Stand-Alone Microgrid with 100% Renewable Energy: A Case Study with Hybrid Solar PV-Battery-Hydrogen

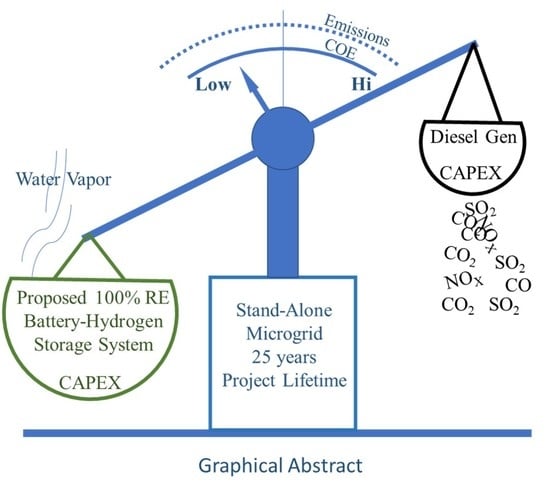

Abstract

:1. Introduction

2. Previous Works

3. Power to Hydrogen to Power System

3.1. Water Electrolysis

- Alkaline water electrolysis (AWE),

- Proton exchange membrane (PEM),

- Solid oxide electrolyte (SOE).

3.2. Hydrogen Storage

3.3. Fuel Cells

4. Methodology

- Scenario 1 (S1): 100% solar PV-battery system.

- Scenario 2 (S2): 100% solar PV-P2H2P system.

- Scenario 3 (S3): 100% solar PV and hybrid battery-P2H2P system.

4.1. Case Study; Hypothesis

4.2. Scenarios Description

5. Results and Analysis

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| RE | Renewable Energy | AWE | Alkaline Water Electrolysis |

| SAHM | Stand-Alone Hybrid Microgrids | PEM | Proton Exchange Membrane |

| RER | Renewable Energy Resources | SOE | Solid Oxide Electrolyte |

| RESS | Renewable Energy Storage System | η | Efficiency |

| P2G | Power to Gas | CAPAX | Capital Cost |

| P2H | Power to Hydrogen | OPEX | Operating Cost |

| P2H2P | Power to Hydrogen to Power | NPC | Net Present Cost |

| DER | Distributed Energy Resources | Ren Frac | Renewable Fraction |

| COE | Cost of Energy | BCS | Base Case Scenario |

| FC | Fuel Cell | S# | Scenario Number # |

References

- The Organisation for Economic Co-operation and Development (OECD). Climate Change Mitigation; OECD Publishing: Paris, France, 2015. [Google Scholar]

- International Energy Agency (IEA). World Energy Outlook 2015; IEA: Paris, France, 2015. [Google Scholar]

- Dawood, F.; Urmee, T.; Shafiullah, G.M. The renewable energy household lighting for Chibayish inhabitant’s in Iraq. Renew. Energy Environ. Sustain. 2017, 2, 15. [Google Scholar] [CrossRef]

- Ghaib, K.; Ben-Fares, F.Z. Power-to-Methane: A state-of-the-art review. Renew. Sustain. Energy Rev. 2018, 81, 433–446. [Google Scholar] [CrossRef]

- Blanco, H.; Faaij, A. A review at the role of storage in energy systems with a focus on Power to Gas and long-term storage. Renew. Sustain. Energy Rev. 2018, 81, 1049–1086. [Google Scholar] [CrossRef]

- Zhang, C.; Wu, J.; Long, C.; Cheng, M. Review of Existing Peer-to-Peer Energy Trading Projects. Energy Procedia 2017, 105, 2563–2568. [Google Scholar] [CrossRef]

- Dawood, F.; Anda, M.; Shafiullah, G.M. Hydrogen production for energy: An overview. Int. J. Hydrog. Energy 2020. [Google Scholar] [CrossRef]

- Lu, B.; Blakers, A.; Stocks, M. 90–100% renewable electricity for the South West Interconnected System of Western Australia. Energy 2017, 122, 663–674. [Google Scholar] [CrossRef]

- Maroufmashat, A.; Fowler, M. Transition of Future Energy System Infrastructure; through Power-to-Gas Pathways. Energies 2017, 10, 1089. [Google Scholar] [CrossRef] [Green Version]

- Stansberry, J.; Mejia, A.H.; Zhao, L.; Brouwer, J. Experimental analysis of photovoltaic integration with a proton exchange membrane electrolysis system for power-to-gas. Int. J. Hydrog. Energy 2017, 42, 30569–30583. [Google Scholar] [CrossRef]

- Dawood, F.; Shafiullah, G.M.; Anda, M. Power to Gas Energy Storage System for Energy Self-sufficient Smart Cities Development; Springer: Cham, Switzerland, 2019; pp. 487–498. [Google Scholar]

- Roslan, M.F.; Hannan, M.A.; Ker, P.J.; Uddin, M.N. Microgrid control methods toward achieving sustainable energy management. Appl. Energy 2019, 240, 583–607. [Google Scholar] [CrossRef]

- Celine Mahieux, A.O. Microgrids Enter the Mainstream. Available online: http://www.renewableenergyfocus.com/view/43345/microgrids-enter-the-mainstream/ (accessed on 31 May 2015).

- Barbato, A.; Capone, A. Optimization Models and Methods for Demand-Side Management of Residential Users: A Survey. Energies 2014, 7, 5787–5824. [Google Scholar] [CrossRef]

- Kueck, R.H.S.J.D.; Labinov, S.D.; Kirby, B.J. Microgrid Energy Management System; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2003. [Google Scholar]

- Vivas, F.J.; de las Heras, A.; Segura, F.; Andújar, J.M. A review of energy management strategies for renewable hybrid energy systems with hydrogen backup. Renew. Sustain. Energy Rev. 2018, 82, 126–155. [Google Scholar] [CrossRef]

- Li, J.; Xiong, R.; Yang, Q.; Liang, F.; Zhang, M.; Yuan, W. Design/test of a hybrid energy storage system for primary frequency control using a dynamic droop method in an isolated microgrid power system. Appl. Energy 2017, 201, 257–269. [Google Scholar] [CrossRef]

- Li, B.; Roche, R.; Paire, D.; Miraoui, A. Sizing of a stand-alone microgrid considering electric power, cooling/heating, hydrogen loads and hydrogen storage degradation. Applied Energy 2017, 205, 1244–1259. [Google Scholar] [CrossRef] [Green Version]

- Sachs, J.; Sawodny, O. Multi-objective three stage design optimization for island microgrids. Appl. Energy 2016, 165, 789–800. [Google Scholar] [CrossRef]

- Dawoud, S.M.; Lin, X.; Okba, M.I. Hybrid renewable microgrid optimization techniques: A review. Renew. Sustain. Energy Rev. 2018, 82, 2039–2052. [Google Scholar] [CrossRef]

- Chen, J.; Yang, P.; Peng, J.; Huang, Y.; Chen, Y.; Zeng, Z. An Improved Multi-Timescale Coordinated Control Strategy for Stand-Alone Microgrid with Hybrid Energy Storage System. Energies 2018, 11, 2150. [Google Scholar] [CrossRef] [Green Version]

- Joung, K.W.; Kim, T.; Park, J. Decoupled Frequency and Voltage Control for Stand-Alone Microgrid with High Renewable Penetration. IEEE Trans. Ind. Appl. 2018, 55, 122–133. [Google Scholar] [CrossRef]

- Siddaiah, R.; Saini, R.P. A review on planning, configurations, modeling and optimization techniques of hybrid renewable energy systems for off grid applications. Renew. Sustain. Energy Rev. 2016, 58, 376–396. [Google Scholar] [CrossRef]

- Liu, Y.; Yu, S.; Zhu, Y.; Wang, D.; Liu, J. Modeling, planning, application and management of energy systems for isolated areas: A review. Renew. Sustain. Energy Rev. 2018, 82, 460–470. [Google Scholar] [CrossRef]

- Shafiullah, G.M. Hybrid renewable energy integration (HREI) system for subtropical climate in Central Queensland, Australia. Renew. Energy 2016, 96, 1034–1053. [Google Scholar] [CrossRef]

- Shoeb, M.A.; Shafiullah, G. Renewable Energy Integrated Islanded Microgrid for Sustainable Irrigation—A Bangladesh Perspective. Energies 2018, 11, 1283. [Google Scholar] [CrossRef] [Green Version]

- Khan, M.J.; Iqbal, M.T. Pre-feasibility study of stand-alone hybrid energy systems for applications in Newfoundland. Renew. Energy 2005, 30, 835–854. [Google Scholar] [CrossRef]

- Ali, I.; Shafiullah, G.M.; Urmee, T. A preliminary feasibility of roof-mounted solar PV systems in the Maldives. Renew. Sustain. Energy Rev. 2018, 83, 18–32. [Google Scholar] [CrossRef]

- Larminie, J.; Dicks, A.; McDonald, M.S. Fuel Cell Systems Explained, 3rd ed.; John Wiley & Sons Ltd.: West Sussex, UK, 2018. [Google Scholar]

- Abadlia, I.; Bahi, T.; Bouzeria, H. Energy management strategy based on fuzzy logic for compound RES/ESS used in stand-alone application. Int. J. Hydrog. Energy 2016, 41, 16705–16717. [Google Scholar] [CrossRef]

- Energy Networks Australia. Decarbonising Australia’s Gas Networks. Energy Networks Australia: Australia, 2017. Available online: www.energynetworks.com.au/gas-vision-2050 (accessed on 4 February 2020).

- Commonwealth of Australia. Hydrogen for Australia’s Future, 2018; Hydrogen Strategy Group: Canberra, Australia, 2018. [Google Scholar]

- ATCO Gas WA, Clean Energy Innovation Hub. Available online: https://yourgas.com.au/energy-future/clean-energy-innovation-hub/ (accessed on 17 November 2019).

- Khosravi, A.; Koury, R.N.N.; Machado, L.; Pabon, J.J.G. Energy, exergy and economic analysis of a hybrid renewable energy with hydrogen storage system. Energy 2018, 148, 1087–1102. [Google Scholar] [CrossRef]

- Robinius, M.; Raje, T.; Nykamp, S.; Rott, T.; Müller, M.; Grube, T.; Katzenbach, B.; Küppers, S.; Stolten, D. Power-to-Gas: Electrolyzers as an alternative to network expansion—An example from a distribution system operator. Appl. Energy 2018, 210, 182–197. [Google Scholar] [CrossRef]

- Wall, D.M.; McDonagh, S.; Murphy, J.D. Cascading biomethane energy systems for sustainable green gas production in a circular economy. Bioresour Technol. 2017, 243, 1207–1215. [Google Scholar] [CrossRef]

- Hydrogenics GmbH. Renewable Hydrogen Solutions; Hydrogenics GmbH: Gladbeck, Germany, 2016. [Google Scholar]

- Hydrogenics GmbH. Grid Balancing, Power to Gas (PtG); Hydrogenics GmbH: Gladbeck, Germany, 2016. [Google Scholar]

- Bailera, M.; Lisbona, P.; Romeo, L.M.; Espatolero, S. Power to Gas projects review: Lab, pilot and demo plants for storing renewable energy and CO2. Renew. Sustain. Energy Rev. 2017, 69, 292–312. [Google Scholar] [CrossRef]

- Horizon Power. Available online: http://horizonpower.com.au/about-us/overview/who-we-are/ (accessed on 18 November 2019).

- Western Power. Available online: https://westernpower.com.au/energy-solutions/projects-and-trials/stand-alone-power-systems-trial/ (accessed on 18 November 2019).

- Petrollese, M.; Valverde, L.; Cocco, D.; Cau, G.; Guerra, J. Real-time integration of optimal generation scheduling with MPC for the energy management of a renewable hydrogen-based microgrid. Appl. Energy 2016, 166, 96–106. [Google Scholar] [CrossRef]

- Zhao, B.; Zhang, X.; Li, P.; Wang, K.; Xue, M.; Wang, C. Optimal sizing, operating strategy and operational experience of a stand-alone microgrid on Dongfushan Island. Appl. Energy 2014, 113, 1656–1666. [Google Scholar] [CrossRef]

- Shafiullah, G.M.; Amanullah, M.T.O.; Ali, A.B.M.S.; Jarvis, D.; Wolfs, P. Prospects of renewable energy—A feasibility study in the Australian context. Renew. Energy 2012, 39, 183–197. [Google Scholar] [CrossRef]

- Rehman, S.; Alam, M.M.; Meyer, J.P.; Al-Hadhrami, L.M. Feasibility study of a wind–pv–diesel hybrid power system for a village. Renew. Energy 2012, 38, 258–268. [Google Scholar] [CrossRef] [Green Version]

- Sawle, Y.; Gupta, S.C.; Bohre, A.K. Review of hybrid renewable energy systems with comparative analysis of off-grid hybrid system. Renew. Sustain. Energy Rev. 2018, 81, 2217–2235. [Google Scholar] [CrossRef]

- Kharel, S.; Shabani, B. Hydrogen as a Long-Term Large-Scale Energy Storage Solution to Support Renewables. Energies 2018, 11, 2825. [Google Scholar] [CrossRef] [Green Version]

- Saba, S.M.; Müller, M.; Robinius, M.; Stolten, D. The investment costs of electrolysis—A comparison of cost studies from the past 30 years. Int. J. Hydrog. Energy 2018, 43, 1209–1223. [Google Scholar] [CrossRef]

- Li, Y.; Shahidehpour, M.; Liu, W.; Wen, F.; Wang, K.; Huang, Y. Optimal Operation Strategy for Integrated Power-to-Gas and Natural Gas Generating Unit Facilities. IEEE Trans. Sustain. Energy 2018, 9, 1870–1879. [Google Scholar] [CrossRef]

- Valverde, L.; Pino, F.J.; Guerra, J.; Rosa, F. Definition, analysis and experimental investigation of operation modes in hydrogen-renewable-based power plants incorporating hybrid energy storage. Energy Convers. Manag. 2016, 113, 290–311. [Google Scholar] [CrossRef]

- US Department of Energy. Pathways to Commercial Success; Pacific Northwest National Laboratory, Fuel Cell Technologies Office, US Department of Energy: Richland, WA, USA, 2016.

- Ren, J.; Ren, X. Sustainability ranking of energy storage technologies under uncertainties. J. Clean. Prod. 2018, 170, 1387–1398. [Google Scholar] [CrossRef]

- Walker, S.B.; van Lanen, D.; Fowler, M.; Mukherjee, U. Economic analysis with respect to Power-to-Gas energy storage with consideration of various market mechanisms. Int. J. Hydrog. Energy 2016, 41, 7754–7765. [Google Scholar] [CrossRef]

- Walker, S.B.; Mukherjee, U.; Fowler, M.; Elkamel, A. Benchmarking and selection of Power-to-Gas utilizing electrolytic hydrogen as an energy storage alternative. Int. J. Hydrog. Energy 2016, 41, 7717–7731. [Google Scholar] [CrossRef]

- Malalasekera, W.; Ibrahim, S.; Liu, B.; Uyanwaththa, A. A Numerical Study of Dust Explosion Properties of Hydrogen Storage Alloy Materials. In Proceedings of the 2018 2nd International Conference on Green Energy and Applications (ICGEA), Singapore, 24–26 March 2018; pp. 124–128. [Google Scholar]

- Uyar, T.S.; Beşikci, D. Integration of hydrogen energy systems into renewable energy systems for better design of 100% renewable energy communities. Int. J. Hydrog. Energy 2017, 42, 2453–2456. [Google Scholar] [CrossRef]

- Gutiérrez-Martín, F.; Rodríguez-Antón, L.M. Power-to-SNG technology for energy storage at large scales. Int. J. Hydrog. Energy 2016, 41, 19290–19303. [Google Scholar] [CrossRef]

- Białobrzeski, A.; Pezda, J.; Jarco, A. Modification of Aluminium-Silicon Near-Eutectic Alloy with Use of Electrolysis of Sodium Salt. Arch. Metall. Mater. 2017, 62, 2371. [Google Scholar] [CrossRef] [Green Version]

- Kharlamova, T.A.; Aliev, Z.M. Use of electrolysis under pressure for destructive oxidation of phenol and azo dyes. Russ. J. Electrochem. 2016, 52, 251–259. [Google Scholar] [CrossRef]

- Endrődi, B.; Simic, N.; Wildlock, M.; Cornell, A. A review of chromium(VI) use in chlorate electrolysis: Functions, challenges and suggested alternatives. Electrochim. Acta 2017, 234, 108–122. [Google Scholar] [CrossRef]

- Vo, T.T.Q.; Wall, D.M.; Ring, D.; Rajendran, K.; Murphy, J.D. Techno-economic analysis of biogas upgrading via amine scrubber, carbon capture and ex-situ methanation. Appl. Energy 2018, 212, 1191–1202. [Google Scholar] [CrossRef]

- Ruuskanen, V.; Koponen, J.; Huoman, K.; Kosonen, A.; Niemelä, M.; Ahola, J. PEM water electrolyzer model for a power-hardware-in-loop simulator. Int. J. Hydrog. Energy 2017, 42, 10775–10784. [Google Scholar] [CrossRef]

- Eichman, K.H.J.; Peters, M. Novel Electrolyzer Applications: Providing More than Just Hydrogen; National Renewable Energy Laboratory: Golden, CO, USA, 2014. [Google Scholar]

- Simonis, B.; Newborough, M. Sizing and operating power-to-gas systems to absorb excess renewable electricity. Int. J. Hydrog. Energy 2017, 42, 21635–21647. [Google Scholar] [CrossRef]

- O’Shea, R.; Wall, D.M.; McDonagh, S.; Murphy, J.D. The potential of power to gas to provide green gas utilising existing CO2 sources from industries, distilleries and wastewater treatment facilities. Renew. Energy 2017, 114, 1090–1100. [Google Scholar] [CrossRef]

- Bailera, M.; Kezibri, N.; Romeo, L.M.; Espatolero, S.; Lisbona, P.; Bouallou, C. Future applications of hydrogen production and CO2 utilization for energy storage: Hybrid Power to Gas-Oxycombustion power plants. Int. J. Hydrog. Energy 2017, 42, 13625–13632. [Google Scholar] [CrossRef] [Green Version]

- Boudellal, M. Power-To-Gas: Renewable Hydrogen Economy; De Gruyter, Inc.: Berlin/Boston, Germany, 2018. [Google Scholar]

- Mulder, M.; Perey, P.; Moraga, J.L. Outlook for a Dutch Hydrogen Market: Economic Conditions and Scenarios; Centre for Energy Economics Research, University of Groningen: Groningen, The Netherlands, 2019. [Google Scholar]

- Sankir, M.; Sankir, N.D. (Eds.) Hydrogen Storage Technologies; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2018. [Google Scholar]

- Sherif, S.A.; Barbir, F.; Veziroglu, T.N. Wind energy and the hydrogen economy—Review of the technology. Sol. Energy 2005, 78, 647–660. [Google Scholar] [CrossRef]

- Social Ventures Australia (SVA). Investing in Very Remote Aboriginal Communities SVA Consulting, Pilbara, WA, Australia. 2018. Available online: https://www.socialventures.com.au/assets/Investing-in-Very-Remote-Aboriginal-Communities-A-cost-benefit-analysis-SVA-Report.pdf (accessed on 25 November 2019).

- NASA Global Data. NASA Surface Meteorology and Solar Energy. Available online: https://data.nasa.gov/Earth-Science/Prediction-Of-Worldwide-Energy-Resources-POWER-/wn3p-qsan/data (accessed on 28 November 2019).

- Homer Energy, Homer Pro 3.11. Available online: https://www.homerenergy.com/products/pro/docs/3.11/hydrogen_load.html (accessed on 28 November 2019).

- Tummuru, N.R.; Manandhar, U.; Ukil, A.; Gooi, H.B.; Kollimalla, S.K.; Naidu, S. Control strategy for AC-DC microgrid with hybrid energy storage under different operating modes. Int. J. Electr. Power Energy Syst. 2019, 104, 807–816. [Google Scholar] [CrossRef]

- Nel, Nel Hydrogen Electrolysers. NASA, ed. 2019. Available online: https://nelhydrogen.com/products/ (accessed on 1 December 2019).

- National Renewable Energy Laboratory (NREL). Current State-of-the-Art Hydrogen Production Cost Estimate Using Water Electrolysis, Colorado, USA. 2009. Available online: http://www.osti.gov/bridge (accessed on 30 November 2019).

- Schmidt, O.; Gambhir, A.; Staffell, I.; Hawkes, A.; Nelson, J.; Few, S. Future cost and performance of water electrolysis: An expert elicitation study. Int. J. Hydrog. Energy 2017, 42, 30470–30492. [Google Scholar] [CrossRef]

| Results/Scenarios | Base Case Scenario (BCS) | S1 | S2 | S3 | |

|---|---|---|---|---|---|

| Optimised Solar PV—direct electric current (DC) Bus (kW) | X | 1708 | 1047 | 953 | |

| System Component | DG1 Capacity(kW) | 200 | X | X | X |

| DG2 Capacity (kW) | 200 | X | X | X | |

| Li-ion Battery Capacity (kWh) | X | 1700 | X | 300 | |

| Fuel Cell (FC) Capacity (kW) | X | X | 200 | 100 | |

| Electrolyser Capacity (kW) | X | X | 250 | 250 | |

| H2 Tank Capacity (kg) | X | X | 300 | 200 | |

| Converter Capacity (kW) | X | 200 | 200 | 200 | |

| Economics | Net Present Cost (NPC) (millions of $) | 6.27 | 3.74 | 4.47 | 3.23 |

| Simple Payback Vs BCS (yr) | BCS | 6.26 | 6.7 | 4.94 | |

| Discounted Payback Vs BCS (yr) | BCS | 7.91 | 8.39 | 6.01 | |

| Cost of Energy (COE) (lifetime of 25 years) ($) | 0.665 | 0.394 | 0.474 | 0.342 | |

| Capital Costs (CAPEX) (millions of $) | 0.20 | 2.96 | 2.53 | 2.30 | |

| Operational Costs (OPEX) ($/yr) | 469,741 | 58,841 | 149,880 | 72,032 | |

| RE | Renewable Energy (RE) Frac (%) | 0.0 | 100.0 | 100.0 | 100.0 |

| System Cap. Short (%) | 0.00 | 0.099 | 0.045 | 0.052 | |

| Excess Elec (%) | 5 | 74.9 | 35.2 | 33 | |

| Excess Elec (kWh/yr) | 39,000 | 2,394,702 | 803,313 | 696,087 | |

| DG 1 | DG1 Operating (hours/yr) | 8760 | X | X | X |

| DG1 Fuel | 231,186 | X | X | X | |

| DG1 O&M Cost ($/yr) | 262.8 | X | X | X | |

| DG1 Fuel Cost ($/yr) | 462,373 | X | X | X | |

| Hydrogen | FC Operating (hours/yr) | X | X | 8757 | 4282 |

| FC Prod. (kWh/yr) | X | X | 322,991 | 325,479 | |

| FC H2 Fuel (kg/yr) | X | X | 14,200 | 12,839 | |

| FC O&M Cost ($/yr) | X | X | 35,028 | 8564 | |

| H2 Tank Autonomy (kg) | X | X | 277 | 177 | |

| H2 Tank Autonomy (1) (hr) | X | X | 120 | 80 | |

| Battery | Battery Autonomy (hr) | X | 16.3 | X | 2.88 |

| Battery Nominal Capacity (kWh) | X | 1700 | X | 300 | |

| Battery Usable Capacity (kWh) | X | 1360 | X | 240 | |

| GHGs | Emissions CO2 kg /yr | 610,004 | 0 | 0 | 0 |

| Emissions NOx /yr | 6066 | 0 | 0 | 0 | |

| Emissions SO2 kg /yr | 1517 | 0 | 0 | 0 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dawood, F.; Shafiullah, G.; Anda, M. Stand-Alone Microgrid with 100% Renewable Energy: A Case Study with Hybrid Solar PV-Battery-Hydrogen. Sustainability 2020, 12, 2047. https://doi.org/10.3390/su12052047

Dawood F, Shafiullah G, Anda M. Stand-Alone Microgrid with 100% Renewable Energy: A Case Study with Hybrid Solar PV-Battery-Hydrogen. Sustainability. 2020; 12(5):2047. https://doi.org/10.3390/su12052047

Chicago/Turabian StyleDawood, Furat, GM Shafiullah, and Martin Anda. 2020. "Stand-Alone Microgrid with 100% Renewable Energy: A Case Study with Hybrid Solar PV-Battery-Hydrogen" Sustainability 12, no. 5: 2047. https://doi.org/10.3390/su12052047