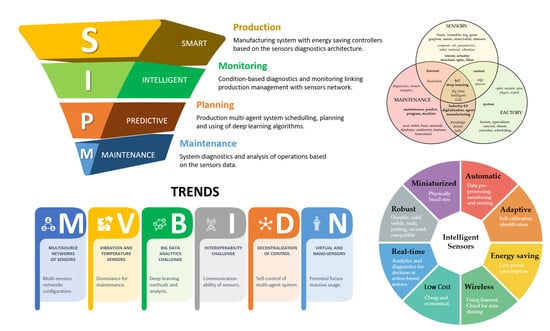

The results are divided into three parts according to the research question: an overview of the main topics, smart and intelligent predictive maintenance, and Industry 4.0 Technologies and Sensors for Smart Factory.

4.1. Main Topics and Trends Overview

First, we identified occurrences of the primary topics “smart factory/production,” “intelligent/smart sensors,” and “predictive/smart maintenance” in the Web of Science and Scopus databases. This part of the research related to the research question 1. All three concepts are connected in the research area by engineering, supplemented by telecommunications and predictive maintenance by medicine, or intelligent sensors in computer science. The total number of publications in the databases is shown in

Figure 4.

The results shown in

Figure 5 show an increase in the number of publications over time. This increase has been apparent for smart factory publications since 2015 and intelligent sensors since 2012. Further, we performed burst detection analysis in the researched areas for Web of Science publications.

The burst detection analysis presents key terms for topics of intelligent sensors, smart factory, and predictive maintenance (see

Figures S1–S3 in Supplementary Materials). For a better overview, we compare the results in three time periods (

Figure 6), and then according to the individual importance of key concepts (

Figure 7). The importance of the terms was expressed using the obtained burst weights. Based on these findings and analysis, we tried to answer research question 1 responsibly.

Top cited papers from smart factory/production areas focus on using ion batteries for smart grids [

59,

60] and nanomaterials’ intelligent design [

61]. The results show that the most used terms in the paper titles are intelligent, Industry 4.0, and agent. Based on

Figure 5, we conclude that the oldest wave in smart factories is associated with classical studies dealing with intelligent, flexible, and automation planning and scheduling of manufacturing systems. This wave is the period 1970–1990, characterised by the burst terms intelligent, system, knowledge, plan, and schedule. The second wave in 1990–2010 with the primary burst terms: agent, manufacturing, control, expert, and process, refers to papers using holon, RFID, or web technologies in factories. Publications on manufacturing control systems [

62,

63] were highly cited in this period. The current trend in smart factory is related to implementing intelligent manufacturing [

64]. In this contemporary wave, burst terms Industry 4.0, digital twin, IoT, deep learning, digitalisation, smart grid, cyber, and sustain dominate. These terms are well-known Industry 4.0 technologies and processes. Top cited papers focused on operational planning of a smart grid [

65], deep learning in agriculture [

66], and big data for the self-organised multiagent system in the smart factory [

67].

Top cited papers from smart/intelligent sensors were in areas related to the Internet of Things [

68], wireless sensor networks [

69], and nanotechnology applications [

70]. We found that the important paper title terms are IoT, structure, and sensor in the burst analysis.

Figure 5 shows that the early history of intelligent sensors, 1970–1990, emphasised the first application of sensors (burst terms sensor, intelligent, process). Later, in 1990–2010 came articles focused on the structure [

71], optic, and control of sensors, and their usage for robots. Some essential publications in this period focused on structural health monitoring [

72], piezoelectric laminate beam [

73], and free vibration behaviour of the beam [

74]. The most contemporary period from 2010 to 2020, similar to the smart factory/production, covered the area of Industry 4.0 new technologies. In addition to the mentioned Internet of Things [

75], there is a significant representation of publications focused on wearable sensor-based systems [

76], deep learning [

77], edge technology [

78], graphene-based smart materials, blockchain, smart city, and grid.

The last area focused on smart/predictive maintenance. After omitting medical and ecological articles, the most cited publications focused on proportional-integral-derivative (PID) control [

79], monitoring, and fault diagnosis in production [

80]. Based on the burst analysis results, we found that the most important terms are maintenance, learning, and predict. We identified three trend waves in area maintenance (

Figure 5). In the first wave from 1970 to 1990, the publications dealt with predictive maintenance. In engineering and production, maintenance is associated with predicting machines’ status [

81] or deterioration of processes [

82]. In the second wave in 1990 to 2010, we found that the publications dealt with burst terms program, diagnostics, intelligence, knowledge, and database. These publications focus, for example, on diagnostics, monitoring, or maintenance of intelligent computer numerical control (CNC) machine tools [

83] or power transformers [

84]. The current trend wave is characterised by Industry 4.0 technologies such as digital twins, deep machine learning, IoT, big data analytics, blockchain, and digitisation for maintenance. The most significant publications of this period focused on big data analytics in logistics and supply chain management [

85], maintenance strategy selection [

86], vibration analysis of rotating machinery, or cloud-enabled prognosis [

87] for predictive maintenance in production.

Based on the burst analysis detection, we conclude that in all three areas in the last 10 years, the focus has been on the concept of Industry 4.0 and related technologies. We arranged the keywords with the highest burst weights into three research areas in

Figure 7. The results show that the terms Internet of Things and deep learning have the highest weight for all topics. The terms Big Data, grid, and intelligent are also common to the area. From this finding, we can conclude that the current trend in the monitored areas is related to the collecting of big data through intelligent sensors on IoT devices and their evaluation using learning algorithms.

The internet, smart grid, and blockchain technology are important for sensors used in maintenance. The use of sensors in smart factories lies mainly in the area of control, with a focus on processes. The sensors, together with actuators, are used to collect data to control and optimise conditions. Piezoelectric, optics, wearable, beam, graphene, and other sensors’ features are used. A special area of sensors lies in robotics, which has experienced rapid development in recent years. In the world’s most industrialised countries, such as South Korea, Japan, Germany, and Sweden, there is the largest share of robots per 10,000 employees in factories [

88]. Automation in smart factories requires new types of sensors that have the ability to automatically calibrate and improve the functions of IoT devices. The IoT is not aiming only at connect two machines with pre-programmed functions. For IoT communication, it is important to connect embedded devices to the Internet and communicate with each other [

89]. It is an intelligent connection of various products, devices, and facilities that provide a wide range of functions that evaluate certain conditions. The interaction between systems brings new possibilities. The key elements are miniature intelligent sensors [

90]. Even though devices and systems were not originally designed to share data, the Internet of Things can. Connecting smart sensors and gateways to existing devices leads to data collection and analysis, understanding, and better decision making [

91].

Publications about smart factory/production are related to cyber-physical systems, planning, scheduling, and sustaining them. Maintenance in smart factories relies on Industry 4.0 technologies, digitisation, data-driven manufacturing, agent-based systems, and digital twins. Predictive maintenance consists of programs for predicting, diagnosing, and analysing future maintenance needs. Based on the rules, features, and conditions, there are machines and devices controlled and repaired to maintain their life and future sustainability. Information and data are collected and shared through databases.

4.2. Smart and Intelligent Predictive Maintenance

We performed a co-occurrence analysis based on original papers’ keywords using VOSviewer. This part of the analysis related to research question 2. The results show that the keywords maintenance, optimisation, predictive maintenance, system, and big data were most often used in publications. Publications were grouped based on keywords into four clusters (

Figure 8).

I4: Industry 4.0 for predictive maintenance in general (keywords: Industry 4.0, Big Data, prognostics, optimisation, performance, predictive maintenance, system).

CbM: Smart manufacturing for condition-based maintenance (keywords: smart manufacturing, manufacture, condition-based maintenance).

SFD: Condition, state, and fault diagnosis for maintenance (keywords: maintenance, condition monitoring, fault diagnosis).

RUL: Prognostics and health management for RUL (keywords: prognostics and health management, signal processing, remaining useful lives).

The first cluster consists of publications that focus on intelligent sensors in smart maintenance factories without preferring specific methods. This cluster is represented, for example, by publications focused on data-driven simulation [

92], big data in an Industry 4.0 environment [

93], or performing predictive maintenance in a bottling plant [

94]. The second cluster consists mainly of publications that emphasise the use of condition-based maintenance. The intelligent condition-based maintenance uses data fusion [

95] and the Internet of Things in connection to learning techniques [

96]. The third cluster related to publications mainly emphasised fault diagnosis’ importance for monitoring and maintenance. The fault diagnosis is used for prognosis in signal processing [

97] and maintenance management systems [

98]. The last cluster is characterised by a focus on determining the current health and the remaining life of devices and machines. This concept is described concerning edge-cloud platforms [

99].

While the concept of condition monitoring has been around for some time, the market for more sophisticated predictive maintenance products is still very young. There are four types of maintenance classified in the literature: corrective, scheduled, condition-based, and statistical-based maintenance [

100,

101]. Predictive maintenance has evolved from corrective maintenance using new technologies and procedures for predicting and preventing failure. Corrective maintenance is based on the reactive strategy to the maintenance process—however, with a proactive strategy related to the preventive or opportunistic approach. Preventive maintenance is then seen as condition-based, dynamic predictive, or scheduled (periodic) maintenance. The corrective maintenance is based on the repair or replacement of assets ex-post. Condition-based maintenance means the decision-making process, usually in real-time, based on selected indicators computed from the gathered data.

Table 6 depicts maintenance process characteristics from analysed papers. The condition-based preventive maintenance is discussed in Farooq et al. [

38], Kumar et al. [

102], Li et al. [

96], Lin et al. [

103], Musselman and Djurdjanovic [

104], Yan et al. [

93], and Sadiki et al. [

105]. Preventive maintenance is regular maintenance of machines, devices, and equipment to prevent their downtime concerning failure state. The preventive maintenance actions were classified by Doostparast et al. [

106] as inspection, low-level repair, and replacement. These actions are based on fault prediction time statistically, upon failure accident, time-based (at the age for old machines), or cycle-based (periodically).

4.3. Industry 4.0 Technologies and Sensors for Smart Factory

Furthermore, full texts of articles concerning Industry 4.0 technologies were analysed. We performed a cluster analysis of the obtained keywords of Industry 4.0 technologies. The results of the analysis are shown in

Figure 9. The most common keywords in the articles were sensor, big data, Internet of Things, machine learning, and cloud. Through cluster analysis, we found three clusters:

A: Intelligent sensors (keywords: sensor, actuator, intelligence, automation).

B: Cloud-related technologies (keywords: cloud, cloud computing, Big Data, RFID, edge, PLC (programmable logic controller), 3D printer).

C: Internet of Things technologies (keywords: Internet of Things, SCADA (Supervisory Control and Data Acquisition), CPS (cyber-physical system), machine learning, artificial intelligence, management, challenge).

Table 7 presents the results of classification of researched papers according to belonging to the clusters. The intelligent cluster sensors mainly focused on sensors in general. Kumar et al. [

102] analysed remaining useful life (RUL) of cutting machines by a polynomial regression method. Musselman and Djurdjanovic [

104] analysed production belt for automation of material handling in the semiconductor industry. The second cluster is focused on Cloud-related technologies. It means that sensors based on RFID [

92] and programmable logic controller [

107] are used for cloud or edge computing [

99] and analysis of big data [

109]. The third cluster concerned the IoT technologies based on CPS systems [

38], SCADA [

94], and data for deep and machine learning.

The different sensors’ data are used for prediction and diagnostics of devices, machines, facilities, and equipment. The results in

Table 8 show that data are usually collected from SCADA systems, PLCs, CNC machine sensors, IoT devices, or other special sensors. Analysed papers mostly used case study and experimental research methods.

If we focus closely on individual types of sensors used for predictive maintenance, we will find a number of them, and we can categorize them according to the method of detection of the desired variable. The types and descriptions of sensors used in publications are shown in

Table 9. Furthermore, the sensors are elaborated in more details. Vibration and temperature sensors were most often used for predictive maintenance.

4.3.1. Motion, Position, Proximity, and Speed Sensors

The first type of sensors are motion-based probes. Position and movement sensors are mounted for monitoring the machine or product position on the production lines. Inductive, photoelectric, potentiometric (resistance-based), capacitive, optical, magnetic, and other sensing methods are used for detection of position. Sensors based on motion detection must meet the requirements in the areas of durability, weight, energy consumption, and at the same time, suitability for mass production regarding to the end user—customer [

123,

124]. Shoabid [

125] describes motion-based sensors as a combination of an accelerometer, gyroscope, magnetometer, and linear acceleration. The application of these sensors can be found primarily in the field of healthcare systems, with various combinations of the above-mentioned sensors. A gyroscope is used mainly for gait analysis, fall detection, or gesture recognition, or in combination with an accelerometer. Proximity sensors detect the presence of an object without contact. These sensors are based on the optical, ultrasonic, inductive, and capacitive nature. Wearable sensors are able to monitor, for example, physiological parameters in real time.

Speed sensors have an opportunity for detecting object speed (usually for wheels, motor, or rotating particles). Enterprises use speedometers, accelerometers, light detection and ranging (LIDAR) sensors, tachometers, Doppler radars, etc. Farooq et al. [

38] discussed genetic-algorithm-based prediction process for intelligent maintenance of textile spinning systems. They used vibration and speed data in a multiagent system for tracking discrepancies and error distribution of machine processing. Integrated Electronics Piezo-Electric accelerometers have been frequently used for machine vibration measurement. Peng et al. [

113] use them for an automatic health condition diagnosis without field worker maintenance effort. The results show that dynamic response signals from the accelerometer increased the completeness and performance of the vibration diagnosis function. Further, Peng and Tsan [

98] developed a sensor diagnosis and monitoring system to classify the health condition of the online integrated IEPE accelerometer. The solution was integrated into a production line.

Goodall et al. [

92] developed, based on the RFID, a data-driven simulation for controlling work-in-process parts in a remanufacturing process and determining the time for operators to process them [

104]. Park et al. [

112] performed experiments on servo motor lifespan using an accelerated degradation testing method based on thermal stresses. The experimental data are used sensors for monitoring the torque, position, electrical resistance, and moment of inertia of rotor. Shan et al. [

114] presented the system architecture and hardware for the welding line, which provides the real-time fine-grained visualisation of the welding robot operation status. The electrocardiogram of intelligent manufacturing equipment technology provides the maintenance of intelligent manufacturing equipment.

4.3.2. Vibration and Torque Sensors

Vibration sensors are used for monitoring the acceleration machine vibration, indicating a potential machine issue. Some sensors have modern fast Fourier transform signal processing to detect failures in machine components. Vibration sensors are the core of preventive maintenance and provide the condition of the device determination.

Barbieri et al. [

99] proposed autonomous health management prognostics for smart manufacturing via on-board sensors. Kiangala and Wang [

94] integrated a practical use of intelligent sensors in a small bottling plant. Predictive maintenance is used for detecting early faults and failures in conveyor motors. Uhlmann et al. [

117] developed a smart sensor network for condition monitoring in factories. Collected data from MEMS sensors are processed in the cloud services and visualised on the mobile platform.

Torsion (torque, rotational) sensors convert a torque reaction and rotary into electrical signal. These sensors measure stationary or dynamic variables, usually in motors, turbines, or generators. Kozlowski et al. [

110] used a torque sensor for designing a classifier for cutting tool condition assessment in RUL prediction. Kumar et al. [

102] evaluated and estimated RUL for particular failures in distinct health states and faults. Vlasov et al. [

119] used wireless vibration sensor networks that allow real-time analysis of the state of the electronic equipment (motor). The purpose of their approach is to minimize the cost of maintenance and develop a system of predictive maintenance for optimisation predictive repair. Zhang et al. [

121] used vibration sensors for accurate prediction of the remaining useful life of the rotatory machines. Deep learning model combined a long short-term memory neural network with an attention mechanism for maintenance in mechanical manufacturing.

4.3.3. Acoustical, Sound, and Ultrasonic Sensors

Another group of sensors are sensors focused on sound detection, usually via microphone devices. When a signal is detected by a sound sensor, the level of voltage is translated to the appropriate sound level. Kaptan [

126] describes the location of city buses using sound sensors and an accelerometer instead of the standard global positioning system (GPS) location. In such a scenario, the accelerometers detect the movement of the vehicle and the microphone sensing distinguishes the sound level inside and outside the vehicle. Compared to GPS location, energy savings of up to 46% occur. Another possible usage of acoustic sensors is described by Ryu [

127] in the field of material detection. Using machine learning techniques, sound sensors are able to estimate relevant information such as the character of an object and its location. Ultrasonic sensors are non-contact devices using the flight of the sound wave greater than that of the human audible range. Similarly, as with sonar, the measurement is based on the Doppler Shift principle. Yan et al. [

120] conducted fusion data mining to predict the remaining life of a key component of machining equipment by multisource sensors (acoustical, vibration, optical, or power).

4.3.4. Pressure, Force, Touch, and Tension Sensors

Pressure sensors identify the pressure deviations in the measurement objects or environment. The change detection is usually based on barometric, piezoelectric, capacitive, optical, or resonant sensing principles. Examples of these types of sensors are Bourdon tubes, diaphragms, pressure gauge, or manometers. Tension sensors help with the deformation and movement of the belt automated material handling system monitoring for intelligent condition-based maintenance [

104].

Force sensors monitor tensile compressive force signal and translate it into an output electric signal. Their application includes lead cells, strain gauges, or sensing resistors. Very popular are piezoelectric and magnetostrictive technologies. Another way of sensing is based on induction, pneumatic, and hydraulic forces.

4.3.5. Optical, Light, and Machine Vision Sensors

Another type of sensors are sensors with a machine vision function. Machine vision technology has grown significantly in recent years and is becoming part of autonomous vehicles, intelligent systems, and robotics. Optical sensor input into the systems makes these systems intelligent. Visual data are captured in the form of a series of images and after the digitisation process are processed using a machine learning algorithm [

128,

129]. In the field of material wear detection, three-dimensional (3D) sensors are also used, which represent new technical means for obtaining information. Three-dimensional data provides more information and at the same time, reduces the deviation of the measured data [

130]. A large group of sensors consists of chemical character sensors. Advances in chemical, sensing, and wireless technologies have accelerated the development of wireless chemical sensors. These devices allow the collection and distribution of biochemical information. The use of these types of sensors can be found in the areas of environmental or health monitoring [

131,

132].

Tarashioon et al. [

115] described the design of solid-state lighting products based on the reliability system diagnostics (self-maintenance). The light sensor design using light-emitting diode technology is used to monitor system ambient light.

4.3.6. Temperature Sensors

Temperature sensors usually detect changes in machine condition or critical state in the factory (especially in hazardous environments.). The sensors obtain temperature information directly (resistive temperature detectors, thermistors, and thermocouples) or indirectly (infrared sensors). Some of these sensors have a temperature display. Infrared (IR) sensors work on the basis of the optical principle using light. We distinguish reflective and transmissive IR sensors. Reflective IR sensors’ transmitter and detector are positioned adjacent to each other facing the object. Transmissive sensors use LED and photo diodes to detect the object passing between them.

Another group of sensors consists of probes measuring temperature and humidity. Advances in biomaterials offer opportunities to design electronics with unique mechanical stability capabilities, i.e., sensors whose material composition offers the possibility of application in medical implants and disposable wearable devices. Suitable applications can be found in the accurate scanning of biological tissues, internal organs, but also in the textile and food industry [

133].

Bekar et al. [

108] analysed the real-world industrial data to implement the PdM strategy for the manufacturing enterprise. They evaluated the quality of the process, vibration and temperature data by understanding outliers, and developed maintenance solutions. Sadiki et al. [

105] show the advantages of condition-based maintenance for real-time intelligent monitoring for the industrial machine. Tmote sky sensors network and Z1 mote operate through the edge router and enhance the maintenance simulation’s purpose. Villalobos et al. [

118] introduced a flexible forecaster analyser system for anticipation of alarms’ activation based on the temperature sensor data. The deep learning techniques based on the short-term memory recurrent neural network contribute to the predictive maintenance approach.

4.3.7. Liquid, Flow, Gas, and Chemical Sensors

Flow sensors enable the possibility to analyse the cooling water and lubrication flow rate. These sensors use magnetic, ultrasonic, or thermal detectors to monitor the current intensity in the pipeline. Chien and Chen [

109] used mass flow controllers for monitoring mode and position of silane reactant flow. Their research is related to a data-driven framework for monitoring equipment’s health condition (RUL).

Oil particle sensors enable the possibility of monitoring contamination levels in lubrication systems (for example, gear boxes). These sensors target to change the level of pollution based on the presence of the number of substances processed. They analysed the light intensity via a laser beam and photo detector.

Humidity (moisture) sensors focused diagnostics on water content in oils to prevent corrosion of machines. These sensors are usually installed in a lubrication or hydraulic tank. Humidity sensors play an essential role in the selected automated manufacturing processes. To achieve the desired atmosphere, it is necessary to detect, monitor, and regulate humidity in conditions of low and high temperatures. The use of sensors for moisture detection can be found, for example, in monitoring systems and networks, as a monitoring device in agriculture, and as a tool for determining soil moisture during irrigation. Furthermore, also in the field of corrosion diagnostics in the areas of infrastructure and construction. The key element in this type of sensor is the materials used and the associated availability of suitable production technologies [

134].

4.3.8. Electronic, Current, Energy, and Magnetic Sensors

Energy and current measurement sensors ensure the density of electrical cable isolation. Their purpose is to measure the current draw of machines. These sensors have been used in many industrial areas but have had shortcomings regarding demands in the areas of miniaturisation, energy consumption, and insufficient stability. At present, optical fibres and magnetic fluids are widely used, due to their versatility of application [

135]. In the case of electronic sensors, these can be, for example, gas sensors that are capable of performing sensitive analysis in real time, thanks to their flexibility and the possibility of integration with intelligent electronics and mechanical resistance in relation to energy consumption, and respectively, the performance of electronic components. However, balancing these variables offers applications not only in the above areas, but also in aviation, aerospace, and nuclear industry [

136] display devices, and there is considerable potential in the area of environmental monitoring [

137]. Zhang et al. [

122] described a data-driven smart production line with installed energy consumption sensors for forecast and fault diagnosis of maintenance.

4.3.9. Virtual Sensors

Virtual sensors are advanced applications in the software layer of the machine that enhance the knowledge of the devices. These state-of-the-art sensors obtained data not only from physical machines (for example robots), but also the knowledge bases [

138]. Al-Jlibawi et al. [

107] call them adaptive soft sensors due to their low cost, parallel work, robust characteristics, easy implementation, and real-time estimation features. They used PLC and SCADA for collecting data in the refinery via a distribution control system.

4.3.10. Nuclear, Chemical, Microparticles, and Nanoparticles Sensors

The last category consists of sensors that are based on modern technologies using chemical processes. These are sensors based on nanoparticles and microparticles, which enable monitoring directly inside the monitored object. Lao et al. [

111] present a robust moving horizon estimation of sensor maintenance based on the observation and monitoring of chemical processes. Comparison of four simulations demonstrates the economic performance advantages of sensor-predictive maintenance. Jia et al. [

139] described the design of the nanosensors for detection of antibiotics to prevent the production of resistance to antibiotics. Nanomaterial chemistry is used for developing current arsenic detection nanostructures [

140]. The main advantages of nanomaterials are the high flexibility, sensitivity, compatibility, and stretchability of sensors in electronics devices [

141].