen, P. Formation of structured protein foods by freeze texturization. Food Technol. 1986, 40, 77–90. [Google Scholar]

- Lozinsky, V.I. Cryogels on the basis of natural and synthetic polymers: Preparation, properties and areas of implementation. Russ. Chem. Rev. 2002, 71, 489–511. [Google Scholar] [CrossRef]

- Zhang, H.; Cooper, A.I. Aligned porous structures by directional freezing. Adv. Mater. 2007, 19, 1529–1533. [Google Scholar] [CrossRef]

- Gutiérrez, M.C.; Ferrer, M.L.; del Monte, F. Ice-templated materials: Sophisticated structures exhibiting enhanced functionalities obtained after unidirectional freezing and ice-segregation-induced self-assembly. Chem. Mater. 2008, 20, 634–648. [Google Scholar] [CrossRef]

- Qian, L.; Zhang, H. Controlled freezing and freeze drying: A versatile route for porous and micro-/nano-structured materials. J. Chem. Technol. Biotechnol. 2011, 86, 172–184. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Okay, O. Basic principles of cryotropic gelation. Adv. Polym. Sci. 2014, 263, 49–102. [Google Scholar] [CrossRef]

- Okay, O.; Lozinsky, V.I. Synthesis, structure-property relationships of cryogels. Adv. Polym. Sci. 2014, 263, 103–157. [Google Scholar] [CrossRef]

- Cheng, Q.; Huang, C.; Antoni, P.; Tomsia, A.P. Freeze casting for assembling bioinspired structural materials. Adv. Mater. 2017, 29, 1703155. [Google Scholar] [CrossRef]

- Okay, O. (Ed.) Polymeric Cryogels: Macroporous Gels with Remarkable Properties; Springer: Cham, Switzerland, 2014; 330p, ISBN 978-3-319-05845-0. [Google Scholar]

- Kumar, A. (Ed.) Supermacroporous Cryogels: Biomedical and Biotechnological Applications; CRC Press: Boca Raton, FL, USA; Taylor & Francis Group: Abingdon, UK, 2016; 480p, ISBN 978-1-4822-281-6. [Google Scholar]

- Nambu, M. Rubber-like poly(vinyl alcohol) gel. Kobunshi Ronbunshu 1990, 47, 695–703. (In Japanese) [Google Scholar] [CrossRef]

- Peppas, N.A.; Stauffer, S.R. Reinforced uncrosslinked poly (vinyl alcohol) gels produced by cyclic freezing-thawing processes: A short review. J. Control Release 1991, 16, 305–310. [Google Scholar] [CrossRef]

- Lozinsky, V.I. Cryotropic gelation of poly(vinyl alcohol) solutions. Russ. Chem. Rev. 1998, 67, 573–586. [Google Scholar] [CrossRef]

- Hassan, C.M.; Peppas, N.A. Structure and applications of poly(vinyl alcohol) hydrogels produced by conventional crosslinking or by freezing/thawing methods. Adv. Polym. Sci. 2000, 153, 37–65. [Google Scholar] [CrossRef]

- Kumakura, M. Preparation method of porous polymer materials by radiatation technique and its application. Polym. Adv. Technol. 2001, 12, 415–421. [Google Scholar] [CrossRef]

- Plieva, F.M.; Galaev, I.Y.; Mattiasson, B. Macroporous polysaccharide gels. In Macroporous Polymers: Production, Properties and Biotechnological/Biomedical Applications; Mattiasson, B., Kumar, A., Galaev, I.Y., Eds.; CRC Press: Boca Raton, FL, USA; Taylor & Francis Group: Abingdon, UK, 2010; pp. 131–154. ISBN 978-1-4200-8561-0. [Google Scholar]

- Kumar, A.; Mishra, R.; Reinwald, Y.; Bhat, S. Cryogels: Freezing unveiled by thawing. Mater. Today 2010, 13, 42–44. [Google Scholar] [CrossRef]

- Kirsebom, H.; Mattiasson, B. Cryostructuration as a tool for preparing highly porous polymer materials. Polym. Chem. 2011, 2, 1059–1062. [Google Scholar] [CrossRef]

- Gun’ko, V.M.; Savina, I.N.; Mikhalovsky, S.V. Cryogels: Morphological, structural and adsorption characterization. Adv. Colloid Interface Sci. 2013, 187–188, 1–46. [Google Scholar] [CrossRef] [Green Version]

- Geidobler, R.; Winter, G. Controlled ice nucleation in the field of freeze-drying: Fundamentals and technology review. Eur. J. Pharm. Biopharm. 2013, 85, 214–222. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, F.; Wu, J. Physically crosslinked hydrogels from polysaccharides prepared by freeze-thaw technique. React. Funct. Polym. 2013, 73, 923–928. [Google Scholar] [CrossRef]

- Tanthapanichakoon, W.; Tamon, H.; Nakagawa, K.; Charinpanitkul, T. Synthesis of porous materials and their microstructural control through ice templating. Eng. J. 2013, 3, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Lozinsky, V.I. A breif history of polymeric cryogels. Adv. Polym. Sci. 2014, 263, 1–48. [Google Scholar] [CrossRef]

- De Rosa, C.; Auriemma, F.; Girolamo, R.D. Kinetic analysis of cryotropic gelation of poly(vinyl alcohol)/water solutions by small-angle neutron scattering. Adv. Polym. Sci. 2014, 263, 159–197. [Google Scholar] [CrossRef]

- Petrov, P.D.; Tsvetanov, C.B. Cryogels via UV irradiation technique. Adv. Polym. Sci. 2014, 263, 199–222. [Google Scholar] [CrossRef]

- Shlyakhtin, O.A. Inorganic cryogels. Adv. Polym. Sci. 2014, 263, 222–244. [Google Scholar] [CrossRef]

- Liu, C.; Tong, G.; Chen, C.; Tan, Z.; Quan, C.; Zhang, C. Polymeric cryogel: Preparation, properties and biomedical applications. Progr. Chem. 2014, 26, 1190–1201. (In Chinese) [Google Scholar] [CrossRef]

- Carvalho, B.M.A.; Da Silva, S.L.; Da Silva, L.H.M.; Minim, V.P.R.; Da Silva, M.C.H.; Carvalho, L.M.; Minim, L.A. Cryogel poly(acrylamide): Synthesis, structure and applications. Sep. Purif. Rev. 2014, 43, 241–262. [Google Scholar] [CrossRef]

- Reichelt, S.; Becher, J.; Weisser, J.; Prager, A.; Decker, U.; Möller, S.; Berg, A.; Schnabelrauch, M. Biocompatible polysaccharide-based cryogels. Mater. Sci. Eng. C 2014, 35, 164–170. [Google Scholar] [CrossRef]

- Dragan, E.S. Design and applications of interpenetrating polymer network hydrogels. Chem. Eng. J. 2014, 243, 572–590. [Google Scholar] [CrossRef]

- Dragan, E.S. Advances in interpenetrating polymer network hydrogels and their applications. Pure Appl. Chem. 2014, 86, 1707–1721. [Google Scholar] [CrossRef]

- Reichelt, S. Introduction to macroporous cryogels. Methods Mol. Biol. 2015, 1286, 173–181. [Google Scholar] [CrossRef]

- Soykeabkaew, N.; Thamomsilp, C.; Suwantong, O. A review: Starch-based composite foams. Compos. Part A Appl. Sci. Manuf. 2015, 78, 246–263. [Google Scholar] [CrossRef]

- Suzuki, A.; Sasaki, S. Swelling and mechanical properties of physically crosslinked poly(vinyl alcohol) hydrogels. J. Eng. Med. 2015, 229, 828–844. [Google Scholar] [CrossRef] [PubMed]

- Hasan, S.M.; Nash, L.D.; Duncan, J.; Maitland, D.J. Porous shape memory polymers: Design and applications. J. Polym. Sci. Part B Polym. Phys. 2016, 54, 1300–1318. [Google Scholar] [CrossRef] [Green Version]

- Karimi, A.; Daud, W.M.A.W. Materials, preparation, and characterization of PVA/MMT nanocomposite hydrogels: A review. Polym. Compos. 2017, 38, 1086–1102. [Google Scholar] [CrossRef]

- Jiang, S.; Agarwal, S.; Greiner, A. Low-density open cellular sponges as functional materials. Angew. Chem. Int. Ed. 2017, 56, 15520–15538. [Google Scholar] [CrossRef]

- Racine, L.; Texier, I.; Auzély-Velty, R. Chitosan-based hydrogels: Recent design concepts to tailor properties and functions. Polym. Int. 2017, 66, 981–998. [Google Scholar] [CrossRef]

- Sano, K.; Ishida, Y.; Aida, T. Synthesis of anisotropic hydrogels and their applications. Angew. Chem. Int. Ed. 2018, 57, 2532–2543. [Google Scholar] [CrossRef]

- Gurikov, P.; Smirnova, I. Non-conventional methods for gelation of alginates. Gels 2018, 4, 14. [Google Scholar] [CrossRef] [Green Version]

- Budtova, T. Cellulose II aerogels: A review. Cellulose 2019, 26, 81–121. [Google Scholar] [CrossRef]

- Tripathi, A.; Melo, J.S. Cryostructurization of polymeric systems for developing macroporous cryogel as a foundational framework in bioengineering applications. J. Chem. Sci. 2019, 131, 92. [Google Scholar] [CrossRef] [Green Version]

- Moradi, Z.; Kalapour, N. Kefaran, a branched polysaccharide: Preparation, properties and applications: A review. Carbohydr. Polym. 2019, 223, 115100. [Google Scholar] [CrossRef] [PubMed]

- Dragan, E.S.; Dinu, M.D. Advances in porous chitosan-based composite hydrogels: Synthesis and applications. React. Funct. Polym. 2020, 146, 104372. [Google Scholar] [CrossRef]

- Kaetsu, I. Radiation synthesis of polymeric materials for biomedical and biochemical applications. Adv. Polym. Sci. 1993, 105, 81–97. [Google Scholar] [CrossRef]

- Suzuki, M.; Hirasa, O. An approach to artificial muscle using polymer gels formed by micro-phase separation. Adv. Polym. Sci. 1993, 110, 241–261. [Google Scholar] [CrossRef]

- Tomasik, P.; Zaranyika, M.F. Nonconventional methods of modification of starch. Adv. Carbohydr. Chem. Biochem. 1995, 51, 243–318. [Google Scholar] [CrossRef] [PubMed]

- Lazzeri, L. Progress in bioartificial polymeric materials. Trends Polym. Sci. 1996, 4, 249–252. [Google Scholar]

- Langer, R.; Peppas, N.A. Advances in biomaterials, drug delivery, and bionanotechnology. AIChE J. 2003, 49, 2990–3006. [Google Scholar] [CrossRef]

- Jugur-Grodzinski, J. Polymers for tissue engineering, medical devices, and regenerative medicine: Concise general review of recent studies. Polym. Adv. Technol. 2006, 17, 395–418. [Google Scholar] [CrossRef]

- Shoichet, M.S. Polymer scaffolds for biomaterials applications. Macromolecules 2010, 43, 581–591. [Google Scholar] [CrossRef]

- Van Vierberghe, S.; Dubruel, P.; Schacht, E. Biopolymer-based hydrogels as scaffolds for tissue engineering applications: A review. Biomacromolecules 2011, 12, 1387–1408. [Google Scholar] [CrossRef] [PubMed]

- Alves, M.H.; Jensen, B.E.B.; Smith, A.A.A.; Zelikin, A.N. Poly(vinyl alcohol) physical hydrogels: New vista on a long serving biomaterial. Macromol. Biosci. 2011, 11, 1293–1313. [Google Scholar] [CrossRef] [PubMed]

- Muzzarelli, R.A.A.; Greco, F.; Busulacchi, A.; Sollazo, V. Chitosan, hyaluronan and chodroitin sulfate in tissue engineering for cartilage regeneration: A review. Carbohydr. Polym. 2012, 89, 723–739. [Google Scholar] [CrossRef]

- Croisier, F.; Jérôme, C. Chitosan-based biomaterials for tissue engineering. Eur. Polym. J. 2013, 49, 780–792. [Google Scholar] [CrossRef] [Green Version]

- Henderson, T.M.A.; Ladewig, K.; Haylock, D.N.; McLean, K.M.; O’Connor, A.J. Cryogels for biomedical applications. J. Mater. Chem. B 2013, 1, 2682–2695. [Google Scholar] [CrossRef]

- Wan, W.; Bannerman, A.D.; Yang, L.; Mak, H. Poly(vinyl alcohol) cryogels for biomedical applications. Adv. Polym. Sci. 2014, 263, 283–321. [Google Scholar] [CrossRef]

- Rose, J.B.; Pacelli, S.; El Haj, A.J.; Dua, H.S.; Hopkinson, A.; White, L.J.; Rose, F.R.A.J. Gelatin-based materials in ocular tissue engineering. Materials 2014, 7, 3106–3135. [Google Scholar] [CrossRef] [Green Version]

- Qi, C.; Yan, X.; Huang, C.; Melerzanov, A.; Du, Y. Biomaterials as carrier, barrier and reactor for cell-based regenerative medicine. Protein Cell 2015, 6, 638–653. [Google Scholar] [CrossRef] [Green Version]

- Hixon, K.R.; Lu, T.; Sell, S.A. A comprehensive review of cryogels and their roles in tissue engineering applications. Acta Biomater. 2017, 62, 29–41. [Google Scholar] [CrossRef]

- Shakya, A.R.; Kandalam, U. Three-dimensional macroporous materials for tissue engineering of craniofacial bone. Brit. J. Oral Maxillofac. Surg. 2017, 55, 875–891. [Google Scholar] [CrossRef]

- Timofejeva, A.; D’Este, M.; Loca, D. Calcium phosphate/polyvinyl alcohol composite hydrogels: A review on the freeze-thaw synthesis approach and applications in regenerative medicine. Eur. Polym. J. 2017, 95, 547–565. [Google Scholar] [CrossRef]

- Lozinsky, V.I. Cryostructuring of polymeric systems as a tool for the creation of innovative materials of biomedical purposes. In Synthesis and Functional Properties of Hydrid Nanoforms of Bioactive and Drug Substances; Melnikov, M.Y., Trakhtenberg, L.I., Eds.; Tekhnosfera Publishing House: Moscow, Russia, 2019; Chapter 3; pp. 68–100. ISBN 978-5-94836-561_3. (In Russian) [Google Scholar]

- Rodionov, I.A.; Sinitskaya, E.S.; Ivanov, R.V.; Tsiskarashvili, A.V.; Lozinsky, V.I. Proteinaceous cryogels and cryostructurates. In Synthesis and Functional Properties of Hydrid Nanoforms of Bioactive and Drug Substances; Melnikov, M.Y., Trakhtenberg, L.I., Eds.; Tekhnosfera Publishing House: Moscow, Russia, 2019; Chapter 4; pp. 101–135. ISBN 978-5-94836-561_4. (In Russian) [Google Scholar]

- Shabatina, T.I.; Vernaya, O.I.; Nuzhdina, A.V.; Shabatin, V.P.; Semenov, A.M.; Lozinsky, V.I.; Melnikov, M.Y. Hybrid nanoforms of antibacterial substances with metallic nanoparticles entrapped in the cryostuctured biopolymeric matices for target delivery. In Synthesis and Functional Properties of Hydrid Nanoforms of Bioactive and Drug Substances; Melnikov, M.Y., Trakhtenberg, L.I., Eds.; Tekhnosfera Publishing House: Moscow, Russia, 2019; Chapter 5; pp. 136–159. ISBN 978-5-94836-561_5. (In Russian) [Google Scholar]

- Kumar, A.; Han, S.S. PVA-based hydrogels for tissue engineering: A review. Int. J. Polym. Mater. Polym. Biomater. 2017, 66, 159–182. [Google Scholar] [CrossRef]

- Zarrintaj, P.; Manouchehria, S.; Ahmadib, Z.; Saeb, M.R.; Urbanska, A.M.; Kaplan, D.L.; Mozafari, M. Agarose-based biomaterials for tissue engineering. Carbohydr. Polym. 2018, 187, 66–84. [Google Scholar] [CrossRef] [PubMed]

- Mahumane, G.D.; Kumar, P.; du Toit, L.C.; Choonara, Y.E.; Pillay, V. 3D scaffolds for brain tissue regeneration: Architectural challenges. Biomater. Sci. 2018, 6, 2812–2837. [Google Scholar] [CrossRef]

- Wubneh, A.; Tsekoura, E.K.; Ayranci, C.; Uludağ, H. Current state of fabrication technologies and materials for bone tissue engineering. Acta Biomater. 2018, 80, 1–30. [Google Scholar] [CrossRef]

- Li, P.; Yang, Z.; Jiang, S. Tissue mimicking materials in image-guided needle-based interventions: A review. Mater. Sci. Eng. C 2018, 93, 1116–1131. [Google Scholar] [CrossRef]

- Minden-Birkenmaier, D.A.; Bowlin, G.L. Honey-based templates in wound healing and tissue engineering. Bioengineering 2018, 5, 46. [Google Scholar] [CrossRef] [Green Version]

- Teodorescu, M.; Bercea, M.; Morariu, S. Biomaterials of poly(vinyl alcohol) and natural polymers. Polym. Rev. 2018, 58, 247–287. [Google Scholar] [CrossRef]

- Teodorescu, M.; Bercea, M.; Morariu, S. Biomaterials of PVA and PVP in medical and pharmaceutical applications: Perspectives and challenges. Biotechnol. Adv. 2019, 37, 109–131. [Google Scholar] [CrossRef]

- Razavi, M.; Qiao, Y.; Thakor, A.S. Three-dimensional cryogels for biomedical applications. J. Biomed. Mater. Res. A 2019, 107, 2736–2755. [Google Scholar] [CrossRef]

- Saylan, S.; Denizli, A. Supermacroporous composite cryogels in biomedical applications. Gels 2019, 5, 20. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Leach, D.G.; Young, S.; Hartgerink, J.D. Advances in immunotherapy delivery from implantable and injectable biomaterials. Acta Biomater. 2019, 88, 15–31. [Google Scholar] [CrossRef] [PubMed]

- Bakhshpour, M.; Idil, M.; Perçin, I.; Denizli, A. Biomedical applications of polymeric cryogels. Appl. Sci. 2019, 9, 553. [Google Scholar] [CrossRef] [Green Version]

- Dragan, E.S.; Dinu, M.V. Polysaccharides constructed hydrogels as vehicles for proteins and peptides: A review. Carbohydr. Polym. 2019, 225, 115210. [Google Scholar] [CrossRef] [PubMed]

- Memic, A.; Colombani, T.; Eggermont, L.J.; Rezaeeyazdi, M.; Steingold, J.; Rogers, Z.J.; Navare, K.J.; Mohammed, H.S.; Bencherif, S.A. Latest advances in cryogel technology for biomedical applications. Adv. Ther. 2019, 2, 1800114. [Google Scholar] [CrossRef] [Green Version]

- Xiang, J.; Shen, L.; Hong, Y. Status and future scope of hydrogels in wound healing: Synthesis, materials and evaluation. Eur. Polym. J. 2020, 130, 109609. [Google Scholar] [CrossRef]

- Hu, H.; Xu, F.-J. Rational design and latest advances of polysaccharide-based hydrogels for wound healing. Biomater. Sci. 2020, 8, 2084–2101. [Google Scholar] [CrossRef]

- Varfolomeev, S.D.; Rainina, E.I.; Lozinsky, V.I.; Kalyuzhnyi, S.B.; Sinitsyn, A.P.; Makhlis, T.A.; Bachurina, G.P.; Bokova, I.G.; Sklyankina, O.A.; Agafonov, E.V. Application of poly(vinyl alcohol) cryogel for immobilization of mesophilic and thermophilic microorganisms. In Physiology of Immobilized Cells; de Bont, J.A.M., Visser, J., Mattiasson, B., Tramper, J., Eds.; Elsevier Science Publisher B.V.: Amsterdam, The Netherlands, 1990; pp. 325–330. ISBN 978-0-4444-2700-7. [Google Scholar]

- Sinitsyn, A.P.; Rainina, E.I.; Lozinsky, V.I.; Spasov, S.D. Immobilized Microbial Cells; St. Okhridsky University: Sofia, Bulgaria, 1991; 288p, ISBN 5-211-00907-X. (In Russian) [Google Scholar]

- Lozinsky, V.I.; Vakula, A.V.; Zubov, A.L. Application of poly(vinyl alcohol) cryogels in biotechnology. IV. Literature data overview. Sov. Biotechnol. 1992, 4, 4–17. [Google Scholar]

- Varfolomeev, S.D.; Rainina, E.I.; Lozinsky, V.I. Cryoimmobilized enzymes and cells in organic synthesis. Pure Appl. Chem. 1992, 64, 1193–1196. [Google Scholar] [CrossRef] [Green Version]

- Lozinsky, V.I.; Plieva, F.M. Poly(vinyl alcohol) cryogels employed as matrices for cell immobilization. 3. Overview of recent research and developments. Enzym. Microb. Technol. 1998, 23, 227–242. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Galaev, I.Y.; Plieva, F.M.; Savina, I.N.; Jungvid, H.; Mattiasson, B. Polymeric cryogels as promising materials of biotechnological interest. Trends Biotechnol. 2003, 21, 445–451. [Google Scholar] [CrossRef] [PubMed]

- Martynenko, N.N.; Gracheva, I.M. Physiological and biochemical characteristics of immobilized champagne yeasts and their participation in sparkling processes. Appl. Biochem. Microbiol. 2003, 39, 439–445. [Google Scholar] [CrossRef]

- Lozinsky, V.I. What new opportunities the use of diverse polymeric cryogels opens for the immobilization of molecules and cells. Chem. Ind. (Belgrade) 2004, 58, 111–115. [Google Scholar]

- Plieva, F.M.; Galaev, I.Y.; Mattiasson, B. Macroporous gels prepared at subzero temperatures as novel materials for chromatography of particulate-containing fluids and cell culture applications. J. Separ. Sci. 2007, 30, 1657–1671. [Google Scholar] [CrossRef]

- Lozinsky, V.I. New generation of macroporous and supermacroporous materials of biotechnological interest—Polymeric cryogels. Russ. Chem. Bull. 2008, 57, 1015–1032. [Google Scholar] [CrossRef]

- Plieva, F.M.; Galaev, I.Y.; Noppe, W.; Mattiasson, B. Cryogel applications in microbiology. Trends Microbiol. 2008, 16, 543–551. [Google Scholar] [CrossRef]

- Efremenko, E.N.; Senko, O.V.; Zubaerova, D.H.; Podorozhko, E.A.; Lozinsky, V.I. Effective immobilized biocatalyst for the treatment of various foodwasters. In Biotechnology: State of the Art and Prospects for Development; Zaikov, G.E., Ed.; Nova Science Publishers Inc.: Hauppauge, NY, USA, 2008; Chapter 11; pp. 103–110. ISBN 978-1-60456-015-2. [Google Scholar]

- Stolarzewicz, I.; Bialecka-Florjańczyk, E.; Majewska, E.; Krzyczkowska, J. Immobilization of yeast on polymeric supports. Chem. Biochem. Eng. Q. 2011, 25, 135–144. [Google Scholar]

- Mattiasson, B. Cryogels for biotechnological applications. Adv. Polym. Sci. 2014, 263, 245–282. [Google Scholar] [CrossRef]

- Ismailov, A.D.; Alekserova, L.E. Photobiosensors containing luminescent bacteria. Biochemistry (Mosc.) 2015, 80, 733–744. [Google Scholar] [CrossRef]

- Efremenko, E.N.; Sen’ko, O.V.; Maslova, O.V.; Stepanov, N.A.; Lozinsky, V.I.; Varfolomeev, S.D. Immobilized fungal cells: General trends in the studies development and regulation methods of functional activity in the precesses of the biologically-active compounds production. In Immobilized Cells: Biocatalysts and Processes; Efremenko, E.N., Ed.; RIOR: Moscow, Russia, 2018; pp. 123–160. ISBN 978-5-369-02004-3. (In Russian) [Google Scholar]

- Efremenko, E.N.; Lyagin, I.V.; Lozinsky, V.I. Biocatalysts immobilized on/in the cryogenically-structured polymeric matrices. In Synthesis and Functional Properties of Hydrid Nanoforms of Bioactive and Drug Substances; Melnikov, M.Y., Trakhtenberg, L.I., Eds.; Tekhnosfera Publishing House: Moscow, Russia, 2019; Chapter 6; pp. 160–210. ISBN 978-5-94836-561_6. (In Russian) [Google Scholar]

- Bagal-Kestwal, D.R.; Chiang, B.-H. Exploration of chitinous scaffold-based interfaces for glucose sensing assemblies. Polymers 2019, 11, 1958. [Google Scholar] [CrossRef] [Green Version]

- Chu, K.C.; Rutt, B.K. Poly(vinyl alcohol) cryogel: An ideal phantom material for MR studies of arterial flow and elasticity. Magn. Reson. Med. 1997, 37, 314–319. [Google Scholar] [CrossRef] [PubMed]

- Hoskins, P.R. Simulation and validation of arterial ultrasound imagining and blood flow. Ultrasound Med. Biol. 2008, 34, 693–717. [Google Scholar] [CrossRef] [PubMed]

- Ghanbari, H.; Viatage, H.; Kidane, A.G.; Burriesci, G.; Tavakoli, M.; Seifalian, A.M. Polymeric heart valves: New materials, emerging hopes. Trends Biotechnol. 2009, 27, 359–367. [Google Scholar] [CrossRef] [PubMed]

- Kundu, B.; Kundu, S.C. Osteogenesis of human stem cells in silk biomaterial for regenerative therapy. Prog. Polym. Sci. 2010, 35, 1116–1127. [Google Scholar] [CrossRef]

- Baker, M.I.; Walsh, S.P.; Schwatz, Z.; Boyan, B.D. A review of polyvinyl alcohol and its uses in cartilage and orthopedic applications. J. Biomed. Mater. Res. B 2012, 100, 1451–1457. [Google Scholar] [CrossRef] [PubMed]

- Gajra, B.; Pandya, S.S.; Vidyasagar, G.; Rabari, H.; Dedania, R.R.; Rao, S. Poly(vinyl alcohol) hydrogel and its pharmaceutical and biomedical applications: A review. Int. J. Pharm. Res. 2012, 4, 20–26. [Google Scholar]

- Iatridis, J.C.; Nicoll, S.B.; Michalek, A.J.; Walter, B.A.; Gupta, M.S. Role of biomechanics in intervertebral disc degeneration and regenerative therapies: What needs repairing in the disc and what are promising biomaterials for its repair? Spine J. 2013, 13, 243–262. [Google Scholar] [CrossRef] [Green Version]

- Teixeira, L.S.M.; Patterson, J.; Luyten, F.P. Skeletal tissue regeneration: Where can hydogels play a role? Int. Orthop. 2014, 38, 1861–1876. [Google Scholar] [CrossRef]

- Beddoes, C.M.; Whitehouse, M.R.; Briscoe, W.H.; Su, B. Hydrogels as a replacement materials for damaged articular hyaline cartilage. Materials 2016, 9, 443. [Google Scholar] [CrossRef] [Green Version]

- Lozinsky, V.I.; Plieva, F.M.; Galaev, I.Y.; Mattiasson, B. The potential of polymeric cryogels in bioseparation. Bioseparation 2001, 10, 163–188. [Google Scholar] [CrossRef]

- Mallik, R.; Hage, D.S. Affinity monolith chromatography. J. Sep. Sci. 2006, 29, 1686–1704. [Google Scholar] [CrossRef] [PubMed]

- Daniak, M.B.; Kumar, A.; Galaev, I.Y.; Mattiasson, B. Methods in cell separations. Adv. Biochem. Eng. Biotechnol. 2007, 106, 1–18. [Google Scholar] [CrossRef]

- Daniak, M.B.; Galaev, I.Y.; Kumar, A.; Plieva, F.M.; Mattiasson, B. Chromatography of living cells using supermacroporous hydrogels, cryogels. Adv. Biochem. Eng. Biotechnol. 2007, 106, 101–127. [Google Scholar] [CrossRef]

- Josic, D.; Clifton, J.G. Use of monolithic supports in proteomics technology. J. Chromatogr. A 2007, 1144, 2–13. [Google Scholar] [CrossRef]

- Kumar, A.; Bhardwaj, A. Methods in cell separation for biomedical application: Cryogels as a new tool. Biomed. Mater. 2008, 3, 034008. [Google Scholar] [CrossRef] [PubMed]

- Jungbauer, A.; Hahn, R. Polymethacrylate monolith for preparative and industrial separation of biomolecular assemblies. J. Chromatorgr. A 2008, 1184, 62–79. [Google Scholar] [CrossRef] [PubMed]

- Nordborg, A.; Hilder, E.F. Recent advances in polymer monoliths for ion-exchange chromatography. Anal. Bioanal. Chem. 2009, 394, 71–84. [Google Scholar] [CrossRef] [PubMed]

- Svec, F. Porous polymer monoliths: Amazingly wide variety of techniques enabling their preparation. J. Chromatogr. A 2010, 1217, 902–924. [Google Scholar] [CrossRef] [Green Version]

- Tetala, K.K.R.; van Beek, T.A. Bioaffinity chromatography on monolithic supports. J. Sep. Sci. 2010, 33, 422–438. [Google Scholar] [CrossRef]

- Kumar, A.; Srivastava, A. Cell separation using cryogel-based affinity chromatography. Nat. Protoc. 2010, 5, 1737–1747. [Google Scholar] [CrossRef]

- Sproß, J.; Sinz, A. Monilithic media for applications in affinity chromatography. J. Sep. Sci. 2011, 34, 1958–1973. [Google Scholar] [CrossRef] [PubMed]

- Arrua, R.D.; Igarzabal, C.I.A. Macropoous monolithic supports for affinity chromatography. J. Sep. Sci. 2011, 34, 1974–1978. [Google Scholar] [CrossRef] [PubMed]

- Plieva, F.M.; Kirsebom, H.; Mattiasson, B. Preparation of macroporous cryostructurated gel monoliths, their characterization and main applications. J. Sep. Sci. 2011, 34, 2164–2172. [Google Scholar] [CrossRef] [PubMed]

- Nordborg, A.; Hilder, E.F.; Haddad, P.R. Monolithic phases for ion chromatography. Annu. Rev. Anal. Chem. 2011, 4, 197–226. [Google Scholar] [CrossRef] [PubMed]

- Connolly, D.; Currivan, S.; Paull, B. Polymeric monolithic materials modified with nanoparticles for separation and detection of biomolecules: A review. Proteomics 2012, 12, 2904–2917. [Google Scholar] [CrossRef] [PubMed]

- Sousa, Â.; Sousa, F.; Queiroz, J.A. Advances in chromatographic supports for pharmaceutical-grade plasmid DNA purification. J. Sep. Sci. 2012, 35, 3046–3058. [Google Scholar] [CrossRef]

- Podgornik, A.; Krajnc, N.L. Application of monoliths for bioparticle isolation. J. Sep. Sci. 2012, 35, 3059–3072. [Google Scholar] [CrossRef]

- Gunasena, D.N.; El Rassi, Z. Organic monoliths for hydrophilic interaction electrochromatography/chromatography and immunoaffinity chromatography. Electrophoresis 2012, 33, 251–261. [Google Scholar] [CrossRef]

- Barroso, T.; Hussain, A.; Roque, A.C.A.; Aguiar-Ricardo, A. Functional monolithic platforms: Chromatographic tools for antibody purification. Biotechnol. J. 2013, 8, 671–681. [Google Scholar] [CrossRef]

- Pfaunmiller, E.L.; Paulemond, M.L.; Dupper, C.M.; Hage, D.S. Affinity monolith chromatography: A review of principles and recent analytical applications. Anal. Bioanal. Chem. 2013, 405, 2133–2145. [Google Scholar] [CrossRef] [Green Version]

- Ertürk, G.; Mattiasson, B. Cryogels—Versatile tools in bioseparation. J. Chromatogr. A 2014, 1357, 24–35. [Google Scholar] [CrossRef] [PubMed]

- Hajizadeh, S.; Mattiasson, B. Cryogels with affinity ligands as tools in protein purification. Methods Mol. Biol. 2015, 1286, 183–200. [Google Scholar] [CrossRef] [PubMed]

- Choudhury, S.; Connolly, D.; White, B. Supermacroporous polyHIPE and cryogel monolithic materials as stationary phases in separation science: A review. Anal. Methods 2015, 7, 6967–6982. [Google Scholar] [CrossRef]

- Vlakh, E.G.; Korzhikov, V.A.; Hubina, A.V.; Tennikova, T.B. Molecular imprinting: A tool of modern chemistry for the preparation of highly selective monolithic sorbents. Russ. Chem. Rev. 2015, 84, 952–980. [Google Scholar] [CrossRef]

- Hande, P.E.; Samui, A.B.; Kulkarni, P.S. Highly selective monitoring of metals using ion-imprinted polymers. Environ. Sci. Polut. Res. 2015, 22, 7375–7404. [Google Scholar] [CrossRef] [PubMed]

- Acquah, C.; Moy, C.K.S.; Michael, K.; Danquah, M.K.; Clarence, M.; Ongkudon, C.M. Development and characteristics of polymer monoliths for advanced LC bioscreening applications: A review. J. Chromatogr. B 2016, 1015–1016, 121–134. [Google Scholar] [CrossRef]

- Andaç, M.; Galaev, I.Y.; Denizli, A. Affinity based and molecularly imprinted cryogels: Applications in biomacromolecule purification. J. Chromatogr. B 2016, 1021, 69–80. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Rodriguez, E.; Azaria, S.; Pekarek, A.; Hage, D.S. Affinity monolith chromatography: A review of general principles and applications. Electrophoresis 2017, 38, 2837–2850. [Google Scholar] [CrossRef]

- Ganewatta, N.; El Rassi, Z. Organic polymer-based monolithic stationary phases with incorporated nanostructured materials for HPLC and CEC. Electrophoresis 2018, 39, 53–66. [Google Scholar] [CrossRef]

- Baimenov, A.; Berillo, D.A.; Poulopoulos, S.G.; Inglezakis, V.J. A review of cryogels synthesis, characterization and applications on the removal of heavy metals from aqueous solutions. Adv. Colloid Interface Sci. 2020, 276, 102088. [Google Scholar] [CrossRef]

- Kudaibergenov, S.E. Physicochemical, complexation and catalytic properties of polyampholyte cryogels. Gels 2019, 5, 8. [Google Scholar] [CrossRef] [Green Version]

- Shlyakhtin, O.A.; Lozinsky, V.I. Low-temperature methods in the synthesis of inorganic nanomaterials and biomaterials originating from the aqueous solutions and suspensions. In Synthesis and Functional Properties of Hydrid Nanoforms of Bioactive and Drug Substances; Melnikov, M.Y., Trakhtenberg, L.I., Eds.; Tekhnosfera Publishing House: Moscow, Russia, 2019; Chapter 7; pp. 211–244. ISBN 978-5-94836-561_7. (In Russian) [Google Scholar]

- Kudaibergenov, S.E.; Dzhardimalieva, G.I. Flow-through catalytic reactors based on metal nanoparticles immobilized within porous polymeric gels and surfaces/hollows of polymeric membranes. Polymers 2020, 12, 572. [Google Scholar] [CrossRef] [Green Version]

- Tolstoguzov, V.B.; Braudo, E.E. Fabricated foodstuffs as multicomponent gels. J. Texture Stud. 1983, 14, 183–212. [Google Scholar] [CrossRef]

- Cassanelli, M.; Norton, I.; Mills, T. Role of gellan gum microstructure in freeze drying and rehydration mechanisms. Food Hydrocolloids 2018, 75, 51–61. [Google Scholar] [CrossRef]

- Altunina, L.K.; Kuvshinov, V.A.; Dolgikh, S.N. Cryogels—A promising material for underground works in permafrost. In Advances in Geological Storage of Carbon Dioxide; NATO Science Series IV, Lombardi, S., Altunina, L.K., Beaubien, S.E., Eds.; Springer: Berlin/Heidelberg, Germany, 2006; Volume 65, pp. 103–110. ISBN 978-1-4020-4469-4. [Google Scholar]

- Vasiliev, N.K.; Pronk, A.D.C.; Shatalina, I.N.; Janssen, F.H.M.E.; Houben, R.W.G. A review on the development of reinforced ice for use as a building material in cold regions. Cold Reg. Sci. Technol. 2015, 115, 56–63. [Google Scholar] [CrossRef]

- Altunina, L.K.; Fufaeva, M.S.; Filatov, D.A.; Scarovskaya, L.I.; Rozhdestvenskii, E.A.; Gan-Erdene, T. Effect of cryogel on soil properties. Euroasian Soil Sci. 2014, 47, 425–431. [Google Scholar] [CrossRef]

- Mastrangelo, R.; Montis, C.; Bonelli, N.; Tempesti, P.; Baglioni, P. Surface cleaning of artworks: Structure and dynamics of nanostructured fluids confined in polymeric hydrogel networks. Phys. Chem. Chem. Phys. 2017, 19, 23762–23772. [Google Scholar] [CrossRef]

- Bonelli, N.; Poggi, G.; Chelazzi, D.; Giorgi, R.; Baglioni, P. Poly(vinyl alcohol)/poly(vinyl pyrrolidone) hydrogels for the cleaning of art. J. Colloid Interface Sci. 2019, 536, 339–348. [Google Scholar] [CrossRef]

- Mastrangelo, R.; Chelazzi, D.; Poggia, G.; Fratinia, E.; Buemi, L.P.; Petruzzellis, M.L.; Baglioni, P. Twin-chain polymer hydrogels based on poly(vinyl alcohol) as new advanced tool for the cleaning of modern and contemporary art. Proc. Natl. Acad. Sci. USA 2020, 117, 7011–7020. [Google Scholar] [CrossRef] [Green Version]

- Manzhai, V.N.; Fufaeva, M.S. Poly(vinyl alcohol) cryogels as an efficient spent-oil utilization method. Chem. Technol. Fuels Oils 2015, 51, 487–492. [Google Scholar] [CrossRef]

- Glazunov, P.A.; Reschetilowski, V.P.; Manzhai, V.N.; Zyatikov, P.N.; Solov’ev, V.V. Physical modeling of briquetting processes on the basis of the wastes polydisperse coke particles and cryogels of a poly(vinyl alcohol). Tomsk State Univ. J. Math. Mech. 2018, 53, 73–83. (In Russian) [Google Scholar] [CrossRef] [Green Version]

- Glushkov, D.O.; Kuznetsov, G.V.; Nigay, A.G.; Yanovsky, V.A.; Yashutin, O.S. Ignition mechanism and characteristics of gel fuels based on oil-free and oil-filled cryogels with fine coal particles. Powder Technol. 2020, 360, 65–79. [Google Scholar] [CrossRef]

- Glushkov, D.O.; Kuznetsov, G.V.; Tabakaev, R.B.; Dariga, B.; Altynbaeva, D.B.; Nigay, A.G. Kinetic properties of gas-phase combustion of gel fuels based on oil-filled cryogels. Thermochim. Acta 2020, 686, 178553. [Google Scholar] [CrossRef]

- Available online: https://ineos.ac.ru/en/history-background (accessed on 7 September 2020).

- Buttkus, H. Accelerated denaturation of myosin in frozen solution. J. Food Sci. 1970, 35, 558–562. [Google Scholar] [CrossRef]

- Labudzińska, A.; Ziabicki, A. Effect of composition and gelation conditions on structural changes accompanying the gelation of PAN, PVA and gelatin solutions. Kolloid-Z. Z. Polym. 1971, 243, 21–27. [Google Scholar] [CrossRef]

- Kaetsu, I.; Okubo, H.; Ito, A.; Hayashi, K. Radiation-induced polymerization of glass-forming systems. I. Effect of temperature on the initial polymerization rate. J. Polym. Sci. A-1 1972, 10, 2203–2214. [Google Scholar] [CrossRef]

- Smith, P.; Pennings, A.J. Eutectic crystallization of pseudo binary systems of polyethylene and high melting diluents. Polymer 1974, 15, 413–419. [Google Scholar] [CrossRef]

- Dianova, V.T.; Tolstoguzov, V.B.; Krokha, N.G.; Shtulboi, V.B.; Strashenko, E.S.; Bushueva, S.G.; Yaroshenko, Y.F.; Gonsales, R.S.; Kupriyanova, N.I. Methods for the preparation of protein gels. SU Patent 924,940; registered, 30 April 1982. [Google Scholar]

- Rogozhin, S.V.; Vainerman, E.S.; Burmistrova, L.M. Method for Producing Protein Jellies from Fishes and Crustaceans. U.S. Patent 4,167,590, 11 September 1979. [Google Scholar]

- Belikov, V.M.; Rogozhin, S.V.; Slonimskii, G.L.; Golovnya, R.V.; Tolstoguzov, V.B. Development of chemical investigations on artificial and synthetic foods. Russ. Chem. Rev. 1969, 38, 699–713. [Google Scholar] [CrossRef]

- Vainerman, E.S.; Lozinsky, V.I.; Rogozhin, S.V. Study of cryostructurization of polymer systems. I. Structure formation in solutions of thiol-containing polymers under freezing-thawing. Colloid Polym. Sci. 1981, 259, 1198–1201. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Vainerman, E.S.; Rogozhin, S.V. Method for the preparation of macroporous polymer materials. SU Patent 1,008,214, 1 December 1982. [Google Scholar]

- Rogozhin, S.V.; Vainerman, E.S.; Lozinsky, V.I. Formation of 3-dimentional cross-linked polymeric structures during freezing of the reacting system. Dokl. Akad. Nauk SSSR 1982, 263, 115–118. (In Russian) [Google Scholar]

- Lozinsky, V.I.; Vainerman, E.S.; Rogozhin, S.V. Study of cryostructurization of polymer systems. II. The influence of freezing of reacting mass on the properties of products in the preparation of covalently cross-linked gels. Colloid Polym. Sci. 1982, 260, 776–780. [Google Scholar] [CrossRef]

- Nikonorov, V.V.; Ivanov, R.V.; Kil’deeva, N.R.; Bulatnikova, L.N.; Lozinsky, V.I. Synthesis and characteristics of chitosan cryogels crosslinked by glutaric aldehyde. Polym. Sci. A 2010, 52, 828–834. [Google Scholar] [CrossRef]

- Nikonorov, V.V.; Ivanov, R.V.; Kil’deeva, N.R.; Lozinsky, V.I. Effect of polymer precursor molecular mass on the formation and properties of covalently crosslinked chitosan cryogels. Polym. Sci. A 2011, 53, 1150–1158. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Korneeva, M.N.; Vainerman, E.S.; Rogozhin, S.V. Structurization during freezing of the polymerizing system consisting of vinyl and divinyl monomers. Dokl. Akad. Nauk SSSR 1983, 270, 101–104. (In Russian) [Google Scholar]

- Lozinsky, V.I.; Vainerman, E.S.; Titova, E.F.; Belavtseva, E.M.; Rogozhin, S.V. Study of cryostructurization of polymer systems. IV. Cryostructurization of the system: Solvent–vinyl monomer–divinyl monomer–initiator of polymerization. Colloid Polym. Sci. 1984, 262, 769–774. [Google Scholar] [CrossRef]

- Belavtseva, E.M.; Titova, E.F.; Lozinsky, V.I.; Vainerman, E.S.; Rogozhin, S.V. Study of cryostructurization of polymer systems. V. Electron microscopic studies of cross-linked polyacrylamide cryogels. Colloid Polym. Sci. 1984, 262, 775–779. [Google Scholar] [CrossRef]

- Rogozhin, S.V.; Lozinsky, V.I.; Vainerman, E.S.; Domotenko, L.V.; Mamtsis, A.M.; Ivanova, S.A.; Shtil’man, M.I.; Korshak, V.V. Noncovalent cryostructurization in polymer systems. Dokl. Akad. Nauk SSSR 1984, 278, 129–133. (In Russian) [Google Scholar]

- Lozinsky, V.I.; Vainerman, E.S.; Korotaeva, G.F.; Rogozhin, S.V. Study of cryostructurization of polymer systems. III. Cryostructurization in organic media. Colloid Polym. Sci. 1984, 262, 617–622. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Vainerman, E.S.; Ivanova, S.A.; Titova, E.F.; Shtil’man, M.I.; Belavtseva, E.M.; Rogozhin, S.V. Study of cryostructurization of polymer systems. VI. The influence of the process temperature on the dynamics of formation and structure of cross-linked polyacrylamide cryogels. Acta Polym. 1986, 37, 142–146. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Domotenko, L.V.; Vainerman, E.S.; Mamtsis, A.M.; Rogozhin, S.V. On the possibility of mechanodestruction of poly(vinyl alcohol) molecules under moderate freezing of its concentrated water solutions. Polym. Bull. 1986, 15, 333–340. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Vainerman, E.S.; Domotenko, L.V.; Mamtsis, A.M.; Titova, E.F.; Belavtseva, E.M.; Rogozhin, S.V. Study of cryostructurization of polymer systems. VII. Structure formation under freezing of poly(vinyl alcohol) aqueous solutions. Colloid Polym. Sci. 1986, 264, 19–24. [Google Scholar] [CrossRef]

- Domotenko, L.V.; Lozinsky, V.I.; Vainerman, E.S.; Rogozhin, S.V. Influence of freezing and thawing conditions of poly(vinyl alcohol) aqueous solutions on the properties of obtained cryogels. Polym. Sci. USSR A 1988, 30, 1758–1764. [Google Scholar] [CrossRef]

- Manolov, R.Z.; Tavobilov, I.M.; Lozinsky, V.I.; Vainerman, E.S.; Titova, E.F.; Belavtseva, E.M.; Bezborodova, S.I.; Rogozhin, S.V.; Bezborodov, A.M. A study of Aspergillus clavatus immobilized cells producing ribonuclease. Appl. Biochem. Microbiol. 1988, 24, 427–431. [Google Scholar]

- Lusta, K.A.; Starostina, N.G.; Gorkina, N.B.; Fikhte, B.A.; Lozinsky, V.I.; Vainerman, E.S.; Rogozhin, S.V. Immobilization of E. coli cells into macroporous cryogels on the poly(acrylamide) basis. Appl. Biochem. Microbiol. 1988, 24, 498–504. [Google Scholar]

- Slabova, O.I.; Nikitin, D.I.; Lozinsky, V.I.; Kulakova, V.K.; Vainerman, E.S.; Rogozhin, S.V. Hydrogen oxidation by olygotrophic bacterial cells immobilized in silica gel and cryosilica gel. Microbiology 1988, 57, 749–753. [Google Scholar]

- Lozinsky, V.I.; Morozova, S.A.; Vainerman, E.S.; Titova, E.F.; Shtil’man, M.I.; Belavtseva, E.M.; Rogozhin, S.V. Study of cryostructurization of polymer systems. VIII. Characteristics features of the formation of cross-linked poly(acrylamide) cryogels under different thermal conditions. Acta Polym. 1989, 40, 8–15. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Golovina, T.O.; Vainerman, E.S.; Rogozhin, S.V. Change of the amount of titrated SH-groups in the poly(acrylamide) thiol derivative during freezing of its aqueous solutions. Polym. Sci. USSR A 1989, 31, 367–372. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Golovina, T.O.; Gusev, D.G. Study of cryostructuration of polymer systems. 13. Some characteristic features of the behaviour of macromolecular thiols in frozen aqueous solutions. Polymer 2000, 41, 35–47. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Vainerman, E.S.; Domotenko, L.V.; Blumenfel’d, A.L.; Rogov, V.V.; Barkovskaya, E.N.; Fedin, E.I.; Rogozhin, S.V. Characteristic features of freezing of concentrated aqueous poly(vinyl alcohol) solutions: Correlation with properties of hydrogels obtained after thawing. Colloid J. USSR 1990, 51, 592–596. [Google Scholar]

- Rogozhin, S.V.; Cheverev, V.G.; Vainerman, E.S.; Lozinsky, V.I.; Gagarin, V.E.; Torbin, V.V.; Barkovskaya, E.N.; Panchenko, V.I.; Rogov, V.V. Method for the preparation of an artificial ice. SU Patent 1,649,219, 15 May 1991. [Google Scholar]

- Lozinsky, V.I.; Domotenko, L.V.; Vainerman, E.S.; Rogozhin, S.V. Some thermomechanical properties of poly(vinyl alcohol) cryogels. Polym. Sci. USSR A 1989, 31, 1983–1988. [Google Scholar] [CrossRef]

- Gusev, D.G.; Lozinsky, V.I.; Vainerman, E.S.; Bakhmutov, V.I. Study of the frozen water-poly(vinyl alcohol) system by 2H and 13C NMR spectroscopy. Magn. Res. Chem. 1990, 28, 651–655. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Vainerman, E.S.; Zubov, A.L.; Kulakova, V.K.; Rogozhin, S.V. Application of poly(vinyl alcohol) cryogels in biotechnology. II. Variation of rheological properties of the gel matrix as a result of yeast cells entrapment. Sov. Biotechnol. 1990, 5, 43–46. [Google Scholar]

- Slabova, O.I.; Nikitin, D.I.; Lozinsky, V.I.; Vainerman, E.S.; Rogozhin, S.V. Some features of gas exchange in hydrogen bacteria immobilized into usual and cryogels of cross-linked poly(acrylamide). Microbiology 1991, 60, 14–18. [Google Scholar]

- Mikhalev, O.I.; Serpinski, M.; Lozinsky, V.I.; Kapanin, P.V.; Chkeidze, I.I.; Alfimov, M.V. Method for determination of liquid microphase volume: Application to the investigation of frozen H2O-poly(vinyl alcohol) system. Cryo-Letters 1991, 12, 197–206. [Google Scholar]

- Lozinsky, V.I.; Zubov, A.L. Method for the preparation of poly(vinyl alcohol) cryogels. Russian Patent 2,070,901, 27 December 1996. [Google Scholar]

- Lozinsky, V.I.; Solodova, E.V.; Zubov, A.L.; Simenel, I.A. Study of cryostructuration of polymer systems. 11. The formation of PVA cryogels by freezing-thawing the polymer aqueous solutions containing additives of some polyols. J. Appl. Polym. Sci. 1995, 58, 171–178. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Zubov, A.I.; Kulakova, V.K.; Titova, E.F.; Rogozhin, S.V. Study of cryostructurization of polymer systems. IX. Poly(vinyl alcohol) cryogels filled with particles of cross-linked dextran gel. J. Appl. Polym. Sci. 1992, 44, 1423–1435. [Google Scholar] [CrossRef]

- Gusev, D.G.; Lozinsky, V.I.; Bakhmutov, V.I. Study of cryostructurization of polymer systems. 10. 1H- and 2H-NMR studies of the formation of crosslinked polyacrylamide cryogels. Eur. Polym. J. 1993, 29, 49–56. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Simenel, I.A.; Chebyshev, A.V. Method for the production of porous polymeric materials. Russian Patent 2,035,476, 20 May 1995. [Google Scholar]

- Lozinsky, V.I.; Zubov, A.L. Method for the preparation of macroporous polymeric material. Russian Patent 2,078,099, 27 April 1997. [Google Scholar]

- Pavlova, L.A.; Kastelyanos-Dominges, O.M. Radical polymerization of 2-hydroxymethylmethacrylate in frozen aqueous solutions. Russ. J. Appl. Chem. 1996, 69, 738–741. [Google Scholar]

- Pavlova, L.A.; Kastelyanos-Dominges, O.M. Preparation of cryogels by polymerization of 2-hydroxyethyl methacrylate in the presence of sodium persulfate-N,N,N′,N′-tetramethylethylenediamine initiating system. Russ. J. Appl. Chem. 1996, 69, 1396–1400. [Google Scholar]

- Lozinsky, V.I.; Zubov, A.L.; Titova, E.F. Swelling behaviour of poly(vinyl alcohol) cryogels employed as matrices for cell immobilization. Enzym. Microb. Technol. 1996, 18, 561–569. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Domotenko, L.V.; Zubov, A.L.; Simenel, I.A. Study of cryostructuration of polymer systems. 12. Poly(vinyl alcohol) cryogels: Influence of low-molecular electrolytes. J. Appl. Polym. Sci. 1996, 61, 1991–1998. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Kalinina, E.V.; Grinberg, V.Y.; Grinberg, N.V.; Chupov, V.A.; Plate, N.A. Thermoresponsive cryogels based on cross-linked poly(N,N-diethylacrylamide). Polym. Sci. Ser. A 1997, 39, 1300–1305. [Google Scholar]

- Lozinsky, V.I.; Zubov, A.L.; Titova, E.I. Poly(vinyl alcohol) cryogels which are used as matrices for cell immobilization. 2. Entrapped cells resemble porous fillers in their effects on the properties of PVA-cryogel carrier. Enzym. Microb. Technol. 1997, 20, 182–190. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Podorozhko, E.A.; Nikitina, Y.B.; Klabukova, L.F.; Vasil’iev, V.G.; Burmistrov, A.A.; Kondrashov, Y.G.; Vasiliev, N.K. A study of cryostructuring of polymeric systems. 45. Effect of porosity of dispersed filler on physicochemical characteristics of composite poly(vinyl alcohol) cryogels. Colloid J. 2017, 79, 497–507. [Google Scholar] [CrossRef]

- Konstantinova, N.R.; Lozinsky, V.I. Cryotropic gelation of ovalbumin solutions. Food Hydrocoll. 1997, 11, 113–123. [Google Scholar] [CrossRef]

- Golovnya, R.V.; Misharina, T.A.; Terenina, M.B. GC evaluation of flavour compound sorption from water solutions by corn starch cryotextures obtained by freezing. Nahrung/Food 1998, 42, 380–384. [Google Scholar] [CrossRef]

- Terenina, M.B.; Misharina, T.A.; Golovnya, R.V. Sorption of aliphatic alcohols from aqueous solutions by starch cryotextures. Russ. Chem. Bull. 1999, 48, 730–733. [Google Scholar] [CrossRef]

- Golovnya, R.V.; Terenina, M.B.; Krikunova, N.I.; Yuryev, V.P.; Misharina, T.A. Formation of supramolecular structures of aroma compounds with polysaccharides of corn starch cryotextures. Starch/Stärke 2001, 53, 269–277. [Google Scholar] [CrossRef]

- Terenina, M.B.; Misharina, T.A.; Krikunova, N.I.; Golovnya, R.V. Sorption of aliphatic ketones from aqueous solutions by starch cryotextures. Russ. Chem. Bull. 2001, 50, 1032–1036. [Google Scholar] [CrossRef]

- Terenina, M.B.; Krikunova, N.I.; Misharina, T.A. Binding of cyclic compounds by starch cryotextures from aqueous solutions. Russ. Chem. Bull. 2002, 51, 1689–1693. [Google Scholar] [CrossRef]

- Terenina, M.B.; Misharina, T.A. Sorption of components from a mixture of essential oils by cryotextured cornstarches. Appl. Biochem. Microbiol. 2002, 41, 407–412. [Google Scholar] [CrossRef]

- Damshkaln, L.G.; Simenel, I.A.; Lozinsky, V.I. Study of cryostructuration of polymer systems. 15. Freeze-thaw-induced formation of cryoprecipitate matter from the low-concentrated aqueous solutions of poly(vinyl alcohol). J. Appl. Polym. Sci. 1999, 74, 1978–1986. [Google Scholar] [CrossRef]

- Podorozhko, E.A.; Kurskaya, E.A.; Kulakova, V.K.; Lozinsky, V.I. Cryotropic structuring of aqueous dispersions of fibrous collagen: The influence of the initial pH values. Food Hydrocoll. 2000, 14, 111–120. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Zubov, A.L.; Savina, I.N.; Plieva, F.M. Study of cryostructuration of polymer systems. 14. Poly(vinyl alcohol) cryogels: Apparent yield of the freeze-thaw-induced gelation of concentrated aqueous solutions of the polymer. J. Appl. Polym. Sci. 2000, 77, 1822–1831. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Damshkaln, L.G.; Brown, C.R.T.; Norton, I.T. Study of cryostructuration of polymer systems. 16. Freeze–thaw-induced effects in the low-concentration systems amylopectin–water. J. Appl. Polym. Sci. 2000, 75, 1740–1748. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Damshkaln, L.G. Study of cryostructuration of polymer systems. 17. Poly(vinyl alcohol) cryogels: Dynamics of the cryotropic gel-formation. J. Appl. Polym. Sci. 2000, 77, 2017–2023. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Damshkaln, L.G.; Brown, C.R.T.; Norton, I.T. Study of cryostructuration of polymer systems. 18. Freeze-thaw-influence on water-solubilized artificial mixtures of amylopectin and amylose. J. Appl. Polym. Sci. 2000, 78, 371–381. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Damshkaln, L.G.; Brown, C.R.T.; Norton, I.T. Study of cryostructuring of polymer systems. 19. On the nature of intermolecular links in the cryogels of locust bean gum. Polym. Int. 2000, 49, 1434–1443. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Damshkaln, L.G. Study of cryostructuration of polymer systems. 20. Foamed poly(vinyl alcohol) cryogels. J. Appl. Polym. Sci. 2001, 82, 1609–1619. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Damshkaln, L.G.; Plieva, F.M.; Galaev, I.Y.; Mattiasson, B. The polymeric composition for the preparation of macroporous agarose gel and the method for the gel producing. Russian Patent 2,220,987, 10 January 2004. [Google Scholar]

- Mattiasson, B.; Galaev, I.; Lozinsky, V.; Plieva, F. Macroporous gel, its preparation and use. U.S. Patent 7,547,395 B2, 16 June 2009. [Google Scholar]

- Lozinsky, V.I.; Savina, I.N.; Davankov, V.A. The Composition for the Preparation of poly(vinyl alcohol) Cryogel and the Method for the Cryogel Producing. Russian Patent 2,190,644, 10 October 2002. [Google Scholar]

- Lozinsky, V.I.; Savina, I.N. Study of cryostructuration of polymer systems. 22. Poly (vinyl alcohol) composite cryogels filled with dispersed particles of various hydrophilicity/hydrophobicity. Colloid J. 2002, 64, 336–343. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Damshkaln, L.G.; Brown, C.R.T.; Norton, I.T. Study of cryostructuration of polymer systems. 21. Cryotropic gel-formation of the water-maltodextrin systems. J. Appl. Polym. Sci. 2002, 83, 1658–1667. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Damshkaln, L.G. Polymeric Composition for the Preparation of poly(vinyl alcohol) Cryogel. Russian Patent 2,252,945, 27 May 2005. [Google Scholar]

- Savina, I.N.; Lozinsky, V.I. Study of cryostructuration of polymer systems. 23. Poly(vinyl alcohol) composite cryogels filled with dispersed particles that contain ionogenic groups. Colloid J. 2004, 66, 343–349. [Google Scholar] [CrossRef]

- Savina, E.N.; Hanora, A.; Plieva, F.M.; Galaev, I.Y.; Mattiasson, B.; Lozinsky, V.I. Study of cryostructuration of polymer systems. 24. Poly(vinyl alcohol) cryogels filled with particles of strong anion-exchanger: Properties of the composite materials and potential application. J. Appl. Polym. Sci. 2005, 95, 529–538. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Damshkaln, L.G.; Kurochkin, I.N.; Kurochkin, I.I. Study of cryostructuration of polymer systems. 25. Influence of surfactants on the properties and structure of gas-filled (foamed) poly(vinyl alcohol) cryogels. Colloid J. 2005, 67, 589–601. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Bakeeva, I.V.; Presnyak, E.P.; Damshkaln, L.G.; Zubov, V.P. Study of cryostructuring of polymer systems. 26. Heterophase organic-inorganic cryogels prepared via freezing-thawing of aqueous solutions of poly(vinyl alcohol) with added tetramethoxysilane. J. Appl. Polym. Sci. 2007, 105, 2689–2702. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Damshkaln, L.G.; Shaskol’skii, B.L.; Babushkina, T.A.; Kurochkin, I.N.; Kurochkin, I.I. Study of cryostructuring of polymer systems. 27. Physicochemical properties of poly(vinyl alcohol) cryogels and features of their macroporous morphology. Colloid J. 2007, 69, 747–764. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Damshkaln, L.G.; Kurochkin, I.N.; Kurochkin, I.I. Study of cryostructuring of polymer systems. 28. Physicochemical and morphological properties of poly(vinyl alcohol) cryogels formed via multiple freezing-thawing technique. Colloid J. 2008, 70, 189–198. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Damshkaln, L.G.; Kurochkin, I.N.; Kurochkin, I.I. Study of cryostructuring of polymer systems. 33. Effect of rate of chilling aqueous poly(vinyl alcohol) solutions during their freezing on physicochemical properties and porous structure of resulting cryogels. Colloid J. 2012, 74, 319–327. [Google Scholar] [CrossRef]

- Ivanov, R.V.; Lozinsky, V.I.; Noh, S.K.; Han, S.S.; Lyoo, W.S. Preparation and characterization of polyacrylamide cryogels produced from a high-molecular weight precursor. I. Influence of the reaction temperature and concentration of the cross-linking agent. J. Appl. Polym. Sci. 2007, 106, 1470–1475. [Google Scholar] [CrossRef]

- Ivanov, R.V.; Lozinsky, V.I.; Noh, S.K.; Lee, Y.R.; Han, S.S.; Lyoo, W.S. Preparation and characterization of polyacrylamide cryogels produced from a high-molecular-weight precursor. II. The influence of the molecular weight of the polymeric precursor. J. Appl. Polym. Sci. 2008, 107, 382–390. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Damshkaln, L.G.; Bloch, K.O.; Vardi, P.; Grinberg, N.V.; Burova, T.V.; Grinberg, V.Y. Cryostructuring of polymer systems. 29. Preparation and characterization of supermacroporous (spongy) agarose-based cryogels used as three-dimensional scaffolds for culturing insulin-producing cell aggregates. J. Appl. Polym. Sci. 2008, 108, 3046–3062. [Google Scholar] [CrossRef]

- Bloch, K.; Lozinsky, V.I.; Galaev, I.Y.; Yavriyanz, K.; Vorobeychik, M.; Azarov, D.; Damshkaln, L.G.; Mattiasson, B.; Vardi, P. Functional activity of insulinoma cells (INS-1E) and pancreatic islets cultured in agarose cryogel sponges. J. Biomed. Mater. Res. A 2005, 75, 802–809. [Google Scholar] [CrossRef] [PubMed]

- Petrenko, Y.A.; Petrenko, A.Y.; Lozinsky, V.I.; Gurin, I.V.; Gorokhova, N.A.; Volkova, N.A.; Sandomirskii, B.P. Culturing of stromal cells-precursors in the 3D carriers. Transplantologiya (Kyev.) 2007, 9, 221–223. (In Russian) [Google Scholar]

- Bloch, K.; Vanichkin, A.; Damshkaln, L.G.; Lozinsky, V.I.; Vardi, P. Vascularization of wide pore agarose-gelatin cryogel scaffolds implanted subcutaneously in diabetic and non diabetic mice. Acta Biomater. 2010, 6, 1200–1205. [Google Scholar] [CrossRef] [PubMed]

- Komarova, G.A.; Starodubtsev, S.G.; Lozinsky, V.I.; Kalinina, E.V.; Landfester, K.; Khokhlov, A.R. Intelligent gels and cryogels with entrapped emulsions. Langmuir 2008, 24, 4467–4469. [Google Scholar] [CrossRef]

- Komarova, G.A.; Starodubtsev, S.G.; Lozinsky, V.I.; Nasimova, I.R.; Khokhlov, A.R. Intelligent gels and cryogels with embedded emulsions of various oils. J. Appl. Polym. Sci. 2013, 127, 2703–2709. [Google Scholar] [CrossRef]

- Wasserman, L.A.; Vasil’ev, V.G.; Motyakin, M.V.; Blaszchak, W.; Fornal, J.; Damshkaln, L.G.; Lozinsky, V.I.; Yuryev, V.P. Influence of gluten and gums additives, as well as of the cryogenic treatment, on physicomechanical properties, morphology and local mobility of water in complex gels of wheat starch. Starch/Stärke 2009, 61, 377–388. [Google Scholar] [CrossRef]

- Podorozhko, E.A.; Korlyukov, A.A.; Lozinsky, V.I. Cryostructuring of polymer systems. 30. Poly(vinyl alcohol)-based composite cryogels filled with small disperse oil droplets: A gel system capable of mechanically-induced releasing of the lipophilic constituents. J. Appl. Polym. Sci. 2010, 117, 1332–1349. [Google Scholar] [CrossRef]

- Podorozhko, E.A.; Vorontsova, T.V.; Lozinsky, V.I. Study of cryostructuring of polymer systems. 32. Morphology and physico-chemical properties of composite poly(vinyl alcohol) cryogels filled with microdroplets of hydrophobic liquid. Colloid J. 2012, 74, 110–120. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Sakhno, N.G.; Damshkaln, L.G.; Bakeeva, I.V.; Zubov, V.P.; Kurochkin, I.N.; Kurochkin, I.I. Study of cryostructuring of polymer systems. 31. Influence of the additives of alkaline metals chlorides on physicochemical properties and morphology of poly(vinyl alcohol) cryogels. Colloid J. 2011, 73, 234–243. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Zaborina, O.E. Process for the Preparation of Cross-Linked Hydrophilic Polymer Exhibiting Superabsorbent Properties. Russian Patent 2,467,017, 20 November 2012. [Google Scholar]

- Zaborina, O.E.; Gasanov, R.G.; Peregudov, A.S.; Lozinsky, V.I. Cryostructuring of polymeric systems. 38. The causes of the covalently-crosslinked cryogels formation upon the homopolymerization of N,N-dimethylacrylamide in moderately-frozen aqueous media. Eur. Polym. J. 2014, 61, 226–239. [Google Scholar] [CrossRef]

- Burova, T.V.; Grinberg, N.V.; Kalinina, E.V.; Ivanov, R.V.; Lozinsky, V.I.; Alvarez-Lorenzo, C.; Grinberg, V.Y. Thermoresponsive copolymer cryogel possessing molecular memory: Synthesis, energetics of collapse and interaction with ligands. Macromol. Chem. Phys. 2011, 212, 72–80. [Google Scholar] [CrossRef]

- Podorozhko, E.A.; D’yakonova, E.A.; Kolosova, O.Y.; Klabukova, L.F.; Lozinsky, V.I. Study of cryostructuring of polymer systems. 34. Composite poly(vinyl alcohol) cryogels filled with microparticles of polymeric dispersion. Colloid J. 2012, 74, 711–719. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Damshkaln, L.G.; Ezernitskaya, M.G.; Glotova, Y.K.; Antonov, Y.A. Cryostructuring of polymer systems. 35. Wide pore poly(vinyl alcohol) cryogels prepared using a combination of liquid-liquid phase separation and cryotropic gel-formation processes. Soft Matter 2012, 8, 8493–8504. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Damshkaln, L.G.; Kurochkin, I.N.; Kurochkin, I.I. Cryostructuring of polymeric systems. 36. Poly(vinyl alcohol) cryogels prepared from solutions of the polymer in water/low-molecular alcohol mixtures. Eur. Polym. J. 2014, 53, 189–205. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Podorozhko, E.A. Method for Molding of the poly(vinyl alcohol) Cryogels. Russian Patent 2,561,120, 28 July 2015. [Google Scholar]

- Podorozhko, E.A.; D’yakonova, E.A.; Lozinsky, V.I. Cryostructuring of polymeric systems. 37. Composite cryogels from dispersions of poly(butadiene-co-styrene) latex in aqueous poly(vinyl alcohol) solution. Colloid J. 2015, 77, 46–57. [Google Scholar] [CrossRef]

- Oschepkova, M.V.; Oschepkov, A.S.; Zaborina, O.E.; Fedorova, O.A.; Fedorov, Y.V.; Lozinsky, V.I. Fluorescent cryogels based on copolymers of N,N-dimethylacrylamide and allyl derivatives of 1,8-naphtalimide. Polym. Sci. Ser. B 2015, 57, 631–637. [Google Scholar] [CrossRef]

- Podorozhko, E.A.; Lunev, I.A.; Ryabev, A.N.; Kil’deeva, N.R.; Lozinsky, V.I. Cryostructuring of polymeric systems. 39. Composite poly(vinyl alcohol) cryogels filled with chitosan microparticles. Colloid J. 2015, 77, 186–195. [Google Scholar] [CrossRef]

- Rodionov, I.A.; Grinberg, N.V.; Burova, T.V.; Grinberg, V.Y.; Lozinsky, V.I. Cryostructuring of polymeric systems. 40. Proteinaceous wide-pore cryogels generated by the action of denaturant/reductant mixtures on bovine serum albumin in moderately-frozen aqueous media. Soft Matter 2015, 11, 4921–4931. [Google Scholar] [CrossRef]

- Podorozhko, E.A.; Ul’yabaeva, G.R.; Kil’deeva, N.R.; Tikhonov, V.E.; Antonov, Y.A.; Zhuravleva, I.L.; Lozinsky, V.I. A Study of cryostructuring of polymer systems. 41. Complex and composite poly(vinyl alcohol) cryogels containing soluble and insoluble forms of chitosan. Colloid J. 2016, 78, 90–101. [Google Scholar] [CrossRef]

- Podorozhko, E.A.; Ul’yabaeva, G.R.; Tikhonov, V.E.; Grachev, A.V.; Vladimirov, L.V.; Antonov, Y.A.; Kil’deeva, N.R.; Lozinsky, V.I. Cryostructuring of polymeric systems. 43. Microstructural features of chitosan-containing complex and composite poly(vinyl alcohol) cryogels. Colloid J. 2017, 79, 94–105. [Google Scholar] [CrossRef]

- Ul’yabaeva, G.R.; Podorozhko, E.A.; Kil’deeva, N.R.; Lozinsky, V.I. Study of the acidic textle dye sorption from aqueous solutions by the chitosan-containing composite cryogel of poly(vinyl alcohol). Fibre Chem. 2019, 51, 199–203. [Google Scholar] [CrossRef]

- Podorozhko, E.A.; Ul’yabaeva, G.R.; Kil’deeva, N.R.; Lozinsky, V.I. A study of cryostructuring of polymer systems. 53. “Anomalous” character of the properties variation for the chitosan-containing composite poly(vinyl alcohol) cryogels as a result of multiple freezing-thawing. Colloid J. 2020, 82, 36–48. [Google Scholar] [CrossRef]

- Rodionov, I.A.; Grinberg, N.V.; Burova, T.V.; Grinberg, V.Y.; Lozinsky, V.I. Study of cryo-structuring of polymeric systems. 42. Physical-chemical properties and microstructure of wide-porous covalently cross-linked albumin cryogels. Colloid J. 2016, 78, 492–504. [Google Scholar] [CrossRef]

- Rodionov, I.A.; Grinberg, N.V.; Burova, T.V.; Grinberg, V.Y.; Shabatina, T.I.; Lozinsky, V.I. Cryostructuring of polymer systems. 44. Freeze-dried and then chemically cross-linked wide porous cryostructurates based on serum albumin. e-Polymers 2017, 17, 263–274. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Leonova, I.M.; Ivanov, R.V.; Bakeeva, I.V. A study of cryostructuring of polymer systems. 46. Physicochemical properties and microstructure of poly(vinyl alcohol) cryogels formed from polymer solutions in mixtures of dimethyl sulfoxide with low-molecular-mass alcohols. Colloid J. 2017, 79, 788–796. [Google Scholar] [CrossRef]

- Kolosova, O.Y.; Kurochkin, I.N.; Kurochkin, I.I.; Lozinsky, V.I. Cryostructuring of polymeric systems. 48. Influence of organic non-ionic and ionic chaotropes or kosmotropes on the cryotropic gel-formation of aqueous poly(vinyl alcohol) solutions, as well as on the properties and microstructure of the resultant cryogels. Eur. Polym. J. 2018, 102, 169–177. [Google Scholar] [CrossRef]

- Kolosova, O.Y.; Lozinsky, V.I. Influence of trehalose additives on the properties of poly(vinyl alcohol) cryogels formed in aqueous, as well as in organic media. IOP Conf. Ser. Mater. Sci. Eng. 2019, 525, 012024. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Kolosova, O.Y.; Michurov, D.A.; Dubovik, A.S.; Vasil’ev, V.G.; Grinberg, V.Y. Cryostructuring of polymeric systems. 49. Unexpected “kosmotropic-like” impact of organic chaotropes on the PVA freeze-thaw-induced gelation in DMSO. Gels 2018, 4, 81. [Google Scholar] [CrossRef] [Green Version]

- Lozinsky, V.I.; Michurov, D.A.; Kolosova, O.Y. Polymeric Composition for the Preparation of poly(vinyl alcohol) Cryogels and Method for Increasing Their Strength and Heat Endurance. Russian Patent 2,678,281, 24 January 2019. [Google Scholar]

- Podorozhko, E.A.; Vasil’ev, V.G.; Vasiliev, N.K.; Lozinsky, V.I. Study of cryostructuring of polymer systems. 51. The combined influence of porous cellulose-containing dispersed fillers and salting-out electrolytes on physicochemical properties of composite poly(vinyl alcohol) cryogels. Colloid J. 2019, 81, 261–271. [Google Scholar] [CrossRef]

- Zvukova, N.D.; Klimova, T.P.; Ivanov, R.V.; Ryabev, A.N.; Tsiskarashvili, A.V.; Lozinsky, V.I. Cryostructuring of polymeric systems. 52. Properties, microstructure and an example of a potential biomedical use of the wide-pore alginate cryostructurastes. Gels 2019, 5, 25. [Google Scholar] [CrossRef] [Green Version]

- Bakeeva, I.V.; Orlova, M.A.; Lozinsky, V.I. Poly(vinyl alcohol) cryogels formed from polymer solutions in dimethyl sulfoxide with tetramethoxysilane additives. Fine Chem. Technol. 2019, 14, 41–50. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Shchekoltsova, A.O.; Sinitskaya, E.S.; Vernaya, O.I.; Nuzhdina, A.V.; Bakeeva, I.V.; Ezernitskaya, M.G.; Semenov, A.M.; Shabatina, T.I.; Melnikov, M.Y. Influence of succinylation of a wide-pore albumin cryogels on their properties, structure, biodegradability, and release dynamics of dioxidine loaded in such spongy carriers. Int. J. Biol. Macromol. 2020, 160, 583–592. [Google Scholar] [CrossRef] [PubMed]

- Rogozhin, S.V.; Slonimskii, G.L.; Rogowina, L.Z.; Vainerman, E.S.; Pivovarov, P.P. Structuration of myofibril krill proteins. Food/Nahrung 1981, 25, 391–396. [Google Scholar] [CrossRef]

- Rogozhin, S.V.; Belavtseva, E.M.; Vernerman, E.S.; Radchenko, L.G.; Pivovarov, P.P.; Golovina, T.O.; Pertsevoy, F.V. Electron-microscopic studies of structure formation of isolated myofibrillar proteins during the freezing-thawing processes. Food/Nahrung 1984, 28, 165–171. [Google Scholar] [CrossRef]

- Vainerman, E.S.; Lozinsky, V.I.; Rogozhin, S.V.; Raskina, L.P.; Shapiro, L.A.; Yakubovich, V.S.; Bronshtein, V.Y. Method for the Preparation of Porous Alginate Material. SU Patent 1,171,474, 8 April 1985. [Google Scholar]

- Vainerman, E.S.; Lozinsky, V.I.; Rogozhin, S.V.; Raskina, L.P.; Shapiro, L.A.; Yakubovich, V.S.; Shenker, M.B.; Komissarova, A.L.; Potapov, V.D.; Gudochkova, V.M. Method for the Preparation of Porous Material Possessing the Wound-Healing Ability. SU Patent 1,171,476, 8 April 1985. [Google Scholar]

- Duda, V.I.; Krivenko, V.I.; Rogozhin, S.V.; Lozinsky, V.I.; Mamtsis, A.M.; Vainerman, E.S.; Domotenko, L.V.; Shtil’man, M.I.; Ivanova, S.A. Method for the Preparation of Solid Nutritional Medium for Culturing of Microorganisms. SU Patent 1,213,069, 22 October 1985. [Google Scholar]

- Lozinsky, V.I.; Vainerman, E.S.; Rogozhin, S.V. Method for the Preparation of Immobilized Cells. SU Patent 1,400,071, 1 February 1988. [Google Scholar]

- Faleev, N.G.; Lozinsky, V.I.; Sadovnikova, M.S.; Vainerman, E.S.; Ruvinov, S.B.; Safiullin, R.M.; Belikov, V.M.; Rogozhin, S.V. Method for the Preparation of the Fluorine-Derivatives of l-tyrosine. SU Patent 1,351,971, 15 July 1987. [Google Scholar]

- Lozinsky, V.I.; Faleev, N.G.; Zubov, A.L.; Ruvinov, S.B.; Antonova, T.A.; Vainerman, E.S.; Belikov, V.M.; Rogozhin, S.V. Use of PVA-cryogel entrapped Citrobacter intermedius cells for continuous production of 3-fluoro-L-tyrosine. Biotechnol. Lett. 1989, 11, 43–48. [Google Scholar] [CrossRef]

- Rainina, E.I.; Lozinsky, V.I.; Galkina, I.A.; Morozova, S.A.; Vainerman, E.S.; Sinitsyn, A.P.; Shtil’man, M.I.; Rogozhin, S.V. Method for the Preparation of Immobilized Yeast Cells Used for Ethanol Production. SU Patent 1,387,412, 8 December 1987. [Google Scholar]

- Tavobilov, I.M.; Lozinsky, V.I.; Manolov, R.G.; Vainerman, E.S.; Bezborodova, S.I.; Rogozhin, S.V.; Bezborodov, A.M. Method for the Cultivation of Mycelium Fungi Capable of Producing Ribonucleases. SU Patent 1,405,310, 22 February 1988. [Google Scholar]

- Alexandrova, I.V.; Vainerman, E.S.; Domotenko, L.V.; Epifanov, A.E.; Kruglova, N.P.; Lozinsky, V.I.; Mamtsis, A.M.; Morozova, O.M.; Nikolaeva, V.V.; Rogozhin, S.V.; et al. Method for Culturing of Isolated Plants Tissues and Cells Capable to Produce the Biologically Active Substances. SU Patent 1,438,236, 15 July 1988. [Google Scholar]

- Rogozhin, S.V.; Egorov, S.N.; Lozinsky, V.I.; Gavrilenko, L.V.; Vainerman, E.S.; Semenova, I.N. Method for the Production of Acid Phosphatase by the Yeast Saccharomyces cerevisiae. SU Patent 1,505,972, 08 May 1989. [Google Scholar]

- Rainina, V.I.; Lozinsky, V.I.; Bachurina, G.P.; Makhlis, T.A.; Sinitsyn, A.P.; Vainerman, E.S.; Morozov, A.M.; Badalov, A.B.; Kleysov, A.A.; Rogozhin, S.V. Method for the Production of Ethanol. SU Patent 1,589,627, 1 May 1990. [Google Scholar]

- Lozinsky, V.I.; Zubov, A.L.; Makhlis, T.A. Entrapment of Zymomonas mobilis cells into PVA-cryogel carrier in the presence of polyol cryoprotectants. Prog. Biotechnol. 1996, 11, 112–117. [Google Scholar]

- Shtil’man, M.I.; Denisova, L.A.; Ostaeva, G.Y.; Donetsky, I.A.; Kondaryuk, V.V.; Pchelintseva, O.A.; Lozinsky, V.I.; Vainerman, E.S.; Rogozhin, S.V. Polymeric Reagent for the Covalent Immobilization of Serum Albumin. SU Patent 1,531,440, 22 August 1989. [Google Scholar]

- Arzumanov, E.N.; Alebian, G.P.; Tozalakian, P.V.; Lozinsky, V.I.; Vainerman, E.S.; Rogozhin, S.V.; Shtil’man, M.I. Method for the Preparation of l-aspartic Acid. SU Patent 1,559,716, 22 December 1989. [Google Scholar]

- Arzumanov, E.N.; Alebian, G.P.; Tozalakian, P.V.; Mkrtchian, M.V.; Lozinsky, V.I.; Vainerman, E.S.; Rogozhin, S.V. Method for the preparation of l-alanine. SU Patent 1,559,719, 22 December 1989. [Google Scholar]

- Alebian, G.P.; Arzumanov, E.N.; Mkrtchian, M.V.; Tozalakian, P.V.; Lozinsky, V.I.; Vainerman, E.S.; Rogozhin, S.V. Kinetic aspects of l-aspartate-β-decarboxylase functioning in free and immobilized Alcaligenes faecalis cells in the course of l-aspartic acid transformation to l-alanine. Sov. Biotechnol. 1990, 6, 36–40. [Google Scholar]

- Rogozhin, S.V.; Vainerman, E.S.; Pichugin, N.M.; Kirilenko, Y.K.; Lozinsky, V.I.; Kosolapov, A.M.; Gnezdilova, T.V.; Chumakov, S.D.; Aboyants, R.K.; Istranov, L.P. Method for the preparation of collagen material. SU Patent 1,603,723, 1 July 1990. [Google Scholar]

- Lozinsky, V.I.; Gnezdilova, T.V. Method for the Preparation of Fungous Collagen-Containing Material. Russian Patent 2,053,796, 10 February 1996. [Google Scholar]

- Podorozhko, E.A.; Kulakova, V.K.; Kurskaya, E.I.; Lozinsky, V.I. Method for the Obtaining of Porous Collagen-Containing Material. Russian Patent 2,116,801, 10 August 1998. [Google Scholar]

- Rogozhin, S.V.; Pichugin, N.M.; Vainerman, E.S.; Gnezdilova, T.V.; Kirilenko, Y.K.; Lozinsky, V.I.; Chumakov, S.D. Method for the Preparation of Collagen Material. SU Patent 1,653,318, 1 February 1991. [Google Scholar]

- Rogozhin, S.V.; Pichugin, N.M.; Vainerman, E.S.; Gnezdilova, T.V.; Kirilenko, Y.K.; Lozinsky, V.I.; Chumakov, S.D. Method for the Preparation of Collagen-Containing Material. SU Patent 1,678,021, 15 May 1991. [Google Scholar]

- Lozinsky, V.I.; Gnezdilova, T.V.; Vainerman, E.S.; Rogozhin, S.V. Method for the Preparation of Collagen-Containing Material. SU Patent 1,769,539, 15 June 1992. [Google Scholar]

- Mikhalev, O.I.; Petrov, A.N.; Gnezdilova, T.V.; Lozinsky, V.I.; Alfimov, M.V. Method for the Preparation of Collagen-Containing Material. Russian Patent 2,008,362, 28 February 1994. [Google Scholar]

- Kalinina, E.V.; Semenova, N.N.; Rogozhin, S.V.; Lozinsky, V.I. Method for the Preparation of Porous-Fibrous Material. Russian Patent 2,116,350, 27 July 1998. [Google Scholar]

- Lozinsky, V.I.; Vainerman, E.S.; Rogozhin, S.V.; Barkovskaya, E.N.; Razbegin, B.N.; Chapaev, A.A.; Maksimyak, R.V. Method for the Fixation of a Thawed Ground. SU Patent 1,705,500, 15 September 1991. [Google Scholar]

- Lozinsky, V.I.; Zubov, A.L. Device for the Formation of Spherical Granules on the Basis of Aqueous Systems. Russian Patent 2,036,095, 27 May 1995. [Google Scholar]

- Lozinsky, V.I.; Zubov, A.L. Set-Up for the Formation of Granules. Russian Patent 2,104,866, 20 February 1998. [Google Scholar]

- Zubov, A.L.; Lozinsky, V.I. Method for the Preparation of Granulated Artificial Bait. Russian Patent 2,054,254, 20 February 1996. [Google Scholar]

- Simonian, A.L.; Rainina, E.I.; Lozinsky, V.I.; Badalian, I.E.; Khachatrian, G.A.; Tatikian, S.S.; Makhlis, T.A.; Varfolomeev, S.D. A biosensor for l-proline determination by use of immobilized microbial cells. Appl. Biochem. Biotechnol. 1992, 36, 199–210. [Google Scholar] [CrossRef]

- Velizarov, S.; Rainina, E.I.; Lozinsky, V.I.; Zubov, A.L.; Sinitsyn, A.P.; Varfolomeev, S.D. l-lysine production by Corynebacterium glutamicum cells entrapped in PVA-cryogel. Biotechnol. Lett. 1992, 14, 291–296. [Google Scholar] [CrossRef]

- Nikitina, O.A.; Zatsepin, S.S.; Kalyuzhnyi, S.V.; Rainina, E.I.; Varfolomeev, S.D.; Zubov, A.L.; Lozinsky, V.I. Production of hydrogen by thermophylic anaerobic bacterium Clostridium thermosaccharolyticum immobilized into polyvinyl alcohol cryogel. Microbiology 1993, 62, 296–301. [Google Scholar]

- Lozinsky, V.I.; Konstantinova, N.R.; Solov’eva, N.R. Method for the Preparation of Porous Protein Gel. Russian Patent 2,058,083, 20 April 1996. [Google Scholar]

- Korolenko, I.I.; Lozinsky, V.I.; Sobolev, A.V.; Fesenko, A.V.; Chebyshev, A.V.; Chuiko, K.K.; Shumilkin, A.V. Method for the Determination of Toxic Substances in Gaseous Mixtures. Russian Patent 2,066,449, 10 September 1996. [Google Scholar]

- Pusheva, M.A.; Ryabokon’, A.N.; Rainina, E.I.; Detkova, E.I.; Zubov, A.L.; Lozinsky, V.I.; Varfolomeev, S.D.; Zavarzin, G.A. Microbial Method for the Preparation of Acetate. Russian Patent 2,080,388, 25 May 1997. [Google Scholar]

- Rainina, E.I.; Pusheva, M.A.; Ryabokon’, A.M.; Bolotina, N.P.; Lozinsky, V.I.; Varfolomeev, S.D. Microbial cells immobilized in poly(vinyl alcohol) cryogels: Biocatalytic reduction of CO2 by the thermophilic homoacetogenic bacterium Acetogenium kivuii. Biotechnol. Appl. Biochem. 1994, 19, 321–329. [Google Scholar]

- Ryabokon’, A.M.; Kevbrina, M.V.; Pusheva, M.A.; Zubov, A.L.; Lozinsky, V.I.; Rainina, E.A. Ecologically pure process of acetate synthesis on diverse gaseous substrates by homoacetogenic bacteria entrapped in poly(vinyl alcohol) cryogel. Prog. Biotechnol. 1996, 11, 106–111. [Google Scholar]

- Fokina, V.V.; Arinbasarova, A.Y.; Zubov, A.L.; Lozinsky, V.I.; Koshcheenko, K.A. Dehydrogenation of sterol substrates by bacterial cells Arthrobacter globiformis 193 entrapped into poly(vinyl alcohol) cryogels. Appl. Biochem. Microbiol. 1995, 31, 184–189. [Google Scholar]

- Fokina, V.; Susina, N.; Arinbasarova, A.; Zubov, A.; Lozinsky, V.; Koshcheenko, K. Immobilization of Arthrobacter globiformis 193 cells into PVA cryogel. Dehydrogenation of steroid substrates. Prog. Biotechnol. 1996, 11, 90–97. [Google Scholar]

- Vainerman, E.S.; Podorozhko, E.A.; Portnaya, I.B. Method for the Preparation of Porous Wares from Polymeric Dispersions. Russian Patent 2,062,277, 15 January 1998. [Google Scholar]

- Vainerman, E.S.; Portnaya, I.B. Methods for the Articles Manufactoring from Polymeric Dispersions. Russian Patent 2,108,350, 10 April 1998. [Google Scholar]

- Vainerman, E.S.; Portnaya, I.B. Porous Polymer Material and the Method for the Preparation Thereof. Russian Patent 2,109,766, 27 April 1998. [Google Scholar]

- Podorozhko, E.A.; Portnaya, I.B.; Kulakova, V.K.; Kurskaya, E.A. Method for the Preparation of Porous Material. Russian Patent 2,115,668, 20 July 1998. [Google Scholar]

- Podorozhko, E.A.; Andreeva, L.M.; Kurskaya, E.A.; Lozinsky, V.I. Method for the Preparation of Porous Protein Texturate. Russian Patent 2,118,495, 10 September 1998. [Google Scholar]

- Lozinsky, V.I.; Plieva, F.M.; Isaeva, E.I.; Zubov, A.L. Method for the Concentrating of Viruses. Russian Patent 2,130,069, 10 May 1999. [Google Scholar]

- Plieva, F.M.; Isaeva, E.I.; Lozinsky, V.I. Application of poly(vinyl alcohol) cryogels in biotechnology. V. Bioaffinity sorbents on the basis of supermacroporous carrier for the manipulation with virus particles. Biotechnol. Russ. 1998, 10, 12–17. [Google Scholar]

- Gough, S.; Barron, N.; Zubov, A.L.; Lozinsky, V.I.; McHale, A.P. Production of ethanol from molasses at 45 °C using Kluyveromyces marxianus IMB3 immobilized in calcium alginate gels and poly(vinyl alcohol) cryogel. Bioprocess Eng. 1998, 19, 87–90. [Google Scholar] [CrossRef]

- Belokon, Y.N.; Kochetkov, K.A.; Plieva, F.M.; Ikonnikov, N.S.; Maleev, V.I.; Parmar, V.S.; Kumar, R.; Lozinsky, V.I. Enantioselective hydrolysis of a Schiff’s base of D,L-phenylalanine ethyl ester in water-poor media through the reaction catalyzed with α-chymotrypsin immobilyzed in hydrophilic macroporous gel support. Appl. Biochem. Biotechnol. 2000, 88, 97–106. [Google Scholar] [CrossRef]

- Markvicheva, E.A.; Lozinsky, V.I.; Plieva, F.M.; Kochetkov, K.A.; Rumsh, L.D.; Zubov, V.P.; Maity, J.; Kumar, R.; Parmar, V.; Belokon, Y.N. Gel-immobilized enzymes as promising biocatalysts: Results from Indo-Russian collaborative studies. Pure Appl. Chem. 2005, 77, 227–236. [Google Scholar] [CrossRef]

- Plieva, F.M.; Kochetkov, K.A.; Singh, I.; Parmar, V.S.; Belokon’, Y.N.; Lozinsky, V.I. Immobilization of hog pancreas lipase in macroporous PVA-cryogel carrier for the biocatalysis in water-poor media. Biotechnol. Lett. 2000, 22, 551–554. [Google Scholar] [CrossRef]

- Bacheva, A.V.; Plieva, F.M.; Lysogorskaya, E.N.; Filippova, I.Y.; Lozinsky, V.I. Peptide synthesis in organic media with subtilisin 72 immobilized on poly(vinyl alcohol)-cryogel carrier. Bioorg. Med. Chem. Lett. 2001, 11, 1005–1008. [Google Scholar] [CrossRef]

- Filippova, I.Y.; Bacheva, A.V.; Baibak, O.V.; Plieva, F.M.; Lysogorskaya, E.N.; Oksenoit, E.S.; Lozinsky, V.I. Biocatalysts for peptide synthesis in organic media—Proteinases immobilized on poly(vinyl alcohol)-cryogel. Russ. Chem. Bull. 2001, 50, 1896–1901. [Google Scholar] [CrossRef]

- Bacheva, A.V.; Baibak, O.V.; Belyaeva, A.V.; Lysogorskaya, E.N.; Oksenoit, E.S.; Lozinsky, V.I.; Filippova, I.Y. Native and modified subtilisin 72 as a catalyst for peptide synthesis in media with a low water content. Russ. J. Bioorgan. Chem. 2003, 29, 502–508. [Google Scholar] [CrossRef] [PubMed]

- Bacheva, A.V.; Baibak, O.V.; Belyaeva, A.V.; Oksenoit, E.S.; Velichko, T.I.; Lysogorskaya, E.N.; Gladilin, A.K.; Lozinsky, V.I.; Filippova, I.Y. Activity and stability of native and modified subtilisin in different media. Biochemistry (Mosc.) 2003, 68, 1261–1266. [Google Scholar] [CrossRef] [PubMed]

- Bacheva, A.V.; Belyaeva, A.V.; Lysogorskaya, E.N.; Oksenoit, E.S.; Lozinsky, V.I.; Filippova, I.Y. Biocatalytic properties of native and immobilized subtilisin 72 in aqueous-organic and low water media. J. Mol. Catal. B Enzym. 2005, 32, 253–260. [Google Scholar] [CrossRef]

- Belyaeva, A.V.; Bacheva, A.V.; Oksenoit, E.S.; Lysogorskaya, E.N.; Lozinsky, V.I.; Filippova, I.Y. Peptide synthesis in organic media with the use of subtilisin 72 immobilised on a poly(vinyl alcohol) cryogel. Russ. J. Bioorgan. Chem. 2005, 31, 529–534. [Google Scholar] [CrossRef]

- Belyaeva, A.V.; Smirnova, Y.A.; Lysogorskaya, E.N.; Oksenoit, E.S.; Timofeeva, A.V.; Lozinsky, V.I.; Filippova, I.Y. Biocatalytic properties of thermolysin immobilized on poly(vinyl alcohol) cryogel. Russ. J. Bioorgan. Chem. 2008, 34, 435–441. [Google Scholar] [CrossRef]

- Lysogorskaya, E.N.; Roslyakova, T.V.; Belyaeva, A.V.; Bacheva, A.V.; Lozinsky, V.I.; Filippova, I.Y. Preparation and catalytic properties of trypsin immobilized on cryogels of poly(vinyl alcohol). Appl. Biochem. Microbiol. 2008, 44, 241–246. [Google Scholar] [CrossRef]