Micromachined Resonators: A Review

Abstract

:1. Introduction

2. Basic Model and Properties

3. Electric Circuit Representation

Modelling of Nonlinearities

4. Resonance Modes

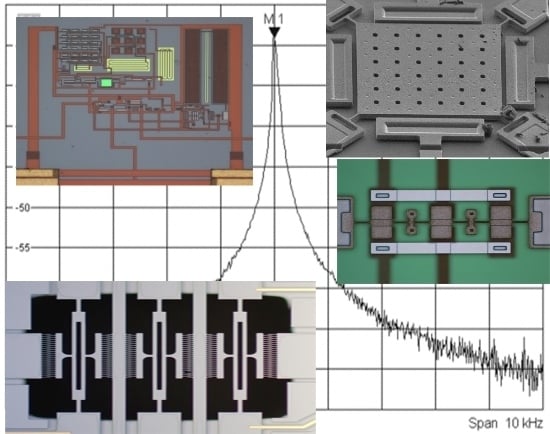

4.1. Flexural Modes

4.2. Bulk Modes

4.3. Shear Modes

4.4. Torsional Modes

4.5. Coupled Resonators

4.6. Other Modes

5. Damping

5.1. Viscous Losses

5.2. Anchor Losses

5.3. Material Losses

5.4. Other Damping Sources

6. Transduction Mechanisms

6.1. Capacitive

6.2. Piezoelectric

6.3. Thermal/Piezoresistive

6.4. Other Transduction Mechanisms

7. Fabrication

7.1. Narrow Gaps

7.2. Piezoelectric Layers

7.3. CMOS MEMS

7.4. Packaging

8. Applications

8.1. Timing

8.2. MEMS Resonator-based Oscillators

8.2.1. Operating Principles

8.2.2. Phase Noise

- The higher the Q-factor of the resonator, the lower the phase noise in the MEMS oscillator because of the enhanced noise filtering.

- The higher the power handling capability of the resonator, the lower the phase noise of the MEMS oscillator because of the increased sustainable amplitude of oscillation.

- The higher the motional resistance, the higher the phase noise of the MEMS oscillator because of the higher gain sustaining amplifier is required, usually required more active devices that generate noise.

- The lower the electronic noise of the sustaining amplifier, the better the phase noise because of the shaping of this noise that causes a significant portion of the overall phase noise.

8.2.3. Temperature Compensation

8.2.4. Sustaining Amplifiers

- a high gain to offset the resonator losses (i.e., at least 1.5 times the resonator’s motional resistance);

- a bandwidth which is an order of magnitude larger than the resonator’s frequency to ensure a small phase shift around the feedback loop;

- low input and output impedances to avoid loading the resonator’s Q-factor;

- an automatic gain control capability to prevent large oscillations from exerting the resonator’s nonlinearities.

8.2.5. Nonlinear Oscillators

8.3. Sensing

8.3.1. Resonant Sensors Based Changes in Effective Mass

8.3.2. Resonant Sensors Based Changes in Effective Stiffness

8.4. Radio-Frequency Systems

9. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Yole Développement. MEMS Markets: Status of the MEMS Industry—Market & Technology Report; Yole Développement: Villeurbanne, France, 2015. [Google Scholar]

- Nathanson, H.C.; Newell, W.E.; Wickstrom, R.A.; Davis, J.R. The resonant gate transistor. IEEE Trans. Electron. Devices 1967, 14, 117–133. [Google Scholar] [CrossRef]

- Hauptmann, P. Resonant sensors and applications. Sens. Actuators Phys. 1991, 26, 371–377. [Google Scholar] [CrossRef]

- Vittoz, E.A.; Degrauwe, M.G.R.; Bitz, S. High-performance crystal oscillator circuits: Theory and application. IEEE J. Solid-State Circuits 1988, 23, 774–783. [Google Scholar] [CrossRef]

- Razavi, B. Architectures and circuits for RF CMOS receivers. In Proceedings of the IEEE 1998 Custom Integrated Circuits Conference, Santa Clara, CA, USA, 11–14 May 1998; pp. 393–400.

- Partridge, A.; Lee, H.-C.; Hagelin, P.; Menon, V. We know that MEMS is replacing quartz. But why? And why now? In 2013 Joint European Frequency and Time Forum International Frequency Control Symposium (EFTF/IFC2013); IEEE: Prague, Czech Republic, 2013; pp. 411–416. [Google Scholar]

- Nguyen, C.T.-C.; Katehi, L.P.B.; Rebeiz, G.M. Micromachined devices for wireless communications. Proc. IEEE 1998, 86, 1756–1768. [Google Scholar] [CrossRef]

- Nguyen, C.T.-C. MEMS technology for timing and frequency control. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2007, 54, 251–270. [Google Scholar] [CrossRef] [PubMed]

- Basu, J.; Bhattacharyya, T.K. Microelectromechanical resonators for radio frequency communication applications. Microsyst. Technol. 2011, 17, 1557–1580. [Google Scholar] [CrossRef]

- Van Beek, J.T.M.; Puers, R. A review of MEMS oscillators for frequency reference and timing applications. J. Micromech. Microeng. 2012, 22, 13001. [Google Scholar] [CrossRef]

- Nguyen, C.T.-C. MEMS-based RF channel selection for true software-defined cognitive radio and low-power sensor communications. IEEE Commun. Mag. 2013, 51, 110–119. [Google Scholar] [CrossRef]

- Uranga, A.; Verd, J.; Barniol, N. CMOS–MEMS resonators: From devices to applications. Microelectron. Eng. 2015, 132, 58–73. [Google Scholar] [CrossRef]

- Tang, W.C.; Nguyen, T.-C.H.; Howe, R.T. Laterally driven polysilicon resonant microstructures. In Proceedings of the 2nd IEEE Micro Electro Mechanical Systems Conference, MEMS’89, Salt Lake City, UT, USA, 20–22 February1989; pp. 53–59.

- Nguyen, C.T.-C. Micromechanical resonators for oscillators and filters. In Proceedings of the 1995 IEEE Ultrasonics Symposium, Seattle, WA, USA, 7–10 November 1995; Volume 1, pp. 489–499.

- Heragu, A.; Ruffieux, D.; Enz, C. A Low Power BAW Resonator Based 2.4-GHz Receiver With Bandwidth Tunable Channel Selection Filter at RF. IEEE J. Solid-State Circuits 2013, 48, 1343–1356. [Google Scholar] [CrossRef]

- Lu, J.; Ikehara, T.; Zhang, Y.; Mihara, T.; Maeda, R. Mechanical quality factor of microcantilevers for mass sensing applications. In Proceedings of the International Society for Optical Engineering 6800, Canberra, Australia, 5 December 2007.

- Rasouli, M.A.; HajHashemi, M.S.; Bahreyni, B. Higher-order Lame mode square microresonator with improved quality factor and f-Q product. In Proceedings of the 2013 Transducers Eurosensors XXVII: The 17th International Conference on Solid-State Sensors, Actuators and Microsystems, Barcelona, Spain, 16–20 June 2013; pp. 498–501.

- Wang, K.; Wong, A.-C.; Nguyen, C.T.-C. VHF Free–Free Beam High-Q Micromechanical Resonators. IEEE J. Microelectromech. Syst. 2000, 9, 347–360. [Google Scholar] [CrossRef]

- Ruby, R.; Merchant, P. Micromachined thin film bulk acoustic resonators. In Proceedings of the 1994 IEEE International Frequency Control Symposium, Boston, MA, USA, 1–3 June 1994; pp. 135–138.

- Ekinci, K.L.; Roukes, M.L. Nanoelectromechanical systems. Rev. Sci. Instrum. 2005, 76, 61101. [Google Scholar] [CrossRef]

- Bahreyni, B. Fabrication and Design of Resonant Microdevices; William Andrew Publishing: New York, NY, USA, 2008. [Google Scholar]

- Graff, K.F. Wave Motion in Elastic Solids; Oxford University Press: Oxford, UK, 1975. [Google Scholar]

- Thomson, W.T. Theory of Vibration with Applications, 2nd ed.; Prentice-Hall: Englewood Cliffs, NJ, USA, 1981. [Google Scholar]

- Senturia, S.D. Microsystem Design; Kluwer Academic Publishers: Boston, MA, USA, 2000. [Google Scholar]

- Tilmans, H.A.C. Equivalent circuit representation of electromechanical transducers: I. Lumped-parameter systems. J. Micromech. Microeng. 1996, 6, 157–176. [Google Scholar] [CrossRef]

- Tilmans, H.A.C. Equivalent circuit representation of electromechanical transducers: II. Distributed-parameter systems. J. Micromech. Microeng. 1997, 7, 285–309. [Google Scholar] [CrossRef]

- Chan, H.B.; Aksyuk, V.A.; Kleiman, R.N.; Bishop, D.J.; Capasso, F. Nonlinear Micromechanical Casimir Oscillator. Phys. Rev. Lett. 2001, 87, 211801-1–211801-4. [Google Scholar] [CrossRef] [PubMed]

- Gui, C.; Legtenberg, R.; Tilmans, H.A.C.; Fluitman, J.H.J.; Elwenspoek, M. Nonlinearity and Hysteresis of Resonant Strain Gauges. IEEE J. Microelectromech. Syst. 1998, 7, 122–127. [Google Scholar]

- Kaajakari, V.; Mattila, T.; Oja, A.; Seppä, H. Nonlinear Limits for Single-Crystal Silicon Microresonators. IEEE J. Microelectromech. Syst. 2004, 13, 715–724. [Google Scholar] [CrossRef]

- Kaajakari, V.; Mattila, T.; Lipsanen, A.; Oja, A. Nonlinear mechanical effects in silicon longitudinal mode beam resonators. Sens. Actuators Phys. 2004, 120, 64–70. [Google Scholar] [CrossRef]

- Bourouina, T.; Garnier, A.; Fujita, H.; Masuzawa, T.; Peuzin, J.-C. Mechanical nonlinearities in a magnetically actuated resonator. J. Micromech. Microeng. 2000, 10, 265–270. [Google Scholar] [CrossRef]

- Younis, M.I.; Nayfeh, A.H. A Study of the Nonlinear Response of a Resonant Microbeam to an Electric Actuation. Nonlinear Dyn. 2003, 31, 91–117. [Google Scholar] [CrossRef]

- Zhang, W.; Meng, G. Nonlinear dynamical system of micro-cantilever under combined parametric and forcing excitations in MEMS. Sens. Actuators Phys. 2005, 119, 291–299. [Google Scholar] [CrossRef]

- King, J.A. (Ed.) Materials Handbook for Hybrid Microelectronics; Artech House: Norwood, MA, USA, 1988.

- Shahmohammadi, M.; Fatemi, H.; Abdolvand, R. Nonlinearity reduction in silicon resonators by doping and re-orientation. In Proceedings of the 2013 IEEE 26th International Conference on Micro Electro Mechanical Systems (MEMS), Taipei, Taiwan, 20–24 January 2013; pp. 793–796.

- Landau, L.D.; Lifshitz, E.M. Theory of Elasticity, 3rd ed.; Butterworth Heinemann: Oxford, UK, 1976. [Google Scholar]

- Nayfeh, A.H.; Mook, D.T. Nonlinear Oscillations; John Wiley & Sons: New York, NY, USA, 2008. [Google Scholar]

- Taheri-Tehrani, P.; Kline, M.; Izyumin, I.; Eminoglu, B.; Yeh, Y.C.; Yang, Y.; Chen, Y.; Flader, I.; Ng, E.J.; Kenny, T.W.; et al. Epitaxially-encapsulated quad mass gyroscope with nonlinearity compensation. In Proceedings of the 2016 IEEE 29th International Conference on Micro Electro Mechanical Systems (MEMS), Shanghai, China, 24–28 January 2016; pp. 966–969.

- Shao, L.C.; Palaniapan, M.; Tan, W.W. The nonlinearity cancellation phenomenon in micromechanical resonators. J. Micromech. Microeng. 2008, 18, 65014. [Google Scholar] [CrossRef]

- Blevins, R.D. Formulas for Natural Frequency and Mode Shape; Krieger Pub Company: Malabar, FL, USA, 2001. [Google Scholar]

- Li, M.; Tang, H.X.; Roukes, M.L. Ultra-sensitive NEMS-based cantilevers for sensing, scanned probe and very high-frequency applications. Nat. Nanotechnol. 2007, 2, 114–120. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Shen, W.; Payer, K.; Burg, T.P.; Manalis, S.R. Toward Attogram Mass Measurements in Solution with Suspended Nanochannel Resonators. Nano Lett. 2010, 10, 2537–2542. [Google Scholar] [CrossRef] [PubMed]

- Burg, T.P.; Manalis, S.R. Suspended microchannel resonators for biomolecular detection. Appl. Phys. Lett. 2003, 83, 2698–2700. [Google Scholar] [CrossRef]

- Arlett, J.L.; Maloney, J.R.; Gudlewski, B.; Muluneh, M.; Roukes, M.L. Self-Sensing Micro- and Nanocantilevers with Attonewton-Scale Force Resolution. Nano Lett. 2006, 6, 1000–1006. [Google Scholar] [CrossRef]

- Burg, T.P.; Godin, M.; Knudsen, S.M.; Shen, W.; Carlson, G.; Foster, J.S.; Babcock, K.; Manalis, S.R. Weighing of biomolecules, single cells and single nanoparticles in fluid. Nature 2007, 446, 1066–1069. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.T.; Ekinci, K.L.; Huang, X.M.H.; Schiavone, L.M.; Roukes, M.L.; Zorman, C.A.; Mehregany, M. Monocrystalline silicon carbide nanoelectromechanical systems. Appl. Phys. Lett. 2001, 78, 162–164. [Google Scholar] [CrossRef]

- Cleland, A.N.; Roukes, M.L. Fabrication of high frequency nanometer scale mechanical resonators from bulk Si crystals. Appl. Phys. Lett. 1996, 69, 18–2653. [Google Scholar] [CrossRef]

- Yang, Y.T.; Callegari, C.; Feng, X.L.; Ekinci, K.L.; Roukes, M.L. Zeptogram-Scale Nanomechanical Mass Sensing. Nano Lett. 2006, 6, 583–586. [Google Scholar] [CrossRef] [PubMed]

- Feng, X.L.; White, C.J.; Hajimiri, A.; Roukes, M.L. A self-sustaining ultrahigh-frequency nanoelectromechanical oscillator. Nat. Nanotechnol. 2008, 3, 342–346. [Google Scholar] [CrossRef] [PubMed]

- Ekinci, K.L. Ultimate limits to inertial mass sensing based upon nanoelectromechanical systems. J. Appl. Phys. 2004, 95, 2682. [Google Scholar] [CrossRef]

- Naik, A.K.; Hanay, M.S.; Hiebert, W.K.; Feng, X.L.; Roukes, M.L. Towards single-molecule nanomechanical mass spectrometry. Nat. Nanotechnol. 2009, 4, 445–450. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.M.H.; Feng, X.L.; Zorman, C.A.; Mehregany, M.; Roukes, M.L. VHF, UHF and microwave frequency nanomechanical resonators. New J. Phys. 2005, 7, 247–247. [Google Scholar] [CrossRef]

- Lu, Y.; Horsley, D.A. Modeling, Fabrication, and Characterization of Piezoelectric Micromachined Ultrasonic Transducer Arrays Based on Cavity SOI Wafers. J. Microelectromech. Syst. 2015, 24, 1142–1149. [Google Scholar] [CrossRef]

- Rufer, L.; Domingues, C.C.; Mir, S.; Petrini, V.; Jeannot, J.-C.; Delobelle, P. A CMOS Compatible Ultrasonic Transducer Fabricated With Deep Reactive Ion Etching. J. Microelectromech. Syst. 2006, 15, 1766–1776. [Google Scholar] [CrossRef]

- Mattila, T.; Kiihamäki, J.; Lamminmäki, T.; Jaakkola, O.; Rantakari, P.; Oja, A.; Seppä, H.; Kattelus, H.; Tittonen, I. A 12 MHz micromechanical bulk acoustic mode oscillator. Sens. Actuators Phys. 2002, 101, 1–9. [Google Scholar] [CrossRef]

- Rahafrooz, A.; Pourkamali, S. High-Frequency Thermally Actuated Electromechanical Resonators with Piezoresistive Readout. IEEE Trans. Electron Devices 2011, 58, 1205–1214. [Google Scholar] [CrossRef]

- Zhu, H.; Tu, C.; Lee, J.E.Y.; Rufer, L. Active electronic cancellation of nonlinearity in a High-Q longitudinal-mode silicon resonator by current biasing. In Proceedings of the 2014 European Frequency and Time Forum (EFTF), Neuchatel, Switzerland, 23–26 June 2014; pp. 12–15.

- Pourkamali, S.; Ho, G.K.; Ayazi, F. Low-Impedance VHF and UHF Capacitive Silicon Bulk Acoustic Wave Resonators—Part I: Concept and Fabrication. IEEE Trans. Electron Devices 2007, 54, 2017–2023. [Google Scholar] [CrossRef]

- GHo, K.; Abdolvand, R.; Sivapurapu, A.; Humad, S.; Ayazi, F. Piezoelectric-on-Silicon Lateral Bulk Acoustic Wave Micromechanical Resonators. J. Microelectromech. Syst. 2008, 17, 512–520. [Google Scholar]

- Kaajakari, V.; Mattila, T.; Oja, A.; Kiihamaki, J.; Seppa, H. Square-Extensional Mode Single-Crystal Silicon Micromechanical Resonator for Low-Phase-Noise Oscillator Applications. IEEE Electron Device Lett. 2004, 25, 173–175. [Google Scholar] [CrossRef]

- Lee, J.E.-Y.; Zhu, Y.; Seshia, A.A. A bulk acoustic mode single-crystal silicon microresonator with a high-quality factor. J. Micromech. Microeng. 2008, 18, 64001. [Google Scholar] [CrossRef]

- Clark, J.R.; Hsu, W.-T.; Abdelmoneum, M.A.; Nguyen, C.T.-C. High-Q UHF micromechanical radial-contour mode disk resonators. J. Microelectromech. Syst. 2005, 14, 1298–1310. [Google Scholar] [CrossRef]

- Wang, J.; Ren, Z.; Nguyen, C.T.-C. 1.156-GHz self-aligned vibrating micromechanical disk resonator. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2004, 51, 1607–1628. [Google Scholar] [CrossRef] [PubMed]

- Piazza, G.; Stephanou, P.J.; Pisano, A.P. One and two port piezoelectric higher order contour-mode MEMS resonators for mechanical signal processing. Solid-State Electron. 2007, 51, 1596–1608. [Google Scholar] [CrossRef]

- Piazza, G.; Stephanou, P.J.; Pisano, A.P. Piezoelectric Aluminum Nitride Vibrating Contour-Mode MEMS Resonators. J. Microelectromech. Syst. 2006, 15, 1406–1418. [Google Scholar] [CrossRef]

- Ruby, R.C.; Bradley, P.; Oshmyansky, Y.; Chien, A.; Larson, J.D. Thin film bulk wave acoustic resonators (FBAR) for wireless applications. In Proceedings of the 2001 IEEE Ultrasonics Symposium, Atlanta, GA, USA, 7–10 October 2001; Volume 1, pp. 813–821.

- Lee, J.E.-Y.; Yan, J.; Seshia, A.A. Low loss HF band SOI wine glass bulk mode capacitive square-plate resonator. J. Micromech. Microeng. 2009, 19, 74003. [Google Scholar] [CrossRef]

- Zhu, H.; Lee, J.E.-Y. Reversed Nonlinear Oscillations in Lame-Mode Single-Crystal-Silicon Microresonators. IEEE Electron Device Lett. 2012, 33, 1492–1494. [Google Scholar] [CrossRef]

- Zhu, H.; Shan, G.C.; Shek, C.H.; Lee, J.E.-Y. Shear dependent nonlinear vibration in a high quality factor single crystal silicon micromechanical resonator. Appl. Phys. Lett. 2012, 101, 34102. [Google Scholar] [CrossRef]

- Lin, A.T.-H.; Yan, J.; Seshia, A.A. Electrostatically transduced face-shear mode silicon MEMS microresonator. In Proceedings of the 2010 IEEE International Frequency Control Symposium, Newport Beach, CA, USA, 1–4 June 2010; pp. 534–538.

- Shao, L.; Palaniapan, M. Effect of etch holes on quality factor of bulk-mode micromechanical resonators. Electron. Lett. 2008, 44, 938–939. [Google Scholar] [CrossRef]

- Tu, C.; Lee, J.E.-Y. Thermoelastic Dissipation in Etch-Hole Filled Lame Bulk-Mode Silicon Microresonators. IEEE Electron Device Lett. 2012, 33, 450–452. [Google Scholar] [CrossRef]

- Lee, J.E.-Y.; Seshia, A.A. 5.4-MHz single-crystal silicon wine glass mode disk resonator with quality factor of 2 million. Sens. Actuators Phys. 2009, 156, 28–35. [Google Scholar] [CrossRef]

- Hao, Z.; Pourkamali, S.; Ayazi, F. VHF single-crystal silicon elliptic bulk-mode capacitive disk resonators-part I: Design and modeling. J. Microelectromech. Syst. 2004, 13, 1043–1053. [Google Scholar] [CrossRef]

- Wei, X.; Seshia, A.A. Analytical formulation of modal frequency split in the elliptical mode of SCS micromechanical disk resonators. J. Micromech. Microeng. 2014, 24, 25011. [Google Scholar] [CrossRef]

- Rasouli, M.A.; Bahreyni, B. Independent tuning of frequency and quality factor of microresonators. Appl. Phys. Lett. 2011, 98, 243508:1–243508:3. [Google Scholar] [CrossRef]

- Cleland, A.N.; Roukes, M.L. A nanometre-scale mechanical electrometer. Nature 1998, 392, 160–162. [Google Scholar] [CrossRef]

- Herrera-May, A.L.; García-Ramírez, P.J.; Aguilera-Cortés, L.A.; Martínez-Castillo, J.; Sauceda-Carvajal, A.; García-González, L.; Figueras-Costa, E. A resonant magnetic field microsensor with high quality factor at atmospheric pressure. J. Micromech. Microeng. 2009, 19, 15016. [Google Scholar] [CrossRef]

- Demirci, M.U.; Nguyen, C.T.C. Mechanically Corner-Coupled Square Microresonator Array for Reduced Series Motional Resistance. J. Microelectromech. Syst. 2006, 15, 1419–1436. [Google Scholar] [CrossRef]

- Li, S.-S.; Lin, Y.-W.; Ren, Z.; Nguyen, C.T.-C. An MSI Micromechanical Differential Disk-Array Filter. In Proceedings of the 2007 International Solid-State Sensors, Actuators and Microsystems Conference, Lyon, France, 10–14 June 2007; pp. 307–311.

- Li, S.-S.; Lin, Y.-W.; Ren, Z.; Nguyen, C.T.-C. A Micromechanical Parallel-Class Disk-Array Filter. In Proceedings of the 2007 IEEE International Frequency Control Symposium, Geneva, Switzerland, 29 May–1 June 2007; pp. 1356–1361.

- Lee, S.; Nguyen, C.T.-C. Mechanically-coupled micromechanical resonator arrays for improved phase noise. In Proceedings of the 2004 IEEE InternationalFrequency Control Symposium and Exposition, Montreal, QC, Canada, 23–27 August 2004; pp. 144–150.

- Lin, Y.-W.; Li, S.-S.; Ren, Z.; Nguyen, C.T.-C. Low phase noise array-composite micromechanical wine-glass disk oscillator. In Proceedings of the IEEE International Electron Devices Meeting on IEDM Technical Digest, Washington, DC, USA, 5–7 December 2005; pp. 289–290.

- Iqbal, A.; Lee, J.E.-Y. Piezoresistive Sensing in a SOI Mechanically Coupled Micromechanical Multiple-Resonator Array. IEEE Trans. Electron. Devices 2012, 59, 3091–3096. [Google Scholar] [CrossRef]

- Zhu, H.; Xu, Y.; Lee, J.E.-Y. Piezoresistive Readout Mechanically Coupled Lame Mode SOI Resonator With Q of a Million. J. Microelectromech. Syst. 2015, 24, 771–780. [Google Scholar] [CrossRef]

- Bannon, F.D.; Clark, J.R.; Nguyen, C.T.-C. High-Q HF microelectromechanical filters. IEEE J. Solid-State Circuits 2000, 35, 512–526. [Google Scholar] [CrossRef]

- Hajhashemi, M.S.; Amini, A.; Bahreyni, B. A micromechanical bandpass filter with adjustable bandwidth and bidirectional control of centre frequency. Sens. Actuators Phys. 2012, 187, 10–15. [Google Scholar] [CrossRef]

- Pourkamali, S.; Ayazi, F. Electrically coupled MEMS bandpass filters: Part I: With coupling element. Sens. Actuators Phys. 2005, 122, 307–316. [Google Scholar] [CrossRef]

- Thiruvenkatanathan, P.; Woodhouse, J.; Yan, J.; Seshia, A.A. Manipulating Vibration Energy Confinement in Electrically Coupled Microelectromechanical Resonator Arrays. J. Microelectromech. Syst. 2011, 20, 157–164. [Google Scholar] [CrossRef]

- Thiruvenkatanathan, P.; Yan, J.; Woodhouse, J.; Aziz, A.; Seshia, A.A. Ultrasensitive mode-localized mass sensor with electrically tunable parametric sensitivity. Appl. Phys. Lett. 2010, 96, 81913. [Google Scholar] [CrossRef]

- Thiruvenkatanathan, P.; Yan, J.; Seshia, A.A. Differential amplification of structural perturbations in weakly coupled MEMS resonators. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2010, 57, 690–697. [Google Scholar] [CrossRef] [PubMed]

- Lin, C.-M.; Lai, Y.-J.; Hsu, J.-C.; Chen, Y.-Y.; Senesky, D.G.; Pisano, A.P. High-Q aluminum nitride Lamb wave resonators with biconvex edges. Appl. Phys. Lett. 2011, 99, 143501. [Google Scholar] [CrossRef]

- Tabrizian, R.; Ayazi, F. Thermo-acoustic engineering of silicon microresonators via evanescent waves. Appl. Phys. Lett. 2015, 106, 263504. [Google Scholar] [CrossRef]

- Brand, O.; Dufour, I.; Heinrich, S. Resonant MEMS: Fundamentals, Implementation, and Application; Wiley: New York, NY, USA, 2015. [Google Scholar]

- Cho, Y.-H.; Pisano, A.P.; Howe, R.T. Viscous damping model for laterally oscillating microstructures. J. Microelectromech. Syst. 1994, 3, 81–87. [Google Scholar] [CrossRef]

- Bao, M.; Yang, H. Squeeze film air damping in MEMS. Sens. Actuators Phys. 2007, 136, 3–27. [Google Scholar] [CrossRef]

- Nayfeh, A.H.; Younis, M.I. A new approach to the modeling and simulation of flexible microstructures under the effect of squeeze-film damping. J. Micromech. Microeng. 2004, 14, 170. [Google Scholar] [CrossRef]

- Hutcherson, S.; Ye, W. On the squeeze-film damping of micro-resonators in the free-molecule regime. J. Micromech. Microeng. 2004, 14, 1726. [Google Scholar] [CrossRef]

- Jimbo, Y.; Itao, K. Energy loss of a cantilever vibrator. J. Horol. Inst. Jpn. 1968, 47, 1–15. [Google Scholar]

- Hao, Z.; Erbil, A.; Ayazi, F. An analytical model for support loss in micromachined beam resonators with in-plane flexural vibrations. Sens. Actuators Phys. 2003, 109, 156–164. [Google Scholar] [CrossRef]

- Park, Y.-H.; Park, K.C. High-fidelity modeling of MEMS resonators. Part I. Anchor loss mechanisms through substrate. J. Microelectromech. Syst. 2004, 13, 238–247. [Google Scholar] [CrossRef]

- Bindel, D.S.; Govindjee, S. Elastic PMLs for resonator anchor loss simulation. Int. J. Numer. Methods Eng. 2005, 64, 789–818. [Google Scholar] [CrossRef]

- Lee, J.E.-Y.; Yan, J.; Seshia, A.A. Study of lateral mode SOI-MEMS resonators for reduced anchor loss. J. Micromech. Microeng. 2011, 21, 45010. [Google Scholar] [CrossRef]

- Pandey, M.; Reichenbach, R.B.; Zehnder, A.T.; Lal, A.; Craighead, H.G. Reducing Anchor Loss in MEMS Resonators Using Mesa Isolation. J. Microelectromech. Syst. 2009, 18, 836–844. [Google Scholar] [CrossRef]

- Harrington, B.P.; Abdolvand, R. In-plane acoustic reflectors for reducing effective anchor loss in lateral?extensional MEMS resonators. J. Micromech. Microeng. 2011, 21, 85021. [Google Scholar] [CrossRef]

- Mohammadi, S.; Eftekhar, A.A.; Hunt, W.D.; Adibi, A. High-Q micromechanical resonators in a two-dimensional phononic crystal slab. Appl. Phys. Lett. 2009, 94, 51906. [Google Scholar] [CrossRef]

- Iii, R.H.O.; El-Kady, I. Microfabricated phononic crystal devices and applications. Meas. Sci. Technol. 2008, 20, 12002. [Google Scholar]

- Sorenson, L.; Fu, J.L.; Ayazi, F. One-dimensional linear acoustic bandgap structures for performance enhancement of AlN-on-Silicon micromechanical resonators. In Proceedings of the 2011 16th International Solid-State Sensors, Actuators and Microsystems Conference, Beijing, China, 5–9 June 2011; pp. 918–921.

- Lin, C.-M.; Hsu, J.-C.; Senesky, D.G.; Pisano, A.P. Anchor loss reduction in ALN Lamb wave resonators using phononic crystal strip tethers. In Proceedings of the 2014 IEEE International Frequency Control Symposium (FCS), Taipei, Taiwan, 19–22 May 2014; pp. 1–5.

- Nowick, A.S.; Berry, B.S. Anelastic Relaxation in Crystalline Solids; Academic Press: New York, NY, USA, 1972. [Google Scholar]

- Ghaffari, S.; Chandorkar, S.A.; Wang, S.; Ng, E.J.; Ahn, C.H.; Hong, V.; Yang, Y.; Kenny, T.W. Quantum Limit of Quality Factor in Silicon Micro and Nano Mechanical Resonators. Sci. Rep. 2013, 3, 3244. [Google Scholar] [CrossRef] [PubMed]

- Lifshitz, R.; Roukes, M.L. Thermoelastic damping in micro- and nanomechanical systems. Phys. Rev. B 2000, 61, 5600. [Google Scholar] [CrossRef]

- Prabhakar, S.; Vengallatore, S. Theory of Thermoelastic Damping in Micromechanical Resonators with Two-Dimensional Heat Conduction. J. Microelectromech. Syst. 2008, 17, 494–502. [Google Scholar] [CrossRef]

- Wong, S.J.; Fox, C.H.J.; McWilliam, S. Thermoelastic damping of the in-plane vibration of thin silicon rings. J. Sound Vib. 2006, 293, 266–285. [Google Scholar] [CrossRef]

- Abdolvand, R.; Johari, H.; Ho, G.K.; Erbil, A.; Ayazi, F. Quality factor in trench-refilled polysilicon beam resonators. J. Microelectromech. Syst. 2006, 15, 471–478. [Google Scholar] [CrossRef]

- Guo, X.; Yi, Y.-B.; Pourkamali, S. A finite element analysis of thermoelastic damping in vented MEMS beam resonators. Int. J. Mech. Sci. 2013, 74, 73–82. [Google Scholar] [CrossRef]

- Duwel, A.; Candler, R.N.; Kenny, T.W.; Varghese, M. Engineering MEMS Resonators with Low Thermoelastic Damping. J. Microelectromech. Syst. 2006, 15, 1437–1445. [Google Scholar] [CrossRef]

- Prabhakar, S.; Vengallatore, S. Thermoelastic Damping in Hollow and Slotted Microresonators. J. Microelectromech. Syst. 2009, 18, 725–735. [Google Scholar] [CrossRef]

- Tabrizian, R.; Rais-Zadeh, M.; Ayazi, F. Effect of phonon interactions on limiting the f.Q product of micromechanical resonators. In Proceedings of the TRANSDUCERS 2009–2009 International Solid-State Sensors, Actuators and Microsystems Conference, Denver, CO, USA, 21–25 June 2009; pp. 2131–2134.

- Jonscher, A.K. Dielectric relaxation in solids. J. Phys. Appl. Phys. 1999, 32, R57. [Google Scholar] [CrossRef]

- Seoánez, C.; Guinea, F.; Neto, A.H.C. Surface dissipation in nanoelectromechanical systems: Unified description with the standard tunneling model and effects of metallic electrodes. Phys. Rev. B 2008, 77, 125107. [Google Scholar] [CrossRef]

- Yang, J.; Ono, T.; Esashi, M. Energy dissipation in submicrometer thick single-crystal silicon cantilevers. J. Microelectromech. Syst. 2002, 11, 775–783. [Google Scholar] [CrossRef]

- Pourkamali, S.; Hashimura, A.; Abdolvand, R.; Ho, G.K.; Erbil, A.; Ayazi, F. High-Q single crystal silicon HARPSS capacitive beam resonators with self-aligned sub-100-nm transduction gaps. IEEE J. Microelectromech. Syst. 2003, 12, 487–496. [Google Scholar] [CrossRef]

- Wang, J.; Butler, J.E.; Feygelson, T.; Nguyen, C.T.C. 1.51-GHz nanocrystalline diamond micromechanical disk resonator with material-mismatched isolating support. In Proceedings of the 2004 17th IEEE International Conference on Micro Electro Mechanical Systems (MEMS), Maastricht, The Netherlands, 2004; pp. 641–644.

- Rocheleau, T.O.; Naing, T.L.; Ren, Z.; Nguyen, C.T.-C. Acoustic whispering gallery mode resonator with Q > 109,000 at 515 MHz. In Proceedings of the 2012 IEEE 25th International Conference on Micro Electro Mechanical Systems (MEMS), Paris, France, 29 January–2 February 2012; pp. 672–675.

- Naing, T.L.; Beyazoglu, T.; Wu, L.; Akgul, M.; Ren, Z.; Rocheleau, T.O.; Nguyen, C.T.-C. 2.97-GHz CVD diamond ring resonator with Q > 40,000. In Proceedings of the 2012 IEEE International Frequency Control Symposium Proceedings, Baltimore, MD, USA, 21–24 May 2012; pp. 1–6.

- Akgul, M.; Kim, B.; Hung, L.-W.; Lin, Y.; Li, W.-C.; Huang, W.-L.; Gurin, I.; Borna, A.; Nguyen, C.T.-C. Oscillator far-from-carrier phase noise reduction via nano-scale gap tuning of micromechanical resonators. In Proceedings of the TRANSDUCERS 2009—2009 International Solid-State Sensors, Actuators and Microsystems Conference, Denver, CO, USA, 21–25 June 2009; pp. 798–801.

- Weinstein, D.; Bhave, S.A. Internal Dielectric Transduction in Bulk-Mode Resonators. J. Microelectromech. Syst. 2009, 18, 1401–1408. [Google Scholar] [CrossRef]

- Weinstein, D.; Bhave, S.A. Internal Dielectric Transduction of a 4.5 GHz Silicon Bar Resonator. In Proceedings of the 2007 IEEE International Electron Devices Meeting, Washington, DC, USA, 10–12 December 2007; pp. 415–418.

- Trolier-McKinstry, S.; Muralt, P. Thin Film Piezoelectrics for MEMS. J. Electroceramics 2004, 12, 7–17. [Google Scholar] [CrossRef]

- Newell, W.E.; Wickstrom, R.A. The tunistor: A mechanical resonator for microcircuits. IEEE Trans. Electron Devices 1969, 16, 781–787. [Google Scholar] [CrossRef]

- Wang, J.S.; Lakin, K.M. Sputtered AlN Films for Bulk-Acoustic-Wave Devices. In Proceedings of the 1981 Ultrasonics Symposium, Chicago, IL, USA, 14–16 October 1981; pp. 502–505.

- Piazza, G.; Abdolvand, R.; Ho, G.K.; Ayazi, F. Voltage-tunable piezoelectrically-transduced single-crystal silicon micromechanical resonators. Sens. Actuators Phys. 2004, 111, 71–78. [Google Scholar] [CrossRef]

- DDeVoe, L.; Pisano, A.P. Modeling and optimal design of piezoelectric cantilever microactuators. J. Microelectromech. Syst. 1997, 6, 266–270. [Google Scholar] [CrossRef]

- Abdolvand, R.; Ayazi, F. Enhanced Power Handling and Quality Factor in Thin-Film Piezoelectric-on-Substrate Resonators. In Proceedings of the IEEE Ultrasonics Symposium, New York, NY, USA, 28–31 October 2007; pp. 608–611.

- Abdolvand, R.; Ho, G.K.; Butler, J.; Ayazi, F. ZNO-on-nanocrystalline diamond lateral bulk acoustic resonators. In Proceedings of the IEEE 20th International Conference on Micro Electro Mechanical Systems (MEMS), Hyogo, Japan, 21–25 January 2007; pp. 795–798.

- Fatemi, H.; Abdolvand, R.; Zeng, H.; Carlisle, J. Very low-loss high frequency lateral-mode resonators on polished ultrananocrystalline diamond. In Proceedings of the 2011 Joint Conference of the IEEE International Frequency Control and the European Frequency and Time Forum (FCS) Proceedings, San Fransisco, CA, USA, 2–5 May 2011; pp. 1–5.

- Lavasani, H.M.; Pan, W.; Harrington, B.; Abdolvand, R.; Ayazi, F. A 76 dB 1.7 GHz 0.18 m CMOS Tunable TIA Using Broadband Current Pre-Amplifier for High Frequency Lateral MEMS Oscillators. IEEE J. Solid-State Circuits 2011, 46, 224–235. [Google Scholar] [CrossRef]

- Fatemi, H.; Shahmohammadi, M.; Abdolvand, R. Ultra-stable nonlinear thin-film piezoelectric-on-substrate oscillators operating at bifurcation. In Proceedings of the 2014 IEEE 27th International Conference on Micro Electro Mechanical Systems (MEMS), San Francisco, CA, USA, 26–30 January 2014; pp. 1285–1288.

- Rinaldi, M.; Zuniga, C.; Piazza, G. 5–10 GHz AlN Contour-Mode Nanoelectromechanical Resonators. In Proceedings of the IEEE 22nd International Conference on Micro Electro Mechanical Systems (MEMS 2009), Sorrento, Italy, 25–29 January 2009; pp. 916–919.

- Zuo, C.; Sinha, N.; Piazza, G. Very high frequency channel-select MEMS filters based on self-coupled piezoelectric AlN contour-mode resonators. Sens. Actuators Phys. 2010, 160, 132–140. [Google Scholar] [CrossRef]

- Piazza, G.; Stephanou, P.J.; Pisano, A.P. Single-Chip Multiple-Frequency ALN MEMS Filters Based on Contour-Mode Piezoelectric Resonators. J. Microelectromech. Syst. 2007, 16, 319–328. [Google Scholar] [CrossRef]

- Seo, J.H.; Brand, O. High Q-Factor In-Plane-Mode Resonant Microsensor Platform for Gaseous/Liquid Environment. J. Microelectromech. Syst. 2008, 17, 483–493. [Google Scholar]

- Rahafrooz, A.; Hajjam, A.; Tousifar, B.; Pourkamali, S. Thermal actuation, a suitable mechanism for high frequency electromechanical resonators. In Proceedings of the 2010 IEEE 23rd International Conference on Micro Electro Mechanical Systems (MEMS), Hong Kong, China, 24–28 Jaunary 2010; pp. 200–203.

- Smith, C. Piezoresistive effects in silicon and germanium. Phys. Rev. 1954, 94, 42–49. [Google Scholar] [CrossRef]

- Beardslee, L.A.; Addous, A.M.; Heinrich, S.; Josse, F.; Dufour, I.; Brand, O. Thermal Excitation and Piezoresistive Detection of Cantilever In-Plane Resonance Modes for Sensing Applications. J. Microelectromech. Syst. 2010, 19, 1015–1017. [Google Scholar] [CrossRef]

- Rahafrooz, A.; Pourkamali, S. Rotational mode disk resonators for high-Q operation in liquid. In Proceedings of the 2010 IEEE Sensors, Kona, HI, USA, 1–4 November 2010; pp. 1071–1074.

- Lin, A.T.-H.; Lee, J.E.-Y.; Yan, J.; Seshia, A.A. Methods for enhanced electrical transduction and characterization of micromechanical resonators. Sens. Actuators Phys. 2010, 158, 263–272. [Google Scholar] [CrossRef]

- Ekinci, K.L. Electromechanical Transducers at the Nanoscale: Actuation and Sensing of Motion in Nanoelectromechanical Systems (NEMS). Small 2005, 1, 786–797. [Google Scholar] [CrossRef] [PubMed]

- Feng, X.L.; He, R.; Yang, P.; Roukes, M.L. Very High Frequency Silicon Nanowire Electromechanical Resonators. 22 June 2007. Available online: http://pubs.acs.org/doi/abs/10.1021/nl0706695 (accessed on 1 May 2016).

- Van Beek, J.T.M.; Verheijden, G.J.A.M.; Koops, G.E.J.; Phan, K.L.; van der Avoort, C.; van Wingerden, J.; Badaroglu, D.E.; Bontemps, J.J.M. Scalable 1.1 GHz fundamental mode piezo-resistive silicon MEMS resonator. In Proceedings of the 2007 IEEE International Electron Devices Meeting, Washington, DC, USA, 10–12 December 2007; pp. 411–414.

- He, R.; Yang, P. Giant piezoresistance effect in silicon nanowires. Nat. Nanotechnol. 2006, 1, 42–46. [Google Scholar] [CrossRef] [PubMed]

- Mile, E.; Jourdan, G.; Bargatin, I.; Labarthe, S.; Marcoux, C.; Andreucci, P.; Hentz, S.; Kharrat, C.; Colinet, E.; Duraffourg, L. In-plane nanoelectromechanical resonators based on silicon nanowire piezoresistive detection. Nanotechnology 2010, 21, 165504. [Google Scholar] [CrossRef] [PubMed]

- Beroulle, V.; Bertrand, Y.; Latorre, L.; Nouet, P. Monolithic piezoresistive CMOS magnetic field sensors. Sens. Actuators Phys. 2003, 103, 23–32. [Google Scholar] [CrossRef]

- Lange, D.; Hagleitner, C.; Herzog, C.; Brand, O.; Baltes, H. Electromagnetic actuation and MOS-transistor sensing for CMOS-integrated micromechanical resonators. Sens. Actuators Phys. 2003, 103, 150–155. [Google Scholar] [CrossRef]

- Arcizet, O.; Cohadon, P.-F.; Briant, T.; Pinard, M.; Heidmann, A.; Mackowski, J.-M.; Michel, C.; Pinard, L.; Français, O.; Rousseau, L. High-Sensitivity Optical Monitoring of a Micromechanical Resonator with a Quantum-Limited Optomechanical Sensor. Phys. Rev. Lett. 2006, 97, 133601. [Google Scholar] [CrossRef] [PubMed]

- Ayazi, F.; Najafi, K. High aspect-ratio combined poly and single-crystal silicon (HARPSS) MEMS technology. J. Microelectromech. Syst. 2000, 9, 288–294. [Google Scholar] [CrossRef]

- Ziaei-Moayyed, M.; Elata, D.; Quévy, E.P.; Howe, R.T. Differential internal dielectric transduction of a Lamé-mode resonator. J. Micromech. Microeng. 2010, 20, 115036. [Google Scholar] [CrossRef]

- Lin, Y.-W.; Li, S.-S.; Xie, Y.; Ren, Z.; Nguyen, C.T.C. Vibrating micromechanical resonators with solid dielectric capacitive transducer gaps. In Proceedings of the 2005 IEEE International Frequency Control Symposium and Exposition, Vancouver, BC, USA, 29–31 August 2005; pp. 128–134.

- Cheng, T.J.; Bhave, S.A. High-Q, low impedance polysilicon resonators with 10 nm air gaps. In Proceedings of the 23rd IEEE International Conference on Micro Electro Mechanical Systems, Hong Kong, China, 24–28 January 2010; pp. 695–698.

- Zuo, C.; van der Spiegel, J.; Piazza, G. 1.05-GHz CMOS oscillator based on lateral- field-excited piezoelectric AlN contour- mode MEMS resonators. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2010, 57, 82–87. [Google Scholar] [PubMed]

- Zuo, C.; Sinha, N.; van der Spiegel, J.; Piazza, G. Multifrequency Pierce Oscillators Based on Piezoelectric AlN Contour-Mode MEMS Technology. J. Microelectromech. Syst. 2010, 19, 570–580. [Google Scholar]

- Rinaldi, M.; Zuniga, C.; Zuo, C.; Piazza, G. Super-high-frequency two-port AlN contour-mode resonators for RF applications. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2010, 57, 38–45. [Google Scholar] [CrossRef] [PubMed]

- Chandrahalim, H.; Bhave, S.A.; Polcawich, R.G.; Pulskamp, J.S.; Kaul, R. PZT transduction of high-overtone contour- mode resonators. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2010, 57, 2035–2041. [Google Scholar] [CrossRef] [PubMed]

- Thakar, V.A.; Wu, Z.; Peczalski, A.; Rais-Zadeh, M. Piezoelectrically Transduced Temperature-Compensated Flexural-Mode Silicon Resonators. J. Microelectromech. Syst. 2013, 22, 815–823. [Google Scholar] [CrossRef]

- Tu, C.; Lee, J.E.-Y. A semi-analytical modeling approach for laterally-vibrating thin-film piezoelectric-on-silicon micromechanical resonators. J. Micromech. Microeng. 2015, 25, 115020. [Google Scholar] [CrossRef]

- Abdolvand, R.; Lavasani, H.M.; Ho, G.K.; Ayazi, F. Thin-film piezoelectric-on-silicon resonators for high-frequency reference oscillator applications. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2008, 55, 2596–2606. [Google Scholar] [CrossRef] [PubMed]

- Lin, C.-M.; Chen, Y.-Y.; Felmetsger, V.V.; Senesky, D.G.; Pisano, A.P. AlN/3C-SiC Composite Plate Enabling High-Frequency and High-Q Micromechanical Resonators. Adv. Mater. 2012, 24, 2722–2727. [Google Scholar] [CrossRef] [PubMed]

- Lin, C.-M.; Chen, Y.-Y.; Pisano, A.P. Theoretical investigation of Lamb wave characteristics in AlN/3C–SiC composite membranes. Appl. Phys. Lett. 2010, 97, 193506. [Google Scholar] [CrossRef]

- Lin, C.-M.; Lien, W.-C.; Felmetsger, V.V.; Hopcroft, M.A.; Senesky, D.G.; Pisano, A.P. AlN thin films grown on epitaxial 3C–SiC (100) for piezoelectric resonant devices. Appl. Phys. Lett. 2010, 97, 141907. [Google Scholar] [CrossRef]

- Fatemi, H.; Abdolvand, R. Low-loss lateral-extensional piezoelectric filters on ultrananocrystalline diamond. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2013, 60, 1978–1988. [Google Scholar] [CrossRef] [PubMed]

- Fatemi, H.; Zeng, H.; Carlisle, J.; Abdolvand, R. High-Frequency Thin-Film AlN-on-Diamond Lateral–Extensional Resonators. J. Microelectromech. Syst. 2013, 22, 678–686. [Google Scholar] [CrossRef]

- Gong, S.; Piazza, G. Design and Analysis of Lithium Niobate-Based High Electromechanical Coupling RF-MEMS Resonators for Wideband Filtering. IEEE Trans. Microw. Theory Tech. 2013, 61, 403–414. [Google Scholar] [CrossRef]

- Shi, L.; Piazza, G. Lithium Niobate on Silicon Dioxide Suspended Membranes: A Technology Platform for Engineering the Temperature Coefficient of Frequency of High Electromechanical Coupling Resonators. J. Microelectromech. Syst. 2014, 23, 1318–1329. [Google Scholar] [CrossRef]

- Gong, S.; Piazza, G. Monolithic Multi-Frequency Wideband RF Filters Using Two-Port Laterally Vibrating Lithium Niobate MEMS Resonators. J. Microelectromech. Syst. 2014, 23, 1188–1197. [Google Scholar] [CrossRef]

- Wang, R.; Bhave, S.A.; Bhattacharjee, K. Design and Fabrication of S0 Lamb-Wave Thin-Film Lithium Niobate Micromechanical Resonators. J. Microelectromech. Syst. 2015, 24, 300–308. [Google Scholar] [CrossRef]

- Verd, J.; Abadal, G.; Teva, J.; Gaudo, M.V.; Uranga, A.; Borrise, X.; Campabadal, F.; Esteve, J.; Costa, E.F.; Perez-Murano, F.; et al. Design, fabrication, and characterization of a submicroelectromechanical resonator with monolithically integrated CMOS readout circuit. J. Microelectromech. Syst. 2005, 14, 508–519. [Google Scholar] [CrossRef]

- Uranga, A.; Verd, J.; López, J.L.; Teva, J.; Abadal, G.; Torres, F.; Esteve, J.; Pérez-Murano, F.; Barniol, N. Fully integrated MIXLER based on VHF CMOS-MEMS clamped-clamped beam resonator. Electron. Lett. 2007, 43, 452. [Google Scholar] [CrossRef]

- Uranga, A.; Teva, J.; Verd, J.; López, J.L.; Torres, F.; Esteve, J.; Abadal, G.; Pérez-Murano, F.; Barniol, N. Fully CMOS integrated low voltage 100 MHz MEMS resonator. Electron. Lett. 2005, 41, 1327. [Google Scholar] [CrossRef]

- Davis, Z.J.; Abadal, G.; Helbo, B.; Hansen, O.; Campabadal, F.; Pérez-Murano, F.; Esteve, J.; Figueras, E.; Verd, J.; Barniol, N.; et al. Monolithic integration of mass sensing nano-cantilevers with CMOS circuitry. Sens. Actuators Phys. 2003, 105, 311–319. [Google Scholar] [CrossRef]

- Lopez, J.L.; Verd, J.; Teva, J.; Murillo, G.; Giner, J.; Torres, F.; Uranga, A.; Abadal, G.; Barniol, N. Integration of RF-MEMS resonators on submicrometric commercial CMOS technologies. J. Micromech. Microeng. 2009, 19, 15002. [Google Scholar] [CrossRef]

- Verd, J.; Uranga, A.; Teva, J.; Lopez, J.L.; Torres, F.; Esteve, J.; Abadal, G.; Perez-Murano, F.; Barniol, N. Integrated CMOS-MEMS with on-chip readout electronics for high-frequency applications. IEEE Electron Device Lett. 2006, 27, 495–497. [Google Scholar] [CrossRef]

- Verd, J.; Uranga, A.; Abadal, G.; Teva, J.L.; Torres, F.; LÓpez, J.; PÉrez-Murano, F.; Esteve, J.; Barniol, N. Monolithic CMOS MEMS Oscillator Circuit for Sensing in the Attogram Range. IEEE Electron. Device Lett. 2008, 29, 146–148. [Google Scholar] [CrossRef]

- Chen, W.-C.; Li, M.-H.; Liu, Y.-C.; Fang, W.; Li, S.-S. A Fully Differential CMOS-MEMS DETF Oxide Resonator with Q > 4800 and Positive TCF. IEEE Electron Device Lett. 2012, 33, 721–723. [Google Scholar] [CrossRef]

- Li, M.-H.; Chen, C.-Y.; Liu, C.-Y.; Li, S.-S. A Sub-150 μW BEOL-Embedded CMOS-MEMS Oscillator with a 138 dBΩ Ultra-Low-Noise TIA. IEEE Electron Device Lett. 2016, 37, 648–651. [Google Scholar]

- Chen, W.-C.; Fang, W.; Li, S.-S. A generalized CMOS-MEMS platform for micromechanical resonators monolithically integrated with circuits. J. Micromech. Microeng. 2011, 21, 65012. [Google Scholar] [CrossRef]

- Chin, C.-H.; Li, M.-H.; Chen, C.-Y.; Wang, Y.-L.; Li, S.-S. A CMOS–MEMS arrayed resonant-gate field effect transistor (RGFET) oscillator. J. Micromech. Microeng. 2015, 25, 115025. [Google Scholar] [CrossRef]

- Cheng, Y.-T.; Hsu, W.-T.; Najafi, K.; Nguyen, C.T.-C.; Lin, L. Vacuum packaging technology using localized aluminum/silicon-to-glass bonding. J. Microelectromech. Syst. 2002, 11, 556–565. [Google Scholar] [CrossRef]

- Cheng, Y.T.; Lin, L.; Najafi, K. Localized silicon fusion and eutectic bonding for MEMS fabrication and packaging. J. Microelectromech. Syst. 2000, 9, 3–8. [Google Scholar] [CrossRef]

- Cheng, Y.-T.; Lin, L.; Najafi, K. A hermetic glass-silicon package formed using localized aluminum/silicon-glass bonding. J. Microelectromech. Syst. 2001, 10, 392–399. [Google Scholar] [CrossRef]

- Koskenvuori, M.; Mattila, T.; Häärä, A.; Kiihamäki, J.; Tittonen, I.; Oja, A.; Seppä, H. Long-term stability of single-crystal silicon microresonators. Sens. Actuators Phys. 2004, 115, 23–27. [Google Scholar] [CrossRef]

- Joseph, P.J.; Monajemi, P.; Ayazi, F.; Kohl, P.A. Wafer-Level Packaging of Micromechanical Resonators. IEEE Trans. Adv. Packag. 2007, 30, 19–26. [Google Scholar] [CrossRef]

- Monajemi, P.; Joseph, P.J.; Kohl, P.A.; Ayazi, F. Wafer-level MEMS packaging via thermally released metal-organic membranes. J. Micromech. Microeng. 2006, 16, 742. [Google Scholar] [CrossRef]

- Fang, J.; Fu, J.; Ayazi, F. Metal-organic thin-film encapsulation for MEMS. J. Micromech. Microeng. 2008, 18, 105002. [Google Scholar] [CrossRef]

- Candler, R.N.; Park, W.; Li, H.; Yama, G.; Partridge, A.; Lutz, M.; Kenny, T.W. Single wafer encapsulation of MEMS devices. IEEE Trans. Adv. Packag. 2003, 26, 227–232. [Google Scholar] [CrossRef]

- Yang, Y.; Ng, E.J.; Chen, Y.; Flader, I.B.; Kenny, T.W. A Unified Epi-Seal Process for Fabrication of High-Stability Microelectromechanical Devices. J. Microelectromech. Syst. 2016, 25, 489–497. [Google Scholar] [CrossRef]

- Ng, E.; Yang, Y.; Hong, V.A.; Ahn, C.H.; Heinz, D.B.; Flader, I.; Chen, Y.; Everhart, C.L.M.; Kim, B.; Melamud, R.; et al. The long path from MEMS resonators to timing products. In Proceedings of the 2015 28th IEEE International Conference on Micro Electro Mechanical Systems (MEMS), Estoril, Portugal, 18–22 January 2015; pp. 1–2.

- Heragu, A.; Ruffieux, D.; Enz, C. A 2.4-GHz MEMS-based PLL-free multi-channel receiver with channel filtering at RF. In Proceedings of the ESSCIRC, Bordeaux, France, 17–21 September 2012; pp. 137–140.

- Arumugam, N.; Hill, G.; Clark, G.; Arft, C.; Grosjean, C.; Palwai, R.; Pedicord, J.; Hagelin, P.; Partridge, A.; Menon, V.; et al. 2-die wafer-level chip scale packaging enables the smallest TCXO for mobile and wearable applications. In Proceedings of the 2015 IEEE 65th Electronic Components and Technology Conference (ECTC), San Diego, CA, USA, 26–29 May 2015; pp. 1338–1342.

- Barrow, H.G.; Naing, T.L.; Schneider, R.A.; Rocheleau, T.O.; Yeh, V.; Ren, Z.; Nguyen, C.T.-C. A real-time 32.768-kHz clock oscillator using a 0.0154-mm2 micromechanical resonator frequency-setting element. In Proceedings of the 2012 IEEE International Frequency Control Symposium (FCS), Baltimore, MD, USA, 21–24 May 2012; pp. 1–6.

- Asl, S.Z.; Mukherjee, S.; Chen, W.; Joo, K.; Palwai, R.; Arumugam, N.; Galle, P.; Phadke, M.; Grosjean, C.; Salvia, J.; et al. A 1.55 × 0.85 mm2 3 ppm 1.0 μA 32.768 kHz MEMS-based oscillator. In Proceedings of the 2014 IEEE International Solid-State Circuits Conference Digest of Technical Papers (ISSCC), San Francisco, CA, USA, 9–13 February 2014; pp. 226–227.

- Zaliasl, S.; Salvia, J.C.; Hill, G.C.; Chen, L.W.; Joo, K.; Palwai, R.; Arumugam, N.; Phadke, M.; Mukherjee, S.; Lee, H.-C.; et al. A 3 ppm 1.5 × 0.8 mm2 1.0 μA 32.768 kHz MEMS-Based Oscillator. IEEE J. Solid-State Circuits 2015, 50, 291–302. [Google Scholar] [CrossRef]

- Ruffieux, D.; Krummenacher, F.; Pezous, A.; Spinola-Durante, G. Silicon Resonator Based 3.2 W Real Time Clock with 10 ppm Frequency Accuracy. IEEE J. Solid-State Circuits 2010, 45, 224–234. [Google Scholar] [CrossRef]

- Perrott, M.H.; Pamarti, S.; Hoffman, E.G.; Lee, F.S.; Mukherjee, S.; Lee, C.; Tsinker, V.; Perumal, S.; Soto, B.T.; Arumugam, N.; et al. A Low Area, Switched-Resistor Based Fractional-N Synthesizer Applied to a MEMS-Based Programmable Oscillator. IEEE J. Solid-State Circuits 2010, 45, 2566–2581. [Google Scholar] [CrossRef]

- Perrott, M.H.; Salvia, J.C.; Lee, F.S.; Partridge, A.; Mukherjee, S.; Arft, C.; Kim, J.; Arumugam, N.; Gupta, P.; Tabatabaei, S.; et al. A Temperature-to-Digital Converter for a MEMS-Based Programmable Oscillator with Frequency Stability and Integrated Jitter. IEEE J. Solid-State Circuits 2013, 48, 276–291. [Google Scholar] [CrossRef]

- Salvia, J.C.; Melamud, R.; Chandorkar, S.A.; Lord, S.F.; Kenny, T.W. Real-Time Temperature Compensation of MEMS Oscillators Using an Integrated Micro-Oven and a Phase-Locked Loop. J. Microelectromech. Syst. 2010, 19, 192–201. [Google Scholar] [CrossRef]

- Wu, Z.; Rais-Zadeh, M. A Temperature-Stable Piezoelectric MEMS Oscillator Using a CMOS PLL Circuit for Temperature Sensing and Oven Control. J. Microelectromech. Syst. 2015, 24, 1747–1758. [Google Scholar] [CrossRef]

- Nabki, F.; Allidina, K.; Ahmad, F.; Cicek, P.-V.; El-Gamal, M.N. A Highly Integrated 1.8 GHz Frequency Synthesizer Based on a MEMS Resonator. IEEE J. Solid-State Circuits 2009, 44, 2154–2168. [Google Scholar] [CrossRef]

- Chen, C.-Y.; Li, M.-H.; Li, C.-S.; Li, S.-S. Design and characterization of mechanically coupled CMOS-MEMS filters for channel-select applications. Sens. Actuators Phys. 2014, 216, 394–404. [Google Scholar] [CrossRef]

- Heragu, A.; Ruffieux, D.; Enz, C.C. A 2.4-GHz MEMS-Based PLL-Free Multi-Channel Receiver With Channel Filtering at RF. IEEE J. Solid-State Circuits 2013, 48, 1689–1700. [Google Scholar] [CrossRef]

- Otis, B.P.; Rabaey, J.M. A 300-mu;W 1.9-GHz CMOS oscillator utilizing micromachined resonators. IEEE J. Solid-State Circuits 2003, 38, 1271–1274. [Google Scholar] [CrossRef]

- Manzaneque, T.; Ruiz-Díez, V.; Hernando-García, J.; Wistrela, E.; Kucera, M.; Schmid, U.; Sánchez-Rojas, J.L. Piezoelectric MEMS resonator-based oscillator for density and viscosity sensing. Sens. Actuators Phys. 2014, 220, 305–315. [Google Scholar] [CrossRef]

- Roy, S.; Ramiah, H.; Reza, A.W. Designing a new high gain CMOS amplifier towards a 17.22 MHz MEMS based Si oscillator for a cost effective clock generator IC. IEICE Electron. Express 2015, 12, 20150272. [Google Scholar] [CrossRef]

- Arndt, G.; Colinet, E.; Arcamone, J.; Juillard, J. A design methodology for fully integrated MEMS and NEMS Pierce oscillators. Sens. Actuators Phys. 2011, 172, 293–300. [Google Scholar] [CrossRef]

- Nabki, F.; El-Gamal, M.N. A high gain-bandwidth product transimpedance amplifier for MEMS-based oscillators. In Proceedings of the 34th European Solid-State Circuits Conference (ESSCIRC), Edinburgh, UK, 15–19 September 2008; pp. 454–457.

- Nguyen, C.T.-C.; Howe, R.T. An integrated CMOS micromechanical resonator high-Q oscillator. IEEE J. Solid-State Circuits 1999, 34, 440–455. [Google Scholar] [CrossRef]

- Salvia, J.; Lajevardi, P.; Hekmat, M.; Murmann, B. A 56 MΩ CMOS TIA for MEMS applications. In Proceedings of the IEEE Custom Integrated Circuits Conference, CICC ’09, San Jose, CA, USA, 13–16 September 2009; pp. 199–202.

- Chen, W.C.; Fang, W.; Li, S.S. High- Integrated CMOS-MEMS Resonators with Deep-Submicrometer Gaps and Quasi-Linear Frequency Tuning. J. Microelectromech. Syst. 2012, 21, 688–701. [Google Scholar] [CrossRef]

- DeMartini, B.E.; Rhoads, J.F.; Turner, K.L.; Shaw, S.W.; Moehlis, J. Linear and Nonlinear Tuning of Parametrically Excited MEMS Oscillators. J. Microelectromech. Syst. 2007, 16, 310–318. [Google Scholar] [CrossRef]

- Pardo, M.; Sorenson, L.; Ayazi, F. An Empirical Phase-Noise Model for MEMS Oscillators Operating in Nonlinear Regime. IEEE Trans. Circuits Syst. Regul. Pap. 2012, 59, 979–988. [Google Scholar] [CrossRef]

- Agrawal, D.K.; Woodhouse, J.; Seshia, A.A. Modeling nonlinearities in MEMS oscillators. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2013, 60, 1646–1659. [Google Scholar] [CrossRef] [PubMed]

- Bouchami, A.; Nabki, F. Non-linear modeling of MEMS-based oscillators using an analog hardware description language. In Proceedings of the 2014 IEEE 12th International New Circuits and Systems Conference (NEWCAS), Trois-Rivieres, QC, Canada, 22–25 June 2014; pp. 257–260.

- Rocheleau, T.O.; Liu, R.; Nilchi, J.N.; Naing, T.L.; Nguyen, C.T.-C. A micromechanical parametric oscillator for frequency division and phase noise reduction. In Proceedings of the 2014 IEEE 27th International Conference on Micro Electro Mechanical Systems (MEMS), San Francisco, CA, USA, 26–30 Januray 2014; pp. 210–213.

- Kourani, A.; Hegazi, E.; Ismail, Y. A 76.8 MHz temperature compensated MEMS reference oscillator for wireless handsets. Microelectron. J. 2015, 46, 496–505. [Google Scholar] [CrossRef]

- Vig, J.R.; Kim, Y. Noise in microelectromechanical system resonators. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1999, 46, 1558–1565. [Google Scholar] [CrossRef] [PubMed]

- Agrawal, D.; Seshia, A. An analytical formulation for phase noise in MEMS oscillators. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2014, 61, 1938–1952. [Google Scholar] [CrossRef] [PubMed]

- Papin, G.; Levy, R.; Lissorgues, G.; Poulichet, P.; Masson, S.; Maréchal, B.; Guérard, J.; Janiaud, D.; Traon, O.L. Behavioural modelling of MEMS oscillators and phase noise simulation. Analog Integr. Circuits Signal Process. 2012, 72, 11–18. [Google Scholar] [CrossRef]

- Vittoz, E.A. The Design of Low-Power High-Q Oscillators. In MEMS-based Circuits and Systems for Wireless Communication; Enz, C.C., Kaiser, A., Eds.; Springer: Berlin, Germany, 2013; pp. 121–154. [Google Scholar]

- Wong, T.S.A.; Palaniapan, M. Micromechanical oscillator circuits: Theory and analysis. Analog Integr. Circuits Signal Process. 2008, 59, 21–30. [Google Scholar] [CrossRef]

- Lin, Y.-W.; Lee, S.; Li, S.-S.; Xie, Y.; Ren, Z.; Nguyen, C.T.-C. Series-resonant VHF micromechanical resonator reference oscillators. IEEE J. Solid-State Circuits 2004, 39, 2477–2491. [Google Scholar] [CrossRef]

- Leeson, D.B. A simple model of feedback oscillator noise spectrum. Proc. IEEE 1966, 54, 329–330. [Google Scholar] [CrossRef]

- Marigó, E.; Verd, J.; López, J.L.; Uranga, A.; Barniol, N. Packaged CMOS–MEMS free–free beam oscillator. J. Micromech. Microeng. 2013, 23, 115018. [Google Scholar] [CrossRef]

- Demir, A. Computing Timing Jitter From Phase Noise Spectra for Oscillators and Phase-Locked Loops With White and Noise. IEEE Trans. Circuits Syst. Regul. Pap. 2006, 53, 1869–1884. [Google Scholar] [CrossRef]

- Hajimiri, A.; Lee, T.H. A general theory of phase noise in electrical oscillators. IEEE J. Solid-State Circuits 1998, 33, 179–194. [Google Scholar] [CrossRef]

- Lavasani, H.M.; Abdolvand, R.; Ayazi, F. A 500 MHz Low Phase-Noise A1N-on-Silicon Reference Oscillator. In Proceedings of the IEEE Custom Integrated Circuits Conference, CICC ’07, San Jose, CA, USA, 16–19 September 2007; pp. 599–602.

- Samori, C.; Lacaita, A.L.; Villa, F.; Zappa, F. Spectrum folding and phase noise in LC tuned oscillators. IEEE Trans. Circuits Syst. II Analog Digit. Signal Process. 1998, 45, 781–790. [Google Scholar] [CrossRef]

- Lee, S.; Nguyen, C.T.-C. Influence of automatic level control on micromechanical resonator oscillator phase noise. In Proceedings of the 2003 IEEE International Frequency Control Symposium and PDA Exhibition Jointly with the 17th European Frequency and Time Forum, Tampa, FL, USA, 4–8 May 2003; pp. 341–349.

- Nabki, F.; El-Gamal, M.N. Modeling and simulation of micro electromechanical (MEM) beam resonator-based oscillators. In Proceedings of the IEEE International Symposium on Circuits and Systems, Seattle, WA, USA, 18–21 May 2008; pp. 1324–1327.

- Serrano, D.E.; Tabrizian, R.; Ayazi, F. Electrostatically tunable piezoelectric-on- silicon micromechanical resonator for real-time clock. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2012, 59, 358–365. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.K.; Melamud, R.; Kim, B.; Hopcroft, M.A.; Salvia, J.C.; Kenny, T.W. Electrostatic Tuning to Achieve Higher Stability Microelectromechanical Composite Resonators. J. Microelectromech. Syst. 2011, 20, 1355–1365. [Google Scholar] [CrossRef]

- Sundaresan, K.; Ho, G.K.; Pourkamali, S.; Ayazi, F. Electronically Temperature Compensated Silicon Bulk Acoustic Resonator Reference Oscillators. IEEE J. Solid-State Circuits 2007, 42, 1425–1434. [Google Scholar] [CrossRef]

- Melamud, R.; Chandorkar, S.A.; Kim, B.; Lee, H.K.; Salvia, J.C.; Bahl, G.; Hopcroft, M.A.; Kenny, T.W. Temperature-Insensitive Composite Micromechanical Resonators. J. Microelectromech. Syst. 2009, 18, 1409–1419. [Google Scholar] [CrossRef]

- Tazzoli, A.; Piazza, G. UHF Clocks Based on Ovenized AlN MEMS Resonators. In Frequency References, Power Management for SoC, and Smart Wireless Interfaces; Baschirotto, A., Makinwa, K.A.A., Harpe, P., Eds.; Springer International Publishing: Basel, Switzerland, 2014; pp. 71–81. [Google Scholar]

- Li, M.-H.; Chen, C.-Y.; Li, C.-S.; Chin, C.-H.; Li, S.-S. A Monolithic CMOS-MEMS Oscillator Based on an Ultra-Low-Power Ovenized Micromechanical Resonator. J. Microelectromech. Syst. 2015, 24, 360–372. [Google Scholar] [CrossRef]

- Partridge, A.; Lee, H.-C.; Hagelin, P.; Menon, V. A MEMS TCXO with Sub-ppm Stability. In Frequency References, Power Management for SoC, and Smart Wireless Interfaces; Baschirotto, A., Makinwa, K.A.A., Harpe, P., Eds.; Springer International Publishing: Basel, Switzerland, 2014; pp. 41–54. [Google Scholar]

- Van Beek, J.T.M.; van der Avoort, C.; Falepin, A.; Goossens, M.J.; Lander, R.J.P.; Menten, S.; Naass, T.; Phan, K.L.; Stikvoort, E.; Wortel, K. A Piezo-resistive, Temperature Compensated, MEMS-Based Frequency Synthesizer. In Frequency References, Power Management for SoC, and Smart Wireless Interfaces; Baschirotto, A., Makinwa, K.A.A., Harpe, P., Eds.; Springer International Publishing: Basel, Switzerland, 2014; pp. 23–39. [Google Scholar]

- Melamud, R.; Kim, B.; Chandorkar, S.A.; Hopcroft, M.A.; Agarwal, M.; Jha, C.M.; Kenny, T.W. Temperature-compensated high-stability silicon resonators. Appl. Phys. Lett. 2007, 90, 244107. [Google Scholar] [CrossRef]

- Ng, E.J.; Hong, V.A.; Yang, Y.; Ahn, C.H.; Everhart, C.L.M.; Kenny, T.W. Temperature Dependence of the Elastic Constants of Doped Silicon. J. Microelectromech. Syst. 2015, 24, 730–741. [Google Scholar] [CrossRef]

- Naing, T.L.; Rocheleau, T.O.; Nguyen, C.T.-C. Simultaneous multi-frequency switchable oscillator and FSK modulator based on a capacitive-gap MEMS disk array. In Proceedings of the 28th IEEE International Conference on Micro Electro Mechanical Systems (MEMS), Estoril, Portugal, 2015; pp. 1024–1027.

- He, L.; Xu, Y.P.; Palaniapan, M. A CMOS Readout Circuit for SOI Resonant Accelerometer with 4- Bias Stability and 20- Resolution. IEEE J. Solid-State Circuits 2008, 43, 1480–1490. [Google Scholar] [CrossRef]

- Baghelani, M.; Ghavifekr, H.B.; Ebrahimi, A. MEMS based oscillator for UHF applications with automatic amplitude control. Microelectron. J. 2013, 44, 292–300. [Google Scholar] [CrossRef]

- Young, D.J.; Pehlivanoğlu, İ.E.; Zorman, C.A. Silicon carbide MEMS-resonator-based oscillator. J. Micromech. Microeng. 2009, 19, 115027. [Google Scholar] [CrossRef]

- Li, M.-H.; Li, C.-S.; Hou, L.-J.; Liu, Y.-C.; Li, S.-S. A 1.57 mW 99 dBΩ CMOS transimpedance amplifier for VHF micromechanical reference oscillators. In Proceedings of the 2012 IEEE International Symposium on Circuits and Systems (ISCAS), Seoul, Korea, 2012; pp. 209–212.

- Kuo, F.Y.; Chang, C.F.; Wen, K.A. CMOS 0.18 μm standard process capacitive MEMS high-Q oscillator with ultra low-power TIA readout system. In Proceedings of the 2014 IEEE Sensors, Valencia, Spain, 2–5 November 2014; pp. 911–914.

- Seth, S.; Wang, S.; Kenny, T.; Murmann, B. A -131-dBc/Hz, 20-MHz MEMS oscillator with a 6.9-mW, 69-kΩ, gain-tunable CMOS TIA. In Proceedings of the ESSCIRC (ESSCIRC), Bordeaux, France, 17–21 September 2012; pp. 249–252.

- Rinaldi, M.; Zuo, C.; van der Spiegel, J.; Piazza, G. Reconfigurable CMOS Oscillator Based on Multifrequency AlN Contour-Mode MEMS Resonators. IEEE Trans. Electron Devices 2011, 58, 1281–1286. [Google Scholar] [CrossRef]

- Zuo, C.; van der Spiegel, J.; Piazza, G. Dual-Mode Resonator and Switchless Reconfigurable Oscillator Based on Piezoelectric AlN MEMS Technology. IEEE Trans. Electron Devices 2011, 58, 3599–3603. [Google Scholar] [CrossRef]

- Pachkawade, V.; Li, M.-H.; Li, C.-S.; Li, S.-S. A CMOS-MEMS Resonator Integrated System for Oscillator Application. IEEE Sens. J. 2013, 13, 2882–2889. [Google Scholar] [CrossRef]

- Mumford, W.W. Some Notes on the History of Parametric Transducers. Proc. IRE 1960, 48, 848–853. [Google Scholar] [CrossRef]

- Komine, V.; Galliou, S.; Makarov, A. A parametric quartz crystal oscillator. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2003, 50, 1656–1661. [Google Scholar] [CrossRef] [PubMed]

- Villanueva, L.G.; Karabalin, R.B.; Matheny, M.H.; Kenig, E.; Cross, M.C.; Roukes, M.L. A Nanoscale Parametric Feedback Oscillator. Nano Lett. 2011, 11, 5054–5059. [Google Scholar] [CrossRef] [PubMed]

- Cassella, C.; Piazza, G. Low phase-noise autonomous parametric oscillator based on a 226.7 MHz AlN contour-mode resonator. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2015, 62, 617–624. [Google Scholar] [CrossRef] [PubMed]

- Jin, D.; Li, X.; Liu, J.; Zuo, G.; Wang, Y.; Liu, M.; Yu, H. High-mode resonant piezoresistive cantilever sensors for tens-femtogram resoluble mass sensing in air. J. Micromech. Microeng. 2006, 16, 1017–1023. [Google Scholar] [CrossRef]

- Ikehara, T.; Lu, J.; Konno, M.; Maeda, R.; Mihara, T. A high quality-factor silicon cantilever for a low detection-limit resonant mass sensor operated in air. J. Micromech. Microeng. 2007, 17, 2491. [Google Scholar] [CrossRef]

- Li, J.-J.; Zhu, K.-D. All-optical mass sensing with coupled mechanical resonator systems. Phys. Rep. 2013, 525, 223–254. [Google Scholar] [CrossRef]

- Wasisto, H.S.; Merzsch, S.; Waag, A.; Uhde, E.; Salthammer, T.; Peiner, E. Airborne engineered nanoparticle mass sensor based on a silicon resonant cantilever. Sens. Actuators B Chem. 2013, 180, 77–89. [Google Scholar] [CrossRef]

- Lavrik, N.V.; Datskos, P.G. Femtogram mass detection using photothermally actuated nanomechanical resonators. Appl. Phys. Lett. 2003, 82, 2697–2699. [Google Scholar] [CrossRef]

- Shen, Z.; Shih, W.Y.; Shih, W.-H. Mass detection sensitivity of piezoelectric cantilevers with a nonpiezoelectric extension. Rev. Sci. Instrum. 2006, 77, 065101:1–065101:10. [Google Scholar] [CrossRef]

- Hajhashemi, M.S.; Rasouli, A.; Bahreyni, B. Improving sensitivity of resonant sensor systems through strong mechanical coupling. J. Microelectromech. Syst. 2016, 25, 52–59. [Google Scholar] [CrossRef]

- Chaste, J.; Eichler, A.; Moser, J.; Ceballos, G.; Rurali, R.; Bachtold, A. A nanomechanical mass sensor with yoctogram resolution. Nat. Nanotechnol. 2012, 7, 301–304. [Google Scholar] [CrossRef] [PubMed]

- Jensen, K.; Kim, K.; Zettl, A. An atomic-resolution nanomechanical mass sensor. Nat. Nanotechnol. 2008, 3, 533–537. [Google Scholar] [CrossRef] [PubMed]

- Prescesky, S.; Parameswaran, M.; Rawicz, A.; Turner, R.F.B.; Reichl, U. Silicon micromachining technology for sub-nanogram discrete mass resonant biosensors. Can. J. Phys. 1992, 70, 1178–1183. [Google Scholar] [CrossRef]

- Naeli, K.; Tandon, P.; Brand, O. Geometrical Optimization of Resonant Cantilever Sensors. In Proceedings of the 2007 International Conference on Solid-State Sensors, Actuators and Microsystems, Lyon, France, 10–14 June 2007; pp. 245–248.

- Hajhashemi, M.S.; Rasouli, A.; Bahreyni, B. Performance optimization of high order RF microresonators in the presence of squeezed film damping. Sens. Actuators Phys. 2014, 216, 266–276. [Google Scholar] [CrossRef]

- Wenzel, S.W.; White, R.M. Analytic comparison of the sensitivities of bulk-wave, surface-wave, and flexural plate-wave ultrasonic gravimetric sensors. Appl. Phys. Lett. 1989, 54, 1976–1978. [Google Scholar] [CrossRef]

- Ying, Y.; Da-Zhong, Z. A Y type SAW mass sensor with metal array reflectors. Sens. Actuators B Chem. 2005, 109, 244–248. [Google Scholar] [CrossRef]

- Wingqvist, G.; Bjurström, J.; Liljeholm, L.; Yantchev, V.; Katardjiev, I. Shear mode AlN thin film electro-acoustic resonant sensor operation in viscous media. Sens. Actuators B Chem. 2007, 123, 466–473. [Google Scholar] [CrossRef]

- Rösler, S.; Lucklum, R.; Borngräber, R.; Hartmann, J.; Hauptmann, P. Sensor system for the detection of organic pollutants in water by thickness shear mode resonators. Sens. Actuators B Chem. 1998, 48, 415–424. [Google Scholar] [CrossRef]

- Zhang, H.; Kim, E.S. Micromachined Acoustic Resonant Mass Sensor. J. Microelectromech. Syst. 2005, 14, 699–706. [Google Scholar] [CrossRef]

- Lin, R.-C.; Chen, Y.-C.; Chang, W.-T.; Cheng, C.-C.; Kao, K.-S. Highly sensitive mass sensor using film bulk acoustic resonator. Sens. Actuators Phys. 2008, 147, 425–429. [Google Scholar] [CrossRef]

- Abdolvand, R.; Hao, Z.; Ayazi, F. A Temperature-Compensated ZnO-on-Diamond Resonant Mass Sensor. In Proceedings of the 5th IEEE Conference on Sensors, Daegu, Korea, 22–25 October 2006; pp. 1297–1300.

- Hajjam, A.; Wilson, J.C.; Pourkamali, S. Individual Air-Borne Particle Mass Measurement Using High-Frequency Micromechanical Resonators. IEEE Sens. J. 2011, 11, 2883–2890. [Google Scholar] [CrossRef]

- Lee, J.E.-Y.; Bahreyni, B.; Zhu, Y.; Seshia, A.A. Ultrasensitive mass balance based on a bulk acoustic mode single-crystal silicon resonator. Appl. Phys. Lett. 2007, 91, 234103. [Google Scholar] [CrossRef]

- Fanget, S.; Hentz, S.; Puget, P.; Arcamone, J.; Matheron, M.; Colinet, E.; Andreucci, P.; Duraffourg, L.; Myers, E.; Roukes, M.L. Gas sensors based on gravimetric detection—A review. Sens. Actuators B Chem. 2011, 160, 804–821. [Google Scholar] [CrossRef]

- Lavrik, N.V.; Sepaniak, M.J.; Datskos, P.G. Cantilever transducers as a platform for chemical and biological sensors. Rev. Sci. Instrum. 2004, 75, 2229–2253. [Google Scholar] [CrossRef]

- Howe, R.T.; Muller, R.S. Resonant-microbridge vapor sensor. IEEE Trans. Electron Devices 1986, 33, 499–506. [Google Scholar] [CrossRef]

- Hosaka, S.; Chiyoma, T.; Ikeuchi, A.; Okano, H.; Sone, H.; Izumi, T. Possibility of a femtogram mass biosensor using a self-sensing cantilever. Curr. Appl. Phys. 2006, 6, 384–388. [Google Scholar] [CrossRef]

- Lange, D.; Hagleitner, C.; Brand, O.; Baltes, H. CMOS resonant beam gas sensing system with on-chip self excitation. In Proceedings of the 14th IEEE International Conference on Micro Electro Mechanical Systems, Interlaken, Switzerland, 21–25 January 2001; pp. 547–552.

- Forsen, E.; Abadal, G.; Ghatnekar-Nilsson, S.; Teva, J.; Verd, J.; Sandberg, R.; Svendsen, W.; Perez-Murano, F.; Esteve, J.; Figueras, E.; et al. Ultrasensitive mass sensor fully integrated with complementary metal-oxide-semiconductor circuitry. Appl. Phys. Lett. 2005, 87, 43507. [Google Scholar] [CrossRef]

- Voiculescu, I.; Zaghloul, M.E.; McGill, R.A.; Houser, E.J.; Fedder, G.K. Electrostatically actuated resonant microcantilever beam in CMOS technology for the detection of chemical weapons. IEEE Sens. J. 2005, 5, 641–647. [Google Scholar] [CrossRef]

- Khoshaman, A.H.; Bahreyni, B. Application of metal organic framework crystals for sensing of volatile organic gases. Sens. Actuators B Chem. 2012, 162, 114–119. [Google Scholar] [CrossRef]

- Khoshaman, A.H.; Li, P.C.H.; Merbouh, N.; Bahreyni, B. Highly sensitive supra-molecular thin films for gravimetric detection of methane. Sens. Actuators B Chem. 2012, 161, 954–960. [Google Scholar] [CrossRef]

- Nieuwenhuizen, M.S.; Nederlof, A.J. A SAW gas sensor for carbon dioxide and water. Preliminary experiments. Sens. Actuators B Chem. 1990, 2, 97–101. [Google Scholar] [CrossRef]

- Nieuwenhuizen, M.S.; Barendsz, A.W.; Nieuwkoop, E.; Vellekoop, M.J.; Venema, A. Transduction mechanisms in SAW gas sensors. Electron. Lett. 1986, 22, 184–185. [Google Scholar] [CrossRef]

- Lang, H.P.; Berger, R.; Battiston, F.; Ramseyer, J.-P.; Meyer, E.; Andreoli, C.; Brugger, J.; Vettiger, P.; Despont, M.; Mezzacasa, T.; et al. A chemical sensor based on a micromechanical cantilever array for the identification of gases and vapors. Appl. Phys. A 1998, 66, S61–S64. [Google Scholar] [CrossRef]

- Lang, H.P.; Baller, M.K.; Berger, R.; Gerber, C.; Gimzewski, J.K.; Battiston, F.M.; Fornaro, P.; Ramseyer, J.P.; Meyer, E.; Guntherodt, H.J. An artificial nose based on a micromechanical cantilever array. Anal. Chim. Acta 1999, 393, 59–65. [Google Scholar] [CrossRef]

- Hagleitner, C.; Hierlemann, A.; Lange, D.; Kummer, A.; Kerness, N.; Brand, O.; Baltes, H. Smart single-chip gas sensor microsystem. Nature 2001, 414, 293–296. [Google Scholar] [CrossRef] [PubMed]

- Eom, K.; Park, H.S.; Yoon, D.S.; Kwon, T. Nanomechanical resonators and their applications in biological/chemical detection: Nanomechanics principles. Phys. Rep. 2011, 503, 115–163. [Google Scholar] [CrossRef]

- Lin, A.T.-H.; Yan, J.; Seshia, A.A. Electrically Addressed Dual Resonator Sensing Platform for Biochemical Detection. J. Microelectromech. Syst. 2012, 21, 34–43. [Google Scholar] [CrossRef]

- Zhang, H.; Marma, M.S.; Kim, E.S.; McKenna, C.E.; Thompson, M.E. A film bulk acoustic resonator in liquid environments. J. Micromech. Microeng. 2005, 15, 1911–1916. [Google Scholar] [CrossRef]

- Zuniga, C.; Rinaldi, M.; Piazza, G. High frequency Piezoelectric Resonant Nanochannel for bio-sensing applications in liquid environment. In Proceedings of the 2010 IEEE Sensors, Kona, HI, USA, 1–4 November 2010; pp. 52–55.

- Bahreyni, B.; Shafai, C. A Resonant Micromachined Magnetic Field Sensor. IEEE Sens. J. 2007, 7, 1326–1334. [Google Scholar] [CrossRef]

- Wojciechowski, K.E.; Boser, B.E.; Pisano, A.P. A MEMS resonant strain sensor operated in air. In Proceedings of the 17th IEEE Micro Electro Mechanical Systems Conference, MEMS ’04, Maastricht, The Netherlands, 25–29 January 2004; pp. 841–845.

- Azevedo, R.G.; Jones, D.G.; Jog, A.V.; Jamshidi, B.; Myers, D.R.; Chen, L.; Fu, X.; Mehregany, M.; Wijesundara, M.B.J.; Pisano, A.P. A SiC MEMS Resonant Strain Sensor for Harsh Environment Applications. IEEE Sens. J. 2007, 7, 568–576. [Google Scholar] [CrossRef]

- Greenwood, J.C. Etched silicon vibrating sensor. J. Phys. E 1984, 17, 650–652. [Google Scholar] [CrossRef]

- Welham, C.J.; Gardner, J.W.; Greenwood, J. A laterally driven micromachined resonant pressure sensor. Sens. Actuators Phys. 1996, 52, 86–91. [Google Scholar] [CrossRef]

- Esashi, M.; Sugiyama, S.; Ikeda, K.; Wang, Y.; Miyashita, H. Vacuum-sealed silicon micromachined pressure sensors. Proc. IEEE 1998, 86, 1627–1639. [Google Scholar] [CrossRef]

- Petersen, K.; Pourahmadi, F.; Brown, J.; Parsons, P.; Skinner, M.; Tudor, J. Resonant beam pressure sensor fabricated with silicon fusion bonding. In Proceedings of the 1991 International Conference on Solid-State Sensors and Actuators, Digest of Technical Papers, TRANSDUCERS ’91, San Francisco, CA, USA, 24–27 June 1991; pp. 664–667.

- Kinnell, P.K.; Craddock, R. Advances in Silicon Resonant Pressure Transducers. Procedia Chem. 2009, 1, 104–107. [Google Scholar] [CrossRef]

- Ikeda, K.; Kuwayama, H.; Kobayashi, T.; Watanabe, T.; Nishikawa, T.; Yoshida, T.; Harada, K. Silicon pressure sensor integrates resonant strain gauge on diaphragm. Sens. Actuators Phys. 1990, 21, 146–150. [Google Scholar] [CrossRef]

- Ikeda, K. Silicon Micromachined Vacuum Encapsulated Resonant Pressure Sensors. In Proceedings of the Digest of Papers of the International Microprocesses and Nanotechnology Conference, Kyoungju, Korea, 13–16 July 1998; pp. 56–57.

- Sunier, R.; Vancura, T.; Li, Y.; Kirstein, K.-U.; Baltes, H.; Brand, O. Resonant Magnetic Field Sensor With Frequency Output. IEEE J. Microelectromech. Syst. 2006, 15, 1098–1107. [Google Scholar] [CrossRef]

- Herrera-May, A.L.; Aguilera-Cortés, L.A.; García-Ramírez, P.J.; Manjarrez, E. Resonant magnetic field sensors based on MEMS technology. Sensors 2009, 9, 7785–7813. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Rouf, V.T.; Thompson, M.J.; Horsley, D.A. Three-Axis Lorentz-Force Magnetic Sensor for Electronic Compass Applications. J. Microelectromech. Syst. 2012, 21, 1002–1010. [Google Scholar] [CrossRef]

- Bahreyni, B. Design, Modeling, Simulation, and Testing of Resonant Micromachined Magnetic Field Sensors. In DeparIEEE Transactions on Magneticsent of Electrical and Computer Engineering; University of Manitoba: Winnipeg, MB, Canada, 2006. [Google Scholar]

- Kádár, Z.; Bossche, A.; Mollinger, J.R.; Sarro, P.M. Magnetic-field measurements using an integrated resonant magnetic-field sensor. Sens. Actuators Phys. 1998, 70, 225–232. [Google Scholar] [CrossRef]

- Emmerich, H.; Schofthaler, M. Magnetic field measurements with a novel surface micromachined magnetic-field sensor. IEEE Trans. Electron Devices 2000, 47, 927–977. [Google Scholar] [CrossRef]

- Seshia, A.A.; Palaniapan, M.; Roessig, T.A.; Howe, R.T.; Gooch, R.W.; Schimert, T.R.; Montague, S. A vacuum packaged surface micromachined resonant accelerometer. IEEE J. Microelectromech. Syst. 2002, 11, 784–793. [Google Scholar] [CrossRef]

- Ferrari, V.; Ghisla, A.; Marioli, D.; Taroni, A. Silicon resonant accelerometer with electronic compensation of input-output cross-talk. Sens. Actuators Phys. 2005, 123–124, 258–266. [Google Scholar] [CrossRef]

- Zou, X.; Seshia, A.A. A high-resolution resonant MEMS accelerometer. In Proceedings of the 2015 Transducers—2015 18th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Anchorage, AK, USA, 21–25 June 2015; pp. 1247–1250.

- Aikele, M.; Bauer, K.; Ficker, W.; Neubauer, F.; Prechtel, U.; Schalk, J.; Seidel, H. Resonant accelerometer with self-test. Sens. Actuators Phys. 2001, 92, 161–167. [Google Scholar] [CrossRef]

- Edalatfar, F.; Hajhashemi, S.; Yaghootkar, B.; Bahreyni, B. Dual mode resonant capacitive MEMS accelerometer. In Proceedings of the 2016 IEEE International Symposium on Inertial Sensors and Systems, Laguna Beach, CA, USA, 22–25 Feburary 2016; pp. 97–100.

- Moussa, H.; Bourquin, R. Theory of direct frequency output vibrating gyroscopes. IEEE Sens. J. 2006, 6, 310–315. [Google Scholar] [CrossRef]

- Zhanshe, G.; Fucheng, C.; Boyu, L.; Le, C.; Chao, L.; Ke, S. Research development of silicon MEMS gyroscopes: A review. Microsyst. Technol. 2015, 21, 2053–2066. [Google Scholar] [CrossRef]

- Liu, K.; Zhang, W.; Chen, W.; Li, K.; Dai, F.; Cui, F.; Wu, X.; Ma, G.; Xiao, Q. The development of micro-gyroscope technology. J. Micromech. Microeng. 2009, 19, 113001. [Google Scholar] [CrossRef]

- Lee, J.E.-Y.; Bahreyni, B.; Seshia, A.A. An axial strain modulated double-ended tuning fork electrometer. Sens. Actuators Phys. 2008, 148, 395–400. [Google Scholar] [CrossRef]

- Zhao, J.; Ding, H.; Xie, J. Electrostatic charge sensor based on a micromachined resonator with dual micro-levers. Appl. Phys. Lett. 2015, 106, 233505. [Google Scholar] [CrossRef]

- Lin, L.; Howe, R.T.; Pisano, A.P. Microelectromechanical filters for signal processing. J. Microelectromech. Syst. 1998, 7, 286–294. [Google Scholar] [CrossRef]

- Wang, K.; Nguyen, C.T.-C. High-order medium frequency micromechanical electronic filters. J. Microelectromech. Syst. 1999, 8, 534–556. [Google Scholar] [CrossRef]

- Nguyen, C.T.-C. Transceiver front-end architectures using vibrating micromechanical signal processors. In Proceedings of the 2001 Topical Meeting on Silicon Monolithic Integrated Circuits in RF Systems, Digest of Papers, Ann Arbor, MI, USA, 14 Septermber 2001; pp. 23–32.

- Nguyen, C.T.-C. Frequency-selective MEMS for miniaturized low-power communication devices. IEEE Trans. Microw. Theory Tech. 1999, 47, 1486–1503. [Google Scholar] [CrossRef]

- Li, S.-S.; Lin, Y.-W.; Ren, Z.; Nguyen, C.T.-C. Self-switching vibrating micromechanical filter bank. In Proceedings of the 2005 IEEE International Frequency Control Symposium and Exposition, Vancouver, BC, Canada, 29–31 August 2005; p. 7.

- Wong, A.-C.; Nguyen, C.T.-C. Micromechanical mixer-filters (‘mixlers’). J. Microelectromech. Syst. 2004, 13, 100–112. [Google Scholar] [CrossRef]

- Shalaby, M.M.; Abdelmoneum, M.A.; Saitou, K. Design of Spring Coupling for High-Q High-Frequency MEMS Filters for Wireless Applications. IEEE Trans. Ind. Electron. 2009, 56, 1022–1030. [Google Scholar] [CrossRef]

- Giner, J.; Uranga, A.; Muñóz-Gamarra, J.L.; Marigó, E.; Barniol, N. A fully integrated programmable dual-band RF filter based on electrically and mechanically coupled CMOS-MEMS resonators. J. Micromech. Microeng. 2012, 22, 55020. [Google Scholar] [CrossRef]

- Nilchi, J.N.; Liu, R.; Nguyen, C.T.-C. 7th order sharp-roll-off bridged micromechanical filter. In Proceedings of the 2015 Transducers—2015 18th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Anchorage, AK, USA, 21–25 June 2015; pp. 137–140.

- Pourkamali, S.; Ayazi, F. Electrically coupled MEMS bandpass filters: Part II. Without coupling element. Sens. Actuators Phys. 2005, 122, 317–325. [Google Scholar] [CrossRef]

- Jang, Y.-H.; Llamas-Garro, I.; Kim, Y.-K.; Kim, J.-M. RF MEMS suspended band-stop resonator and filter for frequency and bandwidth continuous fine tuning. J. Micromech. Microeng. 2012, 22, 15005. [Google Scholar] [CrossRef]

- Kim, B.; Olsson, R.H.; Wojciechowski, K.E. AlN Microresonator-Based Filters with Multiple Bandwidths at Low Intermediate Frequencies. J. Microelectromech. Syst. 2013, 22, 949–961. [Google Scholar] [CrossRef]

- Demirci, M.U.; Nguyen, C.T.C. A low impedance VHF micromechanical filter using coupled-array composite resonators. In Proceedings of the 13th International Conference on Solid-State Sensors, Actuators and Microsystems, Seoul, Korea, 5–9 June 2005; Volume 2, pp. 2131–2134.

- Lopez, J.L.; Verd, J.; Uranga, A.; Giner, J.; Murillo, G.; Torres, F.; Abadal, G.; Barniol, N. A CMOS-MEMS RF-Tunable Bandpass Filter Based on Two High- 22-MHz Polysilicon Clamped-Clamped Beam Resonators. IEEE Electron Device Lett. 2009, 30, 718–720. [Google Scholar] [CrossRef]

| Mechanical Domain | Electrical Domain |

|---|---|

| Force, | Voltage, |

| Velocity, | Current, |

| Displacement, | Charge, |

| Compliance, | Capacitance, |

| Mass, | Inductance, |

| Damping, | Resistance, |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdolvand, R.; Bahreyni, B.; Lee, J.E.-Y.; Nabki, F. Micromachined Resonators: A Review. Micromachines 2016, 7, 160. https://doi.org/10.3390/mi7090160

Abdolvand R, Bahreyni B, Lee JE-Y, Nabki F. Micromachined Resonators: A Review. Micromachines. 2016; 7(9):160. https://doi.org/10.3390/mi7090160

Chicago/Turabian StyleAbdolvand, Reza, Behraad Bahreyni, Joshua E. -Y. Lee, and Frederic Nabki. 2016. "Micromachined Resonators: A Review" Micromachines 7, no. 9: 160. https://doi.org/10.3390/mi7090160