Enhancement of Heavy-Duty Engines Performance and Reliability Using Cylinder Pressure Information

Abstract

:1. Introduction

- Reduction in costs, energy consumption and emissions;

- Increase in workplace safety; and

- Increase in workplace air quality, especially in underground mining.

- Planned preventive maintenance [21];

- To evaluate significant combustion metrics (MFB50, IMEP, Pmax, etc.) starting from the pressure measurement and to compensate aging effects and disparities in the components behavior by using such metrics as inputs for a feedback control system, thus enhancing engine performance;

- To evaluate the engine health, thus determining the best time for the component substitution. Usually, the engine parts (pistons, injectors, cylinder heads, etc.) are replaced after a priori fixed time, often resulting in unnecessary costs due to the substitution of healthy components [34].

2. Experimental Setup

- Cylinder Pressure Sensors (CPS);

- Combustion Control Unit (CCU);

- Engine Control Unit (ECU, Liebherr H-2D Unit [42]).

- A more efficient calibration of the injection actuations (no need for safety margins at the expense of engine efficiency);

- The sensitivity of the performance to the fuel is minimized;

- The ECU can compensate the performance loss originated by components aging or production disparities.

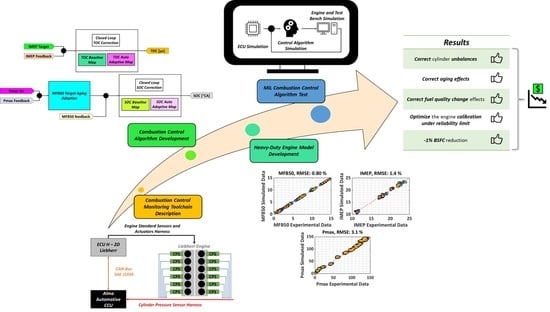

3. Development and Validation of the Controller

3.1. Control Algorithm

- Balancing the cylindrical variation of the indicated torque (so to achieve even cylinders wear, thus maximizing the service period);

- Compensating undesired effects such as the components aging, production disparities and variations in fuel quality.

- IMEP (Indicating Mean Effective Pressure), which is related to engine torque;

- MFB50 (50% of Mass Fraction Burnt), which is strictly related to engine efficiency (BSFC);

- Pmax (peak cylinder pressure), which should not exceed a tolerable threshold, to guarantee the engine reliability.

3.1.1. Definition of TOC

- Constant driver requests (pedal);

- Engine is warmed up;

- Steady-state conditions;

- Absence of faults.

3.1.2. Definition of SOC

3.1.3. Definition of MFB50 Target

- The value of the cylinder MFB50 currently measured is greater than optimum;

- The feedback value of the Pmax is lower than the acceptable limit.

- The “reliability correction state” is defined by the following additional conditions:

- The feedback Pmax value is greater than the acceptable limit;

3.2. Model in the Loop Simulations Approach

- ECU Base Actuations: Base actuations and setpoints are calculated according to the engine speed and pedal request, using lookup tables.

- Combustion Controller: The control strategies described in Section 3 are implemented in this block.

- Engine Model: The engine is represented in terms of combustion metrics flow: the accuracy in representing the main combustion metrics is reported in Table 1. For a realistic data flow representation, cycle-to-cycle variations are statistically described, considering the standard deviation of MFB50. In details, the model can be described by the following equations:

- Minj represents the mass of fuel injected in the cylinder;

- Pmot is the peak pressure inside the cylinder without combustion (motoring pressure);

- Pboost indicates the air pressure after the compressor;

- rc is the volumetric compression ratio; and

- γ is the ratio of the specific heats (constant pressure and the constant volume).

- 4.

- Torque Equilibrium: As already remarked, engine speed is determined solving the torque equilibrium equation:

- Te is the engine torque, which is calculated thanks to the IMEP of the twelve cylinders and the engine friction information, stored in an LUT;

- Tl is the load torque produced by the electric brake;

- Ie represents the engine inertia;

- Il represents the electric motor inertia; and

- ꙍ is the engine speed expressed in rad/s.

- 5.

- Test Bench Electric Brake: The braking torque produced by the electric brake is achieved by means of a PID controller, which is fed with target speed and actual speed.

4. Results and Discussion

- Standard Engine Calibration: It is the reference condition, and the engine control unit uses only the standard calibration, and all the feedback controls are deactivated.

- Only PI Controller: The engine is working using only the PI controller following the MFB50 and IMEP target values.

- PI Controller and Auto Adaptation: The engine is working with the PI and the full auto adaptation strategy (SOC, TOC and MFB50 threshold) activated.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| BMEP | Brake Mean Effective Pressure |

| BSFC | Brake Specific Fuel Consumption |

| CAN | Controller Area Network |

| CCU | Combustion Control Unit |

| COC | Components of Colmar |

| CO2 | Carbon Dioxide |

| CPS | Cylinder Pressure Sensor |

| ECU | Engine Control Unit |

| GHG | Greenhouse Gases |

| Hil | Hardware In the Loop |

| Ie | Engine Inertia |

| Il | Electric Brake Inertia |

| ICE | Internal Combustion Engines |

| IMEP | Indicated Mean Effective Pressure |

| LCCM | Liebherr Combustion Control Monitoring |

| LUT | Lookup Table |

| MFB50 | Crankshaft angle corresponding to 50% of the mass fraction burnt |

| MFB50opt | Optimum value of 50% of the mass fraction burnt |

| MFB50thr | Threshold of 50% of the mass fraction burnt |

| Mil | Model In the Loop |

| Minj | Fuel Injected Mass |

| NOx | Nitrogen Oxides |

| OEM | Original Equipment Manufacturer |

| PI | Proportional Integrative Controller |

| PID | Proportional Integrative Derivative Controller |

| Pboost | Air Pressure after the compressor |

| Pmax | Maximum Peak Pressure reached inside the combustion chamber |

| Pmot | Motoring Pressure |

| RMSE | Root Mean Squared Error |

| Sil | Software in the Loop |

| SCR | Selective Catalyst Reduction |

| SOC | Start of Current |

| SOCFF | Start of Current Feed Forward |

| TCO | Total Cost of Ownership |

| TOC | Time of Current |

| TOCFF | Time of Current Feed Forward |

| Te | Engine Torque |

| Tl | Load Torque |

| rc | Compression Ratio |

| t | Time |

| ∆SOC | Variation of Start of Current |

| ∆SOCcyl# | Variation of Start of Current different from cylinder to cylinder |

| ∆TOC | Variation of Time of Current |

| ∆TOCcyl# | Variation of Time of Current different from cylinder to cylinder |

| γ | Ratio between the specific heat at constant pressure and the specific heat at constant volume |

| ꙍ | Engine Speed in rad/s |

| °CA | Crank Angle Degree |

References

- Monteiro, N.B.R.; da Silva, E.A.; Neto, J.M.M. Sustainable development goals in mining. J. Clean. Prod. 2019, 228, 509–520. [Google Scholar] [CrossRef]

- DieselNet. Emission Standards: Summary of Worldwide Engine and Vehicle Emission Standards. DieselNet. Available online: https://dieselnet.com/standards/ (accessed on 1 May 2021).

- EUR-Lex. Regulation (EU) 2019/1242 of the European Parliament and of the Council of 20 June 2019 Setting CO2 Emission Performance Standards for New Heavy-Duty Vehicles and Amending Regulations (EC) No 595/2009 and (EU) 2018/956 of the European Parliament and of the Council and Council Directive 96/53/EC. European Union. Available online: https://eur-lex.europa.eu/eli/reg/2019/1242/oj (accessed on 1 May 2021).

- McKinsey Sustainability. Climate Risk and Decarbonization: What Every Mining CEO Needs to Know. McKinsey Sustainability. Available online: https://www.mckinsey.com/business-functions/sustainability/our-insights/climate-risk-and-decarbonization-what-every-mining-ceo-needs-to-know (accessed on 1 May 2021).

- MiningMagazine, The Benefits of Predictive and Prescriptive Maintenance in Mine Autonomy. Available online: https://www.miningmagazine.com/partners/partner-content/1396266/the-benefits-of-predictive-and-prescriptive-maintenance-in-mine-autonomy (accessed on 1 May 2021).

- Rogers, W.P.; Kahraman, M.M.; Drews, F.A.; Powell, K.; Haight, J.M.; Wang, Y.; Baxla, K.; Sobalkar, M. Automation in the Mining Industry: Review of Technology, Systems, Human Factors, and Political Risk. Min. Met. Explor. 2019, 36, 607–631. [Google Scholar] [CrossRef]

- Ralston, J.; Reid, D.; Hargrave, C.; Hainsworth, D. Sensing for advancing mining automation capability: A review of underground automation technology development. Int. J. Min. Sci. Technol. 2014, 24, 305–310. [Google Scholar] [CrossRef]

- Ertugrul, N.; Kani, A.; Davies, M.; Sbarbaro, D.; Moran, L. Status of Mine Electrification and Future Potentials. In Proceedings of the 2020 International Conference on Smart Grids and Energy Systems (SGES), Perth, Australia, 23–26 November 2020; pp. 151–156. [Google Scholar] [CrossRef]

- Uno, K.; Imaie, K.; Eng, D.; Maekawa, K.; Smith, G.; Suyama, A.; Hatori, J. Development of Mining Machinery and Future Outlook for Electrification. Hitachi Rev. 2013, 62, 2. Available online: https://www.hitachi.com/rev/pdf/2013/r2013_02_102.pdf (accessed on 1 May 2021).

- Liebherr. Two New Local Zero Emission Excavators from Liebherr: R 976-E and R 980 SME-E Electric Crawler Excavators; Liebherr: Bulle, Switzerland, 2021; Available online: https://www.liebherr.com/en/ind/latest-news/news-press-releases/detail/two-new-local-zero-emission-excavators-from-liebherr-r-976-e-and-r-980-sme-e-electric-crawler-excavators.html (accessed on 1 May 2021).

- IVT International Industrial Vehicle Technology. Liebherr Truck with Overhead Line Projected to Save Mine Three Million Litres of Diesel a Year. IVT International Industrial Vehicle Technology. Available online: https://www.ivtinternational.com/news/mining/liebherr-truck-with-overhead-line-projected-to-save-mine-three-million-litres-of-diesel-a-year.html (accessed on 1 May 2021).

- Paraszczak, J.; Svedlund, E.; Fytas, K.; Laflamme, M. Electrification of Loaders and Trucks–A Step Towards More Sustainable Underground Mining. Renew. Energy Power Qual. J. 2014, 1, 81–86. [Google Scholar] [CrossRef]

- Abdel-baqi, O.; Nasiri, A.; Miller, P. Dynamic Performance Improvement and Peak Power Limiting Using Ultracapacitor Storage System for Hydraulic Mining Shovels. IEEE Trans. Ind. Electron. 2014, 62, 3173–3181. [Google Scholar] [CrossRef]

- Varaschin, J.; De Souza, E. Economics of diesel fleet replacement by electric mining equipment. In Proceedings of the 15th North American Mine VentilaHitachi Revtion Symposium, Blacksburg, VA, USA, 20–25 June 2015; IEEE: Washington, DC, USA, 2015; pp. 1–8. [Google Scholar]

- Cunanan, C.; Tran, M.-K.; Lee, Y.; Kwok, S.; Leung, V.; Fowler, M. A Review of Heavy-Duty Vehicle Powertrain Technologies: Diesel Engine Vehicles, Battery Electric Vehicles, and Hydrogen Fuel Cell Electric Vehicles. Clean Technol. 2021, 3, 474–489. [Google Scholar] [CrossRef]

- Kruczek, P.; Gomolla, N.; Hebda-Sobkowicz, J.; Michalak, A.; Śliwiński, P.; Wodecki, J.; Stefaniak, P.; Wyłomańska, A.; Zimroz, R. Predictive Maintenance of Mining Machines Using Advanced Data Analysis System Based on the Cloud Technology. In Proceedings of the 27th International Symposium on Mine Planning and Equipment Selection-MPES 2018; Springer: Cham, Switzerland, 2019. [Google Scholar] [CrossRef]

- Peralta, S.; Sasmito, A.P.; Kumral, M. Reliability effect on energy consumption and greenhouse gas emissions of mining hauling fleet towards sustainable mining. J. Sustain. Min. 2016, 15, 85–94. [Google Scholar] [CrossRef] [Green Version]

- Jardine, A.; Banjevic, D.; Wiseman, M.; Buck, S.; Joseph, T. Optimizing a mine haul truck wheel motors’ condition monitoring program. Use of proportional hazards modeling. J. Qual. Maintenance Eng. 2001, 7, 286–302. [Google Scholar] [CrossRef]

- Zimroz, R.; Wodecki, J.; Król, R.; Andrzejewski, M.; Sliwinski, P.; Stefaniak, P. Self-propelled mining machine monitoring system—Data validation, processing and analysis. In Mine Planning and Equipment Selection; Springer: Cham, Switzerland, 2014; pp. 1285–1294. [Google Scholar]

- Moczulski, W.; Szulim, R. On case-based control of dynamic industrial processes with the use of fuzzy representation. Eng. Appl. Artif. Intell. 2004, 17, 371–381. [Google Scholar] [CrossRef]

- Paolanti, M.; Romeo, L.; Felicetti, A.; Mancini, A.; Frontoni, E.; Loncarski, J. Machine Learning approach for Predictive Maintenance in Industry 4.0. In Proceedings of the 14th IEEE/ASME International Conference on Mechatronic and Embedded Systems and Applications (MESA), Oulu, Finland, 2–4 July 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Mobley, R.K. An Introduction to Predictive Maintenance; Butterworth-Heinemann: Oxford, UK, 2002. [Google Scholar]

- Scheffer, C.; Girdhar, P. Practical Machinery Vibration Analysis and Predictive Maintenance; Elsevier: Amsterdam, The Netherlands, 2004. [Google Scholar]

- Garcia, M.C.; Sanz-Bobi, M.A.; del Pico, J. SIMAP intelligent system for predictive maintenance: Application to the health condition monitoring of a wind turbine gearbox. Comput. Ind. 2006, 57, 552–568. [Google Scholar] [CrossRef]

- Cavina, N.; De Cesare, M.; Ravaglioli, V.; De Ponti, F.; Covassin, F. Full Load Performance Optimization Based on Turbocharger Speed Evaluation via Acoustic Sensing. In Proceedings of the ASME 2014 Internal Combustion Engine Division Fall Technical Conference, Columbus, Indiana, 19–22 October 2014. [Google Scholar] [CrossRef]

- Ponti, F.; Ravaglioli, V.; Corti, E.; Moro, D.; De Cesare, M. Non-Intrusive Methodology for Estimation of Speed Fluctuations in Automotive Turbochargers under Unsteady Flow Conditions. SAE Int. J. Engines 2014, 7, 1414–1421. [Google Scholar] [CrossRef]

- Ponti, F.; Ravaglioli, V.; Moro, D.; De Cesare, M. Diesel Engine Acoustic Emission Analysis for Combustion Control; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2012. [Google Scholar] [CrossRef]

- Ponti, F.; Ravaglioli, V.; Cavina, N.; De Cesare, M. Diesel Engine Combustion Sensing Methodology Based on Vibration Analysis. J. Eng. Gas Turbines Power 2013, 136, 111503. [Google Scholar] [CrossRef]

- Aqueveque, P.; Radrigan, L.; Pastene, F.; Morales, A.S.; Guerra, E. Data-Driven Condition Monitoring of Mining Mobile Machinery in Non-Stationary Operations Using Wireless Accelerometer Sensor Modules. IEEE Access 2021, 9, 17365–17381. [Google Scholar] [CrossRef]

- Scocozza, G.F.; Silvagni, G.; Brusa, A.; Cavina, N.; Ponti, F.; Ravaglioli, V.; De Cesare, M.; Panciroli, M.; Benedetti, C. Development and Validation of a Virtual Sensor for Estimating the Maximum in-Cylinder Pressure of SI and GCI Engines; SAE Technical Paper 2021-24-0026; SAE International: Warrendale, PA, USA, 2021. [Google Scholar] [CrossRef]

- Corti, E.; Raggini, L.; Rossi, A.; Brusa, A.; Solieri, L.; Corrigan, D.; Silvestri, N.; Cucchi, M. Application of Low-Cost Transducers for Indirect In-Cylinder Pressure Measurements. SAE Int. J. Engines 2022, 16, 18. [Google Scholar] [CrossRef]

- Willems, F. Is Cylinder Pressure-Based Control Required to Meet Future HD Legislation? IFAC-Pap. 2018, 51, 111–118. [Google Scholar] [CrossRef]

- Brusa, A.; Cavina, N.; Rojo, N.; Mecagni, J.; Corti, E.; Ravaglioli, V.; Cucchi, M.; Silvestri, N. Development and Experimental Validation of an Adaptive, Piston-Damage-Based Combustion Control System for SI Engines: Part 1—Evaluating Open-Loop Chain Performance. Energies 2021, 14, 5367. [Google Scholar] [CrossRef]

- You, M.-Y.; Liu, F.; Wang, W.; Meng, G. Statistically Planned and Individually Improved Predictive Maintenance Management for Continuously Monitored Degrading Systems. IEEE Trans. Reliab. 2010, 59, 744–753. [Google Scholar] [CrossRef]

- Dindarloo, S.R.; Siami-Irdemoosa, E. Determinants of fuel consumption in mining trucks. Energy 2016, 112, 240. [Google Scholar] [CrossRef]

- Menendez, J.; Loredo, J. Biomass production in surface mines: Renewable energy source for power plants. WSEAS Trans. Environ. Dev. 2018, 14, 205–211. [Google Scholar]

- Olavson, L.G.; Baker, N.R.; Lynch, F.E.; Mejia, L.C. Hydrogen Fuel for Underground Mining Machinery, SAE Transactions Vol. 93, Section 2: 840222––840402; SAE International: Warrendale, PA, USA, 1984; pp. 109–124. Available online: https://www.jstor.org/stable/44434233 (accessed on 1 May 2021).

- Guerra, C.F.; Reyes-Bozo, L.; Vyhmeister, E.; Caparrós, M.J.; Salazar, J.; Godoy-Faúndez, A.; Clemente-Jul, C.; Verastegui-Rayo, D. Viability analysis of underground mining machinery using green hydrogen as a fuel. Int. J. Hydrog. Energy 2020, 45, 5112–5121. [Google Scholar] [CrossRef]

- Reiter Aaron, J.; Kong, S. Combustion and emissions characteristics of compression-ignition engine using dual ammonia-diesel fuel. Fuel 2011, 90, 87–97. [Google Scholar] [CrossRef] [Green Version]

- Lesmana, H.; Zhang, Z.; Li, X.; Zhu, M.; Xu, W.; Zhang, D. NH3 as a Transport Fuel in Internal Combustion Engines: A Technical Review. ASME J. Energy Resour. Technol. 2019, 141, 070703. [Google Scholar] [CrossRef]

- Corti, E.; Raggini, L.; Rossi, A.; Brusa, A.; Moro, D. Investigation of Aging Effects on Combustion and Performance Characteristics of Mining Engines. SAE Int. J. Engines 2022, 16, 2023. [Google Scholar] [CrossRef]

- Liebherr. ECU2-HD Engine Control Unit. Liebherr. Available online: https://www.liebherr.com/en/aus/products/components/injection-systems/engine-control-units/details/ecu2hd.html (accessed on 1 October 2021).

- Liebherr. D9812 Dieselmotor. Liebherr. Available online: https://www.liebherr.com/en/int/products/components/combustion-engines/diesel-engines/product-portfolio-diesel-engines/details/d9812.html (accessed on 1 January 2023).

- Alma Automotive. OBI-M2 Combustion Analysis System. Alma Automotive. Available online: https://alma-automotive.it/products/obi-m2/ (accessed on 1 January 2020).

- Herfatmanesh, M.R.; Peng, Z.; Ihracska, A.; Lin, Y.; Lu, L.; Zhang, C. Characteristics of pressure wave in common rail fuel injection system of high-speed direct injection diesel engines. Adv. Mech. Eng. 2016, 8. [Google Scholar] [CrossRef]

- Poggio, L.; Ceccarini, D.; Gelmetti, A. A Method for Estimating the Stoichiometric Ratio for a Control System of an Internal Combustion Engine; European Patent Application: Munich, Germany, 2021.

- Eunhwan, K.; Jeongwon, S.; Jaesung, C.; Myoungho, S. Optimal Set-points Generation of MFB50 for Combustion Control in Diesel Engines. In Proceedings of the Paper presented at KSAE 2013 Annual Conference, Seoul, Republic of Korea, 21–23 October 2013. [Google Scholar]

| IMEP | Pmax | MFB50 |

|---|---|---|

| RMSE (%) | RMSE (%) | RMSE (%) |

| 1.4 | 3.1 | 0.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brusa, A.; Corti, E.; Rossi, A.; Moro, D. Enhancement of Heavy-Duty Engines Performance and Reliability Using Cylinder Pressure Information. Energies 2023, 16, 1193. https://doi.org/10.3390/en16031193

Brusa A, Corti E, Rossi A, Moro D. Enhancement of Heavy-Duty Engines Performance and Reliability Using Cylinder Pressure Information. Energies. 2023; 16(3):1193. https://doi.org/10.3390/en16031193

Chicago/Turabian StyleBrusa, Alessandro, Enrico Corti, Alessandro Rossi, and Davide Moro. 2023. "Enhancement of Heavy-Duty Engines Performance and Reliability Using Cylinder Pressure Information" Energies 16, no. 3: 1193. https://doi.org/10.3390/en16031193