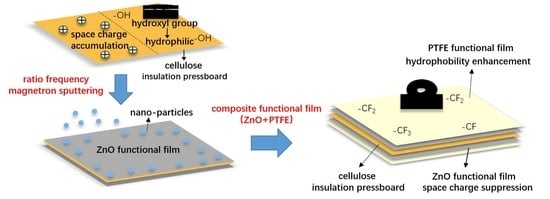

Improvement of the Space Charge Suppression and Hydrophobicity Property of Cellulose Insulation Pressboard by Surface Sputtering a ZnO/PTFE Functional Film

Abstract

:1. Introduction

2. Experiments

2.1. Material Studio Simulation

2.2. Sample Preparation

2.3. Characterization Method

3. Results and Discussion

3.1. Molecular Dynamics Simulation Results

3.2. Chemical Composition Analysis

3.3. Surface Morphology

3.4. Crystalline Structure

3.5. Space Charge Suppression Effect

3.6. Hydrophobicity Analysis

3.7. Tensile Strength and Electric Breakdown Values

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- CIGRE Joint Working Group A2/B4.28. HVDC Converter Transformers Guide Lines for Conducting Design Reviews for HVDC Converter Transformers; CIGRE: Paris, France, 2010. [Google Scholar]

- Dissado, L.A.; Fothergill, J.C. Electrical Degradation and Breakdown in Polymers.; Peter Peregrinus: London, UK, 1992; Volume 620. [Google Scholar]

- Wei, Y.H.; Mu, H.B.; Deng, J.B. Effect of space charge on breakdown characteristics of aged oil-paper insulation under DC voltage. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 3143–3150. [Google Scholar] [CrossRef]

- Hao, M.; Zhou, Y.; Chen, G.; Wilson, G.; Jarman, P. Space charge behavior in oil gap and impregnated pressboard combined system under HVDC stresses. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 848–858. [Google Scholar] [CrossRef]

- Hao, J.; Chen, G.; Liao, R.J. Influence of moisture and temperature on space charge dynamics in multilayer oil-paper insulation. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1456–1464. [Google Scholar] [CrossRef]

- Emsley, A.M.; Stevens, G.C. Review of chemical indicators of degradation of cellulosic electrical paper insulation in oil-filled transformers. IEE Proc. Sci. Meas. Technol. 1994, 141, 324–334. [Google Scholar] [CrossRef]

- Sikorski, W.; Walczak, K.; Przybylek, P. Moisture Migration in an Oil-Paper Insulation System in Relation to Online Partial Discharge Monitoring of Power Transformers. Energies 2016, 9, 1082. [Google Scholar] [CrossRef]

- Lewis, T.J. Nanometric dielectrics. IEEE Trans. Dielectr. Electr. Insul. 1994, 1, 812–825. [Google Scholar] [CrossRef]

- Liao, R.J.; Lv, C.; Wu, W.Q.; Liang, N.C.; Yang, L.J. Insulating properties of insulation paper modified by nano-Al2O3 for power transformer. J. Electr. Power Sci. Technol. 2014, 29, 3–7. [Google Scholar]

- Yan, S.; Liao, R.J.; Yang, L.J.; Zhao, X.T.; Yuan, Y. Influence of nano-Al2O3 on electrical properties of insulation paper under thermal aging. In Proceedings of the 2016 IEEE International Conference on High Voltage Engineering and Application (ICHVE), Chengdu, China, 19–22 September 2016; pp. 1–4. [Google Scholar]

- Wang, S.J.; Zha, J.W.; Li, W.K.; Dang, Z.M. Distinctive electrical properties in sandwich-structured Al2O3/low density polyethylene nanocomposites. Appl. Phys. Lett. 2016, 108, 031605. [Google Scholar] [CrossRef]

- Fleming, R.J.; Ammala, A.; Casey, P.S. Conductivity and space charge in LDPE containing nano- and micro-sized ZnO particles. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 118–126. [Google Scholar] [CrossRef]

- Katayama, J.; Ohki, Y.; Fuse, N.; Kozako, M.; Tanaka, T. Effects of nano-filler materials on the dielectric properties of epoxy nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 157–165. [Google Scholar] [CrossRef]

- Andritsch, T.; Kochetov, R.; Morshuis, P.H.F.; Smit, J.J. Dielectric properties and space charge behaviour of MgO epoxy nanocomposites. In Proceedings of the 2010 10th IEEE International Conference on Solid Dielectrics, Potsdam, Germany, 4–9 July 2010; pp. 1–4. [Google Scholar]

- Kylián, O.; Choukourov, A.; Biederman, H. Nanostructured plasma polymers. Thin Solid Films 2013, 548, 1–17. [Google Scholar] [CrossRef]

- Milliere, L.; Makasheva, K.; Laurent, C. Silver nanoparticles as a key feature of a plasma polymer composite layer in mitigation of charge injection into polyethylene under dc stress. J. Phys. D Appl. Phys. 2016, 49, 15304. [Google Scholar] [CrossRef]

- Takahashi, K.; Yoshikawa, A.; Sandhu, A. Wide Bandgap Semiconductors, Fundamental Properties and Modern Photonic and Electronic Devices; Springer: New York, NY, USA, 2007. [Google Scholar]

- Ellmer, K.; Klein, A.; Rech, B. Transparent Conductive Zinc Oxide; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Yong, J.; Fang, Y.; Chen, F. Femtosecond laser ablated durable superhydrophobic PTFE films with penetrating microholes for oil/water separation: Separating oil from water and corrosive solutions. Appl. Surf. Sci. 2016, 389, 1148–1155. [Google Scholar] [CrossRef]

- Toosi, S.F.; Moradi, S.; Kamal, S.; Hatzikiriakos, S.G. Superhydrophobic laser ablated PTFE substrates. Appl. Surf. Sci. 2015, 349, 715–723. [Google Scholar] [CrossRef]

- Theodorou, D.N.; Suter, U.W. Detailed molecular structure of a vinyl polymer glass. Macromolecules 1985, 18, 1467–1478. [Google Scholar] [CrossRef]

- Mazeau, K.; Heux, L. Molecular Dynamics Simulations of Bulk Native Crystalline and Amorphous Structures of Cellulose. J. Phys. Chem. B 2008, 107, 2394–2403. [Google Scholar] [CrossRef]

- Tang, C.; Zhang, S.; Wang, X.; Hao, J. Enhanced mechanical properties and thermal stability of cellulose insulation paper achieved by doping with melamine-grafted nano-SiO2. Cellulose 2018, 25, 3619–3633. [Google Scholar] [CrossRef]

- Tang, C.; Zhang, S.; Xie, J.; Lv, C. Molecular simulation and experimental analysis of Al2O3-nanoparticle-modified insulation paper cellulose. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1018–1026. [Google Scholar] [CrossRef]

- Berendsen, H.J.C.; Postma, J.P.M.; Van Gunsteren, W.F.; DiNola, A.; Haak, J.R. Molecular dynamics with coupling to an external bath. J. Chem. Phys. 1984, 81, 3684. [Google Scholar] [CrossRef]

- Pan, C.; Zhao, Z.; Wang, C. Effects of sputtering time on the properties of ZnO thin films prepared by magnetron sputtering. In Proceedings of the 2015 IEEE International Vacuum Electronics Conference (IVEC), Beijing, China, 27–29 April 2015. [Google Scholar]

- Xu, Z.Q. Space Charge Measurement and Analysis in Low Density Polyethylene Film. Ph.D. Thesis, University of Southampton, Southampton, UK, 2009. [Google Scholar]

- Yang, L.J.; Liao, R.J.; Sun, C.X.; Zhu, M.Z. Influence of vegetable oil on the thermal aging of transformer paper and its mechanism. IEEE Trans. Dielectr. Electr. Insul. 2012, 18, 2059. [Google Scholar] [CrossRef]

- Liu, J.F.; Zhang, Y.Y.; Xu, J.J.; Rui, J.; Zhang, G.J.; Liu, L.W. Quantitative relationship between aging condition of transformer oil-paper insulation and large time constant of extend debye model. Electr. Power Autom. Equip. 2017, 37, 197–202. [Google Scholar]

- Hao, M.; Zhou, Y.; Chen, G. Space charge behavior in thick oil-impregnated pressboard under HVDC stresses. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 72–80. [Google Scholar] [CrossRef]

- Belgacem, M.N.; Salon-Brochier, M.C.; Krouit, M. Recent advances in surface chemical modification of cellulose fibres. J. Adhesion Sci. Technol. 2011, 25, 661–684. [Google Scholar] [CrossRef]

- Hao, J.; Liu, C.; Li, Y.; Liao, R.; Liao, Q.; Tang, C. Preparation nano-structure polytetrafluoroethylene (PTFE) functional film on the cellulose insulation polymer and its effect on the breakdown voltage and hydrophobicity properties. Materials 2018, 11, 851. [Google Scholar] [CrossRef] [PubMed]

| Sample | Abbreviation |

|---|---|

| Untreated pressboard | UP |

| Pressboard sputtered Zn for 10 min (reactive O2) | Z10 |

| Pressboard sputtered PTFE for 20 min | P20 |

| Pressboard sputtered Zn for 10 min (reactive O2) and PTFE for 20 min | Z10+P20 |

| Sample | Tensile Strength (Mpa) | Standard Value (Mpa) | AC Breakdown (kV/mm) | DC Breakdown (kV/mm) | Standard Value (kV/mm) |

|---|---|---|---|---|---|

| UP | 49.91 | >40 | 55.28 | 136.37 | >40 |

| Z10+P20 | 50.48 | >40 | 56.26 | 144.27 | >40 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Hao, J.; Zhang, J.; Hou, W.; Liu, C.; Liao, R. Improvement of the Space Charge Suppression and Hydrophobicity Property of Cellulose Insulation Pressboard by Surface Sputtering a ZnO/PTFE Functional Film. Polymers 2019, 11, 1610. https://doi.org/10.3390/polym11101610

Li Y, Hao J, Zhang J, Hou W, Liu C, Liao R. Improvement of the Space Charge Suppression and Hydrophobicity Property of Cellulose Insulation Pressboard by Surface Sputtering a ZnO/PTFE Functional Film. Polymers. 2019; 11(10):1610. https://doi.org/10.3390/polym11101610

Chicago/Turabian StyleLi, Yanqing, Jian Hao, Jinfeng Zhang, Wei Hou, Cong Liu, and Ruijin Liao. 2019. "Improvement of the Space Charge Suppression and Hydrophobicity Property of Cellulose Insulation Pressboard by Surface Sputtering a ZnO/PTFE Functional Film" Polymers 11, no. 10: 1610. https://doi.org/10.3390/polym11101610