Highly Deformable Porous Electromagnetic Wave Absorber Based on Ethylene–Propylene–Diene Monomer/Multiwall Carbon Nanotube Nanocomposites

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Compounding and Sample Preparation

2.3. Characterization

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Luo, J.; Wang, L.; Huang, X.; Li, B.; Guo, Z.; Song, X.; Lin, L.; Tang, L.-C.; Xue, H.; Gao, J. Mechanically Durable, Highly Conductive, and Anticorrosive Composite Fabrics with Excellent Self-Cleaning Performance for High-Efficiency Electromagnetic Interference Shielding. ACS Appl. Mater. Interfaces 2019, 11, 10883–10894. [Google Scholar] [CrossRef] [PubMed]

- Geetha, S.; Kumar, K.K.S.; Rao, C.R.K.; Vijayan, M.; Trivedi, D.C. EMI shielding: Methods and materials—A review. J. Appl. Polym. Sci. 2009, 112, 2073–2086. [Google Scholar] [CrossRef]

- Tong, X.C. Advanced Materials and Design for Electromagnetic Interference Shielding; Informa UK Limited: Boca Raton, FL, USA, 2016. [Google Scholar]

- Abbasi, H.; Antunes, M.; Velasco, J.I. Recent advances in carbon-based polymer nanocomposites for electromagnetic interference shielding. Prog. Mater. Sci. 2019, 103, 319–373. [Google Scholar] [CrossRef]

- Yang, Y.; Gupta, M.C.; Dudley, K.L.; Lawrence, R.W. Conductive Carbon Nanofiber-Polymer Foam Structures. Adv. Mater. 2005, 17, 1999–2003. [Google Scholar] [CrossRef]

- Thomassin, J.-M.; Pagnoulle, C.; Bednarz, L.; Huynen, I.; Jérôme, C.; Detrembleur, C. Foams of polycaprolactone/MWNT nanocomposites for efficient EMI reduction. J. Mater. Chem. 2008, 18, 792–796. [Google Scholar] [CrossRef]

- Zhang, H.-B.; Yan, Q.; Zheng, W.-G.; He, Z.; Yu, Z.-Z. Tough Graphene−Polymer Microcellular Foams for Electromagnetic Interference Shielding. ACS Appl. Mater. Interfaces 2011, 3, 918–924. [Google Scholar] [CrossRef]

- Eswaraiah, V.; Sankaranarayanan, V.; Ramaprabhu, S. Functionalized Graphene-PVDF Foam Composites for EMI Shielding. Macromol. Mater. Eng. 2011, 296, 894–898. [Google Scholar] [CrossRef]

- Ameli, A.; Jung, P.; Park, C. Electrical properties and electromagnetic interference shielding effectiveness of polypropylene/carbon fiber composite foams. Carbon 2013, 60, 379–391. [Google Scholar] [CrossRef]

- Ameli, A.; Nofar, M.; Park, C.; Pötschke, P.; Rizvi, G. Polypropylene/carbon nanotube nano/microcellular structures with high dielectric permittivity, low dielectric loss, and low percolation threshold. Carbon 2014, 71, 206–217. [Google Scholar] [CrossRef]

- Bernal, M.M.; Martin-Gallego, M.; Molenberg, I.; Huynen, I.; Lopez-Manchado, M.A.; Verdejo, R. Influence of carbon nanoparticles on the polymerization and EMI shielding properties of PU nanocomposite foams. RSC Adv. 2014, 4, 7911. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Zhang, H.-B.; Huang, Y.; Jiang, Y.; Zheng, W.-G.; Yu, Z.-Z. Magnetic and electrically conductive epoxy/graphene/carbonyl iron nanocomposites for efficient electromagnetic interference shielding. Compos. Sci. Technol. 2015, 118, 178–185. [Google Scholar] [CrossRef]

- Liu, C.; Duan, Y.; Cai, J.; Li, X.; Zhang, D.; Gao, J.; Che, Y. Compressible Fe3O4/MWCNTs-coated polymer foams for high-performance and tunable electromagnetic microwave absorption. Mater. Res. Express 2019, 6, 106114. [Google Scholar] [CrossRef]

- Li, J.; Zhang, G.; Ma, Z.; Fan, X.; Fan, X.; Qin, J.; Shi, X. Morphologies and electromagnetic interference shielding performances of microcellular epoxy/multi-wall carbon nanotube nanocomposite foams. Compos. Sci. Technol. 2016, 129, 70–78. [Google Scholar] [CrossRef]

- Li, Y.; Shen, B.; Yi, D.; Zhang, L.; Zhai, W.; Wei, X.; Zheng, W. The influence of gradient and sandwich configurations on the electromagnetic interference shielding performance of multilayered thermoplastic polyurethane/graphene composite foams. Compos. Sci. Technol. 2017, 138, 209–216. [Google Scholar] [CrossRef]

- Bizhani, H.; Nayyeri, V.; Katbab, A.; Jalali-Arani, A.; Nazockdast, H. Double percolated MWCNTs loaded PC/SAN nanocomposites as an absorbing electromagnetic shield. Eur. Polym. J. 2018, 100, 209–218. [Google Scholar] [CrossRef]

- Jiang, Q.; Liao, X.; Li, J.; Chen, J.; Wang, G.; Yi, J.; Yang, Q.; Li, G. Flexible thermoplastic polyurethane/reduced graphene oxide composite foams for electromagnetic interference shielding with high absorption characteristic. Compos. Part A Appl. Sci. Manuf. 2019, 123, 310–319. [Google Scholar] [CrossRef]

- Bagotia, N.; Choudhary, V.; Sharma, D.K. Synergistic effect of graphene/multiwalled carbon nanotube hybrid fillers on mechanical, electrical and EMI shielding properties of polycarbonate/ethylene methyl acrylate nanocomposites. Compos. Part B Eng. 2019, 159, 378–388. [Google Scholar] [CrossRef]

- Liu, H.; Liang, C.; Chen, J.; Huang, Y.; Cheng, F.; Wen, F.; Xu, B.; Wang, B. Novel 3D network porous graphene nanoplatelets/Fe3O4/epoxy nanocomposites with enhanced electromagnetic interference shielding efficiency. Compos. Sci. Technol. 2019, 169, 103–109. [Google Scholar] [CrossRef]

- Shen, B.; Li, Y.; Zhai, W.; Zheng, W. Compressible Graphene-Coated Polymer Foams with Ultralow Density for Adjustable Electromagnetic Interference (EMI) Shielding. ACS Appl. Mater. Interfaces 2016, 8, 8050–8057. [Google Scholar] [CrossRef]

- Zhan, Y.; Oliviero, M.; Wang, J.; Sorrentino, A.; Buonocore, G.G.; Sorrentino, L.; Lavorgna, M.; Xia, H.; Iannace, S. Enhancing the EMI shielding of natural rubber-based supercritical CO2 foams by exploiting their porous morphology and CNT segregated networks. Nanoscale 2019, 11, 1011–1020. [Google Scholar] [CrossRef]

- Yang, J.; Liao, X.; Li, J.; He, G.; Zhang, Y.; Tang, W.; Wang, G.; Li, G. Light-weight and flexible silicone rubber/MWCNTs/Fe3O4 nanocomposite foams for efficient electromagnetic interference shielding and microwave absorption. Compos. Sci. Technol. 2019, 181, 107670. [Google Scholar] [CrossRef]

- Bizhani, H.; Katbab, A.A.; Verdejo, R. Elastomeric nanocomposite foams with improved properties for extreme conditions. In High-Performance Elastomeric Materials Reinforced by Nano-Carbons; Elsevier BV: Amsterdam, The Netherlands, 2020; pp. 133–147. [Google Scholar]

- Kueseng, P.; Sae-Oui, P.; Rattanasom, N. Mechanical and electrical properties of natural rubber and nitrile rubber blends filled with multi-wall carbon nanotube: Effect of preparation methods. Polym. Test. 2013, 32, 731–738. [Google Scholar] [CrossRef]

- Nakaramontri, Y.; Kummerlöwe, C.; Nakason, C.; Vennemann, N. The effect of surface functionalization of carbon nanotubes on properties of natural rubber/carbon nanotube composites. Polym. Compos. 2014, 36, 2113–2122. [Google Scholar] [CrossRef]

- Stehr, J. Chemical Blowing Agents in the Rubber Industry. Past–Present–and Future? Int. Polym. Sci. Technol. 2016, 43, 1–10. [Google Scholar] [CrossRef]

- Verdejo, R.; Barroso-Bujans, F.; Rodríguez-Perez, M.A.; De Saja, J.A.; Arroyo, M.; Lopez-Manchado, M.A. Carbon nanotubes provide self-extinguishing grade to silicone-based foams. J. Mater. Chem. 2008, 18, 3933. [Google Scholar] [CrossRef]

- Verdejo, R.; Stämpfli, R.; Alvarez-Lainez, M.; Mourad, S.; Rodríguez-Perez, M.A.; Brühwiler, P.; Shaffer, M.S.P. Enhanced acoustic damping in flexible polyurethane foams filled with carbon nanotubes. Compos. Sci. Technol. 2009, 69, 1564–1569. [Google Scholar] [CrossRef]

- Yu, D.-R.; Kim, G.-H. Effects of multi-walled carbon nanotube (MWCNT) content on physical properties and cell structure in ethylene vinyl acetate copolymer (EVA)/MWCNT nanocomposite foams. Polym. Plast. Technol. Eng. 2013, 52, 699–703. [Google Scholar] [CrossRef]

- Pasbakhsh, P.; Ismail, H.; Fauzi, M.A.; Abu Bakar, A. Influence of maleic anhydride grafted ethylene propylene diene monomer (MAH-g-EPDM) on the properties of EPDM nanocomposites reinforced by halloysite nanotubes. Polym. Test. 2009, 28, 548–559. [Google Scholar] [CrossRef]

- Dindarloo, A.S.; Karrabi, M.; Hamid, M.; Ghoreishy, R. Various nano-particles influences on structure, viscoelastic, Vulcanization and mechanical behaviour of EPDM nano-composite rubber foam. Plast. Rubber Compos. 2019, 48, 218–225. [Google Scholar] [CrossRef]

- Xu, Y.; Li, Y.; Hua, W.; Zhang, A.; Bao, J. Light-Weight Silver Plating Foam and Carbon Nanotube Hybridized Epoxy Composite Foams with Exceptional Conductivity and Electromagnetic Shielding Property. ACS Appl. Mater. Interfaces 2016, 8, 24131–24142. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, G.; Gao, Q.; Tang, M.; Ma, Z.; Qin, J.; Wang, M.; Kim, J.-K. Multifunctional microcellular PVDF/Ni-chains composite foams with enhanced electromagnetic interference shielding and superior thermal insulation performance. Chem. Eng. J. 2020, 379, 122304. [Google Scholar] [CrossRef]

- Sánchez-Hidalgo, R.; Blanco, C.; Menendez, R.; Verdejo, R.; Lopez-Manchado, M.A. Multifunctional Silicone Rubber Nanocomposites by Controlling the Structure and Morphology of Graphene Material. Polym. 2019, 11, 449. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shenogin, S. Role of thermal boundary resistance on the heat flow in carbon-nanotube composites. J. Appl. Phys. 2004, 95, 8136. [Google Scholar] [CrossRef]

- Klempner, D.; Sendijareviʹc, V.; Aseeva, R.M. Handbook of Polymeric Foams and Foam Technology; Hanser Publishers: Munich, Germany, 2004. [Google Scholar]

- Solórzano, E.; Lázaro, J.; De Saja, J.A.; Rodríguez-Perez, M.A. Influence of Solid Phase Conductivity and Cellular Structure on the Heat Transfer Mechanisms of Cellular Materials: Diverse Case Studies. Adv. Eng. Mater. 2009, 11, 818–824. [Google Scholar] [CrossRef]

- Jeddi, J.; Katbab, A.; Mehranvari, M. Investigation of microstructure, electrical behavior, and EMI shielding effectiveness of silicone rubber/carbon black/nanographite hybrid composites. Polym. Compos. 2019, 40, 4056–4066. [Google Scholar] [CrossRef]

- Yao, X.; Kou, X.; Qiu, J. Multi-walled carbon nanotubes/polyaniline composites with negative permittivity and negative permeability. Carbon 2016, 107, 261–267. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, J.; Qi, S.; Tian, G.; Wu, D. Permittivity transition from highly positive to negative: Polyimide/carbon nanotube composite’s dielectric behavior around percolation threshold. Appl. Phys. Lett. 2015, 107, 012905. [Google Scholar] [CrossRef]

- Kohlman, R.S.; Joo, J.; Wang, Y.Z.; Pouget, J.P.; Kaneko, H.; Ishiguro, T.; Epstein, A.J. Drude Metallic Response of Polypyrrole. Phys. Rev. Lett. 1995, 74, 773–776. [Google Scholar] [CrossRef]

- Rao, B.V.B.; Kale, N.; Kothavale, B.S.; Kale, S. Fabrication and evaluation of thin layer PVDF composites using MWCNT reinforcement: Mechanical, electrical and enhanced electromagnetic interference shielding properties. AIP Adv. 2016, 6, 65107. [Google Scholar]

- Jana, S.; Garain, S.; Sen, S.; Mandal, D. The influence of hydrogen bonding on the dielectric constant and the piezoelectric energy harvesting performance of hydrated metal salt mediated PVDF films. Phys. Chem. Chem. Phys. 2015, 17, 17429–17436. [Google Scholar] [CrossRef]

- Duand, H.-J.; Zhu, H.; Yang, J.; Gao, J.; Yang, Y.; Xu, L.; Zhao, G.; Liu, Y. Effect of carbon nanofiller dimension on synergistic EMI shielding network of epoxy/metal conductive foams. Compos. Part A Appl. Sci. Manuf. 2019, 118, 41–48. [Google Scholar] [CrossRef]

- Schelkunoff, S. Electromagnetic Waves; Nostrand Company, Inc.: New York, NY, USA, 1943. [Google Scholar]

- Carpi, F.; Gallone, G.; Galantini, F.; De Rossi, D. Enhancing the dielectric permittivity of elastomers. In Dielectric Elastomers Electromechanical Transducers; Elsevier: Amsterdam, The Netherlands, 2008; pp. 51–68. [Google Scholar]

- Zhang, H.; Zhang, G.; Tang, M.; Zhou, L.; Li, J.; Fan, X.; Shi, X.; Qin, J. Synergistic effect of carbon nanotube and graphene nanoplates on the mechanical, electrical and electromagnetic interference shielding properties of polymer composites and polymer composite foams. Chem. Eng. J. 2018, 353, 381–393. [Google Scholar] [CrossRef]

- Yousefi, N.; Sun, X.; Lin, X.; Shen, X.; Jia, J.; Zhang, B.; Tang, B.; Chan, M.; Kim, J.-K. Highly Aligned Graphene/Polymer Nanocomposites with Excellent Dielectric Properties for High-Performance Electromagnetic Interference Shielding. Adv. Mater. 2014, 26, 5480–5487. [Google Scholar] [CrossRef]

| S0 | S2 | S4 | S6 | S8 | S10 | F0 | F2 | F4 | F6 | F8 | F10 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| EPDM | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| EPDM-g-MA | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

| MWCNTs | 0 | 2 | 4 | 6 | 8 | 10 | 0 | 2 | 4 | 6 | 8 | 10 |

| ZnO | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

| STA | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| DCP | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| S | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| OBSH | 0 | 0 | 0 | 0 | 0 | 0 | 5 | 5 | 5 | 5 | 5 | 5 |

| Sample | Tensile Stress (MPa) | Strain at Break (%) | Compressive Stress (MPa) | |||||

|---|---|---|---|---|---|---|---|---|

| 50% | 100% | 300% | 500% | 10% | 30% | 50% | ||

| S0 | 0.62 ± 0.04 | 0.87 ± 0.10 | 1.5 ± 0.1 | 2.1 ± 0.2 | 641 ± 53 | 0.35 ± 0.01 | 1.4 ± 0.02 | 3.6 ± 0.1 |

| S2 | 0.74 ± 0.03 | 1.05 ± 0.03 | 1.9 ± 0.1 | 2.8 ± 0.3 | 630 ± 31 | 0.39 ± 0.02 | 1.5 ± 0.03 | 4.0 ± 0.2 |

| S4 | 0.83 ± 0.05 | 1.19 ± 0.07 | 2.5 ± 0.1 | 3.6 ± 0.1 | 600 ± 39 | 0.52 ± 0.04 | 1.7 ± 0.06 | 4.2 ± 0.1 |

| S6 | 1.05 ± 0.03 | 1.59 ± 0.05 | 3.6 ± 0.1 | 5.2 ± 0.2 | 560 ± 42 | 0.63 ± 0.01 | 2.0 ± 0.07 | 5.3 ± 0.1 |

| S8 | 1.27 ± 0.06 | 1.98 ± 0.07 | 4.6 ± 0.1 | 6.6 ± 0.2 | 520 ± 39 | 0.64 ± 0.04 | 2.2 ± 0.1 | 5.5 ± 0.3 |

| S10 | 1.56 ± 0.07 | 2.51 ± 0.09 | 5.9 ± 0.1 | - | 483 ± 28 | 0.72 ± 0.08 | 2.4 ± 0.1 | 5.8 ± 0.2 |

| F0 | 0.15 ± 0.02 | 0.23 ± 0.03 | 0.5 ± 0.1 | - | 344 ± 40 | 0.04 ± 0.01 | 0.1 ± 0.01 | 0.22 ± 0.02 |

| F2 | 0.29 ± 0.03 | 0.47 ± 0.05 | 1.0 ± 0.2 | - | 351 ± 21 | 0.06 ± 0.02 | 0.15 ± 0.02 | 0.33 ± 0.06 |

| F4 | 0.50 ± 0.05 | 0.77 ± 0.07 | 1.5 ± 0.1 | - | 361 ± 75 | 0.11 ± 0.04 | 0.3 ± 0.1 | 0.70 ± 0.19 |

| F6 | 0.70 ± 0.07 | 1.09 ± 0.07 | 2.3 ± 0.2 | - | 377 ± 54 | 0.18 ± 0.03 | 0.5 ± 0.1 | 1.25 ± 0.03 |

| F8 | 0.91 ± 0.07 | 1.40 ± 0.09 | 3.2 ± 0.1 | - | 392 ± 65 | 0.25 ± 0.06 | 0.7 ± 0.1 | 1.94 ± 0.33 |

| F10 | 0.97 ± 0.10 | 1.54 ± 0.14 | 3.5 ± 0.2 | - | 405 ± 37 | 0.33 ± 0.01 | 1.1 ± 0.1 | 2.94 ± 0.4 |

| Material | Foam Fabrication Procedure | Filler Content (wt.%) | EMI Shielding | Mechanical Properties | Other Characteristics | Ref. | |

|---|---|---|---|---|---|---|---|

| Specific EMI SE (dB/gr cm-3) | Thickness (mm) | ||||||

| NR/MWCNTs | ScCO2 | 6.4 | 40 | 1.3 | Compressive stress at 30%: 0.14 MPa | Segregated CNT network | [21] |

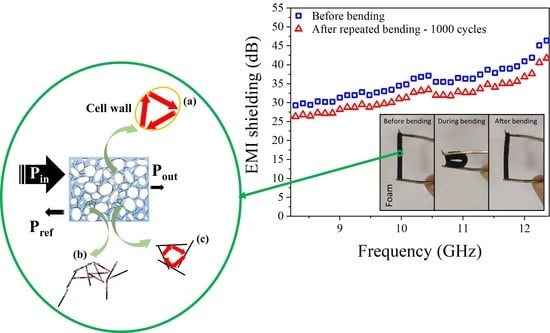

| PDMS/MWCNTs | ScCO2 | 10 | 72 | 2 | N/A | Flexible-Retained EMI shielding properties after bending | [22] |

| EPDM/MWCNTs | OBSH foaming agent | 10 | 52 | 25 | Compressive stress at 30%: 1.06 MPa, tensile stress at 300%: 3.46 MPa, strain at break: 405% | Chemical, moisture, and ozone resistive-Retained EMI shielding properties after bending | This work |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bizhani, H.; Katbab, A.A.; Lopez-Hernandez, E.; Miranda, J.M.; Verdejo, R. Highly Deformable Porous Electromagnetic Wave Absorber Based on Ethylene–Propylene–Diene Monomer/Multiwall Carbon Nanotube Nanocomposites. Polymers 2020, 12, 858. https://doi.org/10.3390/polym12040858

Bizhani H, Katbab AA, Lopez-Hernandez E, Miranda JM, Verdejo R. Highly Deformable Porous Electromagnetic Wave Absorber Based on Ethylene–Propylene–Diene Monomer/Multiwall Carbon Nanotube Nanocomposites. Polymers. 2020; 12(4):858. https://doi.org/10.3390/polym12040858

Chicago/Turabian StyleBizhani, Hasti, Ali Asghar Katbab, Emil Lopez-Hernandez, Jose Miguel Miranda, and Raquel Verdejo. 2020. "Highly Deformable Porous Electromagnetic Wave Absorber Based on Ethylene–Propylene–Diene Monomer/Multiwall Carbon Nanotube Nanocomposites" Polymers 12, no. 4: 858. https://doi.org/10.3390/polym12040858