A Process for the Synthesis and Use of Highly Aromatic Organosilanes as Additives for Poly(Vinyl Chloride) Films

Abstract

:1. Introduction

2. Materials and Methods

2.1. General

2.2. Synthesis of Organosilanes 1–3

2.3. Preparation of PVC Films

2.4. Irradiation of PVC Films

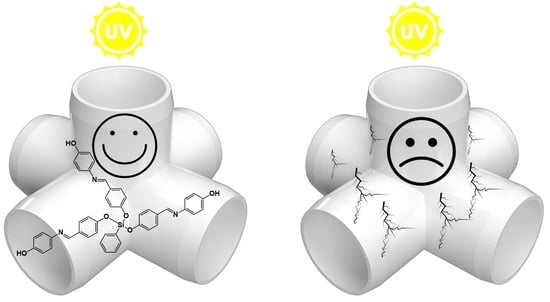

3. Results and Discussion

3.1. Synthesis of Organosilanes 1–3

3.2. FTIR Spectroscopy Study of Photodegradation by UV Irradiation

3.3. Effects of UV Irradiation on Weight Loss and Average Molecular Weight

3.4. Effects of UV Irradiation on Surface Morphology and Chlorine Content by SEM/EDX

3.5. Photostabilization Proposed Mechanisms

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ambrogi, V.; Carfagna, C.; Cerruti, P.; Marturano, V. Additives in Polymers. In Modification of Polymer Properties, 1st ed.; Jasso-Gastinel, C.F., Kenny, J.M., Eds.; William Andrew, Elsevier: Oxford, UK, 2007; pp. 87–108. [Google Scholar] [CrossRef]

- Marturano, V.; Cerruti, P.; Ambrogi, V. Polymer additives. Phys. Sci. Rev. 2017, 6, 20160130. [Google Scholar] [CrossRef]

- Plastics—The Facts 2020. An Analysis of European Plastics Production, Demand and Waste Data. Available online: https://www.plasticseurope.org/en/resources/publications/4312-plastics-facts-2020 (accessed on 29 December 2020).

- Yu, J.; Sun, L.; Ma, C.; Qiao, Y.; Yao, H. Thermal degradation of PVC: A review. Waste Manag. 2016, 48, 300–314. [Google Scholar] [CrossRef]

- Titow, W.V. PVC Technology, 4th ed.; Elsevier Applied Science Publishers: London, UK, 1984. [Google Scholar]

- Nicholson, J.W. The Chemistry of Polymers, 3rd ed.; RSC Publisher: Cambridge, UK, 2012. [Google Scholar]

- Starnes, W.H., Jr. Structural and mechanistic aspects of the thermal degradation of poly(vinyl chloride). Prog. Polym. Sci. 2002, 27, 2133–2170. [Google Scholar] [CrossRef]

- Hahladakis, J.N.; Velis, C.A.; Weber, R.; Iacovidou, E.; Purnell, P. An overview of chemical additives present in plastics: Migration, release, fate and environmental impact during their use, disposal and recycling. J. Hazard. Mater. 2018, 344, 179–199. [Google Scholar] [CrossRef] [PubMed]

- Makris, K.F.; Langeveld, J.; Clemens, F.H.L.R. A review on the durability of PVC sewer pipes: Research vs. practice. Struct. Infrastruct. Eng. 2020, 16, 880–897. [Google Scholar] [CrossRef]

- Chiellini, F.; Ferri, M.; Morelli, A.; Dipaola, L.; Latini, G. Perspectives on alternatives to phthalate plasticized poly(vinyl chloride) in medical devices applications. Prog. Polym. Sci. 2013, 38, 1067–1088. [Google Scholar] [CrossRef] [Green Version]

- Chanda, M.; Roy, S.K. Plastic Technology Handbook, 4th ed.; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Ramos-Devalle, L.; Gilbert, M. PVC/plasticizer compatibility: Evaluation and its relation to processing. J. Vinyl Technol. 1990, 12, 222–225. [Google Scholar] [CrossRef]

- Tickner, J.A.; Schettler, T.; Guidotti, T.; McCally, M.; Rossi, M. Health risks posed by use of di-2-ethylhexyl phthalate (DEHP) in PVC medical devices: A critical review. Am. J. Ind. Med. 2001, 39, 100–111. [Google Scholar] [CrossRef]

- Morgan, A.B.; Gilman, J.W. An overview of flame retardancy of polymeric materials: Application, technology, and future directions. Fire Mater. 2013, 37, 259–279. [Google Scholar] [CrossRef] [Green Version]

- Muir, D.C.G.; De Wit, C.A. Trends of legacy and new persistent organic pollutants in the circumpolar arctic: Overview, conclusions, and recommendations. Sci. Total. Environ. 2010, 408, 3044–3051. [Google Scholar] [CrossRef]

- Levchik, S.V.; Weil, E.D. A review of recent progress in phosphorus-based flame retardants. J. Fire Sci. 2006, 24, 345–364. [Google Scholar] [CrossRef]

- Horn, W.E. Inorganic Hydroxides and Hydroxycarbonates: Their Function and Use as Flame-Retardant Additives; Marcel Dekker: New York, NY, USA, 2000. [Google Scholar]

- Butt, C.M.; Congleton, J.; Hoffman, K.; Fang, M.; Stapleton, H.M. Metabolites of organophosphate flame retardants and 2-ethylhexyl tetrabromobenzoate in urine from paired mothers and toddlers. Environ. Sci. Technol. 2014, 48, 10432–10438. [Google Scholar] [CrossRef] [PubMed]

- Torres, E.; Berard, M.T.; Schiller, M. Impact modifiers and their influence in toughness and plate-out in highly filled rigid PVC formulations. Plast. Rubber Compos. 2008, 37, 392–396. [Google Scholar] [CrossRef]

- Lutz, J.T.; Dunkelberger, D.L. Impact Modifiers for PVC–The History and Practice; John Wiley and Sons Inc.: Hoboken, NJ, USA, 1992. [Google Scholar]

- Cortolano, F.P. Antioxidants and UV stabilizers: A summary of their utilization in PVC. J. Vinyl Technol. 1993, 15, 69–75. [Google Scholar] [CrossRef]

- Jiang, Y.; Yang, Z.; Su, Q.; Chen, L.; Wu, J.; Meng, J. Preparation of magnesium-aluminum hydrotalcite by mechanochemical method and its application as heat stabilizer in poly(vinyl chloride). Materials 2020, 13, 5223. [Google Scholar] [CrossRef]

- Van der Ven, L.; Van Gemert, M.L.M.; Batenburg, L.F.; Keern, J.J.; Gielgens, L.H.; Koster, T.P.M.; Fischer, H.R. On the action of hydrotalcite-like clay materials as stabilizers in polyvinylchloride. Appl. Clay Sci. 2000, 17, 25–34. [Google Scholar] [CrossRef]

- Palin, L.; Rombolà, G.; Milanesio, M.; Boccaleri, E. The use of POSS-based nanoadditives for cable-grade PVC: Effects on its thermal stability. Polymers 2019, 11, 1105. [Google Scholar] [CrossRef] [Green Version]

- Yousif, E.; El-Hiti, G.A.; Hussain, Z.; Altaie, A. Viscoelastic, spectroscopic and microscopic study of the photo irradiation effect on the stability of PVC in the presence of sulfamethoxazole Schiff’s bases. Polymers 2015, 7, 2190–2204. [Google Scholar] [CrossRef] [Green Version]

- Yousif, E.; Al-Amiery, A.A.; Kadihum, A.; Kadhum, A.H.; Mohamad, A. Photostabilizing efficiency of PVC in the presence of Schiff bases as photostabilizers. Molecules 2015, 20, 19886–19899. [Google Scholar] [CrossRef]

- Ahmed, D.S.; El-Hiti, G.A.; Hameed, A.S.; Yousif, E.; Ahmed, A. New tetra-Schiff bases as efficient photostabilizers for poly(vinyl chloride). Molecules 2017, 22, 1506. [Google Scholar] [CrossRef] [Green Version]

- Shaalan, N.; Laftah, N.; El-Hiti, G.A.; Alotaibi, M.H.; Muslih, R.; Ahmed, D.S.; Yousif, E. Poly(vinyl chloride) photostabilization in the presence of Schiff bases containing a thiadiazole moiety. Molecules 2018, 23, 913. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- El-Hiti, G.A.; Alotaibi, M.H.; Ahmed, A.A.; Hamad, B.A.; Ahmed, D.S.; Ahmed, A.; Hashim, H.; Yousif, E. The morphology and performance of poly(vinyl chloride) containing melamine Schiff bases against ultraviolet light. Molecules 2019, 24, 803. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ali, G.Q.; El-Hiti, G.A.; Tomi, I.H.R.; Haddad, R.; Al-Qaisi, A.J.; Yousif, E. Photostability and performance of polystyrene films containing 1,2,4-triazole-3-thiol ring system Schiff bases. Molecules 2016, 21, 1699. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yousif, E.; Hasan, A.; El-Hiti, G.A. Spectroscopic, physical and topography of photochemical process of PVC films in the presence of Schiff base metal complexes. Polymers 2016, 8, 204. [Google Scholar] [CrossRef] [Green Version]

- Ali, M.M.; El-Hiti, G.A.; Yousif, E. Photostabilizing efficiency of poly(vinyl chloride) in the presence of organotin(IV) complexes as photostabilizers. Molecules 2016, 21, 1151. [Google Scholar] [CrossRef] [Green Version]

- Ghazi, D.; El-Hiti, G.A.; Yousif, E.; Ahmed, D.S.; Alotaibi, M.H. The effect of ultraviolet irradiation on the physicochemical properties of poly(vinyl chloride) films containing organotin(IV) complexes as photostabilizers. Molecules 2018, 23, 254. [Google Scholar] [CrossRef] [Green Version]

- Hadi, A.G.; Yousif, E.; El-Hiti, G.A.; Ahmed, D.S.; Jawad, K.; Alotaibi, M.H.; Hashim, H. Long-term effect of ultraviolet irradiation on poly(vinyl chloride) films containing naproxen diorganotin(IV) complexes. Molecules 2019, 24, 2396. [Google Scholar] [CrossRef] [Green Version]

- Hadi, A.G.; Jawad, K.; El-Hiti, G.A.; Alotaibi, M.H.; Ahmed, A.A.; Ahmed, D.S.; Yousif, E. Photostabilization of poly(vinyl chloride) by organotin(IV) compounds against photodegradation. Molecules 2019, 24, 3557. [Google Scholar] [CrossRef] [Green Version]

- Balakit, A.A.; Ahmed, A.; El-Hiti, G.A.; Smith, K.; Yousif, E. Synthesis of new thiophene derivatives and their use as photostabilizers for rigid poly(vinyl chloride). Int. J. Polym. Sci. 2015, 2015, 510390. [Google Scholar] [CrossRef]

- Sabaa, M.W.; Oraby, E.H.; Abdel Naby, A.S.; Mohammed, R.R. Anthraquinone derivatives as organic stabilizers for rigid polyvinyl chloride against photo-degradation. Eur. Polym. J. 2005, 41, 2530–2543. [Google Scholar] [CrossRef]

- Zhao, Y.; Dan, Y. Preparation and characterization of a high molecular weight UV-stabilizer based on a derivative of 2,4-dihydroxybenzophenone and its application in polymer materials. J. Appl. Polym. Sci. 2006, 102, 2203–2211. [Google Scholar] [CrossRef]

- Ahmed, D.S.; El-Hiti, G.A.; Yousif, E.; Hameed, A.S. Polyphosphates as inhibitors for poly(vinyl chloride) photodegradation. Molecules 2017, 22, 1849. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Alotaibi, M.H.; El-Hiti, G.A.; Hashim, H.; Hameed, A.S.; Ahmed, D.S.; Yousif, E. SEM analysis of the tunable honeycomb structure of irradiated poly(vinyl chloride) films doped with polyphosphate. Heliyon 2018, 4, e01013. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- El-Hiti, G.A.; Ahmed, D.S.; Yousif, E.; Alotaibi, M.H.; Satar, H.A.; Ahmed, A.A. Influence of polyphosphates on the physicochemical properties of poly(vinyl chloride) after irradiation with ultraviolet light. Polymers 2020, 12, 193. [Google Scholar] [CrossRef] [Green Version]

- Cheng, Q.; Li, C.; Pavlinek, V.; Saha, P.; Wang, H. Surface-modified antibacterial TiO2/Ag+ nanoparticles: Preparation and properties. Appl. Surf. Sci. 2006, 252, 4154–4160. [Google Scholar] [CrossRef]

- Folarin, O.M.; Sadiku, E.R. Thermal stabilizers for poly(vinyl chloride): A review. Int. J. Phys. Sci. 2011, 6, 4323–4330. [Google Scholar] [CrossRef]

- Mohammed, R.; El-Hiti, G.A.; Ahmed, A.; Yousif, E. Poly(vinyl chloride) doped by 2-(4-isobutylphenyl)propanoate metal complexes: Enhanced resistance to UV irradiation. Arab. J. Sci. Eng. 2017, 42, 4307–4315. [Google Scholar] [CrossRef]

- Ryan, K.M.; Drumm, A.D.; Martin, C.E.; Krumpfer, A.K.; Krumpfer, J.W. Synthetic Methods and Applications of Functional and Reactive Silicone Polymers. In Reactive and Functional Polymers; Gutiérrez, T.J., Ed.; Springer: Oxford, UK, 2020; Volume 1, Chapter 13. [Google Scholar] [CrossRef]

- Hidalgo, M.; González, L.; Mijangos, C. Crosslinking of plasticized poly(vinyl chloride) by substitution and free radical reaction. J. Appl. Polym. Sci. 1996, 61, 1251–1257. [Google Scholar] [CrossRef]

- Sluszny, A.; Silverstein, M.S.; Kababya, S.; Schmidt, A.; Narkis, M. Novel semi-IPN through vinyl silane polymerization and crosslinking within PVC films. J. Appl. Polym. A Polym. Chem. 2001, 39, 8–22. [Google Scholar] [CrossRef]

- Li, L.; Chen, X.; He, B. Crosslinking of rigid poly(vinyl chloride) with epoxysilane. J. Vinyl Addit. Technol. 2007, 13, 103–109. [Google Scholar] [CrossRef]

- Yousif, E.; Haddad, R. Photodegradation and photostabilization of polymers, especially polystyrene: Review. SpringerPlus 2013, 2, 398. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gardette, J.L.; Gaumet, S.; Lemaire, J. Photooxidation of poly(vinyl chloride). 1. A reexamination of the mechanism. Macromolecules 1989, 22, 2576–2581. [Google Scholar] [CrossRef]

- Nief, O.A. Photostabilization of polyvinyl chloride by some new thiadiazole derivatives. Eur. J. Chem. 2015, 6, 242–247. [Google Scholar] [CrossRef] [Green Version]

- Sabaa, M.W.; Oraby, E.H.; Naby, A.S.A.; Mohamed, R.R. N-Phenyl-3-substituted 5-pyrazolone derivatives as organic stabilizers for rigid poly(vinyl chloride) against photodegradation. J. Appl. Polym. Sci. 2006, 101, 1543–1555. [Google Scholar] [CrossRef]

- Andrady, A.L.; Searle, N.D. Photodegradation of rigid PVC formulations. II. Spectral sensitivity to light-induced yellowing by polychromatic light. J. Appl. Polym. Sci. 1989, 37, 2789–2802. [Google Scholar] [CrossRef]

- Jafari, A.J.; Donaldson, J.D. Determination of HCl and VOC emission from thermal degradation of PVC in the absence and presence of copper, copper(II) oxide and copper(II) chloride. J. Chem. 2009, 6, 685–692. [Google Scholar] [CrossRef] [Green Version]

- Allcock, H.; Lampe, F.; Mark, J.E. Contemporary Polymer Chemistry, 3rd ed.; Pearson Prentice-Hall: Upper Saddle River, NJ, USA, 2003. [Google Scholar]

- Mark, J.E. Physical Properties of Polymers Handbook; Springer: New York, NY, USA, 2007. [Google Scholar]

- Kayyarapu, B.; Kumar, M.Y.; Mohommad, H.B.; Neeruganti, G.O.; Chekuri, R. Structural, thermal and optical properties of pure and Mn2+ doped poly(vinyl chloride) films. Mater. Res. 2016, 19, 1167–1175. [Google Scholar] [CrossRef] [Green Version]

- Dragnevski, K.I.; Donald, A.M.; Clarke, S.M.; Maltby, A. Novel applications of ESEM and EDX for the study of molecularly thin amide monolayers on polymer films. Colloids Surf. A Physicochem. Eng. Asp. 2009, 337, 47–51. [Google Scholar] [CrossRef]

- Newbury, D.E. The new X-ray mapping: X-ray spectrum imaging above 100 kHz output count rate with the silicon drift detector. Microsc. Microanal. 2006, 12, 26–35. [Google Scholar] [CrossRef] [Green Version]

- Pospíšil, J.; Klemchuk, P.P. Oxidation Inhibition in Organic Materials; CRC Press: Boca Raton, FL, USA, 1989; Volume 1, pp. 48–49. [Google Scholar]

| Organosilane | X | Color | Yield (%) | Calculated (Found) | ||

|---|---|---|---|---|---|---|

| C | H | N | ||||

| 1 | OH | Brown | 75 | 72.85 (72.90) | 4.76 (4.79) | 5.66 (5.68) |

| 2 | NO2 | Dark brown | 78 | 65.21 (65.23) | 3.89 (3.92) | 10.14 (10.16) |

| 3 | Br | Light brown | 77 | 58.08 (58.12) | 3.47 (3.52) | 4.52 (4.55) |

| Organosilane | FTIR (cm−1) | |||||

|---|---|---|---|---|---|---|

| C−O | Si−O | C=C | C=N | C−H | OH | |

| 1 | 1136 | 1161 | 1526 | 1624 | 3094 | 3460 |

| 2 | 1144 | 1178 | 1518 | 1595 | 3078 | - |

| 3 | 1136 | 1171 | 1502 | 1597 | 3061 | - |

| Organosilane | 1HNMR (500 MHz: δ, ppm, J in Hz) |

|---|---|

| 1 | 9.93 (s, exch., 3H, 3 OH), 8.29 (s, 3H, 3 CH=N), 7.62 (d, J = 8.0 Hz, 6H, Ar), 7.51 (d, J = 8.0 Hz, 6H, Ar), 7.53–7.27 (m, 5H, Ph), 6.90 (d, J = 8.0 Hz, 6H, Ar), 6.41 (d, J = 8.0 Hz, 6H, Ar) |

| 2 | 8.48 (s, 3H, 3 CH = N), 8.20 (d, J = 8.0 Hz, 6H, Ar), 7.75 (d, J = 8.0 Hz, 6H, Ar), 7.51–7.43 (m, 5H, Ph), 7.08 (d, J = 8.0 Hz, 6H, Ar), 6.82 (d, J = 8.0 Hz, 6H, Ar) |

| 3 | 8.73 (s, 3H, 3 CH=N), 7.82 (d, J = 7.9 Hz, 6H, Ar), 7.79 (d, J = 7.9 Hz, 6H, Ar), 7.57–7.44 (m, 5H, Ph), 7.00 (d, J = 7.9 Hz, 6H, Ar), 6.88 (d, J = 8.0 Hz, 6H, Ar) |

| Organosilane | 13CNMR (125 MHz: δ, ppm) |

|---|---|

| 1 | 170.4, 156.9, 154.2, 145.4, 144.3, 132.7, 132.1, 131.6, 129.9, 128.1, 124.3, 120.2, 115.4 |

| 2 | 170.4, 154.2, 151.8, 145.5, 131.9, 131.6, 131.0, 129.9, 129.0, 127.8, 126.1, 122.8, 120.2 |

| 3 | 170.3, 154.2, 150.6, 149.8, 131.4, 130.6, 129.4, 129.1, 128.9, 126.1, 122.8, 120.7, 120.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohamed, S.H.; Hameed, A.S.; El-Hiti, G.A.; Ahmed, D.S.; Kadhom, M.; Baashen, M.A.; Bufaroosha, M.; Ahmed, A.A.; Yousif, E. A Process for the Synthesis and Use of Highly Aromatic Organosilanes as Additives for Poly(Vinyl Chloride) Films. Processes 2021, 9, 91. https://doi.org/10.3390/pr9010091

Mohamed SH, Hameed AS, El-Hiti GA, Ahmed DS, Kadhom M, Baashen MA, Bufaroosha M, Ahmed AA, Yousif E. A Process for the Synthesis and Use of Highly Aromatic Organosilanes as Additives for Poly(Vinyl Chloride) Films. Processes. 2021; 9(1):91. https://doi.org/10.3390/pr9010091

Chicago/Turabian StyleMohamed, Safaa H., Ayad S. Hameed, Gamal A. El-Hiti, Dina S. Ahmed, Mohammed Kadhom, Mohammed A. Baashen, Muna Bufaroosha, Ahmed A. Ahmed, and Emad Yousif. 2021. "A Process for the Synthesis and Use of Highly Aromatic Organosilanes as Additives for Poly(Vinyl Chloride) Films" Processes 9, no. 1: 91. https://doi.org/10.3390/pr9010091