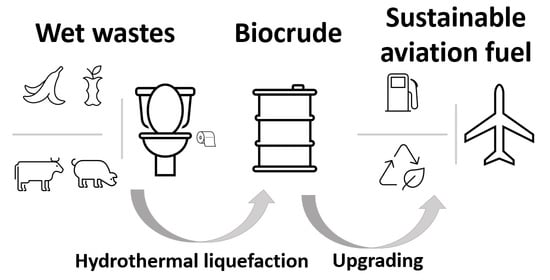

Sustainable Aviation Fuel from Hydrothermal Liquefaction of Wet Wastes

Abstract

:1. Introduction

2. Materials and Methods

2.1. WWHTLB Preparation

2.2. Hydrotreating and Distillation

2.3. Elemental Analysis

2.4. Heat of Combustion (HOC) Determination

2.5. Two-Dimensional Gas-Chromatography Mass-Spectrometry (2D-GC-MS) Analysis

2.6. Simulated Distillation (SIMDIS) Analysis

3. Results and Discussion

3.1. Analysis of WWHTLB

3.2. Production and Analysis of Upgraded WWHTLB

3.3. Jet Fuel Cut of Upgraded WWHTLB

3.4. Tier α and β Testing of Jet Fuel Cut of Upgraded Wet-Waste HTL Biocrude

3.5. 2D-GC-MS Analysis of the HDN Efficacy of WWHTLB Upgrading

3.6. Carbon Balance, Hydrocracking, and Its Impact on SAF Potential from WWHTLB

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

References

- Ramasamy, K.K.; Thorson, M.R.; Billing, J.M.; Holladay, J.E.; Drennan, C.; Hoffman, B.; Haq, Z. Hydrothermal Liquefaction: Path to Sustainable Aviation Fuel; Pacific Northwest National Lab. (PNNL): Richland, WA, USA, 2021. [Google Scholar]

- Heyne, J.; Rauch, B.; Le Clercq, P.; Colket, M. Sustainable aviation fuel prescreening tools and procedures. Fuel 2021, 290, 120004. [Google Scholar] [CrossRef]

- Kramer, S.; Andac, G.; Heyne, J.; Ellsworth, J.; Herzig, P.; Lewis, K.C. Perspectives on fully synthesized sustainable aviation fuels: Direction and opportunities. Front. Energy Res. 2022, 1040. [Google Scholar] [CrossRef]

- Dimitriadis, A.; Bezergianni, S. Hydrothermal liquefaction of various biomass and waste feedstocks for biocrude production: A state of the art review. Renew. Sustain. Energy Rev. 2017, 68, 113–125. [Google Scholar] [CrossRef]

- Marrone, P.A.; Elliott, D.C.; Billing, J.M.; Hallen, R.T.; Hart, T.R.; Kadota, P.; Moeller, J.C.; Randel, M.A.; Schmidt, A.J. Bench-Scale Evaluation of Hydrothermal Processing Technology for Conversion of Wastewater Solids to Fuels: Marrone et al. Water Environ. Res. 2018, 90, 329–342. [Google Scholar] [CrossRef] [PubMed]

- Gollakota, A.R.K.; Kishore, N.; Gu, S. A review on hydrothermal liquefaction of biomass. Renew. Sustain. Energy Rev. 2018, 81, 1378–1392. [Google Scholar] [CrossRef]

- Hu, Y.; Gong, M.; Feng, S.; Xu, C.C.; Bassi, A. A review of recent developments of pre-treatment technologies and hydrothermal liquefaction of microalgae for bio-crude oil production. Renew. Sustain. Energy Rev. 2019, 101, 476–492. [Google Scholar] [CrossRef]

- Yang, C.; Wang, S.; Yang, J.; Xu, D.; Li, Y.; Li, J.; Zhang, Y. Hydrothermal liquefaction and gasification of biomass and model compounds: A review. Green Chem. 2020, 22, 8210–8232. [Google Scholar] [CrossRef]

- Snowden-Swan, L.J.; Billing, J.M.; Thorson, M.R.; Schmidt, A.J.; Jiang, Y.; Santosa, D.M.; Seiple, T.E.; Daniel, R.C.; Burns, C.A.M.; Li, S. Wet Waste Hydrothermal Liquefaction and Biocrude Upgrading to Hydrocarbon Fuels: 2020 State of Technology; Pacific Northwest National Lab. (PNNL): Richland, WA, USA, 2021. [Google Scholar]

- Seiple, T.E.; Coleman, A.M.; Skaggs, R.L. Municipal wastewater sludge as a sustainable bioresource in the United States. J. Environ. Manag. 2017, 197, 673–680. [Google Scholar] [CrossRef] [PubMed]

- Seiple, T.E.; Skaggs, R.L.; Fillmore, L.; Coleman, A.M. Municipal wastewater sludge as a renewable, cost-effective feedstock for transportation biofuels using hydrothermal liquefaction. J. Environ. Manag. 2020, 270, 110852. [Google Scholar] [CrossRef] [PubMed]

- Cronin, D.; Schmidt, A.J.; Billing, J.; Hart, T.R.; Fox, S.P.; Fonoll, X.; Norton, J.; Thorson, M.R. Comparative Study on the Continuous Flow Hydrothermal Liquefaction of Various Wet-Waste Feedstock Types. ACS Sustain. Chem. Eng. 2021, 10, 1255–1256. [Google Scholar] [CrossRef]

- Vardon, D.R.; Sharma, B.; Scott, J.; Yu, G.; Wang, Z.; Schideman, L.; Zhang, Y.; Strathmann, T.J. Chemical properties of biocrude oil from the hydrothermal liquefaction of Spirulina algae, swine manure, and digested anaerobic sludge. Bioresour. Technol. 2011, 102, 8295–8303. [Google Scholar] [CrossRef]

- Haider, M.S.; Castello, D.; Michalski, K.M.; Pedersen, T.H.; Rosendahl, L.A. Catalytic Hydrotreatment of Microalgae Biocrude from Continuous Hydrothermal Liquefaction: Heteroatom Removal and Their Distribution in Distillation Cuts. Energies 2018, 11, 3360. [Google Scholar] [CrossRef] [Green Version]

- Haarlemmer, G.; Guizani, C.; Anouti, S.; Déniel, M.; Roubaud, A.; Valin, S. Analysis and comparison of bio-oils obtained by hydrothermal liquefaction and fast pyrolysis of beech wood. Fuel 2016, 174, 180–188. [Google Scholar] [CrossRef]

- Biller, P.; Sharma, B.K.; Kunwar, B.; Ross, A.B. Hydroprocessing of bio-crude from continuous hydrothermal liquefaction of microalgae. Fuel 2015, 159, 197–205. [Google Scholar] [CrossRef] [Green Version]

- López Barreiro, D.; Gómez, B.R.; Ronsse, F.; Hornung, U.; Kruse, A.; Prins, W. Heterogeneous catalytic upgrading of biocrude oil produced by hydrothermal liquefaction of microalgae: State of the art and own experiments. Fuel Processing Technol. 2016, 148, 117–127. [Google Scholar] [CrossRef]

- Yu, J.; Biller, P.; Mamahkel, A.; Klemmer, M.; Becker, J.; Glasius, M.; Iversen, B.B. Catalytic hydrotreatment of bio-crude produced from the hydrothermal liquefaction of aspen wood: A catalyst screening and parameter optimization study. Sustain. Energy Fuels 2017, 1, 832–841. [Google Scholar] [CrossRef] [Green Version]

- Castello, D.; Haider, M.S.; Rosendahl, L.A. Catalytic upgrading of hydrothermal liquefaction biocrudes: Different challenges for different feedstocks. Renew. Energy 2019, 141, 420–430. [Google Scholar] [CrossRef] [Green Version]

- Subramaniam, S.; Santosa, D.M.; Brady, C.; Swita, M.; Ramasamy, K.K.; Thorson, M.R. Extended Catalyst Lifetime Testing for HTL Biocrude Hydrotreating to Produce Fuel Blendstocks from Wet Wastes. ACS Sustain. Chem. Eng. 2021, 9, 12825–12832. [Google Scholar] [CrossRef]

- Thorson, M.R.; Santosa, D.M.; Hallen, R.T.; Kutnyakov, I.; Olarte, M.V.; Flake, M.; Neuenschwander, G.; Middleton-Smith, L.; Zacher, A.H.; Hart, T.R.; et al. Scaleable Hydrotreating of HTL Biocrude to Produce Fuel Blendstocks. Energy Fuels 2021, 35, 11346–11352. [Google Scholar] [CrossRef]

- IEA. Data and Statistics. 2020. Available online: https://www.iea.org/data-and-statistics (accessed on 28 November 2021).

- Capaz, R.S.; Guida, E.; Seabra, J.E.A.; Osseweijer, P.; Posada, J.A. Mitigating carbon emissions through sustainable aviation fuels: Costs and potential. Biofuels Bioprod. Biorefining 2021, 15, 502–524. [Google Scholar] [CrossRef]

- (IRENA), I.R.E.A. Biofuels for Aviation: Technology Brief. 2017. Available online: https://www.irena.org/publications/2017/Feb/Biofuels-for-aviation-Technology-brief (accessed on 28 November 2021).

- ASTM D7566-15c; Standard Specification for Aviation Turbine Fuel Containing Synthesized Hydrocarbons; ASTM: West Conshohocken, PA, USA, 2015. [CrossRef]

- BETO. Sustainable Aviation Fuel: Review of Technical Pathways Report; BETO: Washington, DC, USA, 2020. [Google Scholar]

- Heyne, J.; Bell, D.; Feldhausen, J.; Yang, Z.; Boehm, R. Towards fuel composition and properties from Two-dimensional gas chromatography with flame ionization and vacuum ultraviolet spectroscopy. Fuel 2022, 312, 122709. [Google Scholar] [CrossRef]

- Yang, Z.; Kosir, S.; Stachler, R.; Shafer, L.; Anderson, C.; Heyne, J.S. A GC × GC Tier α combustor operability prescreening method for sustainable aviation fuel candidates. Fuel 2021, 292, 120345. [Google Scholar] [CrossRef]

- ASTM D4054-14; Standard Practice for Qualification and Approval of New Aviation Turbine Fuels and Fuel Additives; ASTM: West Conshohocken, PA, USA, 2014. [CrossRef]

- Rumizen, M.A. Qualification of Alternative Jet Fuels. Front. Energy Res. 2021, 9, 676. [Google Scholar] [CrossRef]

- Xu, D.; Lin, G.; Guo, S.; Wang, S.; Guo, Y.; Jing, Z. Catalytic hydrothermal liquefaction of algae and upgrading of biocrude: A critical review. Renew. Sustain. Energy Rev. 2018, 97, 103–118. [Google Scholar] [CrossRef]

- Ou, L.; Li, S.; Tao, L.; Phillips, S.; Hawkins, T.; Singh, A.; Snowden-Swan, L.; Cai, H. Techno-economic Analysis and Life-Cycle Analysis of Renewable Diesel Fuels Produced with Waste Feedstocks. ACS Sustain. Chem. Eng. 2022, 10, 382–393. [Google Scholar] [CrossRef]

- Shen, R.; Lu, J.; Yao, Z.; Zhao, L.; Wu, Y. The hydrochar activation and biocrude upgrading from hydrothermal treatment of lignocellulosic biomass. Bioresour. Technol. 2021, 342, 125914. [Google Scholar] [CrossRef] [PubMed]

- Fraga, G.; Batalha, N.; Kumar, A.; Bhaskar, T.; Konarova, M.; Perkins, G. Chapter 5—Advances in liquefaction for the production of hydrocarbon biofuels. In Hydrocarbon Biorefinery; Maity, S.K., Gayen, K., Bhowmick, T.K., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 127–176. [Google Scholar] [CrossRef]

- Anabtawi, J.A.; Ali, S.A.; Ali, M.A. Impact of gasoline and diesel specifications on the refining industry. Energy Sour. 1996, 18, 203–214. [Google Scholar] [CrossRef]

- Gibbs, L.M. Gasoline specifications, regulations, and properties. Automot. Eng. 1996, 104, 10–35. [Google Scholar]

- Elliott, D.C.; Hart, T.R.; Schmidt, A.J.; Neuenschwander, G.G.; Rotness, L.J.; Olarte, M.V.; Zacher, A.H.; Albrecht, K.O.; Hallen, R.T.; Holladay, J.E. Process development for hydrothermal liquefaction of algae feedstocks in a continuous-flow reactor. Algal Res. 2013, 2, 445–454. [Google Scholar] [CrossRef] [Green Version]

- Snowden-Swan, L.J.; Zhu, Y.; Jones, S.B.; Elliott, D.C.; Schmidt, A.J.; Hallen, R.T.; Billing, J.M.; Hart, T.R.; Fox, S.P.; Maupin, G.D. Hydrothermal Liquefaction and Upgrading of Municipal Wastewater Treatment Plant Sludge: A Preliminary Techno-Economic Analysis, Rev.1; Pacific Northwest National Lab. (PNNL): Richland, WA, 2016; 40p. [Google Scholar]

- Elliott, D.C.; Wang, H.; French, R.; Deutch, S.; Iisa, K. Hydrocarbon Liquid Production from Biomass via Hot-Vapor-Filtered Fast Pyrolysis and Catalytic Hydroprocessing of the Bio-oil. Energy Fuels 2014, 28, 5909–5917. [Google Scholar] [CrossRef]

- Zacher, A.H.; Elliott, D.C.; Olarte, M.V.; Wang, H.; Jones, S.B.; Meyer, P.A. Technology advancements in hydroprocessing of bio-oils. Biomass Bioenergy 2019, 125, 151–168. [Google Scholar] [CrossRef]

- Wang, H.; Lee, S.-J.; Olarte, M.V.; Zacher, A.H. Bio-oil Stabilization by Hydrogenation over Reduced Metal Catalysts at Low Temperatures. ACS Sustain. Chem. Eng. 2016, 4, 5533–5545. [Google Scholar] [CrossRef]

- Jarvis, J.M.; Albrecht, K.O.; Billing, J.M.; Schmidt, A.J.; Hallen, R.T.; Schaub, T.M. Assessment of Hydrotreatment for Hydrothermal Liquefaction Biocrudes from Sewage Sludge, Microalgae, and Pine Feedstocks. Energy Fuels 2018, 32, 8483–8493. [Google Scholar] [CrossRef]

- Elliott, D.C. Historical Developments in Hydroprocessing Bio-oils. Energy Fuels 2007, 21, 1792–1815. [Google Scholar] [CrossRef]

- Channiwala, S.A.; Parikh, P.P. A unified correlation for estimating HHV of solid, liquid and gaseous fuels. Fuel 2002, 81, 1051–1063. [Google Scholar] [CrossRef]

- Speight, J.G. The Chemistry and Technology of Petroleum; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Jarvis, J.M.; Billing, J.M.; Hallen, R.T.; Schmidt, A.J.; Schaub, T.M. Hydrothermal Liquefaction Biocrude Compositions Compared to Petroleum Crude and Shale Oil. Energy Fuels 2017, 31, 2896–2906. [Google Scholar] [CrossRef]

- Association, W.N. Heat Values of Various Fuels. 1999. Available online: https://world-nuclear.org/information-library/facts-and-figures/heat-values-of-various-fuels.aspx (accessed on 6 December 2021).

- Elliott, D.C.; Schmidt, A.J.; Hart, T.R.; Billing, J.M. Conversion of a wet waste feedstock to biocrude by hydrothermal processing in a continuous-flow reactor: Grape pomace. Biomass Convers. Biorefinery 2017, 7, 455–465. [Google Scholar] [CrossRef]

- Olarte, M.V.; Padmaperuma, A.B.; Ferrell, J.R., III; Christensen, E.D.; Hallen, R.T.; Lucke, R.B.; Burton, S.D.; Lemmon, T.L.; Swita, M.S.; Fioroni, G. Characterization of upgraded fast pyrolysis oak oil distillate fractions from sulfided and non-sulfided catalytic hydrotreating. Fuel 2017, 202, 620–630. [Google Scholar] [CrossRef]

- Hadaller, O.; Johnson, J. World Fuel Sampling Program; Coordinating Research Council (CRC): Alpharetta, GA, USA, 2006. [Google Scholar]

- Boehm, R.C.; Yang, Z.; Bell, D.C.; Feldhausen, J.; Heyne, J.S. Lower heating value of jet fuel from hydrocarbon class concentration data and thermo-chemical reference data: An uncertainty quantification. Fuel 2021, 311, 122542. [Google Scholar] [CrossRef]

- Lewis, C.; Clark, A. CRC Report AV-29-20. A Review of Current Experimental and Correlation Methods to Determine the Calorific Energy Content of Liquid Fuels; Coordinating Research Council (CRC): Alpharetta, GA, USA, 2021. [Google Scholar]

- Colket, M.; Heyne, J.; Rumizen, M.; Gupta, M.; Edwards, T.; Roquemore, W.M.; Andac, G.; Boehm, R.; Lovett, J.; Williams, R. Overview of the national jet fuels combustion program. AiAA J. 2017, 55, 1087–1104. [Google Scholar] [CrossRef]

- Edwards, J.T. Reference jet fuels for combustion testing. In Proceedings of the 55th AIAA Aerospace Sciences Meeting, Grapevine, TX, USA, 9–13 January 2017; p. 0146. [Google Scholar]

- Manchester, U.K. Trace Nitrogen Contents in Different Types of Diesel; Azo Materials, 2020. Available online: https://www.azom.com/article.aspx?ArticleID=19657 (accessed on 6 December 2021).

- Olivares, J. National Alliance for Advanced Biofuels and Bioproducts Synopsis (NAABB) Final Report; US DOE-EERE Biotechnologies Office: EERE Publication and Product Library: Washington, DC, USA, 2014. [Google Scholar]

- Costanzo, W.; Hilten, R.; Jena, U.; Das, K.C.; Kastner, J.R. Effect of low temperature hydrothermal liquefaction on catalytic hydrodenitrogenation of algae biocrude and model macromolecules. Algal Res. 2016, 13, 53–68. [Google Scholar] [CrossRef] [Green Version]

- Huybrechts, W.; Vanbutsele, G.; Houthoofd, K.J.; Bertinchamps, F.; Narasimhan, L.; Gaigneaux, E.M.; Thybaut, J.W.; Marin, G.B.; Denayer, J.F.; Baron, G. Skeletal isomerization of octadecane on bifunctional ZSM-23 zeolite catalyst. Catal. Lett. 2005, 100, 235–242. [Google Scholar] [CrossRef]

- Brandvold, T.A.; McCall, M.J. Production of Blended Gasoline and Blended Aviation Fuel from Renewable Feedstocks. U.S. Patent 8,324,438, 4 April 2012. [Google Scholar]

- Mäki-Arvela, P.; Azkaar, M.; Engblom, S.; Murzin, D.Y. Catalytic hydroisomerization of long-chain hydrocarbons for the production of fuels. Catalysts 2018, 8, 534. [Google Scholar] [CrossRef] [Green Version]

| Run | Feed Type | Feed Origin |

|---|---|---|

| FW1 | Food waste | Food waste from Ghost Warrior and Courage Inn Restaurants from the United States Air Force Joint Base Lewis–McChord airbase (Washington) |

| FW2 | Food waste | Food waste from Waste Management, Engineered BioSlurry (Boston) |

| S1 | Sewage sludge | A 2:1 mixture of primary and secondary sludge from the Great Lakes Water Authority (Michigan) |

| S2 | Sewage sludge | An equal-parts mixture of primary and secondary sludge from the Great Lakes Water Authority (Michigan) |

| SFOG | Sewage sludge and FOG blend | 80% sludge and 20% FOG (fats, oils, and grease) blend from Contra Costa Central Sanitary District (California) |

| Biocrude Sample | Content of HTL Feed Material Used to Produce Biocrude (wt.%) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Solids | Ash | C | H | N | O | S | Heteroatoms | Carbohydrates | Fat | Fatty Acids | Protein | |

| FW1 | 25.7 | 1.1 | 13.2 | 10.2 | 0.85 | 74.9 | 0.06 | 75.8 | 13.6 | 5.1 | 4.1 | 5.3 |

| FW2 | 18.7 | 1.6 | 9.5 | 10.3 | 0.59 | 78.3 | 0.05 | 78.9 | 7.7 | 5.2 | 4.0 | 4.3 |

| S1 and S2 | 20.9 | 5.6 | 8.8 | 10.1 | 0.88 | 79.9 | 0.21 | 80.9 | 2.8 | 5.4 | 2.5 | 7.1 |

| SFOG | 16.8 | 2.9 | 8.3 | 10.4 | 0.53 | 78.1 | 0.08 | 78.7 | 7.7 | 2.2 | 4.3 | 3.5 |

| Biocrude Sample | C Content (wt.%) | H Content (wt.%) | O Content (wt.%) | N Content (wt.%) | S Content (wt.%) | Approximate Heteroatom Content (wt.%) | HOC (MJ.kg−1) |

|---|---|---|---|---|---|---|---|

| PC | 83–87 | 10–14 | 0.05–1.5 | 0.1–2.0 | 0.05–6.0 | <7 | 42–47 [47] |

| FW1 | 73.41 | 10.24 | 9.15 | 5.57 | 0.38 | 15.10 | 36.7 |

| FW2 | 75.30 | 10.08 | 10.68 | 3.62 | 0.11 | 14.41 | 37.0 |

| S1 | 75.34 | 9.92 | 10.52 | 4.38 | 0.11 | 15.01 | 36.8 |

| S2 | 75.79 | 9.98 | 8.19 | 4.69 | 0.64 | 13.52 | 37.4 |

| SFOG | 70.36 | 10.39 | 13.28 | 3.79 | 0.63 | 17.70 | 35.4 |

| Sample Code | C | H | O | N | S | Heteroatoms | HOC | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Content (wt.%) | Change (%) | Content (wt.%) | Change (%) | Content (wt.%) | Change (%) | Content (wt.%) | Change (%) | Content (wt.%) | Change (%) | Content (wt.%) | Change (%) | Value (MJ.kg−1) | Change (%) | |

| Co-Mo:FW2 (a) | 84.10 | 11.7 | 14.07 | 39.5 | 0.79 | −92.6 | 1.34 | −63.0 | 0.02 | −84.3 | 2.15 | −85.1 | 45.8 | 23.8 |

| Co-Mo:FW2 (JFC) | 84.95 | 12.8 | 14.50 | 43.9 | 0.22 | −98.2 | 0.81 | −77.9 | 0.02 | −81.5 | 1.01 | −93.0 | 46.7 | 26.2 |

| NiMo:FW1 (a) | 84.25 | 14.8 | 13.70 | 33.7 | 0.51 | −89.2 | 0.96 | −82.8 | 0.03 | −91.5 | 1.98 | −86.9 | 45.4 | 23.8 |

| NiMo:FW1 (b) | 84.63 | 15.3 | 13.81 | 34.8 | 0.65 | −92.9 | 1.07 | −80.8 | 0.02 | −96.0 | 1.73 | −88.5 | 45.7 | 24.6 |

| NiMo:S1 (a) | 84.66 | 12.4 | 14.31 | 44.3 | 0.29 | −97.3 | 0.64 | −85.4 | 0.04 | −69.0 | 0.96 | −93.6 | 46.4 | 25.9 |

| NiMo:S1 (b) | 85.10 | 13.0 | 14.34 | 44.7 | 1.40 | −86.7 | 0.71 | −83.8 | 0.03 | −77.9 | 2.13 | −85.8 | 46.5 | 26.1 |

| NiMo:S1 (c) | 85.42 | 13.4 | 14.13 | 42.5 | 0.24 | −97.7 | 0.88 | −80.0 | 0.02 | −82.3 | 1.35 | −92.5 | 46.5 | 26.0 |

| Ni-Mo:S1 (d) | 85.09 | 15.9 | 14.25 | 39.1 | 0.26 | −97.2 | 0.75 | −86.5 | 0.03 | −92.6 | 1.03 | −93.2 | 46.5 | 26.6 |

| NiMo:S1 (JFC) | 84.63 | 12.3 | 14.01 | 41.3 | 0.32 | −97.0 | 1.10 | −74.9 | 0.03 | −72.6 | 1.45 | −90.3 | 46.0 | 24.9 |

| Ni-Mo:S2 | 84.29 | 11.2 | 14.16 | 41.9 | 0.46 | −94.4 | 0.96 | −79.5 | 0.03 | −94.7 | 1.45 | −89.3 | 46.1 | 23.3 |

| Ni-Mo:SFOG | 85.33 | 21.3 | 14.59 | 40.4 | 0.09 | −99.3 | 0.49 | −87.1 | 0.04 | −93.7 | 0.96 | −96.5 | 47.0 | 32.5 |

| Sample Code | C | H | O | N | S | Heteroatoms | HOC | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Content (wt.%) | Change (%) | Content (wt.%) | Change (%) | Content (wt.%) | Change (%) | Content (wt.%) | Change (%) | Content (wt.%) | Change (%) | Content (wt.%) | Change (%) | Value (MJ.kg−1) | Change (%) | |

| CoMo catalyst | 84.53 ± 0.43 | 12.3 ± 0.6 | 14.29 ± 0.22 | 41.7 ± 2.2 | 0.51 ± 0.29 | −95.4 ± 2.8 | 1.08 ± 0.27 | −70.5 ± 7.4 | 0.02 ± 0.00 | −82.9 ± 1.4 | 1.58 ± 0.57 | −89.1 ± 4.0 | 46.3 ± 0.5 | 25.0 ± 1.2 |

| NiMo catalyst | 84.82 ± 0.40 | 14.4 ± 2.8 | 14.14 ± 0.26 | 40.3 ± 3.6 | 0.47 ± 0.36 | −94.6 ± 4.0 | 0.84 ± 0.19 | −82.3 ± 3.7 | 0.03 ± 0.01 | −85.6 ± 9.7 | 1.45 ± 0.41 | −90.7 ± 3.3 | 46.2 ± 0.5 | 26.0 ± 2.5 |

| Food waste feed | 84.48 ± 0.33 | 13.7 ± 1.5 | 14.02 ± 0.31 | 38.0 ± 4.1 | 0.54 ± 0.21 | −93.2 ± 3.2 | 1.05 ± 0.19 | −76.1 ± 7.8 | 0.02 ± 0.00 | −88.3 ± 5.7 | 1.72 ± 0.43 | −88.4 ± 2.9 | 45.9 ± 0.5 | 24.6 ± 1.0 |

| Sewage sludge feed | 84.87 ± 0.37 | 13.0 ± 1.5 | 14.20 ± 0.11 | 42.3 ± 1.9 | 0.50 ± 0.41 | −95.1 ± 3.9 | 0.84 ± 0.16 | −81.7 ± 4.0 | 0.03 ± 0.01 | −81.5 ± 9.5 | 1.40 ± 0.38 | −90.8 ± 2.7 | 46.3 ± 0.2 | 25.5 ± 1.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cronin, D.J.; Subramaniam, S.; Brady, C.; Cooper, A.; Yang, Z.; Heyne, J.; Drennan, C.; Ramasamy, K.K.; Thorson, M.R. Sustainable Aviation Fuel from Hydrothermal Liquefaction of Wet Wastes. Energies 2022, 15, 1306. https://doi.org/10.3390/en15041306

Cronin DJ, Subramaniam S, Brady C, Cooper A, Yang Z, Heyne J, Drennan C, Ramasamy KK, Thorson MR. Sustainable Aviation Fuel from Hydrothermal Liquefaction of Wet Wastes. Energies. 2022; 15(4):1306. https://doi.org/10.3390/en15041306

Chicago/Turabian StyleCronin, Dylan J., Senthil Subramaniam, Casper Brady, Alan Cooper, Zhibin Yang, Joshua Heyne, Corinne Drennan, Karthikeyan K. Ramasamy, and Michael R. Thorson. 2022. "Sustainable Aviation Fuel from Hydrothermal Liquefaction of Wet Wastes" Energies 15, no. 4: 1306. https://doi.org/10.3390/en15041306