Structure–Properties Relationship of Electrospun PVDF Fibers

Abstract

:1. Introduction

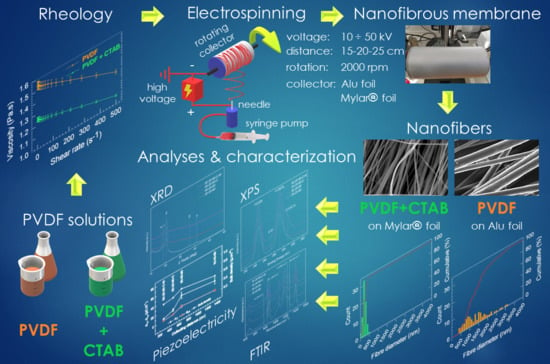

2. Materials and Methods

3. Results and Discussion

3.1. PVDF Electrospinning Optimization

3.2. Characterization of Electrospun PVDF Fibers under Optimized Processing Parameters

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Martins, P.; Lopes, A.C.; Lanceros-Mendez, S. Electroactive phases of poly(vinylidene fluoride): Determination, processing and applications. Prog. Polym. Sci. 2014, 39, 683–706. [Google Scholar] [CrossRef]

- Rajabi, A.H.; Jaffe, M.; Arinzeh, T.L. Piezoelectric materials for tissue regeneration: A review. Acta Biomater. 2015, 24, 12–23. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zheng, Q.; Shi, B.; Li, Z.; Wang, Z.L. Recent Progress on Piezoelectric and Triboelectric Energy Harvesters in Biomedical Systems. Adv. Sci. 2017, 4, 1700029. [Google Scholar] [CrossRef] [PubMed]

- Yan, J.; Liu, M.; Jeong, Y.G.; Kang, W.M.; Li, L.; Zhao, Y.X.; Deng, N.P.; Cheng, B.W.; Yang, G. Performance enhancements in poly(vinylidene fluoride)-based piezoelectric nanogenerators for efficient energy harvesting. Nano Energy 2019, 56, 662–692. [Google Scholar] [CrossRef]

- Mokhtari, F.; Latifi, M.; Shamshirsaz, M. Electrospinning/electrospray of polyvinylidene fluoride (PVDF): Piezoelectric nanofibers. J. Text. Inst. 2016, 107, 1037–1055. [Google Scholar] [CrossRef]

- Gebrekrstos, A.; Madras, G.; Bose, S. Journey of Electroactive beta-Polymorph of Poly(vinylidenefluoride) from Crystal Growth to Design to Applications. Cryst. Growth Des. 2019, 19, 5441–5456. [Google Scholar] [CrossRef]

- Saha, S.; Yauvana, V.; Chakraborty, S.; Sanyal, D. Synthesis and Characterization of Polyvinylidene-fluoride (PVDF) Nanofiber for Application as Piezoelectric Force Sensor. Mater. Today Proc. 2019, 18, 1450–1458. [Google Scholar] [CrossRef]

- Tarasova, E.; Tamberg, K.G.; Viirsalu, M.; Savest, N.; Gudkova, V.; Krasnou, I.; Märtson, T.; Krumme, A. Formation of uniform PVDF fibers under ultrasound exposure in presence of anionic surfactant. J. Electrost. 2015, 76, 39–47. [Google Scholar] [CrossRef]

- Hu, P.H.; Zheng, D.C.; Zhao, C.X.; Zhang, Y.Y.; Niu, J. Linear dependence between content of effective piezo-phase and mechanical-to-electrical conversion in electrospun poly(vinylidene fluoride) fibrous membrane. Mater. Lett. 2018, 218, 71–75. [Google Scholar] [CrossRef]

- Shao, H.; Fang, J.; Wang, H.X.; Lin, T. Effect of electrospinning parameters and polymer concentrations on mechanical-to-electrical energy conversion of randomly-oriented electrospun poly(vinylidene fluoride) nanofiber mats. RSC Adv. 2015, 5, 14345–14350. [Google Scholar] [CrossRef]

- Lei, T.P.; Yu, L.K.; Zheng, G.F.; Wang, L.Y.; Wu, D.Z.; Sun, D.H. Electrospinning-induced preferred dipole orientation in PVDF fibers. J. Mater. Sci. 2015, 50, 4342–4347. [Google Scholar] [CrossRef]

- Yang, L.; Ji, H.; Qiu, J.; Zhu, K.; Shao, B. Effect of temperature on the crystalline phase and dielectric and ferroelectric properties of poly(vinylidene fluoride) film. J. Intell. Mater. Syst. Struct. 2014, 25, 858–864. [Google Scholar] [CrossRef]

- Chinaglia, D.L.; Gregorio, R., Jr.; Stefanello, J.C.; Pisani Altafim, R.A.; Wirges, W.; Wang, F.; Gerhard, R. Influence of the solvent evaporation rate on the crystalline phases of solution-cast poly(vinylidene fluoride) films. J. Appl. Polym. Sci. 2010, 116, 785–791. [Google Scholar] [CrossRef]

- Davis, G.T.; McKinney, J.E.; Broadhurst, M.G.; Roth, S.C. Electric-field-induced phase changes in poly(vinylidene fluoride). J. Appl. Phys. 1978, 49, 4998–5002. [Google Scholar] [CrossRef]

- Zheng, J.; He, A.; Li, J.; Han, C.C. Polymorphism Control of Poly(vinylidene fluoride) through Electrospinning. Macromol. Rapid Commun. 2007, 28, 2159–2162. [Google Scholar] [CrossRef]

- Salimi, A.; Yousefi, A.A. Analysis Method: FTIR studies of β-phase crystal formation in stretched PVDF films. Polym. Test. 2003, 22, 699–704. [Google Scholar] [CrossRef]

- Huang, F.L.; Wei, Q.F.; Wang, J.X.; Cai, Y.B.; Huang, Y.B. Effect of temperature on structure, morphology and crystallinity of PVDF nanofibers via electrospinning. e-Polymers 2008. [Google Scholar] [CrossRef]

- Liu, J.; Lu, X.L.; Wu, C.R.; Zhao, C. Effect of preparation conditions on the morphology, polymorphism and mechanical properties of polyvinylidene fluoride membranes formed via thermally induced phase separation. J. Polym. Res. 2013, 20. [Google Scholar] [CrossRef]

- Cai, X.; Lei, T.; Sun, D.; Lin, L. A critical analysis of the α, β and γ phases in poly(vinylidene fluoride) using FTIR. RSC Adv. 2017, 7, 15382–15389. [Google Scholar] [CrossRef] [Green Version]

- Roy, R.E.; Bhuvaneswari, S.; Vijayalakshmi, K.P.; Dimple, R.; Soumyamol, P.B.; Rajeev, R.S.N. Energy-induced polymorphic changes in poly(vinylidene fluoride): How ultrasonication results in polymer with predominantly γ phase. J. Polym. Sci. Part B Polym. Phys. 2019, 57, 40–50. [Google Scholar] [CrossRef]

- Zheng, J.Y.; Zhuang, M.F.; Yu, Z.J.; Zheng, G.F.; Zhao, Y.; Wang, H.; Sun, D.H. The Effect of Surfactants on the Diameter and Morphology of Electrospun Ultrafine Nanofiber. J. Nanomater. 2014. [Google Scholar] [CrossRef]

- Fong, H.; Chun, I.; Reneker, D.H. Beaded nanofibers formed during electrospinning. Polymer 1999, 40, 4585–4592. [Google Scholar] [CrossRef]

- Safari, N.H.M.; Hassan, A.R.; Takwa, C.W.I.C.W.; Rozali, S. Deduction of Surfactants Effect on Performance, Morphology, Thermal and Molecular Properties of Polymeric Polyvinylidene Fluoride (PVDF) Based Ultrafiltration Membrane. Period. Polytech. Chem. Eng. 2019, 63, 27–35. [Google Scholar] [CrossRef]

- Wu, C.M.; Chou, M.H.; Zeng, W.Y. Piezoelectric Response of Aligned Electrospun Polyvinylidene Fluoride/Carbon Nanotube Nanofibrous Membranes. Nanomaterials (Basel) 2018, 8, 420. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.; Xu, S.; Kuang, X.; Wang, X. Ultra-long MWCNTs highly oriented in electrospun PVDF/MWCNT composite nanofibers with enhanced β phase. RSC Adv. 2016, 6, 106690–106696. [Google Scholar] [CrossRef]

- Gregorio, R.; Ueno, E.M. Effect of crystalline phase, orientation and temperature on the dielectric properties of poly (vinylidene fluoride) (PVDF). J. Mater. Sci. 1999, 34, 4489–4500. [Google Scholar] [CrossRef]

- Da Silva, A.B.; Wisniewski, C.; Esteves, J.V.A.; Gregorio, R. Effect of drawing on the dielectric properties and polarization of pressed solution cast β-PVDF films. J. Mater. Sci. 2010, 45, 4206–4215. [Google Scholar] [CrossRef]

- Xia, W.; Zhang, Z. PVDF-based dielectric polymers and their applications in electronic materials. In IET Nanodielectrics; Institution of Engineering and Technology: London, UK, 2018; Volume 1, pp. 17–31. [Google Scholar]

- Li, J.; Meng, Q.; Li, W.; Zhang, Z. Influence of crystalline properties on the dielectric and energy storage properties of poly(vinylidene fluoride). J. Appl. Polym. Sci. 2011, 122, 1659–1668. [Google Scholar] [CrossRef]

- Liao, Y.; Wang, R.; Tian, M.; Qiu, C.; Fane, A.G. Fabrication of polyvinylidene fluoride (PVDF) nanofiber membranes by electro-spinning for direct contact membrane distillation. J. Membr. Sci. 2013, 425–426, 30–39. [Google Scholar] [CrossRef]

- Lalia, B.S.; Guillen-Burrieza, E.; Arafat, H.A.; Hashaikeh, R. Fabrication and characterization of polyvinylidenefluoride-co-hexafluoropropylene (PVDF-HFP) electrospun membranes for direct contact membrane distillation. J. Membr. Sci. 2013, 428, 104–115. [Google Scholar] [CrossRef]

- Guo, H.; Pu, B.; Chen, H.; Yang, J.; Zhou, Y.; Yang, J.; Bismark, B.; Li, H.; Niu, X. Surfactant-assisted solvothermal synthesis of pure nickel submicron spheres with microwave-absorbing properties. Nanoscale Res. Lett. 2016, 11, 352. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Huang, F.; Yuan, Y.; Jiang, Z.; Tang, B.; Zhang, S. Microstructures and properties of glass fiber reinforced PTFE composite substrates with laminated construction. Mater. Res. Express 2019, 6, 075305. [Google Scholar] [CrossRef]

- Li, X.; Chen, S.T.; Yao, K.; Tay, F.E.H. Ferroelectric Poly(vinylidene fluoride) PVDF Films Derived from the Solutions with Retainable Water and Controlled Water Loss. J. Polym. Sci. Polym. Phys. 2009, 47, 2410–2418. [Google Scholar] [CrossRef]

- Benz, M.; Euler, W.B.; Gregory, O.J. The Role of Solution Phase Water on the Deposition of Thin Films of Poly(vinylidene fluoride). Macromolecules 2002, 35, 2682–2688. [Google Scholar] [CrossRef]

- Vahidi, K.; Seyed Jalili, Y. Modification of surface energy and electrical and thermal properties of spherical polypyrrole nanoparticles synthesized by CTAB for potential application as a conductive ink. J. Theor. Appl. Phys. 2013, 7, 42. [Google Scholar] [CrossRef] [Green Version]

- Wan, C.; Bowen, C.R. Multiscale-structuring of polyvinylidene fluoride for energy harvesting: The impact of molecular-, micro- and macro-structure. J. Mater. Chem. A 2017, 5, 3091–3128. [Google Scholar] [CrossRef] [Green Version]

- Saedi, S.; Madaeni, S.S.; Shamsabadi, A.A.; Mottaghi, F. The effect of surfactants on the structure and performance of PES membrane for separation of carbon dioxide from methane. Sep. Purif. Technol. 2012, 99, 104–119. [Google Scholar] [CrossRef]

- Nurul Syuhada Mohd, A.; Abdul Rahman, H. The Effect of CTAB and SDS Surfactant on the Morphology and Performance of Low Pressure Active Reverse Osmosis Membrane. Malays. J. Anal. Sci. 2016, 20, 510–516. [Google Scholar] [CrossRef]

| Sample | Voltage (kV) | Collecting Distance (cm) | Collection Time (min) | CTAB in Solution (wt%) | Collector Foil | Feeding Rate (µL min−1) | Comment to Process |

|---|---|---|---|---|---|---|---|

| 10-15-15 | 10 | 15 | 15 | 0 | aluminum | 18 | unspinnable |

| 10-20-15 | 20 | unspinnable | |||||

| 10-25-15 | 25 | unspinnable | |||||

| 25-15-15 | 25 | 15 | 15 | 0 | aluminum | 18 | unstable spinning |

| 25-20-15 | 20 | spinnable | |||||

| 25-25-15 | 25 | spinnable | |||||

| 35-15-15 | 35 | 15 | 15 | 0 | aluminum | 18 | spinnable |

| 35-20-15 | 20 | spinnable | |||||

| 35-25-15 | 25 | spinnable | |||||

| 45-15-15 | 45 | 15 | 15 | 0 | aluminum | 18 | spinnable |

| 45-20-15 | 20 | spinnable | |||||

| 45-25-15 | 25 | spinnable | |||||

| 50-15-15 | 50 | 15 | 15 | 0 | aluminum | 18 | spinnable |

| 50-20-15 | 20 | spinnable | |||||

| 50-25-15 | 25 | spinnable | |||||

| 25-20-90 | 25 | 20 | 90 | 0 | aluminum | 18 | spinnable |

| 50-20-90 | 50 | 20 | 90 | 0 | aluminum | 18 | spinnable |

| 50-20-90-C | 50 | 20 | 90 | 1 | aluminum | 20 | spinnable |

| 50-20-90-C-M | 50 | 20 | 90 | 1 | Mylar® | 20 | spinnable |

| Sample | Conductivity (μS cm−1) | Viscosity a (Pa s) | Surface Tension b (mN m−1) | N c | Crystallinity Xc (%) |

|---|---|---|---|---|---|

| DMSO-Ac | 2.2 | 0.0086 | 29.9 (0.05) | 3 | ------- |

| PVDF//DMSO-Ac | 1.4 | 1.54 ± 0.03 | 36.6 (0.23) | 3 | 60.6 |

| PVDF//DMSO-Ac + CTAB | 536.0 | 1.25 ± 0.02 | 35.5 (0.20) | 3 | 80.6 |

| Sample | Voltage (kV) | Collecting Distance (cm) | Comment to Process | Fiber Diameter a (nm) | N b | γ- + β-/β-Phase Content (wt%) |

|---|---|---|---|---|---|---|

| 10-15-15 | 10 | 15 | unspinnable | --- | --- | --- |

| 10-20-15 | 20 | unspinnable | --- | --- | --- | |

| 10-25-15 | 25 | unspinnable | --- | --- | --- | |

| 25-15-15 | 25 | 15 | unstable spinning | --- | --- | --- |

| 25-20-15 | 20 | 1343 ± 109 | 75 | 83.2/76.2 | ||

| 25-25-15 | 25 | 1292 ± 122 | 75 | 86.7/79.4 | ||

| 35-15-15 | 35 | 15 | 958 ± 64 | 75 | 90.1/83.5 | |

| 35-20-15 | 20 | 1026 ± 90 | 75 | 84.8/80.5 | ||

| 35-25-15 | 25 | 994 ± 127 | 75 | 84.2/78.9 | ||

| 45-15-15 | 45 | 15 | 1169 ± 58 | 75 | 87.2/76.9 | |

| 45-20-15 | 20 | 1392 ± 75 | 75 | 90.8/78.8 | ||

| 45-25-15 | 25 | 1012 ± 82 | 75 | 82.0/74.8 | ||

| 50-15-15 | 50 | 15 | 709 ± 42 | 75 | 91.8/89.5 | |

| 50-20-15 | 20 | 678 ± 39 | 75 | 90.3/85.7 | ||

| 50-25-15 | 25 | 666 ± 44 | 75 | 86.6/82.5 |

| Sample a | Fiber Diameter b (nm) | γ- + β-/β-/γ Phase Content (wt%) | Crystallinity Xc (%) | Bulk Density b (g·cm−3) | Dielectric Constant ε b (-) | Dielectric Loss tanδ (10−3) b (-) | dTr b (pC N−1) | dLo b (pC N−1) |

|---|---|---|---|---|---|---|---|---|

| 25-20-90 | 1346 ± 141 | 83.2/74.4/8.8 | 54.7 | 0.581 ± 0.010 | 2.2 ± 0.2 | 2.6 ± 0.2 | 23.7 ± 2.0 | 4.3 ± 0.6 |

| 50-20-90 | 649 ± 50 | 92.1/82.3/9.8 | 56.3 | 0.721 ± 0.012 | 2.0 ± 0.1 | 2.5 ± 0.2 | 33.0 ± 2.6 | 10.4 ± 1.1 |

| 50-20-90-C | 474 ± 28 | 88.4/84.8/3.6 | 61.1 | 0.624 ± 0.013 | 1.7 ± 0.2 | 14.0 ± 2.0 | 12.3 ± 1.1 | 3.2 ± 0.3 |

| 50-20-90-C-M | 276 ± 26 | 90.8/89.5/1.3 | 64.0 | 0.592 ± 0.015 | 1.1 ± 0.02 | 14.0 ± 2.4 | 5.1 ± 0.6 | 1.0 ± 0.2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Castkova, K.; Kastyl, J.; Sobola, D.; Petrus, J.; Stastna, E.; Riha, D.; Tofel, P. Structure–Properties Relationship of Electrospun PVDF Fibers. Nanomaterials 2020, 10, 1221. https://doi.org/10.3390/nano10061221

Castkova K, Kastyl J, Sobola D, Petrus J, Stastna E, Riha D, Tofel P. Structure–Properties Relationship of Electrospun PVDF Fibers. Nanomaterials. 2020; 10(6):1221. https://doi.org/10.3390/nano10061221

Chicago/Turabian StyleCastkova, Klara, Jaroslav Kastyl, Dinara Sobola, Josef Petrus, Eva Stastna, David Riha, and Pavel Tofel. 2020. "Structure–Properties Relationship of Electrospun PVDF Fibers" Nanomaterials 10, no. 6: 1221. https://doi.org/10.3390/nano10061221