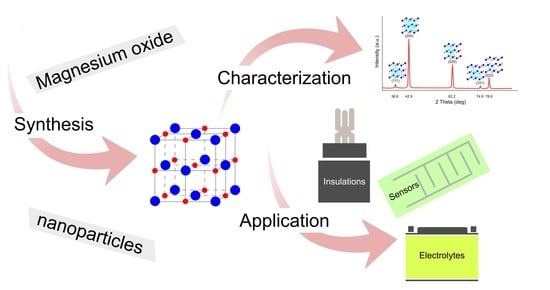

Synthesis, Properties, and Selected Technical Applications of Magnesium Oxide Nanoparticles: A Review

Abstract

:1. Introduction

2. Synthesis of Magnesium Oxide Nanoparticles

2.1. Co-Precipitation

2.2. Sol–Gel Method

2.3. Solvo- and Hydrothermal Method

2.4. Combustion Method

2.5. Green Synthesis

| Co-Precipitation Method | |||||||

|---|---|---|---|---|---|---|---|

| Precursor | Precipitation agent | Reaction temperature | Calcination temperature | Calcination time | Size | Expected application | Ref. |

| Mg(NO) | NHHO | 60; 70; 80 °C | 550 °C | 2 h | 50 nm | - | [73] |

| Mg(NO) | NHOH | 100 °C | 600 °C | 4–6 h | 11 nm | antibacterial | [74] |

| Mg(NO) | NaOH | room | 500 °C | 4 h | 14–16 nm | antibacterial | [75] |

| (NH)CO | MgCl | 80 °C | 550 °C | 4 h | 24 nm | - | [76] |

| Mg(NO) | NaOH | - | 440 °C | 4.5 h | ca. 15 nm | catalyst | [77] |

| Mg(NO) | NaOH | room | room | - | 78 nm | antibacterial | [78] |

| Sol–Gel Method | |||||||

| Precursor | Solvent | Gel drying temperature | Calcination temperature | Calcination time | Size | Expected application | Ref. |

| Mg(CHCOO) | CHO | - | 600 °C | 6 h | - | - | [82] |

| Mg(CHCOO) | CHO | 200 °C | 950 °C | 6 h | - | - | [83] |

| Mg(NO) | NaOH | 300 °C | 500 °C | 2 h | 50–60 nm | adsorber | [84] |

| Mg(OCH) | CHOH; CH | - | 500 °C | 5 h | 200–300 nm | - | [85] |

| Mg(OCH) | CHOH; CH | 60 °C | 450 °C | - | ca. 8 nm | - | [86] |

| Mg(NO) | dHO | 150 °C | 500 °C | 2 h | 60 nm | - | [87] |

| Mg(NO) | CHO; CHO; | 350 °C | 550; 800 °C | 2 h | 12 nm | catalyst | [88] |

| Solvo- and Hydrothermal Method | |||||||

| Precursor | Solvent | Autoclave temperature | Calcination temperature | Calcination time | Size | Expected application | Ref. |

| Mg(NO) | NaOH | 130 °C | 400–800 °C | 2 h | 25 nm | - | [91] |

| Mg(CHCOO) | NHCONH | 180 °C | 600 °C | 1 h | 6 nm | antibacterial | [92] |

| Mg(NO) | NaOH | 80 °C | 280–450 °C | 1; 2; 2 h | 50 nm | catalyst | [93] |

| MgSO | NHHO; en-HO | 180 °C | 280–450 °C | 1; 2; 2 h | 100–200 nm | catalyst | [93] |

| Mg | HO | 220 °C | - | - | 18 nm | antibacterial | [94] |

| Mg(NO) | NaOH | 100 °C | 500 °C | 4 h | 40–60 nm | adsorber | [95] |

| Oxidizer | Fuel | Ignition temperature | Calcination temperature | Calcination time | Size | Expected application | Ref. |

| Mg(NO) | NHCONH | 70-80 °C | 500 °C | 3 h | 22 nm | adsorber | [38] |

| Mg(NO) | NHCONH | 100 °C | 300 °C | 2 h | 18–53 nm | - | [100] |

| Mg(NO) | NHCHCOOH | 170 °C | 600 °C | 2 h | ca. 21 nm | fuel additive | [101] |

| Mg(NO) | CHO | 100 °C | 400 °C | 15 min | 20–35 nm | antibacterial | [102] |

| Mg(NO) | Parthenium | 400 °C | - | - | 27–35 nm | photocatalyst | [103] |

| extract | |||||||

| Green Synthesis | |||||||

| Precursor solution | Reagent extract | Reaction temperature | Calcination temperature | Calcination time | Size | Expected application | Ref. |

| Mg(NO) | Nephelium | 80 °C | 450 °C | - | 55 nm | - | [109] |

| lappaceum | |||||||

| Mg(NO) | Trigonella | 80 °C | 600 °C | 4 h | 14 nm | antibacterial | [110] |

| foenum-graecum | |||||||

| Mg(NO) | Rosa floribunda | 90 °C | - | - | 10 nm | antibacterial | [111] |

| Bulk MgO | Rosmarinus | 70 °C | - | - | ca. 9 nm | antibacterial | [112] |

| officinalis | |||||||

| Mg(NO) | Dalbergia sissoo | 30–70 °C | - | - | 50 nm | photocatalyst | [113] |

| Mg(NO) | Saussurea costus | 80 °C | 450 °C | 3 h | 30 nm | photocatalyst | [114] |

| Mg(NO) | Swertia chirayaita | 55 °C | 400 °C | 4 h | <20 nm | antibacterial | [115] |

| MgCl | Moringa oleifera | 90 °C | 600 °C | 5 h | ca. 21 nm | antibacterial | [116] |

| Mg(NO) | Tecoma stans | 90 °C | 550 °C | 6 h | 20–50 nm | adsorber | [117] |

3. Selected Technical Applications of Magnesium Oxide

3.1. Sensors Based on MgO

3.2. Electrical Insulating Materials Filled with MgO

3.3. Polymer-Based Electrolytes Doped with MgO

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Trotta, F.; Mele, A. Nanomaterials: Classification and Properties. In Nanosponges; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2019; pp. 142–149. ISBN 978-3-527-34100-9. [Google Scholar]

- Hannah, W.; Thompson, P.B. Nanotechnology, Risk and the Environment: A Review. J. Environ. Monit. 2008, 10, 291–300. [Google Scholar] [CrossRef] [PubMed]

- Jeevanandam, J.; Barhoum, A.; Chan, Y.S.; Dufresne, A.; Danquah, M.K. Review on Nanoparticles and Nanostructured Materials: History, Sources, Toxicity and Regulations. Beilstein J. Nanotechnol. 2018, 9, 1050–1074. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mitra, S.B. Chapter 2-Nanoparticles for dental materials: Synthesis, analysis, and applications. In Emerging Nanotechnologies in Dentistry, 2nd ed.; Subramani, K., Ahmed, W., Eds.; Micro and Nano Technologies; William Andrew Publishing: Norwich, NY, USA, 2018; pp. 17–39. ISBN 978-0-12-812291-4. [Google Scholar]

- Baig, N.; Kammakakam, I.; Falath, W. Nanomaterials: A Review of Synthesis Methods, Properties, Recent Progress, and Challenges. Mater. Adv. 2021, 2, 1821–1871. [Google Scholar] [CrossRef]

- Saleh, T.A. Nanomaterials: Classification, Properties, and Environmental Toxicities. Environ. Technol. Innov. 2020, 20, 101067. [Google Scholar] [CrossRef]

- Malhotra, B.D.; Ali, M.A. Chapter 1-Nanomaterials in Biosensors: Fundamentals and Applications. In Nanomaterials for Biosensors; Malhotra, B.D., Ali, M.D.A., Eds.; Micro and Nano Technologies; William Andrew Publishing: Norwich, NY, USA, 2018; pp. 1–74. ISBN 978-0-323-44923-6. [Google Scholar]

- Khalid, K.; Tan, X.; Mohd Zaid, H.F.; Tao, Y.; Lye Chew, C.; Chu, D.-T.; Lam, M.K.; Ho, Y.-C.; Lim, J.W.; Chin Wei, L. Advanced in Developmental Organic and Inorganic Nanomaterial: A Review. Bioengineered 2020, 11, 328–355. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ealia, S.A.M.; Saravanakumar, M.P. A Review on the Classification, Characterisation, Synthesis of Nanoparticles and Their Application. IOP Conf. Ser. Mater. Sci. Eng. 2017, 263, 032019. [Google Scholar] [CrossRef]

- Cartwright, A.; Jackson, K.; Morgan, C.; Anderson, A.; Britt, D.W. A Review of Metal and Metal-Oxide Nanoparticle Coating Technologies to Inhibit Agglomeration and Increase Bioactivity for Agricultural Applications. Agronomy 2020, 10, 1018. [Google Scholar] [CrossRef]

- Sánchez-López, E.; Gomes, D.; Esteruelas, G.; Bonilla, L.; Lopez-Machado, A.L.; Galindo, R.; Cano, A.; Espina, M.; Ettcheto, M.; Camins, A.; et al. Metal-Based Nanoparticles as Antimicrobial Agents: An Overview. Nanomaterials 2020, 10, 292. [Google Scholar] [CrossRef] [Green Version]

- Yaqoob, A.A.; Ahmad, H.; Parveen, T.; Ahmad, A.; Oves, M.; Ismail, I.M.I.; Qari, H.A.; Umar, K.; Mohamad Ibrahim, M.N. Recent Advances in Metal Decorated Nanomaterials and Their Various Biological Applications: A Review. Front. Chem. 2020, 8, 341. [Google Scholar] [CrossRef]

- Cousin, P.; Ross, R.A. Preparation of Mixed Oxides: A Review. Mater. Sci. Eng. A 1990, 130, 119–125. [Google Scholar] [CrossRef]

- Danish, M.S.S.; Bhattacharya, A.; Stepanova, D.; Mikhaylov, A.; Grilli, M.L.; Khosravy, M.; Senjyu, T. A Systematic Review of Metal Oxide Applications for Energy and Environmental Sustainability. Metals 2020, 10, 1604. [Google Scholar] [CrossRef]

- Chavali, M.S.; Nikolova, M.P. Metal Oxide Nanoparticles and Their Applications in Nanotechnology. SN Appl. Sci. 2019, 1, 607. [Google Scholar] [CrossRef] [Green Version]

- Ahamed, M.; Akhtar, M.J.; Alhadlaq, H.A. Co-Exposure to SiO2 Nanoparticles and Arsenic Induced Augmentation of Oxidative Stress and Mitochondria-Dependent Apoptosis in Human Cells. Int. J. Environ. Res. Public Health 2019, 16, 3199. [Google Scholar] [CrossRef] [Green Version]

- Yang, C.; Chen, H.; Guan, C. Hybrid CoO Nanowires Coated with Uniform Polypyrrole Nanolayers for High-Performance Energy Storage Devices. Nanomaterials 2019, 9, 586. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liang, Y.-C.; Chang, Y.-C.; Zhao, W.-C. Design and Synthesis of Novel 2D Porous Zinc Oxide-Nickel Oxide Composite Nanosheets for Detecting Ethanol Vapor. Nanomaterials 2020, 10, 1989. [Google Scholar] [CrossRef]

- Monteserín, C.; Blanco, M.; Murillo, N.; Pérez-Márquez, A.; Maudes, J.; Gayoso, J.; Laza, J.M.; Aranzabe, E.; Vilas, J.L. Effect of Different Types of Electrospun Polyamide 6 Nanofibres on the Mechanical Properties of Carbon Fibre/Epoxy Composites. Polymers 2018, 10, 1190. [Google Scholar] [CrossRef] [Green Version]

- Duffy, T.; Madhusudhan, N.; Lee, K.K.M. 2.07-Mineralogy of Super-Earth Planets. In Treatise on Geophysics, 2nd ed.; Schubert, G., Ed.; Elsevier: Oxford, UK, 2015; pp. 149–178. ISBN 978-0-444-53803-1. [Google Scholar]

- Cheremisinoff, N.P.V. Condensed Encyclopedia of Polymer Engineering Terms; Cheremisinoff, N.P., Ed.; Butterworth-Heinemann: Boston, MA, USA, 2001; pp. 340–347. ISBN 978-0-08-050282-3. [Google Scholar]

- Akinwekomi, A.D.; Tang, C.-Y.; Tsui, G.C.-P.; Law, W.-C.; Chen, L.; Yang, X.-S.; Hamdi, M. Synthesis and Characterisation of Floatable Magnesium Alloy Syntactic Foams with Hybridised Cell Morphology. Mater. Des. 2018, 160, 591–600. [Google Scholar] [CrossRef]

- Singh, J.P.; Chae, K.H. D° Ferromagnetism of Magnesium Oxide. Condens. Matter 2017, 2, 36. [Google Scholar] [CrossRef] [Green Version]

- Collaboration: Authors and editors of the volumes III/17B-22A-41B Magnesium oxide (MgO) crystal structure, lattice parameters, thermal expansion. In II-VI and I-VII Compounds; Semimagnetic Compounds; Madelung, O.; Rössler, U.; Schulz, M. (Eds.) Landolt-Börnstein-Group III Condensed Matter; Springer: Berlin/Heidelberg, Germany, 1999; Volume 41b, pp. 1–6. ISBN 978-3-540-64964-9. [Google Scholar]

- Green, J. Calcination of Precipitated Mg(OH)2 to Active MgO in the Production of Refractory and Chemical Grade MgO. J. Mater. Sci. 1983, 18, 637–651. [Google Scholar] [CrossRef]

- Diachenko, O.V.; Opanasuyk, A.S.; Kurbatov, D.I.; Opanasuyk, N.M.; Kononov, O.K.; Nam, D.; Cheong, H. Surface Morphology, Structural and Optical Properties of MgO Films Obtained by Spray Pyrolysis Technique. Acta Phys. Pol. A 2016, 130, 805–810. [Google Scholar] [CrossRef]

- Ashok, C.H.; Venkateswara, R.K.; Shilpa-Chakra, C.H. Synthesis and Characterization of MgO/TiO2 Nanocomposites. J. Nanomed Nanotechnol 2015, 6. [Google Scholar] [CrossRef] [Green Version]

- Almontasser, A.; Parveen, A.; Azam, A. Synthesis, Characterization and Antibacterial Activity of Magnesium Oxide (MgO) Nanoparticles. IOP Conf. Ser. Mater. Sci. Eng. 2019, 577, 012051. [Google Scholar] [CrossRef]

- Nemade, K.R.; Waghuley, S.A. Synthesis of MgO Nanoparticles by Solvent Mixed Spray Pyrolysis Technique for Optical Investigation. Int. J. Met. 2014, 2014, e389416. [Google Scholar] [CrossRef]

- Dobrucka, R. Synthesis of MgO Nanoparticles Using Artemisia Abrotanum Herba Extract and Their Antioxidant and Photocatalytic Properties. Iran. J. Sci. Technol. Trans. Sci. 2018, 42, 547–555. [Google Scholar] [CrossRef] [Green Version]

- Alexander, L.; Klug, H.P. Determination of Crystallite Size with the X-Ray Spectrometer. J. Appl. Phys. 1950, 21, 137–142. [Google Scholar] [CrossRef] [Green Version]

- Holzwarth, U.; Gibson, N. The Scherrer Equation versus the “Debye-Scherrer Equation”. Nat. Nanotech 2011, 6, 534. [Google Scholar] [CrossRef] [PubMed]

- Al-Tabbakh, A.A.; Karatepe, N.; Al-Zubaidi, A.B.; Benchaabane, A.; Mahmood, N.B. Crystallite Size and Lattice Strain of Lithiated Spinel Material for Rechargeable Battery by X-Ray Diffraction Peak-Broadening Analysis. Int. J. Energy Res. 2019, 43, 1903–1911. [Google Scholar] [CrossRef]

- Nath, D.; Singh, F.; Das, R. X-Ray Diffraction Analysis by Williamson-Hall, Halder-Wagner and Size-Strain Plot Methods of CdSe Nanoparticles- a Comparative Study. Mater. Chem. Phys. 2020, 239, 122021. [Google Scholar] [CrossRef]

- Canchanya-Huaman, Y.; Mayta-Armas, A.F.; Pomalaya-Velasco, J.; Bendezú-Roca, Y.; Guerra, J.A.; Ramos-Guivar, J.A. Strain and Grain Size Determination of CeO2 and TiO2 Nanoparticles: Comparing Integral Breadth Methods versus Rietveld, μ-Raman, and TEM. Nanomaterials 2021, 11, 2311. [Google Scholar] [CrossRef]

- Mote, V.; Purushotham, Y.; Dole, B. Williamson-Hall Analysis in Estimation of Lattice Strain in Nanometer-Sized ZnO Particles. J. Theor. Appl. Phys. 2012, 6. [Google Scholar] [CrossRef] [Green Version]

- Selvam, N.C.S.; Kumar, R.T.; Kennedy, L.J.; Vijaya, J.J. Comparative Study of Microwave and Conventional Methods for the Preparation and Optical Properties of Novel MgO-Micro and Nano-Structures. J. Alloy. Compd. 2011, 509, 9809–9815. [Google Scholar] [CrossRef]

- Balakrishnan, G.; Velavan, R.; Mujasam Batoo, K.; Raslan, E.H. Microstructure, Optical and Photocatalytic Properties of MgO Nanoparticles. Results Phys. 2020, 16, 103013. [Google Scholar] [CrossRef]

- Chizallet, C.; Costentin, G.; Lauron-Pernot, H.; Krafft, J.M.; Bazin, P.; Saussey, J.; Delbecq, F.; Sautet, P.; Che, M. Role of Hydroxyl Groups in the Basic Reactivity of MgO: A Theoretical and Experimental Study. Oil Gas Sci.-Technol.-Rev. Ifp 2006, 61, 479–488. [Google Scholar] [CrossRef] [Green Version]

- Kumar, A.; Kumar, J. On the Synthesis and Optical Absorption Studies of Nano-Size Magnesium Oxide Powder. J. Phys. Chem. Solids 2008, 69, 2764–2772. [Google Scholar] [CrossRef]

- Sutradhar, N.; Sinhamahapatra, A.; Roy, B.; Bajaj, H.C.; Mukhopadhyay, I.; Panda, A.B. Preparation of MgO Nano-Rods with Strong Catalytic Activity via Hydrated Basic Magnesium Carbonates. Mater. Res. Bull. 2011, 46, 2163–2167. [Google Scholar] [CrossRef]

- Kimiagar, S.; Abrinaei, F. Effect of Temperature on the Structural, Linear, and Nonlinear Optical Properties of MgO-Doped Graphene Oxide Nanocomposites. Nanophotonics 2018, 7, 243–251. [Google Scholar] [CrossRef]

- Verma, R.; Naik, K.K.; Gangwar, J.; Srivastava, A.K. Morphology, Mechanism and Optical Properties of Nanometer-Sized MgO Synthesized via Facile Wet Chemical Method. Mater. Chem. Phys. 2014, 148, 1064–1070. [Google Scholar] [CrossRef]

- Soma, H.; Uchino, T. Blue and Orange Photoluminescence and Surface Band-Gap Narrowing in Lithium-Doped MgO Microcrystals. J. Phys. Chem. C 2017, 121, 1884–1892. [Google Scholar] [CrossRef]

- Li, J.; Khalid, A.; Verma, R.; Abraham, A.; Qazi, F.; Dong, X.; Liang, G.; Tomljenovic-Hanic, S. Silk Fibroin Coated Magnesium Oxide Nanospheres: A Biocompatible and Biodegradable Tool for Noninvasive Bioimaging Applications. Nanomaterials 2021, 11, 695. [Google Scholar] [CrossRef] [PubMed]

- Hornak, J.; Trnka, P.; Kadlec, P.; Michal, O.; Mentlík, V.; Šutta, P.; Csányi, G.M.; Tamus, Z.Á. Magnesium Oxide Nanoparticles: Dielectric Properties, Surface Functionalization and Improvement of Epoxy-Based Composites Insulating Properties. Nanomaterials 2018, 8, 381. [Google Scholar] [CrossRef] [Green Version]

- Polanský, R.; Kadlec, P.; Kolská, Z.; Švorčík, V. Influence of Dehydration on the Dielectric and Structural Properties of Organically Modified Montmorillonite and Halloysite Nanotubes. Appl. Clay Sci. 2017, 147, 19–27. [Google Scholar] [CrossRef]

- Hornak, J. Interaction of Inhomogeneous Dielectric with an Electric Field. Ph.D. Thesis, University of West Bohemia, Pilsen, Czech Republic, 2018. [Google Scholar]

- Fernandes, M.; RB Singh, K.; Sarkar, T.; Singh, P.; Pratap Singh, R. Recent Applications of Magnesium Oxide (MgO) Nanoparticles in Various Domains. Adv. Mater. Lett. 2020, 11, 1–10. [Google Scholar] [CrossRef]

- Pilarska, A.A.; Klapiszewski, Ł.; Jesionowski, T. Recent Development in the Synthesis, Modification and Application of Mg(OH)2 and MgO: A Review. Powder Technol. 2017, 319, 373–407. [Google Scholar] [CrossRef]

- Balducci, G.; Diaz, L.B.; Gregory, D.H. Recent Progress in the Synthesis of Nanostructured Magnesium Hydroxide. CrystEngComm 2017, 19, 6067–6084. [Google Scholar] [CrossRef] [Green Version]

- Abinaya, S.; Kavitha, H.P.; Prakash, M.; Muthukrishnaraj, A. Green Synthesis of Magnesium Oxide Nanoparticles and Its Applications: A Review. Sustain. Chem. Pharm. 2021, 19, 100368. [Google Scholar] [CrossRef]

- Praveen Kumar, P.; Laxmi Deepak Bhatlu, M.; Sukanya, K.; Karthikeyan, S.; Jayan, N. Synthesis of Magnesium Oxide Nanoparticle by Eco Friendly Method (Green Synthesis)—A Review. Mater. Today Proc. 2021, 37, 3028–3030. [Google Scholar] [CrossRef]

- Ruhaimi, A.H.; Aziz, M.A.A.; Jalil, A.A. Magnesium Oxide-Based Adsorbents for Carbon Dioxide Capture: Current Progress and Future Opportunities. J. Co2 Util. 2021, 43, 101357. [Google Scholar] [CrossRef]

- Ngo, C.; Voorde, M. van de Nanotechnology in a Nutshell: From Simple to Complex Systems; Atlantis Press: Paris, France, 2014; ISBN 978-94-6239-011-9. [Google Scholar]

- Baraket, L.; Ghorbel, A. Control preparation of aluminium chromium mixed oxides by Sol-Gel process. In Studies in Surface Science and Catalysis; Delmon, B., Jacobs, P.A., Maggi, R., Martens, J.A., Grange, P., Poncelet, G., Eds.; Preparation of Catalysts VII; Elsevier: Amsterdam, The Netherlands, 1998; Volume 118, pp. 657–667. [Google Scholar]

- Feng, S.-H.; Li, G.-H. Chapter 4-Hydrothermal and Solvothermal Syntheses. In Modern Inorganic Synthetic Chemistry, 2nd ed.; Xu, R., Xu, Y., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 73–104. ISBN 978-0-444-63591-4. [Google Scholar]

- Yeh, C.-L. Combustion Synthesis: Principles and Applications. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2016; ISBN 978-0-12-803581-8. [Google Scholar]

- Rane, A.V.; Kanny, K.; Abitha, V.K.; Thomas, S. Chapter 5-Methods for Synthesis of Nanoparticles and Fabrication of Nanocomposites. In Synthesis of Inorganic Nanomaterials; Mohan Bhagyaraj, S., Oluwafemi, O.S., Kalarikkal, N., Thomas, S., Eds.; Micro and Nano Technologies; Woodhead Publishing: Cambridge, UK, 2018; pp. 121–139. ISBN 978-0-08-101975-7. [Google Scholar]

- Pal, G.; Rai, P.; Pandey, A. Chapter 1-Green synthesis of nanoparticles: A greener approach for a cleaner future. In Green Synthesis, Characterization and Applications of Nanoparticles; Shukla, A.K., Iravani, S., Eds.; Micro and Nano Technologies; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1–26. ISBN 978-0-08-102579-6. [Google Scholar]

- Escudero, A.; Carrillo-Carrión, C.; Romero-Ben, E.; Franco, A.; Rosales-Barrios, C.; Castillejos, M.C.; Khiar, N. Molecular Bottom-Up Approaches for the Synthesis of Inorganic and Hybrid Nanostructures. Inorganics 2021, 9, 58. [Google Scholar] [CrossRef]

- Burlakov, V.M.; Goriely, A. Reverse Coarsening and the Control of Particle Size Distribution through Surfactant. Appl. Sci. 2020, 10, 5359. [Google Scholar] [CrossRef]

- Antúnez-García, J.; Mejía-Rosales, S.; Pérez-Tijerina, E.; Montejano-Carrizales, J.M.; José-Yacamán, M. Coalescence and Collisions of Gold Nanoparticles. Materials 2011, 4, 368–379. [Google Scholar] [CrossRef] [Green Version]

- Whitehead, C.B.; Özkar, S.; Finke, R.G. LaMer’s 1950 Model for Particle Formation of Instantaneous Nucleation and Diffusion-Controlled Growth: A Historical Look at the Model’s Origins, Assumptions, Equations, and Underlying Sulfur Sol Formation Kinetics Data. Chem. Mater. 2019, 31, 7116–7132. [Google Scholar] [CrossRef]

- Hemery, G. Synthesis of Magnetic and Thermosensitive Iron Oxide Based Nanoparticles for Biomedical Applications. Ph.D. Thesis, Université de Bordeaux, Bordeaux, France, 2017. [Google Scholar]

- Zhang, B.; Jin, H.; Liu, X.; Guo, X.; He, G.; Yang, S. The Formation and Application of Submicron Spherical BaTiO3 Particles for the Diffusion Layer of Medical Dry Films. Crystals 2019, 9, 594. [Google Scholar] [CrossRef] [Green Version]

- Mantzaris, N.V. Liquid-Phase Synthesis of Nanoparticles: Particle Size Distribution Dynamics and Control. Chem. Eng. Sci. 2005, 60, 4749–4770. [Google Scholar] [CrossRef]

- Swihart, M.T. Vapor-Phase Synthesis of Nanoparticles. Curr. Opin. Colloid Interface Sci. 2003, 8, 127–133. [Google Scholar] [CrossRef]

- Benrabaa, R.; Boukhlouf, H.; Bordes-Richard, E.; Vannier, R.N.; Barama, A. Nanosized nickel ferrite catalysts for CO2 reforming of methane at low temperature: Effect of preparation method and acid-base properties. In Studies in Surface Science and Catalysis; Gaigneaux, E.M., Devillers, M., Hermans, S., Jacobs, P.A., Martens, J.A., Ruiz, P., Eds.; Scientific Bases for the Preparation of Heterogeneous Catalysts; Elsevier: Amsterdam, The Netherlands, 2010; Volume 175, pp. 301–304. [Google Scholar]

- Huang, G.; Lu, C.-H.; Yang, H.-H. Chapter 3-Magnetic Nanomaterials for Magnetic Bioanalysis. In Novel Nanomaterials for Biomedical, Environmental and Energy Applications; Wang, X., Chen, X., Eds.; Micro and Nano Technologies; Elsevier: Amsterdam, The Netherlands, 2019; pp. 89–109. ISBN 978-0-12-814497-8. [Google Scholar]

- Rashid, H.; Manson, A.M.; Haider, B.; Nasir, R.; Hamid, S.B.A.; Abdulrahman, A. Synthesis and Characterization of Magnetite Nano Particles with High Selectivity Using in-Situ Precipitation Method. Sep. Sci. Technol. 2020, 6, 1207–1215. [Google Scholar] [CrossRef] [Green Version]

- Tartaj, P.; del Puerto Morales, M.; Veintemillas-Verdaguer, S.; González-Carreño, T.; Serna, C.J. The Preparation of Magnetic Nanoparticles for Applications in Biomedicine. J. Phys. D Appl. Phys. 2003, 36, R182–R197. [Google Scholar] [CrossRef]

- Mahshad, A.; Mona, J.; Alimorad, R. Simple and Economical Method for the Preparation of MgO Nanostructures with Suitable Surface Area. Iran. J. Chem. Chem. Eng. 2014, 33, 21–28. [Google Scholar]

- Kumar, R.; Sharma, A.; Kishore, N. Preparation and Characterization of MgO Nanoparticles by Co-Precipitation Method. Available online: https://www.semanticscholar.org/paper/Preparation-and-Characterization-of-MgO-by-Method-Kumar-Sharma/e3c8ca1d9a9b4b8b06c4cd74a138d11904d631ae (accessed on 14 October 2021).

- Karthikeyan, V.; Dhanapandian, S.; Manoharan, C. Characterization and Antibacterial Behavior of MgO-PEG Nanoparticles Synthesized via Co-Precipitation Method. Int. Lett. Chem. Phys. Astron. 2016, 70, 33–41. [Google Scholar] [CrossRef] [Green Version]

- Frantina, Y.I.; Fajaroh, F.; Nazriati; Yahmin; Sumari. Synthesis of MgO/CoFe2O4 Nanoparticles with Coprecipitation Method and Its Characterization. AIP Conf. Proc. 2021, 2330, 070003. [Google Scholar] [CrossRef]

- Kushwaha, A.; Bagchi, T. MgO NPs Synthesis, Capping and Enhanced Free Radical Effect on the Bacteria and Its Cell Morphology. AIP Conf. Proc. 2018, 1961, 030010. [Google Scholar] [CrossRef]

- Surfactant Free Synthesis of Magnesium Oxide Nanotubes by Simple Chemical Co-Precipitation Method. IJITEE 2020, 9, 2504–2506. [CrossRef]

- Soytaş, S.H.; Oğuz, O.; Menceloğlu, Y.Z. 9-Polymer Nanocomposites With Decorated Metal Oxides. In Polymer Composites with Functionalized Nanoparticles; Pielichowski, K., Majka, T.M., Eds.; Micro and Nano Technologies; Elsevier: Amsterdam, The Netherlands, 2019; pp. 287–323. ISBN 978-0-12-814064-2. [Google Scholar]

- Ebelmen, J.J. Recherches sur les Combinaisons des Acides Borique et Silicique Avec les éthers; s.n.: Paris, France, 1846. [Google Scholar]

- Sham, E.L.; Murgia, V.; Gottifredi, J.C.; Farfán-Torres, E.M. V2O5-SiO2 Catalyst Prepared by the sol–gel Process in the Oxidative Dehydrogenation of n-butane. In Studies in Surface Science and Catalysis; Delmon, B., Jacobs, P.A., Maggi, R., Martens, J.A., Grange, P., Poncelet, G., Eds.; Preparation of Catalysts VII; Elsevier: Amsterdam, The Netherlands, 1998; Volume 118, pp. 669–678. [Google Scholar]

- Mastuli, M.S.; Ansari, N.S.; Nawawi, M.A.; Mahat, A.M. Effects of Cationic Surfactant in Sol-Gel Synthesis of Nano Sized Magnesium Oxide. APCBEE Procedia 2012, 3, 93–98. [Google Scholar] [CrossRef] [Green Version]

- Sutapa, I.W.; Wahab, A.W.; Taba, P.; Nafie, N.L. Dislocation, Crystallite Size Distribution and Lattice Strain of Magnesium Oxide Nanoparticles. J. Phys. Conf. Ser. 2018, 979, 012021. [Google Scholar] [CrossRef]

- Wahab, R.; Ansari, S.G.; Dar, M.A.; Kim, Y.S.; Shin, H.S. Synthesis of Magnesium Oxide Nanoparticles by Sol-Gel Process. Mater. Sci. Forum 2007, 558–559, 983–986. [Google Scholar] [CrossRef]

- Boddu, V.M.; Viswanath, D.S.; Maloney, S.W. Synthesis and Characterization of Coralline Magnesium Oxide Nanoparticles. J. Am. Ceram. Soc. 2008, 91, 1718–1720. [Google Scholar] [CrossRef]

- Dercz, G.; Prusik, K.; Pajak, L.; Pielaszek, R.; Malinowski, J.J.; Pudło, W. Structure Studies on Nanocrystalline Powder of MgO Xerogel Prepared by the Sol-Gel Method. Mater. Sci. 2009, 27, 201–207. [Google Scholar]

- Rani, N.; Chahal, S.; Chauhan, A.S.; Kumar, P.; Shukla, R.; Singh, S.K. X-Ray Analysis of MgO Nanoparticles by Modified Scherer’s Williamson-Hall and Size-Strain Method. Mater. Today Proc. 2019, 12, 543–548. [Google Scholar] [CrossRef]

- Nassar, M.Y.; Mohamed, T.Y.; Ahmed, I.S.; Samir, I. MgO Nanostructure via a Sol-Gel Combustion Synthesis Method Using Different Fuels: An Efficient Nano-Adsorbent for the Removal of Some Anionic Textile Dyes. J. Mol. Liq. 2017, 225, 730–740. [Google Scholar] [CrossRef]

- Ng, J.J.; Leong, K.H.; Sim, L.C.; Oh, W.-D.; Dai, C.; Saravanan, P. Chapter 10-Environmental remediation using nano-photocatalyst under visible light irradiation: The case of bismuth phosphate. In Nanomaterials for Air Remediation; Abdeltif, A., Assadi, A.A., Nguyen-Tri, P., Nguyen, T.A., Rtimi, S., Eds.; Micro and Nano Technologies; Elsevier: Amsterdam, The Netherlands, 2020; pp. 193–207. ISBN 978-0-12-818821-7. [Google Scholar]

- Williams, M.J.; Corr, S.A. Chapter 2-Magnetic Nanoparticles for Targeted Cancer Diagnosis and Therapy. In Frontiers of Nanoscience; Summers, H., Ed.; Nanomedicine; Elsevier: Amsterdam, The Netherlands, 2013; Volume 5, pp. 29–63. [Google Scholar]

- Devaraja, P.B.; Avadhani, D.N.; Prashantha, S.C.; Nagabhushana, H.; Sharma, S.C.; Nagabhushana, B.M.; Nagaswarupa, H.P. Synthesis, Structural and Luminescence Studies of Magnesium Oxide Nanopowder. Spectrochim. Acta Part Mol. Biomol. Spectrosc. 2014, 118, 847–851. [Google Scholar] [CrossRef] [PubMed]

- Al-Hazmi, F.; Alnowaiser, F.; Al-Ghamdi, A.A.; Al-Ghamdi, A.A.; Aly, M.M.; Al-Tuwirqi, R.M.; El-Tantawy, F. A New Large—Scale Synthesis of Magnesium Oxide Nanowires: Structural and Antibacterial Properties. Superlattices Microstruct. 2012, 52, 200–209. [Google Scholar] [CrossRef] [Green Version]

- Ding, Y.; Zhang, G.; Wu, H.; Hai, B.; Wang, L.; Qian, Y. Nanoscale Magnesium Hydroxide and Magnesium Oxide Powders: Control over Size, Shape, and Structure via Hydrothermal Synthesis. Chem. Mater. 2001, 13, 435–440. [Google Scholar] [CrossRef]

- Rukh, S.; Sofi, A.H.; Shah, M.A.; Yousuf, S. Antibacterial Activity of Magnesium Oxide Nanostructures Prepared by Hydrothermal Method. Asian J. Nanosci. Mater. 1999, 2, 425–430. [Google Scholar] [CrossRef]

- Duong, T.H.Y.; Nguyen, T.N.; Oanh, H.T.; Dang Thi, T.A.; Giang, L.N.T.; Phuong, H.T.; Anh, N.T.; Nguyen, B.M.; Tran Quang, V.; Le, G.T.; et al. Synthesis of Magnesium Oxide Nanoplates and Their Application in Nitrogen Dioxide and Sulfur Dioxide Adsorption. J. Chem. 2019, 2019, e4376429. [Google Scholar] [CrossRef]

- Varma. A.V.; Mukasyan, A.S.; Rogachev, A.S.; Manukyan, K.V. Solution Combustion Synthesis of Nanoscale Materials. Chem. Rev. 2016, 116, 14493–14586. [Google Scholar] [CrossRef]

- Mukasyan, A.S.; Manukyan, K.V. Chapter 4-One- and Two-Dimensional Nanostructures Prepared by Combustion Synthesis. In Nanomaterials Synthesis; Beeran Pottathara, Y., Thomas, S., Kalarikkal, N., Grohens, Y., Kokol, V., Eds.; Micro and Nano Technologies; Elsevier: Amsterdam, The Netherlands, 2019; pp. 85–120. ISBN 978-0-12-815751-0. [Google Scholar]

- Stojanovic, B.D.; Dzunuzovic, A.S.; Ilic, N.I. 17-Review of methods for the preparation of magnetic metal oxides. In Magnetic, Ferroelectric, and Multiferroic Metal Oxides; Stojanovic, B.D., Ed.; Metal Oxides; Elsevier: Amsterdam, The Netherlands, 2018; pp. 333–359. ISBN 978-0-12-811180-2. [Google Scholar]

- Mukasyan, A.S.; Dinka, P. Novel Approaches to Solution-Combustion Synthesis of Nanomaterials. Int. J Self-Propag. High-Temp. Synth. 2007, 16, 23–35. [Google Scholar] [CrossRef]

- Rao, K.V.; Sunandana, C.S. Structure and Microstructure of Combustion Synthesized MgO Nanoparticles and Nanocrystalline MgO Thin Films Synthesized by Solution Growth Route. J. Mater. Sci. 2008, 43, 146–154. [Google Scholar] [CrossRef]

- Ranjan, A.; Dawn, S.S.; Jayaprabakar, J.; Nirmala, N.; Saikiran, K.; Sai Sriram, S. Experimental Investigation on Effect of MgO Nanoparticles on Cold Flow Properties, Performance, Emission and Combustion Characteristics of Waste Cooking Oil Biodiesel. Fuel 2018, 220, 780–791. [Google Scholar] [CrossRef]

- Tharani, K.; Jegatha Christy, A.; Sagadevan, S.; Nehru, L.C. Fabrication of Magnesium Oxide Nanoparticles Using Combustion Method for a Biological and Environmental Cause. Chem. Phys. Lett. 2021, 763, 138216. [Google Scholar] [CrossRef]

- Kumar, D.; Yadav, L.S.R.; Lingaraju, K.; Manjunath, K.; Suresh, D.; Prasad, D.; Nagabhushana, H.; Sharma, S.C.; Naika, H.R.; Chikkahanumantharayappa; et al. Combustion Synthesis of MgO Nanoparticles Using Plant Extract: Structural Characterization and Photoluminescence Studies. AIP Conf. Proc. 2015, 1665, 050145. [Google Scholar] [CrossRef]

- Devatha, C.P.; Thalla, A.K. Chapter 7-Green Synthesis of Nanomaterials. In Synthesis of Inorganic Nanomaterials; Mohan Bhagyaraj, S., Oluwafemi, O.S., Kalarikkal, N., Thomas, S., Eds.; Micro and Nano Technologies; Woodhead Publishing: Cambridge, UK, 2018; pp. 169–184. ISBN 978-0-08-101975-7. [Google Scholar]

- Verma, R.; Pathak, S.; Srivastava, A.K.; Prawer, S.; Tomljenovic-Hanic, S. ZnO Nanomaterials: Green Synthesis, Toxicity Evaluation and New Insights in Biomedical Applications. J. Alloy. Compd. 2021, 876, 160175. [Google Scholar] [CrossRef]

- Zhu, X.; Pathakoti, K.; Hwang, H.-M. Chapter 10-Green synthesis of titanium dioxide and zinc oxide nanoparticles and their usage for antimicrobial applications and environmental remediation. In Green Synthesis, Characterization and Applications of Nanoparticles; Shukla, A.K., Iravani, S., Eds.; Micro and Nano Technologies; Elsevier: Amsterdam, The Netherlands, 2019; pp. 223–263. ISBN 978-0-08-102579-6. [Google Scholar]

- Bhardwaj, K.; Dhanjal, D.S.; Sharma, A.; Nepovimova, E.; Kalia, A.; Thakur, S.; Bhardwaj, S.; Chopra, C.; Singh, R.; Verma, R.; et al. Conifer-Derived Metallic Nanoparticles: Green Synthesis and Biological Applications. Int. J. Mol. Sci. 2020, 21, 9028. [Google Scholar] [CrossRef] [PubMed]

- Kumar, H.; Bhardwaj, K.; Kuča, K.; Kalia, A.; Nepovimova, E.; Verma, R.; Kumar, D. Flower-Based Green Synthesis of Metallic Nanoparticles: Applications beyond Fragrance. Nanomaterials 2020, 10, 766. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Suresh, J.; Yuvakkumar, R.; Sundrarajan, M.; Hong, S.I. Green Synthesis of Magnesium Oxide Nanoparticles. Adv. Mater. Res. 2014, 952, 141–144. [Google Scholar] [CrossRef]

- Vergheese, M.; Vishal, S.K. Green Synthesis of Magnesium Oxide Nanoparticles Using Trigonella Foenum-Graecum Leaf Extract and Its Antibacterial Activity. J. Pharmacogn Phytochem. 2018, 7, 1193–1200. [Google Scholar]

- Younis, I.Y.; El-Hawary, S.S.; Eldahshan, O.A.; Abdel-Aziz, M.M.; Ali, Z.Y. Green Synthesis of Magnesium Nanoparticles Mediated from Rosa Floribunda Charisma Extract and Its Antioxidant, Antiaging and Antibiofilm Activities. Sci. Rep. 2021, 11, 16868. [Google Scholar] [CrossRef] [PubMed]

- Abdallah, Y.; Ogunyemi, S.O.; Abdelazez, A.; Zhang, M.; Hong, X.; Ibrahim, E.; Hossain, A.; Fouad, H.; Li, B.; Chen, J. The Green Synthesis of MgO Nano-Flowers Using Rosmarinus Officinalis L. (Rosemary) and the Antibacterial Activities against Xanthomonas Oryzae Pv. Oryzae. BioMed Res. Int. 2019, e5620989. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Khan, M.I.; Akhtar, M.N.; Ashraf, N.; Najeeb, J.; Munir, H.; Awan, T.I.; Tahir, M.B.; Kabli, M.R. Green Synthesis of Magnesium Oxide Nanoparticles Using Dalbergia Sissoo Extract for Photocatalytic Activity and Antibacterial Efficacy. Appl. Nanosci. 2020, 10, 2351–2364. [Google Scholar] [CrossRef]

- Amina, M.; Musayeib, N.M.A.; Alarfaj, N.A.; El-Tohamy, M.F.; Oraby, H.F.; Hamoud, G.A.A.; Bukhari, S.I.; Moubayed, N.M.S. Biogenic Green Synthesis of MgO Nanoparticles Using Saussurea Costus Biomasses for a Comprehensive Detection of Their Antimicrobial, Cytotoxicity against MCF-7 Breast Cancer Cells and Photocatalysis Potentials. PLoS ONE 2020, 15, e0237567. [Google Scholar] [CrossRef]

- Sharma, G.; Soni, R.; Jasuja, N.D. Phytoassisted Synthesis of Magnesium Oxide Nanoparticles with Swertia Chirayaita. J. Taibah Univ. Sci. 2017, 11, 471–477. [Google Scholar] [CrossRef] [Green Version]

- Fatiqin, A.; Amrulloh, H.; Simanjuntak, W. Green Synthesis of MgO Nanoparticles Using Moringa Oleifera Leaf Aqueous Extract for Antibacterial Activity. Bull. Chem. Soc. Ethiop. 2021, 35, 161–170. [Google Scholar] [CrossRef]

- Nguyen, D.T.C.; Dang, H.H.; Vo, D.-V.N.; Bach, L.G.; Nguyen, T.D.; Tran, T.V. Biogenic Synthesis of MgO Nanoparticles from Different Extracts (Flower, Bark, Leaf) of Tecoma Stans (L.) and Their Utilization in Selected Organic Dyes Treatment. J. Hazard. Mater. 2021, 404, 124146. [Google Scholar] [CrossRef] [PubMed]

- Polte, J. Fundamental Growth Principles of Colloidal Metal Nanoparticles—A New Perspective. CrystEngComm 2015, 17, 6809–6830. [Google Scholar] [CrossRef] [Green Version]

- Mitra, A.; De, G. Chapter 6-Sol-Gel Synthesis of Metal Nanoparticle Incorporated Oxide Films on Glass. In Glass Nanocomposites; Karmakar, B., Rademann, K., Stepanov, A.L., Eds.; William Andrew Publishing: Boston, MA, USA, 2016; pp. 145–163. ISBN 978-0-323-39309-6. [Google Scholar]

- Tao, X.-Y.; Ma, J.; Hou, R.-L.; Song, X.-Z.; Guo, L.; Zhou, S.-X.; Guo, L.-T.; Liu, Z.-S.; Fan, H.-L.; Zhu, Y.-B. Template-Free Synthesis of Star-Like ZrO2 Nanostructures and Their Application in Photocatalysis. Adv. Mater. Sci. Eng. 2018, e8191095. [Google Scholar] [CrossRef] [Green Version]

- Deganello, F.; Tyagi, A.K. Solution Combustion Synthesis, Energy and Environment: Best Parameters for Better Materials. Prog. Cryst. Growth Charact. Mater. 2018, 64, 23–61. [Google Scholar] [CrossRef]

- Singh, A.; Gautam, P.K.; Verma, A.; Singh, V.; Shivapriya, P.M.; Shivalkar, S.; Sahoo, A.K.; Samanta, S.K. Green Synthesis of Metallic Nanoparticles as Effective Alternatives to Treat Antibiotics Resistant Bacterial Infections: A Review. Biotechnol. Rep. 2020, 25, e00427. [Google Scholar] [CrossRef]

- Wen, N.; Zhang, L.; Jiang, D.; Wu, Z.; Li, B.; Sun, C.; Guo, Z. Emerging Flexible Sensors Based on Nanomaterials: Recent Status and Applications. J. Mater. Chem. A 2020, 8, 25499–25527. [Google Scholar] [CrossRef]

- Murkute, P.; Ghadi, H.; Patil, S.; Rawool, H.; Pandey, S.; Chakrabarti, S. Emerging Material Zinc Magnesium Oxide Based Nanorods: Growth Process Optimization and Sensor Application towards Humidity Detection. Sens. Actuators Chem. 2018, 256, 204–216. [Google Scholar] [CrossRef]

- Shukla, S.K.; Parashar, G.K.; Mishra, A.P.; Misra, P.; Yadav, B.C.; Shukla, R.K.; Bali, L.M.; Dubey, G.C. Nano-like Magnesium Oxide Films and Its Significance in Optical Fiber Humidity Sensor. Sensors Actuators Chem. 2004, 98, 5–11. [Google Scholar] [CrossRef]

- Pandey, S.K.; Kim, K.-H.; Tang, K.-T. A Review of Sensor-Based Methods for Monitoring Hydrogen Sulfide. TrAC Trends Anal. Chem. 2012, 32, 87–99. [Google Scholar] [CrossRef]

- El-Shamy, A.G. New Nano-Composite Based on Carbon Dots (CDots) Decorated Magnesium Oxide (MgO) Nano-Particles (CDots@MgO) Sensor for High H2S Gas Sensitivity Performance. Sens. Actuators Chem. 2021, 329, 129154. [Google Scholar] [CrossRef]

- Trávníček, P.; Kotek, L.; Nejtek, V.; Koutný, T.; Junga, P.; Vítěz, T. Flare Stacks on Agricultural Biogas Plants–Safety and Operational Requirements. Res. Agric. Eng. 2019, 65, 98–104. [Google Scholar] [CrossRef]

- Sertel, B.C.; Sonmez, N.A.; Kaya, M.D.; Ozcelik, S. Development of MgO:TiO2 Thin Films for Gas Sensor Applications. Ceram. Int. 2019, 45, 2917–2921. [Google Scholar] [CrossRef]

- Tao, Y.; Cao, X.; Peng, Y.; Liu, Y. A Novel Cataluminescence Gas Sensor Based on MgO Thin Film. Sens. Actuators Chem. 2010, 148, 292–297. [Google Scholar] [CrossRef]

- Kokulnathan, T.; Jothi, A.I.; Chen, S.-M.; Almutairi, G.; Ahmed, F.; Arshi, N.; AlOtaibi, B. Integrating Graphene Oxide with Magnesium Oxide Nanoparticles for Electrochemical Detection of Nitrobenzene. J. Environ. Chem. Eng. 2021, 9, 106310. [Google Scholar] [CrossRef]

- Pallon, L.K.H.; Hoang, A.T.; Pourrahimi, A.M.; Hedenqvist, M.S.; Nilsson, F.; Gubanski, S.; Gedde, U.W.; Olsson, R.T. The Impact of MgO Nanoparticle Interface in Ultra-Insulating Polyethylene Nanocomposites for High Voltage DC Cables. J. Mater. Chem. A 2016, 4, 8590–8601. [Google Scholar] [CrossRef]

- Paramane, A.; Chen, X.; Dai, C.; Guan, H.; Yu, L.; Tanaka, Y. Electrical Insulation Performance of Cross-Linked Polyethylene/MgO Nanocomposite Material for ±320 KV High-Voltage Direct-Current Cables. Polym. Compos. 2020, 41, 1936–1949. [Google Scholar] [CrossRef]

- Lin, X.; Siew, W.H.; Given, M.; Liggat, J.; He, J. Nanocomposites Based on Magnesium-Oxide/Aluminum-Nitride/Polypropylene for HVDC Cable Insulation. In Proceedings of the 2020 IEEE International Conference on High Voltage Engineering and Application (ICHVE), Beijing, China, 6–10 September 2020; pp. 1–4. [Google Scholar]

- Hu, S.; Zhou, Y.; Yuan, C.; Wang, W.; Hu, J.; Li, Q.; He, J. Surface-Modification Effect of MgO Nanoparticles on the Electrical Properties of Polypropylene Nanocomposite. High Volt. 2020, 5, 249–255. [Google Scholar] [CrossRef]

- Zhu, X.; Wu, J.; Wang, Y.; Yin, Y. Characteristics of Partial Discharge and AC Electrical Tree in XLPE and MgO/XLPE Nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2020, 27, 450–458. [Google Scholar] [CrossRef]

- Kiaei, M.; Moghdam, Y.R.; Kord, B.; Samariha, A.; Kiaei, M.; Moghdam, Y.R.; Kord, B.; Samariha, A. The Effect of Nano-MgO on the Mechanical and Flammability Properties of Hybrid Nano Composites from Wood Flour-Polyethylene. Maderas. Cienc. Tecnol. 2017, 19, 471–480. [Google Scholar] [CrossRef] [Green Version]

- Hornak, J.; Kubes, T.; Trnka, P. Effect of Nanometric Oxides on Dielectric and Mechanical Properties of Epoxy Resin. In Proceedings of the 2020 International Conference on Diagnostics in Electrical Engineering (Diagnostika), Pilsen, Czech Republic, 1–4 September 2020; pp. 1–4. [Google Scholar]

- Hornak, J.; Mentlík, V.; Trnka, P.; Šutta, P. Synthesis and Diagnostics of Nanostructured Micaless Microcomposite as a Prospective Insulation Material for Rotating Machines. Appl. Sci. 2019, 9, 2926. [Google Scholar] [CrossRef] [Green Version]

- Hornak, J.; Prosr, P.; Trnka, P.; Kadlec, P.; Michal, O.; Hardon, S. Effect of MgO Nanoparticles on Material Properties of Cold-Curing Epoxy and Polyurethane Mixtures. AIP Conf. Proc. 2021, 2411, 050005. [Google Scholar] [CrossRef]

- Hornak, J.; Mentlík, V.; Trnka, P.; Gutten, M. Vliv funkcionalizace povrchu oxidu hořečnatého na dielektrické vlastnosti kompozitního dielektrika. Chem. Listy 2018, 112, 246–249. [Google Scholar]

- Peddamallu, N.; Nagaraju, G.; Sridharan, K.; Velmurugan, R.; Vasa, N.J.; Nakayama, T.; Sarathi, R. Understanding the Electrical, Thermal, and Mechanical Properties of Epoxy Magnesium Oxide Nanocomposites. IET Sci. Meas. Technol. 2019, 13, 632–639. [Google Scholar] [CrossRef]

- Ge, G.; Tang, Y.; Li, Y.; Huang, L. Effect of Environmental Temperature on the Insulating Performance of Epoxy/MgO Nanocomposites. Appl. Sci. 2020, 10, 7018. [Google Scholar] [CrossRef]

- Wereszczak, A.A.; Morrissey, T.G.; Volante, C.N.; Farris, P.J.; Groele, R.J.; Wiles, R.H.; Wang, H. Thermally Conductive MgO-Filled Epoxy Molding Compounds. IEEE Trans. Components Packag. Manuf. Technol. 2013, 3, 1994–2005. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, K.; Ding, F.; Liu, X. Recent Advances in Solid Polymer Electrolytes for Lithium Batteries. Nano Res. 2017, 10, 4139–4174. [Google Scholar] [CrossRef]

- Jaschin, P.W.; Gao, Y.; Li, Y.; Bo, S.-H. A Materials Perspective on Magnesium-Ion-Based Solid-State Electrolytes. J. Mater. Chem. A 2020, 8, 2875–2897. [Google Scholar] [CrossRef]

- Masoud, E.M.; El-Bellihi, A.-A.; Bayoumy, W.A.; Mohamed, E.A. Polymer Composite Containing Nano Magnesium Oxide Filler and Lithiumtriflate Salt: An Efficient Polymer Electrolyte for Lithium Ion Batteries Application. J. Mol. Liq. 2018, 260, 237–244. [Google Scholar] [CrossRef]

- Wu, N.; Wang, W.; Wei, Y.; Li, T. Studies on the Effect of Nano-Sized MgO in Magnesium-Ion Conducting Gel Polymer Electrolyte for Rechargeable Magnesium Batteries. Energies 2017, 10, 1215. [Google Scholar] [CrossRef]

- Zaky, M.M.; Eyssa, H.M.; Sadek, R.F. Improvement of the Magnesium Battery Electrolyte Properties through Gamma Irradiation of Nano Polymer Electrolytes Doped with Magnesium Oxide Nanoparticles. J. Vinyl Addit. Technol. 2019, 25, 243–254. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hornak, J. Synthesis, Properties, and Selected Technical Applications of Magnesium Oxide Nanoparticles: A Review. Int. J. Mol. Sci. 2021, 22, 12752. https://doi.org/10.3390/ijms222312752

Hornak J. Synthesis, Properties, and Selected Technical Applications of Magnesium Oxide Nanoparticles: A Review. International Journal of Molecular Sciences. 2021; 22(23):12752. https://doi.org/10.3390/ijms222312752

Chicago/Turabian StyleHornak, Jaroslav. 2021. "Synthesis, Properties, and Selected Technical Applications of Magnesium Oxide Nanoparticles: A Review" International Journal of Molecular Sciences 22, no. 23: 12752. https://doi.org/10.3390/ijms222312752