Industrial Energy Consumption in Northeast China under the Revitalisation Strategy: A Decomposition and Policy Analysis

Abstract

:1. Introduction

2. Literature Review

3. Method

3.1. Decomposition Analysis Method

3.2. Data Collection and Description

4. Results

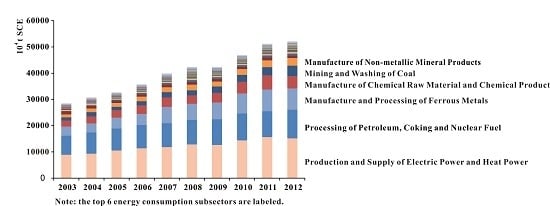

4.1. Changes of Energy Consumption

4.2. Impacts of Different Factors

4.2.1. The Activity Effect

4.2.2. The Structure Effect

4.2.3. The Intensity Effect

5. Conclusions and Discussion

Acknowledgments

Author Contributions

Conflicts of Interest

References

- National Bureau of Statistics. China Energy Statistical Yearbook 2013; China Statistics Press: Beijing, China, 2013.

- Trudeau, N.; Tam, C.; Graczyk, D.; Taylor, P. Energy transition for industry: India and the global context. In IEA Energy Papers; No. 2011/02; Organisation of Economic Co-operation and Development (OECD) Publishing: Paris, France, 2011. [Google Scholar]

- Ministry of Industry and Information Technology of China. The “12th Five-Year” Plan for Industrial Energy Saving of China. 2012. Available online: http://www.bjeit.gov.cn/zwgk/zcfg/gjflfggfxwj/83820.htm (accessed on 20 March 2016). [Google Scholar]

- The State Council of China. The “12th Five-Year” Plan for Energy Consumption of China. 2013. Available online: http://www.gov.cn/zwgk/2013-01/23/content_2318554.htm (accessed on 20 March 2016). [Google Scholar]

- General Office of the State Council of China. Strategic Plan for Energy Consumption of China: 2014–2020. 2014. Available online: http://www.gov.cn/zhengce/content/2014-11/19/content_9222.htm (accessed on 20 March 2016). [Google Scholar]

- Zhang, P. Revitalizing old industrial base of Northeast China: Process, policy and challenge. Chin. Geogr. Sci. 2008, 18, 109–118. [Google Scholar] [CrossRef]

- Statistical Bureau of Jilin Province. Statistical Yearbook of Jilin Province 1996; China Statistics Press: Beijing, China, 1996.

- Statistical Bureau of Liaoning Province. Statistical Yearbook of Liaoning Province 1996; China Statistics Press: Beijing, China, 1996.

- Statistical Bureau of Heilongjiang Province. Statistical Yearbook of Heilongjiang Province 1996; China Statistics Press: Beijing, China, 1996.

- Statistical Bureau of Jilin Province. Statistical Yearbook of Jilin Province 2013; China Statistics Press: Beijing, China, 2013.

- Statistical Bureau of Liaoning Province. Statistical Yearbook of Liaoning Province 2013; China Statistics Press: Beijing, China, 2013.

- Statistical Bureau of Heilongjiang Province. Statistical Yearbook of Heilongjiang Province 2013; China Statistics Press: Beijing, China, 2013.

- Li, H.; Lo, K.; Wang, M. Economic transformation of mining cities in transition economies: Lessons from Daqing, Northeast China. Int. Dev. Plan. Rev. 2015, 37, 311–328. [Google Scholar] [CrossRef]

- Wang, L.; Wei, H. Strategy and Policy of Economic Regeneration in Northeast China; Social Sciences Academic Press: Beijing, China, 2005. [Google Scholar]

- Wang, M.; Cheng, Z.; Zhang, P.; Tong, L.; Ma, Y. Old Industrial Cities Seeking New Road of Reindustrialisation: Models of Revitalising Northeast China; World Scientific Publishing: Singapore, 2013. [Google Scholar]

- National Bureau of Statistics of China. China Statistical Yearbook 2004; China Statistics Press: Beijing, China, 2004.

- National Bureau of Statistics of China. China Statistical Yearbook 2013; China Statistics Press: Beijing, China, 2013.

- Statistical Bureau of Jilin Province. Statistical Yearbook of Jilin Province 2004; China Statistics Press: Beijing, China, 2004.

- Statistical Bureau of Liaoning Province. Statistical Yearbook of Liaoning Province 2004; China Statistics Press: Beijing, China, 2004.

- Statistical Bureau of Heilongjiang Province. Statistical Yearbook of Heilongjiang Province 2004; China Statistics Press: Beijing, China, 2004.

- Li, H. Evolution and Decomposition Analysis of Industrial CO2 Emissions in Northeast China: 1995–2009. Resour. Sci. 2012, 34, 309–315. [Google Scholar]

- Wu, L.; Kaneko, S.; Matsuoka, S. Driving forces behind the stagnancy of China’s energy-related CO2 emissions from 1996 to 1999: The relative importance of structural change, intensity change and scale change. Energy Policy 2005, 33, 319–335. [Google Scholar] [CrossRef]

- Wu, L.; Kaneko, S.; Matsuoka, S. Dynamics of energy-related CO2 emissions in China during 1980 to 2002: The relative importance of energy supply-side and demand-side effects. Energy Policy 2006, 34, 3549–3572. [Google Scholar] [CrossRef]

- Yuan, R.; Zhao, T. Changes in CO2 emissions from China’s energy-intensive industries: A subsystem input–output decomposition analysis. J. Clean. Prod. 2016, 117, 98–109. [Google Scholar] [CrossRef]

- Zhao, X.; Ma, C.; Hong, D. Why did China’s energy intensity increase during 1998–2006: Decomposition and policy analysis. Energy Policy 2010, 38, 1379–1388. [Google Scholar] [CrossRef]

- Ke, J.; Price, L.; Ohshita, S.; Fridley, D.; Khanna, N.; Zhou, N.; Levine, M.D. China’s industrial energy consumption trends and impacts of the Top-1000 Enterprises Energy-Saving Program and the Ten Key Energy-Saving Projects. Energy Policy 2012, 50, 562–569. [Google Scholar] [CrossRef]

- Liu, N.; Ma, Z.; Kang, J. Changes in carbon intensity in China’s industrial sector: Decomposition and attribution analysis. Energy Policy 2015, 87, 28–38. [Google Scholar] [CrossRef]

- Chen, L.; Yang, Z. A spatio-temporal decomposition analysis of energy-related CO2 emission growth in China. J. Clean. Prod. 2015, 103, 49–60. [Google Scholar] [CrossRef]

- Wang, S.; Li, G.; Feng, K. CO2, economic growth, and energy consumption in China’s provinces: Investigating the spatiotemporal and econometric characteristics of China’s CO2 emissions. Ecol. Indic. 2016, 69, 184–195. [Google Scholar] [CrossRef]

- Li, A.; Hu, M.; Wang, M.; Cao, Y. Energy consumption and CO2 emissions in Eastern and Central China: A temporal and a cross-regional decomposition analysis. Technol. Forecast. Soc. Chang. 2016, 103, 284–297. [Google Scholar] [CrossRef]

- Zhang, W.; Li, K.; Zhou, D.; Zhang, W.; Gao, H. Decomposition of intensity of energy-related CO2 emission in Chinese provinces using the LMDI method. Energy Policy 2016, 92, 369–381. [Google Scholar] [CrossRef]

- Ang, B.W. Decomposition analysis for policymaking in energy: which is the preferred method? Energy Policy 2004, 32, 1131–1139. [Google Scholar] [CrossRef]

- Hoekstra, R.; van Den Bergh, J.C. Comparing structural decomposition analysis and index. Energy Econ. 2003, 25, 39–64. [Google Scholar] [CrossRef]

- Su, B.; Ang, B. Structural decomposition analysis applied to energy and emissions: Some methodological developments. Energy Econ. 2012, 34, 177–188. [Google Scholar] [CrossRef]

- Sun, J.W. Changes in energy consumption and energy intensity: A complete decomposition model. Energy Econ. 1998, 20, 85–100. [Google Scholar] [CrossRef]

- Lo, K. A critical review of China’s rapidly developing renewable energy and energy efficiency policies. Renew. Sustain. Energy Rev. 2014, 29, 508–516. [Google Scholar] [CrossRef]

- Lo, K.; Li, H.; Wang, M. Energy conservation in China’s energy-intensive enterprises: An empirical study of the Ten-Thousand Enterprises Program. Energy Sustain. Dev. 2015, 27, 105–111. [Google Scholar] [CrossRef]

- Kostka, G.; Moslener, U.; Andreas, J. Barriers to increasing energy efficiency: Evidence from small-and medium-sized enterprises in China. J. Clean. Prod. 2013, 57, 59–68. [Google Scholar] [CrossRef]

- Government of Jilin Province. The “12th Five-Year” Plan for Economic and Social Development in Jilin Province. 2011. Available online: http://www.jl.gov.cn/zjjl/fzgh_47966/201502/t20150205_1933899.html#e (accessed on 20 March 2016). [Google Scholar]

- Government of Liaoning Province. The “12th Five-Year”Plan for Economic and Social Development in Liaoning Province. 2011. Available online: http://www.ln.gov.cn/zfxx/fzgh/ztgh/201110/t20111009_723938.html (accessed on 20 March 2016). [Google Scholar]

- Government of Heilongjiang Province. The Implementation Plan for Energy Saving and Emission Reduction in Heilongjiang Province 2014–2015. 2014. Available online: http://www.hlj.gov.cn/wjfg/system/2014/12/12/010698047.shtml (accessed on 20 March 2016). [Google Scholar]

- Zhao, X.; Zhang, S.; Yang, R.; Wang, M. Constraints on the effective utilization of wind power in China: An illustration from the northeast China grid. Renew. Sustain. Energy Rev. 2012, 16, 4508–4514. [Google Scholar] [CrossRef]

| Scale | Ref. | Method | Factors | Conclusion |

|---|---|---|---|---|

| National scale | [22] | Three-level perfect decomposition | intensity effect, structure effect, sectoral-specific activity intensity effect, sectoral-specific activity size effect | Energy-related CO2 emissions in China in 1985–1999 were driven by a trade-off between the positive sectoral-specific scale effects and the negative energy intensity effects. Structural change accounted for only a small portion. |

| [23] | Overall energy system model | 23 factors on energy demand side and energy supply side | Increase in C-TPES before 1996 were mainly driven by changes on the energy demand side, declined C-TPES in 1996–2000 attributed to the acceleration of efficiency improvements in end-use and transformation sectors. | |

| [24] | Subsystem input–output decomposition analysis | emissions intensity effect, the technological effect and the demand effect | The technological effect was the main contributor to decrease the CO2 emissions in energy-intensive industries during 2005–2010. The emissions intensities had positive effects on reducing the CO2 emissions in energy-intensive industries. The increased CO2 emissions mainly derived from the demand effect. | |

| [25] | LMDI method | output effect, structural effect, intensity effect | Industrial energy savings over 1998-2006 were mainly the results of efficiency improvement, whereas the expansion of production scale and the shift towards a heavier industrial structure contributed to an increase in overall energy consumption. | |

| [26] | LMDI method | activity effect, intensity effect, structural effect | The production effect was the dominant cause of the rapid growth in industrial energy consumption from 1996 to 2010, the intensity effect was the major factors slowing the growth of industrial energy consumption, while the cumulative structure effect was negligible. | |

| [27] | LMDI method | emission coefficient effect, energy intensity effect, and structure effect | The energy intensity effect was the dominant factor in reducing carbon intensity of industrial sector in 1996–2012, the structure effect did not show a strong impact on carbon intensity, the emission coefficient effect gradually increased the carbon intensity. | |

| Provincial scale | [28] | Three-level perfect decomposition | intensity effect, structure effect, sectoral-specific activity intensity effect, sectoral-specific activity size effect | Energy intensity of production sector was the dominant negative driving factor from 1995 to 2011, the changes of economic structure in most of the provinces favored the growth of CO2 emissions, but the contribution value was not obvious. |

| [29] | Econometric models | economic growth | A long-run, bidirectional, positive relationship exists between economic growth, energy consumption, and CO2 emissions during 1995–2012. | |

| [30] | LMDI method | economic structure effects, energy efficiency effects, energy structure effects and CO2 emission coefficient effects | In 1990–2010, energy efficiency effects remained the primary driving force to the downward trend of CO2 emissions per unit of GDP by region, economic structure effects contributed more and more to increase the levels of CO2 emissions per unit of GDP in most studied regions. | |

| [31] | LMDI method | carbon emission density and energy consumption intensity | Due to the rapid development of the heavy industrial sectors, Carbon emission intensity (CI) did not decrease in 2003–2005, Energy intensity (EI) is the more significant driver for decrease of CI in 1995–2012.The most contribution of EI's decrease came from secondary industries. |

| Year | Yeffect | Seffect | Ieffect | Actual Change (104t SCE) | Change of CO2 Emission (104 t) | |||

|---|---|---|---|---|---|---|---|---|

| Contribution Value (104t CE) | Contribution Rate (%) | Contribution Value (104t CE) | Contribution Rate (%) | Contribution Value (104t CE) | Contribution Rate (%) | |||

| 2003–2004 | 6178.6 | 277.2 | 3598.5 | 161.4 | −7548.0 | −338.6 | 2229.1 | 5557.1 |

| 2004–2005 | 4962.3 | 256.4 | 743.2 | 38.4 | −3769.8 | −194.7 | 1935.7 | 4825.7 |

| 2005–2006 | 6642.0 | 220.1 | −1700.6 | −56.3 | −1923.1 | −63.7 | 3018.3 | 7524.6 |

| 2006–2007 | 7631.0 | 180.6 | −2202.8 | −52.1 | −1203.0 | −28.5 | 4225.3 | 10,533.7 |

| 2007–2008 | 7537.9 | 307.7 | −2918.7 | −119.2 | −2169.8 | −88.6 | 2449.3 | 6106.1 |

| 2008–2009 | 7709.8 | 35,416.6 | −2296.0 | −10,546.9 | −5392.1 | −24,969.7 | 21.8 | 54.3 |

| 2009–2010 | 8026.9 | 177.6 | −1846.0 | −40.9 | −1662.2 | −36.8 | 4518.6 | 11,264.9 |

| 2010–2011 | 5359.1 | 125.1 | −2450.1 | −57.2 | 1376.2 | 32.1 | 4285.3 | 10,683.3 |

| 2011–2012 | 9819.3 | 1013.5 | −95.5 | −9.9 | −8755.0 | −903.7 | 968.8 | 2415.2 |

| 2003–2012 | 76,233.8 | 323.6 | −8973.7 | −38.1 | −43,699.5 | −185.5 | 23,560.6 | 58,736.6 |

| Industrial Sector/Subsectors | Output Value (Billion Yuan) | Increase of Output Value (Billion Yuan) | |

|---|---|---|---|

| 2003 | 2012 | ||

| Industrial sector | 1124.9 | 5549.1 | 4424.2 |

| Processing of agricultural products | 51.9 | 639.8 | 587.9 |

| Manufacture of automobiles and transport equipment | 192.9 | 656.7 | 463.8 |

| Manufacture and processing of ferrous metals | 105.7 | 444.9 | 339.2 |

| Manufacture of non-metallic mineral products | 32.8 | 362.8 | 330.0 |

| Manufacture of general purpose machinery | 44.6 | 329.8 | 285.2 |

| Manufacture of chemical raw material and chemical products | 67.0 | 336.6 | 269.6 |

| Processing of petroleum, coking and nuclear fuel | 146.0 | 406.9 | 260.9 |

| Manufacture of special purpose machinery | 23.3 | 214.1 | 190.8 |

| Production and supply of electric power and heat power | 62.3 | 246.2 | 183.9 |

| Manufacture of electrical machinery & equipment | 23.7 | 180.6 | 156.9 |

| Proportion (%) | 66.7 | 68.8 | 69.4 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Lo, K.; Wang, M.; Zhang, P.; Xue, L. Industrial Energy Consumption in Northeast China under the Revitalisation Strategy: A Decomposition and Policy Analysis. Energies 2016, 9, 549. https://doi.org/10.3390/en9070549

Li H, Lo K, Wang M, Zhang P, Xue L. Industrial Energy Consumption in Northeast China under the Revitalisation Strategy: A Decomposition and Policy Analysis. Energies. 2016; 9(7):549. https://doi.org/10.3390/en9070549

Chicago/Turabian StyleLi, He, Kevin Lo, Mark Wang, Pingyu Zhang, and Longyi Xue. 2016. "Industrial Energy Consumption in Northeast China under the Revitalisation Strategy: A Decomposition and Policy Analysis" Energies 9, no. 7: 549. https://doi.org/10.3390/en9070549