Recent Development in Nanoconfined Hydrides for Energy Storage

Abstract

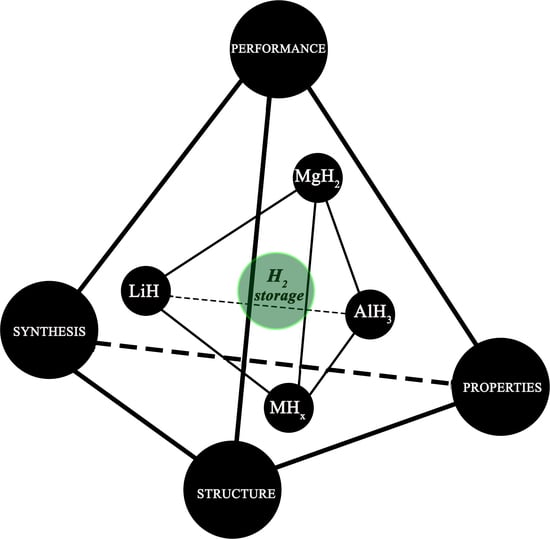

:1. Introduction

2. Characterization Methods: Old, New, and Their Pitfalls

3. Bulk vs. Nanomaterials

3.1. Physical and Chemical Aspects of Nanoconfinement Effects

3.2. Nanocomposites

4. Types of Hosts Used as Hydride Matrix

4.1. Siloxanic Materials (MCM-41, SBA-15, SBA-48, etc.)

4.2. Carbonaceous Materials (C-Replica of Mesoporous Silica, C-NTs, C-Foam, C-Spheres, Graphene, Graphene Oxide GO, Reduced Graphene Oxide r-GO)

4.3. Metal-Organic Frameworks (MOFs) and Functionalized-MOFs

4.4. Main Group and TM (Transition Metal)-Oxides, Sulfides and Nitrides

4.5. Metal Component/Host

4.6. Gas Selective-Permeable Polymers

4.7. MXene

4.8. Catalytic Effects of Doping the Host and/or Substitution of the Hydride Species

4.9. (Nano)Catalyst Addition

5. Inclusion Methods of Hydride Materials into Appropriate Host—State-of-the-Art and Limitations

5.1. Direct Synthesis

5.2. Infiltration Methods

5.2.1. Melt Infiltration

5.2.2. Solvent Infiltration

5.2.3. Solvent-Assisted Ball-Milling

6. Metal Hydrides and Their Recent Nanoconfinement Studies

6.1. LiH

6.2. MgH2

6.3. AlH3

6.4. TM-Hydrides

7. Conclusions and Outlook

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Agarwal, A.K.; Martínez, A.G.; Kalwar, A.; Valera, H. Energy, Environment, and Sustainability—Advanced Combustion for Sustainable Transport; Springer Nature: Singapore, 2022; pp. 299–330. [Google Scholar] [CrossRef]

- Černý, R.; Brighi, F.M.M. Metal hydroborates: From hydrogen stores to solid electrolytes. J. Alloys Compd. 2022, 895, 162659. [Google Scholar] [CrossRef]

- He, T.; Cao, H.; Chen, P. Complex Hydrides for Energy Storage, Conversion, and Utilization. Adv. Mater. 2019, 31, 1902757. [Google Scholar] [CrossRef] [PubMed]

- Schneemann, A.; White, J.L.; Kang, S.Y.; Jeong, S.; Wan, L.F.; Cho, E.S.; Heo, T.W.; Prendergast, D.; Urban, J.J.; Wood, B.C.; et al. Nanostructured Metal Hydrides for Hydrogen Storage. Chem. Rev. 2018, 118, 10775–10839. [Google Scholar] [CrossRef] [PubMed]

- US DOE Target Explanation Document: Onboard Hydrogen Storage for Light-Duty Fuel Cell Vehicles. Available online: https://www.energy.gov/eere/fuelcells/downloads/target-explanation-document-onboard-hydrogen-storage-light-duty-fuel-cell (accessed on 10 May 2022).

- US DOE Hydrogen & Fuel Cells Program. Available online: https://www.hydrogen.energy.gov/ (accessed on 10 May 2022).

- Shen, H.; Li, H.; Yang, Z.; Li, C. Magic of hydrogen spillover: Understanding and application. Green Energy Environ. 2022. [Google Scholar] [CrossRef]

- Hirscher, M.; Yartys, V.A.; Baricco, M.; von Colbe, J.B.; Blanchard, D.; Bowman, R.C.; Broom, D.P.; Buckley, C.E.; Chang, F.; Chen, P.; et al. Materials for hydrogen-based energy storage—Past, recent progress and future outlook. J. Alloys Compd. 2020, 827, 153548. [Google Scholar] [CrossRef]

- Lai, Q.; Sun, Y.; Wang, T.; Modi, P.; Cazorla, C.; Demirci, U.B.; Fernandez, J.R.A.; Leardini, F.; Aguey-Zinsou, K.-F. How to Design Hydrogen Storage Materials? Fundamentals, Synthesis, and Storage Tanks. Adv. Sustain. Syst. 2019, 3, 1900043. [Google Scholar] [CrossRef]

- Abe, J.O.; Popoola, A.P.I.; Ajenifuja, E.; Popoola, O.M. Hydrogen energy, economy and storage: Review and recommendation. Int. J. Hydrogen Energy 2019, 44, 15072–15086. [Google Scholar] [CrossRef]

- Kumar, R.; Karkamkar, A.; Bowden, M.; Autrey, T. Solid-state hydrogen rich boron–nitrogen compounds for energy storage. Chem. Soc. Rev. 2019, 48, 5350–5380. [Google Scholar] [CrossRef]

- Hagemann, H. Boron Hydrogen Compounds: Hydrogen Storage and Battery Applications. Molecules 2021, 26, 7425. [Google Scholar] [CrossRef]

- Lee, S.-Y.; Lee, J.-H.; Kim, Y.-H.; Kim, J.-W.; Lee, K.-J.; Park, S.-J. Recent Progress Using Solid-State Materials for Hydrogen Storage: A Short Review. Processes 2022, 10, 304. [Google Scholar] [CrossRef]

- Hadjixenophontos, E.; Dematteis, E.M.; Berti, N.; Wołczyk, A.R.; Huen, P.; Brighi, M.; Le, T.T.; Santoru, A.; Payandeh, S.; Peru, F.; et al. A Review of the MSCA ITN ECOSTORE—Novel Complex Metal Hydrides for Efficient and Compact Storage of Renewable Energy as Hydrogen and Electricity. Inorganics 2020, 8, 17. [Google Scholar] [CrossRef] [Green Version]

- Broom, D.P.; Hirscher, M. Improving Reproducibility in Hydrogen Storage Material Research. ChemPhysChem 2021, 22, 2141–2157. [Google Scholar] [CrossRef] [PubMed]

- Comanescu, C. Complex Metal Borohydrides: From Laboratory Oddities to Prime Candidates in Energy Storage Applications. Materials 2022, 15, 2286. [Google Scholar] [CrossRef]

- Kharbachi, A.E.; Dematteis, E.M.; Shinzato, K.; Stevenson, S.C.; Bannenberg, L.J.; Heere, M.; Zlotea, C.; Szilágyi, P.Á.; Bonnet, J.-P.; Grochala, W.; et al. Metal Hydrides and Related Materials. Energy Carriers for Novel Hydrogen and Electrochemical Storage. J. Phys. Chem. C 2020, 124, 7599–7607. [Google Scholar] [CrossRef] [Green Version]

- Zheng, J.; Wang, C.-G.; Zhou, H.; Ye, E.; Xu, J.; Li, Z.; Loh, X.J. Current Research Trends and Perspectives on Solid-State Nanomaterials in Hydrogen Storage. AAAS Res. 2021, 2021, 3750689. [Google Scholar] [CrossRef] [PubMed]

- He, T.; Cao, H.; Chen, P. The Roles of Alkali/Alkaline Earth Metals in the Materials Design and Development for Hydrogen Storage. Acc. Mater. Res. 2021, 2, 726–738. [Google Scholar] [CrossRef]

- Huang, Y.; An, C.; Zhang, Q.; Zang, L.; Shao, H.; Liu, Y.; Zhang, Y.; Yuan, H.; Wang, C.; Wang, Y. Cost-effective Mechanochemical Synthesis of Highly Dispersed Supported Transition Metal Catalysts for Hydrogen Storage. Nano Energy 2021, 80, 105535. [Google Scholar] [CrossRef]

- Li, Z.; Wei, B. Topological materials and topologically engineered materials: Properties, synthesis, and applications for energy conversion and storage. J. Mater. Chem. A 2021, 9, 1297–1313. [Google Scholar] [CrossRef]

- Wood, B.C.; Heo, T.W.; Kang, S.Y.; Wan, L.F.; Li, S. Beyond Idealized Models of Nanoscale Metal Hydrides for Hydrogen Storage. Ind. Eng. Chem. Res. 2020, 59, 5786–5796. [Google Scholar] [CrossRef]

- Callini, E.; Atakli, Z.Ö.K.; Hauback, B.C.; Orimo, S.-i.; Jensen, C.; Dornheim, M.; Grant, D.; Cho, Y.W.; Chen, P.; Hjorvarsson, B.; et al. Complex and liquid hydrides for energy storage. Appl. Phys. A 2016, 122, 353. [Google Scholar] [CrossRef]

- Milanese, C.; Jensen, T.R.; Hauback, B.C.; Pistidda, C.; Dornheim, M.; Yang, H.; Lombardo, L.; Zuettel, A.; Filinchuk, Y.; Ngene, P.; et al. Complex hydrides for energy storage. Int. J. Hydrogen Energy 2019, 44, 7860–7874. [Google Scholar] [CrossRef] [Green Version]

- Ngene, P.; Longo, A.; Mooij, L.; Bras, W.; Dam, B. Metal-hydrogen systems with an exceptionally large and tunable thermodynamic destabilization. Nat. Commun. 2017, 8, 1846. [Google Scholar] [CrossRef] [PubMed]

- Huot, J.; Cuevas, F.; Deledda, S.; Edalati, K.; Filinchuk, Y.; Grosdidier, T.; Hauback, B.C.; Heere, M.; Jensen, T.R.; Latroche, M.; et al. Mechanochemistry of Metal Hydrides: Recent Advances. Materials 2019, 12, 2778. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Witman, M.; Ling, S.; Grant, D.M.; Walker, G.S.; Agarwal, S.; Stavila, V.; Allendorf, M.D. Extracting an Empirical Intermetallic Hydride Design Principle from Limited Data via Interpretable Machine Learning. J. Phys. Chem. Lett. 2020, 11, 40–47. [Google Scholar] [CrossRef]

- Liu, Y.; Li, H.W.; Huang, Z. Editorial: Metal Hydride-Based Energy Storage and Conversion Materials. Front. Chem. 2020, 8, 675. [Google Scholar] [CrossRef]

- Andersson, J.; Gronkvist, S. Large-scale storage of hydrogen. Int. J. Hydrogen Energy 2019, 44, 11901–11919. [Google Scholar] [CrossRef]

- Kweon, J.J.; Kim, H.-I.; Lee, S.-h.; Kim, J.; Lee, S.K. Quantitative probing of hydrogen environments in quasicrystals by high-resolution NMR spectroscopy. Acta Mater. 2022, 226, 117657. [Google Scholar] [CrossRef]

- Misaki, T.; Oikawa, I.; Takamura, H. Negative Knight Shift in Ba-Ti Oxyhydride: An Indication of the Multiple Hydrogen Occupation. Chem. Mater. 2019, 31, 18–7178. [Google Scholar] [CrossRef]

- Liu, Y.-S.; Jeong, S.; White, J.; Feng, X.; Cho, E.S.; Stavila, V.; Allendorf, M.; Urban, J.; Guo, J. In-situ/operando X-ray characterization of metal hydrides. ChemPhysChem 2019, 20, 1261–1271. [Google Scholar] [CrossRef] [Green Version]

- NaraseGowda, S.; Brown, C.M.; Tyagi, M.; Jenkins, T.; Dobbins, T.A. Quasi-Elastic Neutron Scattering Studies of Hydrogen Dynamics for Nanoconfined NaAlH4. J. Phys. Chem. C 2016, 120, 14863–14873. [Google Scholar] [CrossRef]

- Zhou, C.; Gao, Y.; Bowman, R.C., Jr.; Zhang, J.; Liu, H.; Sun, P.; Fang, Z.Z. A high throughput dynamic method for characterizing thermodynamic properties of catalyzed magnesium hydrides by thermogravimetric analysis. Phys. Chem. Chem. Phys. 2021, 23, 15374. [Google Scholar] [CrossRef] [PubMed]

- Luong, H.M.; Pham, M.T.; Guin, T.; Madhogaria, R.P.; Phan, M.-H.; Larsen, G.K.; Nguyen, T.D. Sub-second and ppm-level optical sensing of hydrogen using templated control of nano-hydride geometry and composition. Nat. Commun. 2021, 12, 2414. [Google Scholar] [CrossRef] [PubMed]

- Valero-Pedraza, M.J.; Gascón, V.; Carreón, M.A.; Leardini, F.; Ares, J.R.; Martín, Á.; Sánchez-Sánchez, M.; Bañares, M.A. Operando Raman-mass spectrometry investigation of hydrogen release by thermolysis of ammonia borane confined in mesoporous materials. Microporous Mesoporous Mater. 2016, 226, 454–465. [Google Scholar] [CrossRef]

- Surrey, A.; Nielsch, K.; Rellinghaus, B. Comments on “Evidence of the hydrogen release mechanism in bulk MgH2”. Sci. Rep. 2017, 7, 44216. [Google Scholar] [CrossRef] [Green Version]

- Petit, J.-F.; Demirci, U.B. Discrepancy in the thermal decomposition/dehydrogenation of ammonia borane screened by thermogravimetric analysis. Int. J. Hydrogen Energy 2019, 44, 14201–14206. [Google Scholar] [CrossRef]

- Wu, Y.-J.; Wang, C.-Y. Insight into the Catalytic Effects of Open Metal Sites in Metal−Organic Frameworks on Hydride Dehydrogenation via Nanoconfinement. ACS Sustain. Chem. Eng. 2019, 7, 16013–16025. [Google Scholar] [CrossRef]

- Prabhakaran, P.K.; Catoire, L.; Deschamps, J. Aluminium doping composite metal-organic framework by alane nanoconfinement: Impact on the room temperature hydrogen uptake. Microporous Mesoporous Mater. 2017, 243, 214–220. [Google Scholar] [CrossRef]

- Pukazhselvan, D.; Sandhya, K.S.; Fagg, D.P. 5—Nanostructured advanced materials for hydrogen storage. In Nanomaterials for Sustainable Energy and Environmental Remediation—Materials Today; Elsevier: Amsterdam, The Netherlands, 2020; pp. 97–163. [Google Scholar] [CrossRef]

- Lai, Q.; Yang, Y.; Aguey-Zinsou, K.-F. Nanoconfinement of borohydrides in hollow carbon spheres: Melt infiltration versus solvent impregnation for enhanced hydrogen storage. Int. J. Hydrogen Energy 2019, 44, 23225–23238. [Google Scholar] [CrossRef]

- Zhang, J.; Yan, S.; Qu, H. Recent progress in magnesium hydride modified through catalysis and nanoconfinement. Int. J. Hydrogen Energy 2018, 43, 1545–1565. [Google Scholar] [CrossRef]

- Wang, L.; Rawal, A.; Aguey-Zinsou, K.-F. Hydrogen storage properties of nanoconfined aluminium hydride (AlH3). Chem. Eng. Sci. 2019, 194, 64–70. [Google Scholar] [CrossRef]

- Javadian, P.; Sheppard, D.A.; Buckley, C.E.; Jensen, T.R. Hydrogen Desorption Properties of Bulk and Nanoconfined LiBH4-NaAlH4. Crystals 2016, 6, 70. [Google Scholar] [CrossRef] [Green Version]

- Rueda, M.; Sanz-Moral, L.M.; Martín, Á. Innovative methods to enhance the properties of solid hydrogen storage materials based on hydrides through nanoconfinement: A review. J. Supercrit. Fluids 2018, 141, 198–217. [Google Scholar] [CrossRef]

- Le, T.T.; Pistidda, C.; Nguyen, V.H.; Singh, P.; Raizada, P.; Klassen, T.; Dornheim, M. Nanoconfinement effects on hydrogen storage properties of MgH2 and LiBH4. Int. J. Hydrogen Energy 2021, 46, 23723–23736. [Google Scholar] [CrossRef]

- Zhang, S.; Hedtke, T.; Zhou, X.; Elimelech, M.; Kim, J.-H. Environmental Applications of Engineered Materials with Nanoconfinement. ACS EST Eng. 2021, 1, 706–724. [Google Scholar] [CrossRef]

- Salman, M.S.; Rawal, A.; Aguey-Zinsou, K.-F. Tunable NaBH4 Nanostructures Revealing Structure-Dependent Hydrogen Release. Adv. Energy Sustain. Res. 2021, 2, 2100063. [Google Scholar] [CrossRef]

- Chen, W.; You, L.; Xia, G.; Yu, X. A balance between catalysis and nanoconfinement towards enhanced hydrogen storage performance of NaAlH4. J. Mater. Sci. Technol. 2021, 79, 205–211. [Google Scholar] [CrossRef]

- Stavila, V.; Li, S.; Dun, C.; Marple, M.A.T.; Mason, H.E.; Snider, J.L.; Reynolds III, J.E.; Gabaly, F.E.; Sugar, J.D.; Spataru, C.D.; et al. Defying Thermodynamics: Stabilization of Alane Within Covalent Triazine Frameworks for Reversible Hydrogen Storage. Angew. Chem. Int. Ed. 2021, 60, 25815–25824. [Google Scholar] [CrossRef]

- Goh, P.S.; Ismail, A.F. Nanocomposites for Environmental and Energy Applications. Nanomaterials 2021, 11, 345. [Google Scholar] [CrossRef]

- Huen, P.; Paskevicius, M.; Richter, B.; Ravnsbæk, D.B.; Jensen, T.R. Hydrogen Storage Stability of Nanoconfined MgH2 upon Cycling. Inorganics 2017, 5, 57. [Google Scholar] [CrossRef]

- Wood, B.C.; Stavila, V.; Poonyayant, N.; Heo, T.W.; Ray, K.G.; Klebanoff, L.E.; Udovic, T.J.; Lee, J.R.I.; Angboonpong, N.; Sugar, J.D.; et al. Nanointerface-Driven Reversible Hydrogen Storage in the Nanoconfined Li–N–H System. Adv. Mater. Interfaces 2017, 4, 1600803. [Google Scholar] [CrossRef]

- Liu, Y.-S.; Ray, K.G.; Jørgensen, M.; Mattox, T.M.; Cowgill, D.F.; Eshelman, H.V.; Sawvel, A.M.; Snider, J.L.; York, W.; Wijeratne, P.; et al. Nanoscale Mg–B via Surfactant Ball Milling of MgB2: Morphology, Composition, and Improved Hydrogen Storage Properties. J. Phys. Chem. C 2020, 124, 21761–21771. [Google Scholar] [CrossRef]

- Das, S.; Ngene, P.; Norby, P.; Vegge, T.; de Jongh, P.E.; Blanchard, D. All-Solid-State Lithium-Sulfur Battery Based on a Nanoconfined LiBH4 Electrolyte. J. Electrochem. Soc. 2016, 163, A2029–A2034. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.L.; Liu, Y.F.; Zhang, X.; Hu, J.J.; Gao, M.X.; Pan, H.G. Empowering hydrogen storage performance of MgH2 by nanoengineering and nanocatalysis. Mater. Today Nano 2020, 9, 100064. [Google Scholar] [CrossRef]

- Rabkin, E.; Skripnyuk, V.; Estrin, Y. Ultrafine-Grained Magnesium Alloys for Hydrogen Storage Obtained by Severe Plastic Deformation. Front. Mater. 2019, 6, 240. [Google Scholar] [CrossRef]

- Stavila, V.; Klebanoff, L.E. Nanostructured Metal Amides and Nitrides for Hydrogen Storage. U.S. Patent No. US10000377B1, 19 June 2018. Available online: https://patents.google.com/patent/US10000377B1/en (accessed on 16 May 2022).

- Li, L.; Huang, Y.; An, C.; Wang, Y. Lightweight hydrides nanocomposites for hydrogen storage: Challenges, progress and prospects. Sci. China Mater. 2019, 62, 1597–1625. [Google Scholar] [CrossRef] [Green Version]

- Sun, Y.; Shen, C.; Lai, Q.; Liu, W.; Wang, D.-W.; Aguey-Zinsou, K.-F. Tailoring magnesium based materials for hydrogen storage through synthesis: Current state of the art. Energy Storage Mater. 2018, 10, 168–198. [Google Scholar] [CrossRef]

- Callini, E.; Aguey-Zinsou, K.-F.; Ahuja, R.; Ares, J.R.; Bals, S.; Biliškov, N.; Chakraborty, S.; Charalambopoulou, G.; Chaudhary, A.-L.; Cuevas, F.; et al. Nanostructured materials for solid-state hydrogen storage: A review of the achievement of COST Action MP1103. Int. J. Hydrogen Energy 2016, 41, 14404–14428. [Google Scholar] [CrossRef]

- Turani-Belloto, K.; Castilla-Martinez, C.A.; Cot, D.; Petit, E.; Benarib, S.; Demirci, U.B. Nanosized ammonia borane for solid-state hydrogen storage: Outcomes, limitations, challenges and opportunities. Int. J. Hydrogen Energy 2021, 46, 7351–7370. [Google Scholar] [CrossRef]

- Valero-Pedraza, M.-J.; Cot, D.; Petit, E.; Aguey-Zinsou, K.-F.; Alauzun, J.G.; Demirci, U.B. Ammonia Borane Nanospheres for Hydrogen Storage. ACS Appl. Nano Mater. 2019, 2, 1129–1138. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhu, Y.; Liu, J.; Ma, Z.; Zhang, J.; Liu, Y.; Li, Y.; Li, L. Enhancing hydrogen storage properties of MgH2 by core-shell CoNi@C. J. Alloys Compd. 2021, 862, 158004. [Google Scholar] [CrossRef]

- de Kort, L.M.; Gulino, V.; de Jongh, P.E.; Ngene, P. Ionic conductivity in complex metal hydride-based nanocomposite materials: The impact of nanostructuring and nanocomposite formation. J. Alloys Compd. 2022, 901, 163474. [Google Scholar] [CrossRef]

- Pasquini, L. Design of Nanomaterials for Hydrogen Storage. Energies 2020, 13, 3503. [Google Scholar] [CrossRef]

- Malouche, A.; Zlotea, C.; Szilágyi, P.Á. Interactions of hydrogen with Pd@MOF composites. ChemPhysChem 2019, 20, 1282–1295. [Google Scholar] [CrossRef] [PubMed]

- EHuang, Y.; Shao, H.; Zhang, Q.; Zang, L.; Guo, H.; Liu, Y.; Jiao, L.; Yuan, H.; Wang, Y. Layer-by-layer uniformly confined Graphene-NaAlH4 composites and hydrogen storage performance. Int. J. Hydrogen Energy 2020, 45, 28116–28122. [Google Scholar] [CrossRef]

- Zheng, J.; Yao, Z.; Xiao, X.; Wang, X.; He, J.; Chen, M.; Cheng, H.; Zhang, L.; Chen, L. Enhanced hydrogen storage properties of high-loading nanoconfined LiBH4-Mg(BH4)2 composites with porous hollow carbon nanospheres. Int. J. Hydrogen Energy 2021, 46, 852–864. [Google Scholar] [CrossRef]

- Boateng, E.; Chen, A. Recent advances in nanomaterial-based solid-state hydrogen storage. Mater. Today Adv. 2020, 6, 100022. [Google Scholar] [CrossRef]

- Luo, Y.; Wang, Q.; Li, J.; Xu, F.; Sun, L.; Zou, Y.; Chu, H.; Li, B.; Zhang, K. Enhanced Hydrogen Storage/Sensing of Metal Hydrides by Nano-modification. Mater. Today Nano 2020, 9, 100071. [Google Scholar] [CrossRef]

- Castilla-Martinez, C.A.; Moury, R.; Ould-Amara, S.; Demirci, U.B. Destabilization of Boron-Based Compounds for Hydrogen Storage in the Solid-State: Recent Advances. Energies 2021, 14, 7003. [Google Scholar] [CrossRef]

- Luo, X.; Rawal, A.; Aguey-Zinsou, K.-F. Investigating the Factors Affecting the Ionic Conduction in Nanoconfined NaBH4. Inorganics 2021, 9, 2. [Google Scholar] [CrossRef]

- Biswas, P.; Ghildiyal, P.; Kwon, H.; Wang, H.; Alibay, Z.; Xu, F.; Wang, Y.; Wong, B.M.; Zachariah, M.R. Rerouting Pathways of Solid-State Ammonia Borane Energy Release. J. Phys. Chem. C 2022, 126, 48–57. [Google Scholar] [CrossRef]

- Bannenberg, L.J.; Boshuizen, B.; Nugroho, F.A.A.; Schreuders, H. Hydrogenation Kinetics of Metal Hydride Catalytic Layers. ACS Appl. Mater. Interfaces 2021, 13, 52530–52541. [Google Scholar] [CrossRef] [PubMed]

- El-Eskandarany, M.S.; Al-Ajmi, F.; Banyan, M.; Al-Duweesh, A. Synergetic effect of reactive ball milling and cold pressing on enhancing the hydrogen storage behavior of nanocomposite MgH2/10 wt% TiMn2 binary system. Int. J. Hydrogen Energy 2019, 44, 26428–26443. [Google Scholar] [CrossRef]

- Huang, X.; Xiao, X.; He, Y.; Yao, Z.; Ye, X.; Kou, H.; Chen, C.; Huang, T.; Fan, X.; Chen, L. Probing an intermediate state by X-ray absorption near-edge structure in nickel-doped 2LiBH4-MgH2 reactive hydride composite at moderate temperature. Mater. Today Nano 2020, 12, 100090. [Google Scholar] [CrossRef]

- Guo, Q.; Chen, R.; Guo, J.; Qin, C.; Xiong, Z.; Yan, H.; Gao, W.; Pei, Q.; Wu, A.; Chen, P. Enabling Semihydrogenation of Alkynes to Alkenes by Using a Calcium Palladium Complex Hydride. J. Am. Chem. Soc. 2021, 143, 20891–20897. [Google Scholar] [CrossRef] [PubMed]

- Ma, Z.; Panda, S.; Zhang, Q.; Sun, F.; Khan, D.; Ding, W.; Zou, J. Improving hydrogen sorption performances of MgH2 through nanoconfinement in a mesoporous CoS nano-boxes scaffold. J. Chem. Eng. 2021, 406, 126790. [Google Scholar] [CrossRef]

- Ngene, P.; Verkuijlen, M.H.W.; Barre, C.; Kentgens, A.P.M.; de Jongh, P.E. Reversible Li-insertion in nanoscaffolds: A promising strategy to alter the hydrogen sorption properties of Li-based complex hydrides. Nano Energy 2016, 22, 169–178. [Google Scholar] [CrossRef] [Green Version]

- Paskevicius, M.; Filsø, U.; Karimi, F.; Puszkiel, J.; Pranzas, P.K.; Pistidda, C.; Hoell, A.; Welter, E.; Schreyer, A.; Klassen, T.; et al. Cyclic stability and structure of nanoconfined Ti-doped NaAlH4. Int. J. Hydrogen Energy 2016, 41, 4159–4167. [Google Scholar] [CrossRef]

- Sanz-Moral, L.M.; Navarrete, A.; Sturm, G.; Link, G.; Rueda, M.; Stefanidis, G.; Martín, A. Release of hydrogen from nanoconfined hydrides by application of microwaves. J. Power Sources 2017, 353, 131–137. [Google Scholar] [CrossRef] [Green Version]

- Pasquini, L. The effects of nanostructure on the hydrogen sorption properties of magnesium-based metallic compounds: A review. Crystals 2018, 8, 106. [Google Scholar] [CrossRef] [Green Version]

- Liu, W.; Stoddart, J.F. Emergent behavior in nanoconfined molecular containers. Chem. 2021, 7, 919–947. [Google Scholar] [CrossRef]

- Li, X.; Yang, X.; Xue, H.; Pang, H.; Xu, Q. Metal–organic frameworks as a platform for clean energy applications. EnergyChem 2020, 2, 100027. [Google Scholar] [CrossRef]

- Lambregts, S.F.H.; van Eck, E.R.H.; Suwarno; Ngene, P.; de Jongh, P.E.; Kentgens, A.P.M. Phase Behavior and Ion Dynamics of Nanoconfined LiBH4 in Silica. J. Phys. Chem. C 2019, 123, 25559–25569. [Google Scholar] [CrossRef] [Green Version]

- Mishra, S.; Kang, P.-C.; Guo, R.-F.; Wang, C.-Y.; Nebhani, L. Combined Effect of Functionality and Pore Size on Dehydrogenation of Ammonia Borane via Its Nanoconfinement in Polyacrylamide-Grafted Organically Modified Mesoporous Silica. ACS Appl. Energy Mater. 2021, 4, 6585–6598. [Google Scholar] [CrossRef]

- Yang, Q.; Lu, F.; Liu, Y.; Zhang, Y.; Wang, X.; Pang, Y.; Zheng, S. Li2(BH4)(NH2) Nanoconfined in SBA-15 as Solid-State Electrolyte for Lithium Batteries. Nanomaterials 2021, 11, 946. [Google Scholar] [CrossRef]

- Rueda, M.; Sanz-Moral, L.M.; Segovia, J.J.; Martín, Á. Improvement of the kinetics of hydrogen release from ammonia borane confined in silica aerogel. Microporous Mesoporous Mater. 2017, 237, 189–200. [Google Scholar] [CrossRef]

- de Kort, L.M.; Harmel, J.; de Jongh, P.E.; Ngene, P. The effect of nanoscaffold porosity and surface chemistry on the Li-ion conductivity of LiBH4-LiNH2/metal oxide nanocomposites. J. Mater. Chem. A 2020, 8, 20687–20697. [Google Scholar] [CrossRef]

- Jia, Y.; Yao, X. Carbon scaffold modified by metal (Ni) or non-metal (N) to enhance hydrogen storage of MgH2 through nanoconfinement. Int. J. Hydrogen Energy 2017, 42, 22933–22941. [Google Scholar] [CrossRef] [Green Version]

- Wu, R.; Zhang, X.; Liu, Y.; Zhang, L.; Hu, J.; Gao, M.; Pan, H. A Unique Double-Layered Carbon Nanobowl-Confined Lithium Borohydride for Highly Reversible Hydrogen Storage. Small 2020, 16, 2001963. [Google Scholar] [CrossRef]

- Hu, M.; Xie, X.; Chen, M.; Zhu, C.; Liu, T. TiCX-decorated Mg nanoparticles confined in carbon shell: Preparation and catalytic mechanism for hydrogen storage. J. Alloys Compd. 2020, 817, 152813. [Google Scholar] [CrossRef]

- Zhang, M.; Xiao, X.; Mao, J.; Lan, Z.; Huang, X.; Lu, Y.; Luo, B.; Liu, M.; Chen, M.; Chen, L. Synergistic catalysis in monodispersed transition metal oxide nanoparticles anchored on amorphous carbon for excellent low-temperature dehydrogenation of magnesium hydride. Mater. Today Energy 2019, 12, 146–154. [Google Scholar] [CrossRef]

- Wang, L.; Rawal, A.; Quadir, M.Z.; Aguey-Zinsou, K.-F. Nanoconfined lithium aluminium hydride (LiAlH4) and hydrogen reversibility. Int. J. Hydrogen Energy 2017, 42, 14144–14153. [Google Scholar] [CrossRef]

- Zlotea, C.; Oumellal, Y.; Berrú, J.J.S.; Aguey-Zinsou, K.-F. On the feasibility of the bottom-up synthesis of Mg2CoH5 nanoparticles supported on a porous carbon and their hydrogen desorption behaviour. Nano-Struct. Nano-Objects 2018, 16, 144–150. [Google Scholar] [CrossRef]

- Huang, Y.; Xia, G.; Chen, J.; Zhang, B.; Li, Q.; Yu, X. One-step uniform growth of magnesium hydride nanoparticles on graphene. Prog. Nat. Sci. Mater. Int. 2017, 27, 81–87. [Google Scholar] [CrossRef]

- Zhou, H.; Wang, X.; Liu, H.; Yan, M. Enhanced hydrogen storage properties of 2LiBH4-LiAlH4 nanoconfined in resorcinol formaldehyde carbon aerogel. J. Alloys Compd. 2017, 726, 525–531. [Google Scholar] [CrossRef]

- Zhou, H.; Liu, H.-z.; Gao, S.-c.; Wang, X.-h. Enhanced dehydrogenation kinetic properties and hydrogen storage reversibility of LiBH4 confined in activated charcoal. Trans. Nonferrous Met. Soc. China 2018, 28, 1618–1625. [Google Scholar] [CrossRef]

- Xia, Y.; Wei, S.; Huang, Q.; Li, J.; Cen, X.; Zhang, H.; Chu, H.; Sun, L.; Xu, F.; Huang, P. Facile synthesis of NiCo2O4-anchored reduced graphene oxide nanocomposites as efficient additives for improving the dehydrogenation behavior of lithium alanate. Inorg. Chem. Front. 2020, 7, 1257–1272. [Google Scholar] [CrossRef]

- Wang, Y.; Ding, Z.; Li, X.; Ren, S.; Zhou, S.; Zhang, H.; Li, Y.; Han, S. Improved hydrogen storage properties of MgH2 by nickel@nitrogen-doped carbon spheres. Dalton Trans. 2020, 49, 3495–3502. [Google Scholar] [CrossRef]

- Zhang, B.; Xia, G.; Sun, D.; Fang, F.; Yu, X. Magnesium Hydride Nanoparticles Self-Assembled on Graphene as Anode Material for High-Performance Lithium-Ion Batteries. ACS Nano 2018, 12, 3816–3824. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.; Gao, M.; Xian, K.; Li, Z.; Shen, Y.; Yao, Z.; Liu, Y.; Pan, H. LiBH4 Nanoconfined in Porous Hollow Carbon Nanospheres with High Loading, Low Dehydrogenation Temperature, Superior Kinetics, and Favorable Reversibility. ACS Appl. Energy Mater. 2020, 3, 3928–3938. [Google Scholar] [CrossRef]

- Aditya, M.V.V.S.; Panda, S.; Tatiparti, S.S.V. Boron from net charge acceptor to donor and its effect on hydrogen uptake by novel Mg-B-electrochemically synthesized reduced graphene oxide. Sci. Rep. 2021, 11, 10995. [Google Scholar] [CrossRef]

- Wang, S.; Gao, M.; Yao, Z.; Liu, Y.; Wu, M.; Li, Z.; Liu, Y.; Sun, W.; Pan, H. A nanoconfined-LiBH4 system using a unique multifunctional porous scaffold of carbon wrapped ultrafine Fe3O4 skeleton for reversible hydrogen storage with high capacity. Chem. Eng. J. 2022, 428, 131056. [Google Scholar] [CrossRef]

- Zhang, J.; Zhu, Y.; Lin, H.; Liu, Y.; Zhang, Y.; Li, S.; Ma, Z.; Li, L. Metal Hydride Nanoparticles with Ultrahigh Structural Stability and Hydrogen Storage Activity Derived from Microencapsulated Nanoconfinement. Adv. Mater. 2017, 29, 1700760. [Google Scholar] [CrossRef] [PubMed]

- Sitthiwet, C.; Thiangviriya, S.; Thaweelap, N.; Meethom, S.; Kaewsuwan, D.; Chanlek, N.; Utke, R. Hydrogen sorption and permeability of compacted LiBH4 nanoconfined into activated carbon nanofibers impregnated with TiO2. J. Phys. Chem. Solids 2017, 110, 344–353. [Google Scholar] [CrossRef]

- Duan, C.; Wu, M.; Cao, Y.; Fu, D.; Zhang, Y.; Su, Z.; Sun, Z.; Wu, Y. Novel core–shell structured MgH2/AlH3@CNT nanocomposites with extremely high dehydriding–rehydriding properties derived from nanoconfinement. J. Mater. Chem. A 2021, 9, 10921. [Google Scholar] [CrossRef]

- Han, D.J.; Bang, K.R.; Cho, H.; Cho, E.S. Effect of carbon nanoscaffolds on hydrogen storage performance of magnesium hydride. Korean J. Chem. Eng. 2020, 37, 1306–1316. [Google Scholar] [CrossRef]

- Cho, Y.J.; Li, S.; Snider, J.L.; Marple, M.A.T.; Strange, N.A.; Sugar, J.D.; Gabaly, F.E.; Schneemann, A.; Kang, S.; Kang, M.-h.; et al. Reversing the Irreversible: Thermodynamic Stabilization of LiAlH4 Nanoconfined Within a Nitrogen-Doped Carbon Host. ACS Nano 2021, 15, 10163–10174. [Google Scholar] [CrossRef]

- Gasnier, A.; Luguet, M.; Pereira, A.G.; Troiani, H.; Zampieri, G.; Gennari, F.C. Entanglement of N-doped graphene in resorcinol-formaldehyde: Effect over nanoconfined LiBH4 for hydrogen storage. Carbon 2019, 147, 284–294. [Google Scholar] [CrossRef]

- Gasnier, A.; Amica, G.; Juan, J.; Troiani, H.; Gennari, F.C. N-Doped Graphene-Rich Aerogels Decorated with Nickel and Cobalt Nanoparticles: Effect on Hydrogen Storage Properties of Nanoconfined LiBH4. J. Phys. Chem. C 2020, 124, 115–125. [Google Scholar] [CrossRef]

- Xia, G.; Tan, Y.; Chen, X.; Fang, F.; Sun, D.; Li, X.; Guo, Z.; Yu, X. Oxygen-free Layer-by-Layer Assembly of Lithiated Composites on Graphene for Advanced Hydrogen Storage. Adv. Sci. 2016, 4, 1600257. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Q.; Huang, Y.; Xu, L.; Zang, L.; Guo, H.; Jiao, L.; Yuan, H.; Wang, Y. Highly Dispersed MgH2 Nanoparticle–Graphene Nanosheet Composites for Hydrogen Storage. ACS Appl. Nano Mater. 2019, 2, 3828–3835. [Google Scholar] [CrossRef]

- Comanescu, C.; Capurso, G.; Maddalena, A. Nanoconfinement in activated mesoporous carbon of calcium borohydride for improved reversible hydrogen storage. Nanotechnology 2012, 23, 385401. [Google Scholar] [CrossRef] [PubMed]

- Wan, L.F.; Cho, E.S.; Marangoni, T.; Shea, P.; Kang, S.Y.; Rogers, C.; Zaia, E.; Cloke, R.R.; Wood, B.C.; Fischer, F.R.; et al. Edge-Functionalized Graphene Nanoribbon Encapsulation to Enhance Stability and Control Kinetics of Hydrogen Storage Materials. Chem. Mater. 2019, 31, 2960–2970. [Google Scholar] [CrossRef]

- Wang, S.; Gao, M.; Yao, Z.; Xian, K.; Wu, M.; Liu, Y.; Sun, W.; Pan, H. High-loading, ultrafine Ni nanoparticles dispersed on porous hollow carbon nanospheres for fast (de)hydrogenation kinetics of MgH2. J. Magnes. Alloys 2021. [Google Scholar] [CrossRef]

- Morse, J.R.; Zugell, D.A.; Patterson, E.; Baldwin, J.W.; Willauer, H.D. Hydrogenated graphene: Important material properties regarding its application for hydrogen storage. J. Power Sources 2021, 494, 229734. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, L.; Zhang, W.; Ren, Z.; Huang, Z.; Hu, J.; Gao, M.; Pan, H.; Liu, Y. Nano-synergy enables highly reversible storage of 9.2 wt% hydrogen at mild conditions with lithium borohydride. Nano Energy 2021, 83, 105839. [Google Scholar] [CrossRef]

- Han, D.J.; Kim, S.; Cho, E.S. Revealing the role of defects in graphene oxide in the evolution of magnesium nanocrystals and the resulting effects on hydrogen storage. J. Mater. Chem. A 2021, 9, 9875. [Google Scholar] [CrossRef]

- Dun, C.; Jeong, S.; Kwon, D.-H.; Kang, S.Y.; Stavila, V.; Zhang, Z.; Lee, J.-W.; Mattox, T.M.; Heo, T.W.; Wood, B.C.; et al. Hydrogen Storage Performance of Preferentially Oriented Mg/rGO Hybrids. Chem. Mater. 2022, 34, 2963–2971. [Google Scholar] [CrossRef]

- Martínez, A.A.; Gasnier, A.; Gennari, F.C. Pore Filling of a Carbon Matrix by Melt-Impregnated LiBH4. J. Phys. Chem. C 2022, 126, 66–78. [Google Scholar] [CrossRef]

- Cho, H.; Hyeon, S.; Park, H.; Kim, J.; Cho, E.S. Ultrathin Magnesium Nanosheet for Improved Hydrogen Storage with Fishbone Shaped One-Dimensional Carbon Matrix. ACS Appl. Energy Mater. 2020, 3, 8143–8149. [Google Scholar] [CrossRef]

- Ko, Y.; Lombardo, L.; Li, M.; Oveisi, E.; Yang, H.; Zuüttel, A. Interfacial Effect between Aluminum-Based Complex Hydrides and Nickel-Containing Porous Carbon Sheets. ACS Appl. Energy Mater. 2020, 3, 9685–9695. [Google Scholar] [CrossRef]

- Jeong, S.; Heo, T.W.; Oktawiec, J.; Shi, R.; Kang, S.Y.; White, J.L.; Schneemann, A.; Zaia, E.W.; Wan, L.F.; Ray, K.G.; et al. A Mechanistic Analysis of Phase Evolution and Hydrogen Storage Behavior in Nanocrystalline Mg(BH4)2 within Reduced Graphene Oxide. ACS Nano 2020, 14, 1745–1756. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Beatrice, C.A.G.; Moreira, B.R.; de Oliveira, A.D.; Passador, F.R.; de Almeida Neto, G.R.; Leiva, D.R.; Pessan, L.A. Development of polymer nanocomposites with sodium alanate for hydrogen storage. Int. J. Hydrogen Energy 2020, 45, 5337–5346. [Google Scholar] [CrossRef]

- Carr, C.L.; Jayawardana, W.; Zou, H.; White, J.L.; Gabaly, F.E.; Conradi, M.S.; Stavila, V.; Allendorf, M.D.; Majzoub, E.H. Anomalous H2 Desorption Rate of NaAlH4 Confined in Nitrogen-Doped Nanoporous Carbon Frameworks. Chem. Mater. 2018, 30, 2930–2938. [Google Scholar] [CrossRef]

- Do, H.W.; Kim, H.; Cho, E.S. Enhanced hydrogen storage kinetics and air stability of nanoconfined NaAlH4 in graphene oxide framework. RSC Adv. 2021, 11, 32533. [Google Scholar] [CrossRef] [PubMed]

- Dansirima, P.; Thiangviriya, S.; Plerdsranoy, P.; Utke, O.; Utke, R. Small hydrogen storage tank filled with 2LiBH4-MgH2 nanoconfined in activated carbon: Reaction mechanisms and performances. Int. J. Hydrogen Energy 2019, 44, 10752–10762. [Google Scholar] [CrossRef]

- Magnin, Y.; Villermaux, E.; Amara, H.; Bichara, C.; Pellenq, R.J.M. Morphology control of metallic nanoparticles supported on carbon substrates in catalytic conditions. Carbon 2020, 159, 504–511. [Google Scholar] [CrossRef]

- Wahab, M.A.; Young, D.J.; Karim, A.; Fawzia, S.; Beltramini, J.N. Low-temperature hydrogen desorption from Mg(BH4)2 catalysed by ultrafine Ni nanoparticles in a mesoporous carbon matrix. Int. J. Hydrogen Energy 2016, 41, 20573–20582. [Google Scholar] [CrossRef]

- Wang, L.; Quadir, M.Z.; Aguey-Zinsou, K.-F. Direct and reversible hydrogen storage of lithium hydride (LiH) nanoconfined in high surface area graphite. Int. J. Hydrogen Energy 2016, 41, 18088–18094. [Google Scholar] [CrossRef]

- Utke, R.; Thiangviriya, S.; Javadian, P.; Jensen, T.R.; Milanese, C.; Klassen, T.; Dornheim, M. 2LiBH4–MgH2 nanoconfined into carbon aerogel scaffold impregnated with ZrCl4 for reversible hydrogen storage. Mater. Chem. Phys. 2016, 169, 136–141. [Google Scholar] [CrossRef]

- Plerdsranoy, P.; Javadian, P.; Jensen, N.D.; Nielsen, U.G.; Jensen, T.R.; Utke, R. Compaction of LiBH4-LiAlH4 nanoconfined in activated carbon nanofibers: Dehydrogenation kinetics, reversibility, and mechanical stability during cycling. Int. J. Hydrogen Energy 2017, 42, 1036–1047. [Google Scholar] [CrossRef]

- Pandey, A.P.; Bhatnagar, A.; Shukla, V.; Soni, P.K.; Singh, S.; Verma, S.K.; Shaneeth, M.; Sekkar, V.; Srivastava, O.N. Hydrogen storage properties of carbon aerogel synthesized by ambient pressure drying using new catalyst triethylamine. Int. J. Hydrogen Energy 2020, 45, 30818–30827. [Google Scholar] [CrossRef]

- Shinde, S.S.; Kim, D.H.; Yu, J.Y.; Lee, J.H. Self-assembled air-stable magnesium hydride embedded in 3-D activated carbon for reversible hydrogen storage. Nanoscale 2017, 9, 7094–7103. [Google Scholar] [CrossRef]

- Cho, E.S.; Ruminski, A.M.; Aloni, S.; Liu, Y.-S.; Guo, J.; Urban, J.J. Graphene oxide/metal nanocrystal multilaminates as the atomic limit for safe and selective hydrogen storage. Nat. Commun. 2016, 7, 10804. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fang, M.H.; Wu, S.Y.; Chang, Y.H.; Narwane, M.; Chen, B.H.; Liu, W.L.; Kurniawan, D.; Chiang, W.H.; Lin, C.H.; Chuang, Y.C.; et al. Mechanistic Insight into the Synergetic Interaction of Ammonia Borane and Water on ZIF-67-Derived Co@Porous Carbon for Controlled Generation of Dihydrogen. ACS Appl. Mater. Interfaces 2021, 13, 47465–47477. [Google Scholar] [CrossRef] [PubMed]

- Cao, Z.; Ouyang, L.; Felderhoff, M.; Zhu, M. Low temperature dehydrogenation properties of ammonia borane within carbon nanotube arrays: A synergistic effect of nanoconfinement and alane. RSC Adv. 2020, 10, 19027–19033. [Google Scholar] [CrossRef] [PubMed]

- So, S.H.; Jang, J.H.; Sung, S.J.; Yang, S.J.; Nam, K.T.; Park, C.R. Demonstration of the nanosize effect of carbon nanomaterials on the dehydrogenation temperature of ammonia borane. Nanoscale Adv. 2019, 1, 4697–4703. [Google Scholar] [CrossRef] [Green Version]

- Champet, S.; van den Berg, J.; Szczesny, R.; Godula-Jopek, A.; Gregory, D.H. Nano-inclusion in one step: Spontaneous ice-templating of porous hierarchical nanocomposites for selective hydrogen release. Sustain. Energy Fuels 2019, 3, 396–400. [Google Scholar] [CrossRef] [Green Version]

- Liu, H.; Chen, S.; Liu, M.; Cui, J.; Wang, Z.; Yu, P. Enhanced dehydrogenation performance of ammonia borane con-catalyzed by novel TiO2(B) nanoparticles and bio-derived carbon with well-organized pores. Int. J. Hydrogen Energy 2020, 45, 28070–28077. [Google Scholar] [CrossRef]

- Yang, Z.; Zhou, D.; Chen, B.; Liu, Z.; Xia, Q.; Zhu, Y.; Xia, Y. Improved hydrogen release from ammonia borane confined in microporous carbon with narrow pore size distribution. J. Mater. Chem. A 2017, 5, 15395–15400. [Google Scholar] [CrossRef]

- Fang, L.; Feng, J.J.; Shi, X.; Si, T.; Song, Y.; Jia, H.; Li, Y.; Li, H.-W.; Zhang, Q. Turn Bulks into 0D, 1D and 2D Metallic Nanomaterials by Selective Aqueous Corrosion. Chem. Commun. 2019, 55, 10476–10479. [Google Scholar] [CrossRef]

- Zhang, X.; Leng, Z.; Gao, M.; Hu, J.; Du, F.; Yao, J.; Pan, H.; Liu, Y. Enhanced hydrogen storage properties of MgH2 catalyzed with carbon-supported nanocrystalline TiO2. J. Power Sources 2018, 398, 183–192. [Google Scholar] [CrossRef]

- Zhang, L.; Nyahuma, F.M.; Zhang, H.; Cheng, C.; Zheng, J.; Wu, F.; Chen, L. Metal organic framework supported niobium pentoxide nanoparticles with exceptional catalytic effect on hydrogen storage behavior of MgH2. Green Energy Environ. 2022. [Google Scholar] [CrossRef]

- Wang, T.C.; White, J.L.; Bie, B.; Deng, H.; Edgington, J.; Sugar, J.D.; Stavila, V.; Allendorf, M.D. Design Rules for Metal-Organic Framework Stability in High-Pressure Hydrogen Environments. ChemPhysChem 2019, 20, 1305–1310. [Google Scholar] [CrossRef] [PubMed]

- Ma, Z.; Zhang, Q.; Panda, S.; Zhu, W.; Sun, F.; Khan, D.; Dong, J.; Ding, W.; Zou, J. In-situ catalyzed and nanoconfined magnesium hydride nanocrystals in a Ni-MOF scaffold for hydrogen storage. Sustain. Energy Fuels 2020, 4, 4694–4703. [Google Scholar] [CrossRef]

- Callini, E.; Szilagyi, P.A.; Paskevicius, M.; Stadie, N.P.; Rehault, J.; Buckley, C.E.; Borgschulte, A.; Zuttel, A. Stabilization of volatile Ti(BH4)3 by nanoconfinement in a metal–organic framework. Chem. Sci. 2016, 7, 666–672. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Schneemann, A.; Wan, L.F.; Lipton, A.S.; Liu, Y.-S.; Snider, J.L.; Baker, A.A.; Sugar, J.D.; Spataru, C.D.; Guo, J.; Autrey, T.S.; et al. Nanoconfinement of Molecular Magnesium Borohydride Captured in a Bipyridine-Functionalized Metal−Organic Framework. ACS Nano 2020, 14, 10294–10304. [Google Scholar] [CrossRef]

- Bobbitt, N.S.; Snurr, R.Q. Molecular modelling and machine learning for high-throughput screening of metal-organic frameworks for hydrogen storage. Mol. Simul. 2019, 45, 1069–1081. [Google Scholar] [CrossRef]

- Chung, J.-Y.; Liao, C.-W.; Chang, Y.-W.; Chang, B.K.; Wang, H.; Li, J.; Wang, C.-Y. Influence of Metal−Organic Framework Porosity on Hydrogen Generation from Nanoconfined Ammonia Borane. J. Phys. Chem. C 2017, 121, 27369–27378. [Google Scholar] [CrossRef]

- Peil, S.; Wisser, D.; Stähle, M.; Roßmann, P.K.; Avadhut, Y.S.; Hartmann, M. Hydrogen Release from Ammonia Borane Nanoconfined in Metal−Organic Frameworks with MIL-53 Topology. J. Phys. Chem. C 2021, 125, 9990–10000. [Google Scholar] [CrossRef]

- Ullman, A.M.; Brown, J.W.; Foster, M.E.; Leonard, F.; Leong, K.; Stavila, V.; Allendorf, M.D. Transforming MOFs for Energy Applications Using the Guest@MOF Concept. Inorg. Chem. 2016, 55, 7233–7249. [Google Scholar] [CrossRef]

- Zhou, Z.; Yu, F.; Ma, J. Nanoconfinement engineering for enhanced adsorption of carbon materials, metal–organic frameworks, mesoporous silica, MXenes and porous organic polymers: A review. Environ. Chem. Lett. 2022, 20, 563–595. [Google Scholar] [CrossRef]

- Wang, Y.; Lan, Z.; Huang, X.; Liu, H.; Guo, J. Study on catalytic effect and mechanism of MOF (MOF = ZIF-8, ZIF-67, MOF-74) on hydrogen storage properties of magnesium. Int. J. Hydrogen Energy 2019, 44, 28863–28873. [Google Scholar] [CrossRef]

- Huang, T.; Huang, X.; Hu, C.; Wang, J.; Liu, H.; Ma, Z.; Zou, J.; Ding, W. Enhancing hydrogen storage properties of MgH2 through addition of Ni/CoMoO4 nanorods. Mater. Today Energy 2021, 19, 100613. [Google Scholar] [CrossRef]

- Leick, N.; Strange, N.A.; Schneemann, A.; Stavila, V.; Gross, K.; Washton, N.; Settle, A.; Martinez, M.B.; Gennett, T.; Christensen, S.T. Al2O3 Atomic Layer Deposition on Nanostructured γ-Mg(BH4)2 for H2 Storage. ACS Appl. Energy Mater. 2021, 4, 1150–1162. [Google Scholar] [CrossRef]

- Habibi, P.; Vlugt, T.J.H.; Dey, P.; Moultos, O.A. Reversible Hydrogen Storage in Metal-Decorated Honeycomb Borophene Oxide. ACS Appl. Mater. Interfaces 2021, 13, 43233–43240. [Google Scholar] [CrossRef]

- Zettl, R.; Gombotz, M.; Clarkson, D.; Greenbaum, S.G.; Ngene, P.; de Jongh, P.E.; Wilkening, H.M.R. Li-Ion Diffusion in Nanoconfined LiBH4-LiI/Al2O3: From 2D Bulk Transport to 3D Long-Range Interfacial Dynamics. ACS Appl. Mater. Interfaces 2020, 12, 38570–38583. [Google Scholar] [CrossRef]

- Salameh, C.; Moussa, G.; Bruma, A.; Fantozzi, G.; Malo, S.; Miele, P.; Demirci, U.B.; Bernard, S. Robust 3D Boron Nitride Nanoscaffolds for Remarkable Hydrogen Storage Capacity from Ammonia Borane. Energy Technol. 2018, 6, 570–577. [Google Scholar] [CrossRef] [Green Version]

- Cho, E.S.; Ruminski, A.M.; Liu, Y.-S.; Shea, P.T.; Kang, S.Y.; Zaia, E.W.; Park, J.Y.; Chuang, Y.-D.; Yuk, J.M.; Zhou, X.; et al. Hierarchically Controlled Inside-Out Doping of Mg Nanocomposites for Moderate Temperature Hydrogen Storage. Adv. Funct. Mater. 2017, 27, 1704316. [Google Scholar] [CrossRef]

- Fan, J.; Cui, X.; Yu, S.; Gu, L.; Zhang, Q.; Meng, F.; Peng, Z.; Ma, L.; Ma, J.-Y.; Qi, K.; et al. Interstitial Hydrogen Atom Modulation to Boost Hydrogen Evolution in Pd-Based Alloy Nanoparticles. ACS Nano 2019, 13, 12987–12995. [Google Scholar] [CrossRef]

- Abbas, A.; Rajagopal, V.; Huang, S.J. Magnesium metal matrix composites and their applications. In Magnesium Alloys; IntechOpen: London, UK, 2021. [Google Scholar] [CrossRef]

- Li, Z.; Yu, J.Z.; Zhang, Y.; Liu, D.M.; Wang, C.Y.; Si, T.Z.; Li, Y.T.; Zhang, Q.A. Coupling of nanoconfinement with metallic catalysis in supported NaAlH4 for low-temperature hydrogen storage. J. Power Sources 2021, 491, 229611. [Google Scholar] [CrossRef]

- Ianni, E.; Sofianos, M.V.; Rowles, M.R.; Sheppard, D.A.; Humphries, T.D.; Buckley, C.E. Synthesis of NaAlH4/Al composites and their applications in hydrogen storage. Int. J. Hydrogen Energy 2018, 43, 17309–17317. [Google Scholar] [CrossRef]

- Khan, D.; Zou, J.; Pan, M.; Ma, Z.; Zhu, W.; Huang, T.; Zeng, X.; Ding, W. Hydrogen storage properties of nanostructured 2MgH2-Co powders: The effect of high-pressure compression. Int. J. Hydrogen Energy 2019, 44, 15146–15158. [Google Scholar] [CrossRef]

- Rizo-Acosta, P.; Cuevas, F.; Latroche, M. Hydrides of early transition metals as catalysts and grain growth inhibitors for enhanced reversible hydrogen storage in nanostructured magnesium. J. Mater. Chem. A 2019, 7, 23064–23075. [Google Scholar] [CrossRef]

- Patelli, N.; Migliori, A.; Morandi, V.; Pasquini, L. Interfaces within biphasic nanoparticles give a boost to magnesium-based hydrogen storage. Nano Energy 2020, 72, 104654. [Google Scholar] [CrossRef]

- Lai, Q.; Rawal, A.; Quadir, M.Z.; Cazorla, C.; Demirci, U.B.; Aguey-Zinsou, K.-F. Nanosizing Ammonia Borane with Nickel: A Path toward the Direct Hydrogen Release and Uptake of B-N-H Systems. Adv. Sustain. Syst. 2018, 2, 1700122. [Google Scholar] [CrossRef]

- Ma, Z.; Liu, J.; Zhu, Y.; Zhao, Y.; Lin, H.; Zhang, Y.; Li, H.; Zhang, J.; Liu, Y.; Gao, W.; et al. Crystal-facet-dependent catalysis of anatase TiO2 on hydrogen storage of MgH2. J. Alloys Compd. 2020, 822, 153553. [Google Scholar] [CrossRef]

- Le, T.T.; Pistidda, C.; Abetz, C.; Georgopanos, P.; Garroni, S.; Capurso, G.; Milanese, C.; Puszkiel, J.; Dornheim, M.; Abetz, V.; et al. Enhanced Stability of Li-RHC Embedded in an Adaptive TPX™ Polymer Scaffold. Materials 2020, 13, 991. [Google Scholar] [CrossRef] [Green Version]

- Nugroho, F.A.A.; Darmadi, I.; Cusinato, L.; Susarrey-Arce, A.; Schreuders, H.; Bannenberg, L.J.; da Silva Fanta, A.B.; Kadkhodazadeh, S.; Wagner, J.B.; Antosiewicz, T.J.; et al. Metal–polymer hybrid nanomaterials for plasmonic ultrafast hydrogen detection. Nat. Mater. 2019, 18, 489–495. [Google Scholar] [CrossRef] [Green Version]

- Ploszajski, A.R.; Billing, M.; Cockcroft, J.K.; Skipper, N.T. Crystalline structure of an ammonia borane–polyethylene oxide cocrystal: A material investigated for its hydrogen storage potential. CrystEngComm 2018, 20, 4436–4440. [Google Scholar] [CrossRef] [Green Version]

- Kumar, J.A.; Prakash, P.; Krithiga, T.; Amarnath, D.J.; Premkumar, J.; Rajamohan, N.; Vasseghian, Y.; Saravanan, P.; Rajasimman, M. Methods of synthesis, characteristics, and environmental applications of MXene: A comprehensive review. Chemosphere 2022, 286, 131607. [Google Scholar] [CrossRef]

- Wu, Z.; Fang, J.; Liu, N.; Wu, J.; Kong, L. The Improvement in Hydrogen Storage Performance of MgH2 Enabled by Multilayer Ti3C2. Micromachines 2021, 12, 1190. [Google Scholar] [CrossRef] [PubMed]

- Xia, Y.; Zhang, H.; Sun, Y.; Sun, L.; Xu, F.; Sun, S.; Zhang, G.; Huang, P.; Du, Y.; Wang, J.; et al. Dehybridization effect in improved dehydrogenation of LiAlH4 by doping with two-dimensional Ti3C2. Mater. Today Nano 2019, 8, 100054. [Google Scholar] [CrossRef]

- Chen, G.; Zhang, Y.; Cheng, H.; Zhu, Y.; Li, L.; Lin, H. Effects of two-dimension MXene Ti3C2 on hydrogen storage performances of MgH2-LiAlH4 composite. Chem. Phys. 2019, 522, 178–187. [Google Scholar] [CrossRef]

- Ronchi, R.M.; Arantes, J.T.; Santos, S.F. Synthesis, structure, properties and applications of MXenes: Current status and perspectives. Ceram. Int. 2019, 45, 18167–18188. [Google Scholar] [CrossRef]

- Liu, Y.; Gao, H.; Zhu, Y.; Li, S.; Zhang, J.; Li, L. Excellent catalytic activity of a two-dimensional Nb4C3Tx (MXene) on hydrogen storage of MgH2. Appl. Surf. Sci. 2019, 493, 431440. [Google Scholar] [CrossRef]

- Yadav, A.; Dashora, A.; Patel, N.; Miotello, A.; Press, M.; Kothari, D.C. Study of 2D MXene Cr2C material for hydrogen storage using density functional theory. Appl. Surf. Sci. 2016, 389, 88–95. [Google Scholar] [CrossRef]

- Wu, R.; Du, H.; Wang, Z.; Gao, M.; Pan, H.; Liu, Y. Remarkably improved hydrogen storage properties of NaAlH4 doped with 2D titanium carbide. J. Power Sources 2016, 327, 519–525. [Google Scholar] [CrossRef]

- Shen, Z.; Wang, Z.; Zhang, M.; Gao, M.; Hu, J.; Du, F.; Liu, Y.; Pan, H. A novel solid-solution MXene (Ti0.5V0.5)3C2 with high catalytic activity for hydrogen storage in MgH2. Materialia 2018, 1, 114–120. [Google Scholar] [CrossRef]

- Fan, Y.; Chen, D.; Liu, X.; Fan, G.; Liu, B. Improving the hydrogen storage performance of lithium borohydride by Ti3C2 MXene. Int. J. Hydrogen Energy 2019, 44, 29297–29303. [Google Scholar] [CrossRef]

- Jiang, R.; Xiao, X.; Zheng, J.; Chen, M.; Chen, L. Remarkable hydrogen absorption/desorption behaviors and mechanism of sodium alanates in-situ doped with Ti-based 2D MXene. Mater. Chem. Phys. 2020, 242, 122529. [Google Scholar] [CrossRef]

- Feng, X.; Yuan, J.; Lv, Y.; Liu, B.; Huang, H.; Zhang, B.; Yan, Y.; Han, S.; Wu, Y. Improvement of desorption performance of Mg(BH4)2 by two-dimensional Ti3C2 MXene addition. Int. J. Hydrogen Energy 2020, 45, 16654–16662. [Google Scholar] [CrossRef]

- Yuan, Z.; Fan, Y.; Chen, Y.; Liu, X.; Liu, B.; Han, S. Two-dimensional C@TiO2/Ti3C2 composite with superior catalytic performance for NaAlH4. Int. J. Hydrogen Energy 2020, 45, 21666–21675. [Google Scholar] [CrossRef]

- Zheng, J.; Cheng, H.; Xiao, X.; Chen, M.; Chen, L. Enhanced low temperature hydrogen desorption properties and mechanism of Mg(BH4)2 composited with 2D MXene. Int. J. Hydrogen Energy 2019, 44, 24292–24300. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, X.; Ren, Z.; Liu, Y.; Hu, J.; Li, H.; Gao, M.; Pan, H.; Liu, Y. In situ formed ultrafine NbTi nanocrystals from a NbTiC solid-solution MXene for hydrogen storage in MgH2. J. Mater. Chem. A 2019, 7, 14244–14252. [Google Scholar] [CrossRef]

- Xian, K.X.; Gao, M.; Li, Z.; Gu, J.; Shen, Y.; Wang, S.; Yao, Z.; Liu, Y.; Pan, H. Superior Kinetic and Cyclic Performance of a 2D Titanium Carbide Incorporated 2LiH + MgB2 Composite toward Highly Reversible Hydrogen Storage. ACS Appl. Energy Mater. 2019, 2, 4853–4864. [Google Scholar] [CrossRef]

- Gao, H.; Liu, Y.; Zhu, Y.; Zhang, J.; Li, L. Catalytic effect of sandwich-like Ti3C2/TiO2(A)-C on hydrogen storage performance of MgH2, Nanotechnology 2020, 31, 115404. Nanotechnology 2020, 31, 115404. [Google Scholar] [CrossRef]

- Liu, Y.; Du, H.; Zhang, X.; Yang, Y.; Gao, M.; Pan, H. Superior catalytic activity derived from a two-dimensional Ti3C2 precursor towards the hydrogen storage reaction of magnesium hydride. Chem. Commun. 2016, 52, 705–708. [Google Scholar] [CrossRef]

- Li, Y.; Guo, Y.; Chen, W.; Jiao, Z.; Ma, S. Reversible hydrogen storage behaviors of Ti2N MXenes predicted by first-principles calculations. J. Mater. Sci. 2019, 54, 493–505. [Google Scholar] [CrossRef]

- Veit, R.D.; Farber, R.G.; Sitaraman, N.S.; Arias, T.A.; Sibener, S.J. Suppression of nano-hydride growth on Nb(100) due to nitrogen doping. J. Chem. Phys. 2020, 152, 214703. [Google Scholar] [CrossRef]

- Liu, Y.; Zhu, J.; Liu, Z.; Zhu, Y.; Zhang, J.; Li, L. Magnesium Nanoparticles with Pd Decoration for Hydrogen Storage. Front. Chem. 2020, 7, 949. [Google Scholar] [CrossRef] [Green Version]

- Feng, Y.F.; Zhou, X.; Yang, J.-h.; Gao, X.; Yin, L.; Zhao, Y.; Zhang, B. Encapsulation of Ammonia Borane in Pd/Halloysite Nanotubes for Efficient Thermal Dehydrogenation. ACS Sustain. Chem. Eng. 2020, 8, 2122–2129. [Google Scholar] [CrossRef]

- Snider, J.L.; Mattox, T.M.; Liu, Y.-S.; Wan, L.F.; Wijeratne, P.; Allendorf, M.D.; Stavila, V.; Wood, B.C.; Klebanoff, L.E. The influence of LiH and TiH2 on hydrogen storage in MgB2 II. XPS study of surface and near-surface phenomena. Int. J. Hydrogen Energy 2022, 47, 403–419. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, X.; Zhang, H.; Xia, G.; Sun, D.; Yu, X. Heterostructures Built in Metal Hydrides for Advanced Hydrogen Storage Reversibility. Adv. Mater. 2020, 32, 2002647. [Google Scholar] [CrossRef] [PubMed]

- Dekura, S.; Kobayashi, H.; Kusada, K.; Kitagawa, H. Hydrogen and Storage Properties of Palladium and Related Nanomaterials: Size, Shape, Alloying, and Metal–Organic Framework Coating Effects. ChemPhysChem 2019, 20, 1158–1176. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, X.; Ji, L.; Yan, N.; Sun, Z.; Lu, X.; Zhang, L.; Zhu, X.; Chen, L. Superior catalytic effect of FeCo nanosheets on MgH2 for hydrogen storage. Dalton Trans. 2019, 48, 12699–12706. [Google Scholar] [CrossRef]

- Yang, X.; Hou, Q.; Yua, L.; Zhang, J. Improvement of the hydrogen storage characteristics of MgH2 with a flake Ni nano-catalyst composite. Dalton Trans. 2021, 50, 1797. [Google Scholar] [CrossRef]

- Duan, C.; Cao, Y.; Hu, L.; Fu, D.; Ma, J.; Youngblood, J. An efficient mechanochemical synthesis of alpha-aluminum hydride: Synergistic effect of TiF3 on the crystallization rate and selective formation of alpha-aluminum hydride polymorph. J. Hazard. Mater. 2019, 373, 141–151. [Google Scholar] [CrossRef] [Green Version]

- Huang, X.; Xiao, X.; Zhang, W.; Fan, X.; Zhang, L.; Cheng, C.; Li, S.; Ge, H.; Wang, Q.; Chen, L. Transition metal (Co, Ni) nanoparticles wrapped with carbon and their superior catalytic activities for the reversible hydrogen storage of magnesium hydride. Phys. Chem. Chem. Phys. 2017, 19, 4019–4029. [Google Scholar] [CrossRef]

- Chen, Y.; Dai, J.; Song, Y. Catalytic mechanisms of TiH2 thin layer on dehydrogenation behavior of fluorite-type MgH2: A first principles study. Int. J. Hydrogen Energy 2020, 45, 21600–21610. [Google Scholar] [CrossRef]

- Zhao, S.; Liang, L.; Liu, B.; Wang, L.; Liang, F. Superior Dehydrogenation Performance of α-AlH3 Catalyzed by Li3N: Realizing 8.0 wt.% Capacity at 100 °C. Small 2022, 18, 2107983. [Google Scholar] [CrossRef]

- Dun, C.; Jeong, S.; Liu, Y.-S.; Leick, N.; Mattox, T.M.; Guo, J.; Lee, J.-W.; Gennett, T.; Stavila, V.; Urban, J.J. Additive Destabilization of Porous Magnesium Borohydride Framework with Core-Shell Structure. Small 2021, 17, 2101989. [Google Scholar] [CrossRef] [PubMed]

- Ding, Z.; Zhang, L.; Fu, Y.; Wang, W.; Wang, Y.; Bi, J.; Li, Y.; Han, S. Enhanced kinetics of MgH2 via in situ formed catalysts derived from MgCCo1.5Ni1.5. J. Alloys Compd. 2020, 822, 153621. [Google Scholar] [CrossRef]

- Ding, Z.; Fu, Y.; Wang, Y.; Bi, J.; Zhang, L.; Peng, D.; Li, Y.; Han, S. MgCNi3 prepared by powder metallurgy for improved hydrogen storage properties of MgH2. Int. J. Hydrogen Energy 2019, 44, 8347–8356. [Google Scholar] [CrossRef]

- Ding, X.; Ding, H.; Song, Y.; Xiang, C.; Li, Y.; Zhang, Q. Activity-Tuning of Supported Co–Ni Nanocatalysts via Composition and Morphology for Hydrogen Storage in MgH2. Front. Chem. 2020, 7, 937. [Google Scholar] [CrossRef]

- Patelli, N.; Migliori, A.; Pasquini, L. Reversible metal-hydride transformation in Mg-Ti-H nanoparticles at remarkably low temperatures. Chem. Phys. Chem. 2019, 20, 1325–1333. [Google Scholar] [CrossRef] [Green Version]

- Kumar, S.; Pavloudis, T.; Singh, V.; Nguyen, H.; Steinhauer, S.; Pursell, C.; Clemens, B.; Kioseoglou, J.; Grammatikopoulos, P.; Sowwan, M. Hydrogen Flux through Size Selected Pd Nanoparticles into Underlying Mg Nanofilms. Adv. Energy Mater. 2018, 8, 1701326. [Google Scholar] [CrossRef]

- Rossin, A.; Tuci, G.; Luconi, L.; Giambastiani, G. Metal–Organic Frameworks as Heterogeneous Catalysts in Hydrogen Production from Lightweight Inorganic Hydrides. ACS Catal. 2017, 7, 5035–5045. [Google Scholar] [CrossRef]

- Sun, Y.; Aguey-Zinsou, K.-F. Light-activated hydrogen storage in Mg, LiH and NaAlH4. ChemPlusChem 2018, 83, 904–908. [Google Scholar] [CrossRef]

- White, J.L.; Baker, A.A.; Marcus, M.A.; Snider, J.L.; Wang, T.C.; Lee, J.R.I.; Kilcoyne, D.A.L.; Allendorf, M.D.; Stavila, V.; Gabaly, F.E. The Inside-Outs of Metal Hydride Dehydrogenation: Imaging the Phase Evolution of the Li-N-H Hydrogen Storage System. Adv. Mater. Interfaces 2020, 7, 1901905. [Google Scholar] [CrossRef]

- Bannenberg, L.J.; Heere, M.; Benzidi, H.; Montero, J.; Dematteis, E.M.; Suwarno, S.; Jaron, T.; Winny, M.; Orłowski, P.A.; Wegner, W.; et al. Metal (boro-) hydrides for high energy density storage and relevant emerging technologies. Int. J. Hydrogen Energy 2020, 45, 33687–33730. [Google Scholar] [CrossRef]

- Kim, H.; Choi, W.I.; Jang, Y.; Balasubramanian, M.; Lee, W.; Park, G.O.; Park, S.B.; Yoo, J.; Hong, J.S.; Choi, Y.-S.; et al. Exceptional Lithium Storage in a Co(OH)2 Anode: Hydride Formation. ACS Nano 2018, 12, 2909–2921. [Google Scholar] [CrossRef] [PubMed]

- Yartys, V.A.; Lototskyy, M.V.; Akiba, E.; Albert, R.; Antonov, V.E.; Ares, J.R.; Baricco, M.; Bourgeois, N.; Buckley, C.E.; Bellosta von Colbe, J.M.; et al. Magnesium based materials for hydrogen based energy storage: Past, present and future. Int. J. Hydrogen Energy 2019, 44, 7809–7859. [Google Scholar] [CrossRef]

- Zhang, B.; Wu, Y. Recent advances in improving performances of the lightweight complex hydrides Li-Mg-N-H system. Prog. Nat. Sci. 2017, 27, 21–33. [Google Scholar] [CrossRef]

- Zhang, J.; Zhu, Y.; Yao, L.; Xu, C.; Liu, Y.; Li, L. State of the art multi-strategy improvement of Mg-based hydrides for hydrogen storage. J. Alloys Compd. 2019, 782, 796–823. [Google Scholar] [CrossRef]

- El-Eskandarany, M.S. Recent developments in the fabrication, characterization and implementation of MgH2-based solid-hydrogen materials in the Kuwait Institute for Scientific Research. RSC Adv. 2019, 9, 9907. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, X.; Liu, Y.; Ren, Z.; Zhang, X.; Hu, J.; Huang, Z.; Lu, Y.; Gao, M.; Pan, H. Realizing 6.7 wt% reversible storage of hydrogen at ambient temperature with non-confined ultrafine magnesium hydride. Energy Environ. Sci. 2021, 14, 2302–2313. [Google Scholar] [CrossRef]

- Wang, N.; Huang, S. Molecular dynamics study on magnesium hydride nanoclusters with machine-learning interatomic potential. Phys. Rev. B 2020, 102, 094111. [Google Scholar] [CrossRef]

- Gigante, A.; Leick, N.; Lipton, A.S.; Tran, B.; Strange, N.A.; Bowden, M.; Martinez, M.B.; Moury, R.; Gennett, T.; Hagemann, H.; et al. Thermal Conversion of Unsolvated Mg(B3H8)2 to BH4− in the Presence of MgH2. ACS Appl. Energy Mater. 2021, 4, 3737–3747. [Google Scholar] [CrossRef]

- Crivello, J.-C.; Dam, B.; Denys, R.V.; Dornheim, M.; Grant, D.M.; Huot, J.; Jensen, T.R.; de Jongh, P.; Latroche, M.; Milanese, C.; et al. Review of magnesium hydride-based materials: Development and optimisation. Appl. Phys. A Mater. Sci. Process. 2016, 122, 97. [Google Scholar] [CrossRef] [Green Version]

- Yu, X.; Tang, Z.; Sun, D.; Ouyang, L.; Zhu, M. Recent advances and remaining challenges of nanostructured materials for hydrogen storage applications. Prog. Mater. Sci. 2017, 88, 1–48. [Google Scholar] [CrossRef]

- Duan, C.; Su, Z.; Cao, Y.; Hu, L.; Fu, D.; Ma, J.; Zhang, Y. Synthesis of core-shell α-AlH3@Al(OH)3 nanocomposite with improved low-temperature dehydriding properties by mechanochemical mixing and ionic liquid treatment. J. Clean. Prod. 2021, 283, 124635. [Google Scholar] [CrossRef]

- Zhao, Y.; Mei, Z.; Zhao, F.-Q.; Xu, S.-Y.; Ju, X.-H. Thermal Decomposition Mechanism of 1,3,5,7-Tetranitro-1,3,5,7-tetrazocane Accelerated by Nano-Aluminum Hydride (AlH3): ReaxFF-Lg Molecular Dynamics Simulation. ACS Omega 2020, 5, 23193–23200. [Google Scholar] [CrossRef]

- Jiang, W.; Wang, H.; Zhu, M. AlH3 as a hydrogen storage material: Recent advances, prospects and challenges. Rare Met. 2021, 40, 3337–3356. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, W.; Zhang, L.; Huang, Z.; Hu, J.; Gao, M.; Pan, H.; Liu, Y. Single-pot solvothermal strategy toward support-free nanostructured LiBH4 featuring 12 wt% reversible hydrogen storage at 400 °C. Chem. Eng. J. 2022, 428, 132566. [Google Scholar] [CrossRef]

- Xian, K.; Nie, B.; Li, Z.; Gao, M.; Li, Z.; Shang, C.; Liu, Y.; Guo, Z.; Pan, H. TiO2 decorated porous carbonaceous network structures offer confinement, catalysis and thermal conductivity for effective hydrogen storage of LiBH4. Chem. Eng. J. 2021, 407, 127156. [Google Scholar] [CrossRef]

- Wang, X.-K.; Zhao, Y.; Zhao, F.-Q.; Xu, S.-Y.; Ju, X.-H. Atomic perspective revealing for combustion evolution of nitromethane/nano-aluminum hydride composite. J. Mol. Graph. Model. 2021, 108, 107987. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, L.; Ma, H.; Lu, C.; Luo, H.; Wang, X.; Huang, X.; Lan, Z.; Guo, J. Aluminum hydride for solid-state hydrogen storage: Structure, synthesis, thermodynamics, kinetics, and regeneration. J. Energy Chem. 2021, 52, 428–440. [Google Scholar] [CrossRef]

- Rahm, J.M.; Löfgren, J.; Erhart, P. Quantitative predictions of thermodynamic hysteresis: Temperature-dependent character of the phase transition in Pd–H. Acta Mater. 2022, 227, 117697. [Google Scholar] [CrossRef]

- Huen, P.; Peru, F.; Charalambopoulou, G.; Steriotis, T.A.; Jensen, T.R.; Ravnsbæk, D.B. Nanoconfined NaAlH4 Conversion Electrodes for Li Batteries. ACS Omega 2017, 2, 1956–1967. [Google Scholar] [CrossRef] [Green Version]

- Dematteis, E.M.; Pistidda, C.; Dornheim, M.; Baricco, M. Exploring Ternary and Quaternary Mixtures in the LiBH4-NaBH4-KBH4-Mg(BH4)2-Ca(BH4)2 System. ChemPhysChem 2019, 20, 1348–1359. [Google Scholar] [CrossRef] [Green Version]

- Zhang, W.; Zhang, X.; Huang, Z.; Li, H.-W.; Gao, M.; Pan, H.; Liu, Y. Recent Development of Lithium Borohydride-Based Materials for Hydrogen Storage. Adv. Energy Sustain. Res. 2021, 2, 2100073. [Google Scholar] [CrossRef]

- Wu, R.; Ren, Z.; Zhang, X.; Lu, Y.; Li, H.; Gao, M.; Pan, H.; Liu, Y. Nanosheet-like Lithium Borohydride Hydrate with 10 wt % Hydrogen Release at 70 °C as a Chemical Hydrogen Storage Candidate. J. Phys. Chem. Lett. 2019, 10, 1872–1877. [Google Scholar] [CrossRef] [PubMed]

- Puszkiel, J.; Gasnier, A.; Amica, G.; Gennari, F. Tuning LiBH4 for Hydrogen Storage: Destabilization, Additive, and Nanoconfinement Approaches. Molecules 2020, 25, 163. [Google Scholar] [CrossRef] [Green Version]

- Bergemann, N.; Pistidda, C.; Uptmoor, M.; Milanese, C.; Santoru, A.; Emmler, T.; Puszkiel, J.; Dornheim, M.; Klassen, T. A new mutually destabilized reactive hydride system: LiBH4–Mg2NiH4. J. Energy Chem. 2019, 34, 240–254. [Google Scholar] [CrossRef] [Green Version]

- Wang, T.; Aguey-Zinsou, K.-F. Controlling the growth of NaBH4 nanoparticles for hydrogen storage. Int. J. Hydrogen Energy 2020, 45, 2054–2067. [Google Scholar] [CrossRef]

- White, J.L.; Strange, N.A.; Sugar, J.D.; Snider, J.L.; Schneemann, A.; Lipton, A.S.; Toney, M.F.; Allendorf, M.D.; Stavila, V. Melting of Magnesium Borohydride under High Hydrogen Pressure: Thermodynamic Stability and Effects of Nanoconfinement. Chem. Mater. 2020, 32, 5604–5615. [Google Scholar] [CrossRef]

- Albanese, E.; Corno, M.; Baricco, M.; Civalleri, B. Simulation of nanosizing effects in the decomposition of Ca(BH4)2 through atomistic thin film models. Res. Chem. Intermed. 2021, 47, 345–356. [Google Scholar] [CrossRef]

- Demirci, U.B. Ammonia borane, a material with exceptional properties for chemical hydrogen storage. Int. J. Hydrogen Energy 2017, 42, 9978–10013. [Google Scholar] [CrossRef]

- Demirci, U.B. Mechanistic insights into the thermal decomposition of ammonia borane, a material studied for chemical hydrogen storage. Inorg. Chem. Front. 2021, 8, 1900–1930. [Google Scholar] [CrossRef]

- Demirci, U.B. Ammonia Borane: An Extensively Studied, Though Not Yet Implemented, Hydrogen Carrier. Energies 2020, 13, 3071. [Google Scholar] [CrossRef]

- Diaz, L.B.; Hanlon, J.M.; Bielewski, M.; Milewska, A.; Gregory, D.H. Ammonia Borane Based Nanocomposites as Solid-State Hydrogen Stores for Portable Power Applications. Energy Technol. 2018, 6, 583–594. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, X.; Jiang, L. 1D Nanoconfined Ordered-Assembly Reaction. Adv. Mater. Interfaces 2019, 6, 1900104. [Google Scholar] [CrossRef]

- Chen, Z.; Kirlikovali, K.O.; Idrees, K.B.; Wasson, M.C.; Farha, O.K. Porous materials for hydrogen storage. Chem 2022, 8, 693–716. [Google Scholar] [CrossRef]

- Ali, N.A.; Sazelee, N.A.; Ismail, M. An overview of reactive hydride composite (RHC) for solid-state hydrogen storage materials. Int. J. Hydrogen Energy 2021, 46, 31674–31698. [Google Scholar] [CrossRef]

- Broom, D.P.; Webb, C.J. Pitfalls in the characterisation of the hydrogen sorption properties of materials. Int. J. Hydrogen Energy 2017, 42, 29320–29343. [Google Scholar] [CrossRef]

- Wang, X.; Song, S.; Zhang, H. A redox interaction-engaged strategy for multicomponent nanomaterials. Chem. Soc. Rev. 2020, 49, 736–764. [Google Scholar] [CrossRef]

- Wu, P.; Tan, S.; Moon, J.; Yan, Z.; Fung, V.; Li, N.; Yang, S.-Z.; Cheng, Y.; Abney, C.W.; Wu, Z.; et al. Harnessing strong metal–support interactions via a reverse route. Nat. Commun. 2020, 11, 3042. [Google Scholar] [CrossRef]

| Silica Type | Hydrogen Storage Material | Nanoconfinement Method | Ref. |

|---|---|---|---|

| MSU-H | LiBH4 | solvent infiltration | [16] |

| MCM-41 | NaBH4 | melt impregnation | [74] |

| MCM-41, SBA-15 | LiBH4 | melt impregnation | [87] |

| poly(acryalamide)-grafted mesoporous silica nanoparticles (PAM-MSN) | NH3BH3 (AB) | melt impregnation | [88] |

| SBA-15 | Li2(BH4)(NH2). | melt impregnation | [89] |

| silica aerogel | NH3BH3 (AB) | aerogel drying and AB gas antisolvent precipitation | [90] |

| MCM-41, SBA-15 | LiBH4-LiNH2 | melt infiltration | [91] |

| Carbon Type | Hydrogen Storage Material | Nanoconfinement Method | Ref. |

|---|---|---|---|

| MOFs incorporating activated carbon (AC) and aluminum doping | AlH3 | solution impregnation method | [40] |

| Hollow carbon spheres (HCNs) | M(BH4)x (M = Li, Na, Mg, Ca) | solvent impregnation (best results, lower Td), melt infiltration | [42] |

| Carbon aerogels with different porosities | Mg/MgH2 | direct solvent-based synthesis of MgH2 from MgBu2 | [53] |

| Core-shell CoNi@C | MgH2 obtained by hydriding combustion synthesis (HCS) | high energy ball milling under Ar atmosphere | [65] |

| Graphene | NaAlH4 | solvent infiltration (THF; bottom-up strategy (90% loading) | [69] |

| Porous hollow carbon nanospheres | LiBH4-Mg(BH4)2 eutectic (LMBH) | melt-infiltration | [70] |

| xNi-CMK-3; N-CMK-3 (x = 1 and 5 wt.%) | MgH2 | in situ generated from MgBu2 soln. in heptane | [92] |

| Double-Layered Carbon Nanobowl | LiBH4 | melt infiltration | [93] |

| Carbon shell (2–3 nm thick) | Mg/MgH2 | reactive gas evaporation | [94] |

| TiO2-decorated amorphous carbon (AC) | MgH2 | ball milling | [95] |

| High Surface Area Graphite (HSAG) | LiAlH4 | solvent infiltration/incipient wetness method | [96] |

| Porous carbon, High Surface Area Graphite (HSAG-500) | Mg2CoH5 | bottom-up approach (Co2+ salt reduction, MgBu2 hydrogenation and solid-gas reaction Co + 2MgH2 + 0.5H2) | [97] |

| Graphene | MgH2 | solvent-free, MgBu2 thermal decomposition | [98] |

| Resorcinol-formaldehyde carbon aerogel (RFC) | 2LiBH4-LiAlH4 | two-step melt-infiltration | [99] |

| Activated charcoal (AC) | LiBH4 | melt-infiltration | [100] |

| NiCo2O4-anchored reduced graphene oxide (NiCo2O4@rGO) | LiAlH4 | low-temperature solution method coupled with annealing treatment; to yield NiCo2O4@rGO nanocomposites | [101] |

| Nickel@nitrogen-doped carbon spheres (Ni@NCS) | MgH2 | hydriding combustion and subsequent high-energy ball milling | [102] |

| Ultrathin, flexible Graphene (GR) | MgH2 | bottom-up self-assembly strategy (from MgBu2 in C6H12) | [103] |

| Porous Hollow Carbon Nanospheres (PHCNSs) | LiBH4 | mortar grounded, then melt infiltration (300 °C, 30 min, 100 bar H2) | [104] |

| Electrochemically synthesized reduced graphene oxide (erGO) | Mg-B | ball milling | [105] |

| Fe3O4@C, Multifunctional porous scaffold of carbon wrapped ultrafine Fe3O4 | LiBH4 | melting infiltration (300 °C, 30 min, 100 bar H2) | [106] |

| Activated carbon nanofibers (ACNF) impregnated with TiO2 | LiBH4 | mortar grinding (1:1, wt.), melt infiltration (310 °C at 5 °C/min rate under 60 bar H2, dwelling at 310 °C for 45 min, cooling to rt) | [108] |

| Carbon nanotube (CNT) | xMgH2/AlH3 (x = 1–4) | ball milling (200 rpm, 1 h, under H2 atmosphere) for xMgH2/AlH3; ball milling in steel container (1 h, under H2 atmosphere) for MgH2/AlH3@CNTs | [109] |

| Carbon nanoscaffolds (Graphite, CMK-3, Graphene, CNT) | MgH2 | solvent, melt infiltration | [110] |

| N-doped CMK-3 carbon (NCMK-3) | LiAlH4 | solution infiltration of LiAlH4 freshly recrystallized from diethyl ether | [111] |

| N-doped graphene hydrogels (resorcinol-formaldehyde) | LiBH4 | ball milling (300 min, 400 rpm), melt impregnation (30 min, 300 °C, 60 bar H2) | [112] |

| N-Doped Graphene-Rich Aerogels Decorated with Ni and Co Nanoparticles | LiBH4 | pre-mixing (mortar, pestle; 30 min), then melt impregnation (30 min, 300 °C, 60 bar H2). | [113] |

| Graphene sheets (G) | LiH (LiBH4, LiNH2BH3) | one-step solvothermal reaction of butyllithium supported by graphene in cyclohexane under a H2 pressure of 50 atm. | [114] |

| Graphene Nanosheet (G) | MgH2 | solid-state reaction (metathesis MgCl2, LiH), ball milling (30 h, 0.5 MPa H2, 500 rpm) | [115] |

| Activated mesoporous carbon (MC-a) | Ca(BH4)2 | incipient wetness method (0.1 M Ca(BH4)2.MTBE methyl tert-butyl ether, anhydrous) | [116] |

| Edge-Functionalized Graphene Nanoribbon (GNRs): unfunctionalized cGNR, nitrogen edge-doped N2-cGNR and N4-cGNR, and fluorenone GNR (f-cGNR) | Mg(/MgH2) | Rieke-like reaction (up to 98% Mg wt.%) | [117] |

| Ultrafine Ni nanoparticles dispersed on porous hollow carbon nanospheres (PHCNSs) | MgH2 (Mg2Ni/Mg2NiH4) | ball-milling (50 bar H2, 24 h, planetary ball mill QM-3SP4, Nanjing, 500 rpm, ball-to-sample weight ratio of 120:1) | [118] |

| Hydrogenated graphene (HG) | N/A | Li-reduction in graphene(G), then CH3OH hydrogenation | [119] |

| Graphene decorated with Ni nanocrystals | LiBH4 | solvothermal reaction (50 bar H2 at 100 °C, 24 h, continuous stirring); nBuLi hydrogenation (to LiH) and C6H15NBH3 reaction (to LiBH4-C6H15N); Cp2Ni (for Ni) | [120] |

| Defected graphene oxide (GO) or reduced graphene oxide (rGO) | Mg/MgH2 | in situ generation of Mg from a THF soln. of Cp2Mg | [121] |

| Reduced graphene oxide (rGO)/Li foil | Mg/MgH2 | direct solvent-based synthesis of MgH2 from MgCp2 | [122] |

| Carbon Matrix | LiBH4 | melt-impregnation | [123] |

| 1D Carbon Matrix (Fishbone Shaped): CNF, GNF | Mg/MgH2 | direct solvent-based synthesis of MgH2 from sonicated, solvent(THF)-impregnated MgCp2-CNF/GNF | [124] |

| Nickel-Containing Porous Carbon Sheets (Ni-PCSs) | LiAlH4, NaAlH4, and Mg(AlH4)2 | pre-mixing in mortar (15 min.), high energy ball-milling (SPEX M8000 mixer/mill, 15 min.) w/ball-to-powder weight ratio 40:1. | [125] |

| Reduced graphene oxide (rGO) | Mg(BH4)2 | in situ generation of rGO/Mg(BH4)2: rGO slurry with 1 M MgBu2 in heptane, added over BH3·S(CH3)2. | [126] |

| MWCNT (w/TiO2 2 mol% relative to NaAlH4) | NaAlH4 | physical mixture; PEIS/MWCNT/NaAlH4; polyaniline (Pani) or sulfonated polyetherimide (PEIS) as polymer matrices | [127] |

| Nitrogen-Doped Nanoporous Carbon Frameworks (N-doped NPC) | NaAlH4 | pre-mixing (mortar/pestle, 10 min), melt infiltration (Sievert apparatus, 190 bar H2, 45 min, 200 °C) | [128] |

| Graphene oxide (GO) framework | NaAlH4 | incipient wetness impregnation | [129] |

| Activated carbon (AC) | 2LiBH4-MgH2 | milling 2LiBH4:Mg in stainless-steel vial planetary ball mill; 20:1 ball-to-powder weight ratio (BPR), 10 h milling time, 580 rpm | [130] |

| Ordered mesoporous carbon structures (CMK) | N/A (Ni NP) | Ni NPs inserting by wetting the CMK structures | [131] |

| ultrafine Ni nanoparticles in a mesoporous carbon matrix (MC-Niinsitu) | Mg(BH4)2 | Mg(BH4)2 (45 wt.%) solution (THF, Et2O) slowly impregnated into the MC variant | [132] |

| High surface area graphite (HSAG) | LiH | catalytic hydrogenation of lithium naphthalenide (for LiH), stirring at 400 rpm, 0.35 MPa H2, 40 °C, aged overnight. | [133] |

| Fe-benzenetricarboxylate (Fe-BTC) | NaAlH4 | solution infiltration using tetrahydrofuran (THF) | [134] |

| Activated carbon nanofibers (ACNF) | LiBH4-LiAlH4 | solution impregnation of LiAlH4 (Et2O) then melt infiltration of LiBH4 (310 °C, 110 bar H2, 45 min.) | [135] |

| Carbon aerogel (CA) by resorcinol (R) and formaldehyde (F) process | N/A | triethylamine (as catalyst) | [136] |

| 3-D activated carbon (M-3D C) | MgH2 | solvent-reduction (NH2NH2) of a slurry MgBu2 (1 M, heptane) in M-3D C | [137] |

| Reduced graphene oxide (rGO)/metal nanocrystal multilaminates | Mg/MgH2 | solution-based co-reduction method of MgCp2/GO with lithium naphthalenide solution (2 h stirring, then 20 min centrifuged @10,000 rpm) | [138] |

| ZIF-67-Derived Co@Porous Carbon | NH3BH3 (AB, Ammonia Borane) | infiltration | [139] |

| Carbon nanotube arrays (CMK-5) | AlH3 and NH3BH3 | pre-mixed (mortar, hand-milling); solvent (THF) infiltration into CMK-5. | [140] |

| carbon nanomaterials MDC (based on calcined MOF-5) | NH3BH3 | solvent infiltration | [141] |

| Ice templating sheets of graphene oxide (GO) or partially reduced graphene oxide (rGO) | NH3BH3 | solvent infiltration (AB infiltrated to a solvent suspension of GO) | [142] |

| Bio-derived micro/mesoporous carbon with well-organized pores (TiO2/B co-catalysts) | NH3BH3 | solvent immersion (AB methanol solution into C-TiO2(B)), then vaporization | [143] |

| Microporous carbon (ECMC, narrow PSD, obtained by CVD from ethylene-filled Zeolite EMC-2) | NH3BH3 | solvent infiltration (of AB methanol solution to ECMC) | [144] |

| V2O3-supported cubic C-nanoboxes | MgH2 | ball milling (500 rpm, 24 h, BPR:120:1, 50 bar H2). | [146] |

| MOF Type | Hydrogen Storage Material | Nanoconfinement Method | Ref. |

|---|---|---|---|

| Cu-BDC(DMF) (BDC = benzenedicarboxylate; DMF-dimethylformamide, used as removal/capping solvent) | AB (NH3BH3) | hand grinding (5 min, under Ar); AB: Cu-BDC(DMF) weight ration: 1:20, based on pore filling estimation | [39] |

| MIL-101-NORIT-RB3 decorated (an activated carbon AC added in situ during synthesis of MOF) | AlH3 | solvent impregnation (THF, under Ar) | [40] |

| Various MOFs (of type MOF-5, MIL, UiO, ZIF, IRMOF etc.) | Pg/PdH2 | Various: Liquid impregnation, Metal-Organic Chemical Vapour Deposition; Sol-Gel; Double Solvent Method | [68] |

| HKUST-1, IRMOF-1, IRMOF-10, UiO-66, UiO-67, and MIL-53(Al), MIL-101, MOF-74(Mg) | AB (NH3BH3), NaAlH4, MHx (M = Li, Na, Mg, Ca, Al) | solvent- and melt infiltration | [86] |

| Nb2O5@MOF (Zn-based MOF, ZIF-8 (Zn(2-methylimidazole)2)) | MgH2 | ball milling (400 rpm, 4 h, ball to powder ratio 40:1) yielding MgH2@7 wt.% Nb2O5@MOF | [147] |

| MOF-5, MOF-177, HKUST-1, NOTT-100, Mg-IRMOF-74-I, NiIRMOF-74-I, Mg-IRMOF-74-II and Ni2(mdobdc) | Mg/MgH2; Ni/NiH2 | Hydrogen release/uptake in Ni-based MOFs | [148] |

| Ni-MOF scaffold (Ni2(TMA), TMA-trimasic acid) | MgH2 | in-situ synthesis; infiltration of MgBu2 (1 M in heptane) in Ni-MOF porosity, hydrogenation (453 K, 4.8 MPa H2, 20 h) to yield MgH2@Ni-MOF | [149] |

| UiO-66 (Zr6O4(BDC)6, BDC = 1,4-benzenedicarboxylate) | Ti(BH4)3 | gas adsorption of Ti(BH4)3 at dry-ice conditions (N2-carrier gas) into UiO-66 | [150] |

| UiO-67bpy (Zr6O4(OH)4(bpydc)6 with bpydc2– = 2,2′-bipyridine-5,5′-dicarboxylate) | Mg(BH4)2 | solvent impregnation | [151] |

| Various (High-throughput molecular simulations) | N/A | theoretical study (machine learning) | [152] |

| IRMOF-1, IRMOF-10, UiO-66, UiO-67, and MIL-53(Al) | AB (NH3BH3) | solvent infiltration (CH3OH) | [153] |

| MIL-53 | AB (NH3BH3) | incipient wetness impregnation method (CH3OH saturated solution) | [154] |

| MIL-101-NH2 (Al) | Al/AlH3 | solvothermal treatment involving N,N-dimethylformamide (DMF) as solvent | [155] |

| MOF-5 | M/MHx | post-confinement, in-situ confinement, double-solvent method (better efficiency) | [156] |

| MOF = ZIF-8, ZIF-67, MOF-74 | Mg/MgH2 | in situ reduction in Mg2+-decorated MOFs by NpLi solution in THF | [157] |

| Metal Oxide/Sulfide/Nitride | Hydrogen Storage Material | Nanoconfinement Method | Ref. |

|---|---|---|---|

| CoS nano-boxes (ZIF-67-derived) | MgH2 | infiltration MgBu2 (1 M in heptane; 1000 rpm, 48 h), followed by hydrogenation (453 K, 4.8 MPa H2, 24 h) | [80] |

| Al-SBA-15, γ -Al2O3 | LiBH4-LiNH2 | melt infiltration | [91] |

| Metal oxide nanoparticles (TiO2) anchored on amorphous carbon (SCNPs/AC) | MgH2 | in-situ pyrolysis assisted with quickly cooling | [95] |

| NiCo2O4-anchored reduced graphene oxide (rGO) | LiAlH4 | low-temperature solution method coupled with annealing treatment; to yield NiCo2O4@rGO nanocomposites | [101] |

| Fe3O4@C, Multifunctional porous scaffold of carbon wrapped ultrafine Fe3O4 | LiBH4 | melting infiltration (300 °C, 30 min, 100 bar H2) | [106] |

| Nb2O5@MOF (Zn-based MOF, ZIF-8 (Zn(2-methylimidazole)2)) | MgH2 | ball milling (400 rpm, 4 h, ball to powder ratio BPR 40:1) yielding MgH2@7 wt.% Nb2O5@MOF | [147] |

| Ni/CoMoO4 nanorods | MgH2 | ball milling (400 rpm, BPR: 60:1, 6 h); MgH2 is the host for NiCoO4/NiMoO4 nanorods to yield MgH2-10 wt.% Ni/CoMoO4 | [158] |

| Al2O3 | γ-Mg(BH4)2 | Atomic Layer Deposition (ALD) | [159] |

| B2O (Metal-Decorated Honeycomb Borophene Oxide) | Li/LiH; Na/NaH and K/KH. | Theoretical study: dispersion corrected density functional theory (DFT-D2) | [160] |

| Al2O3 | LiBH4-LiI | melt infiltration (50 bar H2, 295 °C, 3 °C min−1, 30 min); 4LiBH4:LiI–manual grinding in mortar, added to Al2O3 (130% pore filling) | [161] |

| (3D) boron nitride (BN) | AB (NH3BH3) | solvent impregnation of AB (6.92 M in THF) into mBN1000 and mBN1450 | [162] |

| TiO2 (anatase) | MgH2 | crystal-facet-dependent catalysis ({001} and {101}) | [172] |

| Metal as Host or Component | Hydrogen Storage Material | Nanoconfinement Method/Obs. | Ref. |

|---|---|---|---|

| Al | Al/AlH3@MIL-101-NORIT-RB3 decorated | solvent impregnation | [40] |

| Pd | Pd@MOF | Various: Liquid impregnation, Metal-Organic Chemical Vapour Deposition; Sol-Gel; Double Solvent Method | [68] |

| TiCx/Mg | Mg/MgH2 | reactive gas evaporation | [94] |

| N-doped graphene | LiBH4 | ball milling | [112] |

| Mg nanocrystals | Mg/MgH2@GO; Mg/MgH2@rGO | LiNp reduction in Cp2Mg/(r)GO slurry in THF. Various degrees of GO reduction (to rGO) to fine tune H2 storage properties by morphology modification of Mg confined in xGO/(1-x)rGO matrix. | [121] |

| Mg | Mg/rGO | One-step growth of Mg particles; chemical reduction in Cp2Mg by Li-methyl-naphtalenide (LiNpMe) in THF, followed by addition of the reactive mixture over single layer GO (30 min sonication). Mg w/high-index {21̅1̅6} crystal surface exhibits increased hydrogen absorption up to 6.2 wt %. | [122] |

| Mg | GO/Mg/MgH multilaminates | solution-based co-reduction method of MgCp2/GO with NpLi | [138] |

| Mg@(rGO/Ni) | Mg/MgH2 | in situ reduction in (Cp2Mg and Cp2Ni)@GO,THF-sonicated slurry, with a THF sol. of LiN; 6.5 H2 wt.% of total composite; H2 uptake under 1 bar H2. | [163] |

| Pd | Pd-Based Alloy Nanoparticles *RhPd-H NPs); PdH0.43 NPs (when np Pd used, control experiment) | one-pot solvothermal method-reduction of acetylacetonates Pd(acac)2 and Rh(acac)3 in mixed benzyl alcohol /acetaldehyde solvents with polyvinylpyrrolidone (PVP), at 180 °C in 30 min. RhPd confirmed by EDX. (111) diffraction peak outside that of either Rh/Pd, implying an expanded structure due to interstitial H atoms. | [164] |

| Mg (as matrix) | Mg/MgH2 | (review) of solid-state processing: physical vapor deposition, powder blending and consolidation, and additive manufacturing. | [165] |

| Raney Ni (3 nm pore size) as host | NaAlH4 to form NaAlH4/Raney Ni | wet impregnation | [166] |

| Al/Ti (Ti-based doped porous Al scaffold) | NaAlH4/Al | melt-infiltrated | [167] |

| Co | 2MgH2-Co (Mg2CoH5 and Mg6Co2H11) | compression to pellets (4.43 wt.% hydrogen storage) vs. powder (2.32 wt.% capacity) | [168] |

| Mg | MgH2 and ETM hydrides (ScH2, YH3, TiH2, ZrH2, VH and NbH) | mechanochemistry under hydrogen gas; 5 mol% of Early Transition Metals (ETM = Sc, Y, Ti, Zr, V, and Nb) as hydrogenation catalysts | [169] |