Organic Compounds as Corrosion Inhibitors for Carbon Steel in HCl Solution: A Comprehensive Review

Abstract

:| Contents | |

| 1. Introduction | 2 |

| 2. Corrosion and inhibition mechanism of carbon steel/HCl solution systems | 4 |

| 2.1. Corrosion mechanism | 4 |

| 2.2. Inhibition mechanism | 5 |

| 3. Experimental and theoretical research methods and characterization techniques | 7 |

| 3.1. Inhibition performance evaluation methods and experimental parameters | 7 |

| 3.1.1. Weight loss measurements (WL) | 8 |

| 3.1.2. Potentiodnamic polarization (PDP) | 8 |

| 3.1.3. Electrochemical impedance spectroscopy (EIS) | 9 |

| 3.1.4. Electrochemical frequency modulation (EFM) | 10 |

| 3.1.5. Other evaluation methods | 9 |

| 3.2. Adsorption isotherms and Thermodynamic parameters | 12 |

| 3.2.1. Adsorption isotherms | 12 |

| 3.2.2. Thermodynamic parameters | 13 |

| 3.3. Theoretical calculations | 14 |

| 3.3.1. DFT calculations | 15 |

| (1) Global reactivity descriptors | 15 |

| (2) Local reactivity descriptors | 17 |

| 3.3.2. MD and MC simulations | 20 |

| 3.4. Physicochemical and morphology characterization techniques | 24 |

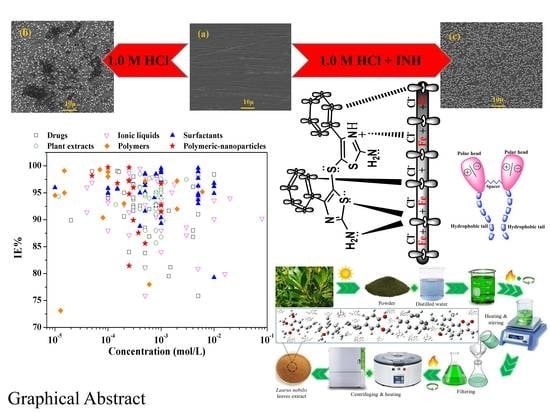

| 4. Classification and statistical analysis | 25 |

| 4.1. Drug molecules | 25 |

| 4.2. Ionic liquids | 28 |

| 4.3. Surfactants | 30 |

| 4.4. Plant extracts | 33 |

| 4.5. Polymers and Polymeric-nanoparticles | 37 |

| 4.6. Statistical analyses | 42 |

| 5. Conclusions | 45 |

| References | 47 |

1. Introduction

2. Corrosion and Inhibition Mechanism of Carbon Steel/HCl Solution Systems

2.1. Corrosion Mechanism

2.2. Inhibition Mechanism

3. Experimental and Theoretical Research Methods and Characterization Techniques

3.1. Inhibition Performance Evaluation Methods and Experimental Parameters

3.1.1. WL Measurements

3.1.2. PDP Technique

3.1.3. EIS Measurements

3.1.4. EFM Technique

3.1.5. Other Evaluation Methods

3.2. Adsorption Isotherms and Thermodynamic Parameters

3.2.1. Adsorption Isotherms

3.2.2. Thermodynamic parameters

3.3. Theoretical Calculations

3.3.1. DFT Calculations

- (1)

- Global Reactivity Descriptors

- (2)

- Local Reactivity Descriptors

3.3.2. MD and MC Simulations

3.4. Physicochemical and Morphology Characterization Techniques

4. Classification and Statistical Analysis

4.1. Drug Molecules

4.2. Ionic Liquids

4.3. Surfactants

4.4. Plant Extracts

4.5. Polymers and Polymeric-Nanoparticles

4.6. Statistical Analyses

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Choi, Y.-S.; Shim, J.-J.; Kim, J.-G. Effects of Cr, Cu, Ni and Ca on the corrosion behavior of low carbon steel in synthetic tap water. J. Alloys Compd. 2005, 391, 162–169. [Google Scholar] [CrossRef]

- Li, D.; Feng, Y.; Bai, Z.; Zhu, J.; Zheng, M. Influence of temperature, chloride ions and chromium element on the electronic property of passive film formed on carbon steel in bicarbonate/carbonate buffer solution. Electrochim. Acta 2007, 52, 7877–7884. [Google Scholar] [CrossRef]

- Liu, C.; Revilla, R.I.; Liu, Z.; Zhang, D.; Li, X.; Terryn, H. Effect of inclusions modified by rare earth elements (Ce, La) on localized marine corrosion in Q460NH weathering steel. Corros. Sci. 2017, 129, 82–90. [Google Scholar] [CrossRef]

- Ma, Q.; Tong, Z.; Wang, W.; Dong, G. Fabricating robust and repairable superhydrophobic surface on carbon steel by nanosecond laser texturing for corrosion protection. Appl. Surf. Sci. 2018, 455, 748–757. [Google Scholar] [CrossRef]

- Shibaeva, T.V.; Laurinavichyute, V.; Tsirlina, G.; Arsenkin, A.M.; Grigorovich, K.V. The effect of microstructure and non-metallic inclusions on corrosion behavior of low carbon steel in chloride containing solutions. Corros. Sci. 2014, 80, 299–308. [Google Scholar] [CrossRef]

- Wang, Y.; Jiang, Z.; Yao, Z.; Tang, H. Microstructure and corrosion resistance of ceramic coating on carbon steel prepared by plasma electrolytic oxidation. Surf. Coat. Technol. 2010, 204, 1685–1688. [Google Scholar] [CrossRef]

- Brito, V.S.; Bastos, I.; Costa, H. Corrosion resistance and characterization of metallic coatings deposited by thermal spray on carbon steel. Mater. Des. 2012, 41, 282–288. [Google Scholar] [CrossRef]

- Chen, X.; Chen, C.; Xiao, H.; Cheng, F.; Zhang, G.; Yi, G. Corrosion behavior of carbon nanotubes–Ni composite coating. Surf. Coat. Technol. 2005, 191, 351–356. [Google Scholar] [CrossRef]

- Ye, Y.; Liu, Z.; Liu, W.; Zhang, D.; Zhao, H.; Wang, L.; Li, X. Superhydrophobic oligoaniline-containing electroactive silica coating as pre-process coating for corrosion protection of carbon steel. Chem. Eng. J. 2018, 348, 940–951. [Google Scholar] [CrossRef]

- Negm, N.A.; Kandile, N.G.; Badr, E.A.; Mohammed, M.A. Gravimetric and electrochemical evaluation of environmentally friendly nonionic corrosion inhibitors for carbon steel in 1M HCl. Corros. Sci. 2012, 65, 94–103. [Google Scholar] [CrossRef]

- Kermani, M.B.; Morshed, A. Carbon Dioxide Corrosion in Oil and Gas Production—A Compendium. Corrosion 2003, 59, 659–683. [Google Scholar] [CrossRef]

- Migahed, M.A.; Al-Sabagh, A.M. Beneficial Role of Surfactants as Corrosion Inhibitors in Petroleum Industry: A Review Article. Chem. Eng. Commun. 2009, 196, 1054–1075. [Google Scholar] [CrossRef]

- Kuzin, A.V.; Gorichev, I.G.; Lainer, Y.A. Stimulating effect of phosphate ions on the dissolution kinetics of iron oxides in an acidic medium. Russ. Met. 2013, 2013, 652–657. [Google Scholar] [CrossRef]

- Lozanoa, I.; Mazariob, E.; Olivares-Xometla, C.O.; Likhanovac, N.V.; Herrastib, P. Corrosion behaviour of API 5LX52 steel in HCl and H2SO4 media in the presence of 1,3-dibencilimidazolio acetate and 1,3-dibencilimidazolio dodecanoate ionic liquids as inhibitors. Mater. Chem. Phys. 2014, 147, 191–197. [Google Scholar] [CrossRef]

- Chaubey, N.; Savita; Qurashi, A.; Chauhan, D.S.; Quraishi, M. Frontiers and advances in green and sustainable inhibitors for corrosion applications: A critical review. J. Mol. Liq. 2021, 321, 114385. [Google Scholar] [CrossRef]

- Alrefaee, S.H.; Rhee, K.Y.; Verma, C.; Quraishi, M.; Ebenso, E.E. Challenges and advantages of using plant extract as inhibitors in modern corrosion inhibition systems: Recent advancements. J. Mol. Liq. 2021, 321, 114666. [Google Scholar] [CrossRef]

- Hassan, H.H.; Abdelghani, E.; Amin, M.A. Inhibition of mild steel corrosion in hydrochloric acid solution by triazole derivatives: Part I. Polarization and EIS studies. Electrochim. Acta 2007, 52, 6359–6366. [Google Scholar] [CrossRef]

- Refaey, S.; El-Rehim, S.A.; Taha, F.; Saleh, M.; Ahmed, R. Inhibition of chloride localized corrosion of mild steel by PO43−, CrO42−, MoO42−, and NO2− anions. Appl. Surf. Sci. 2000, 158, 190–196. [Google Scholar] [CrossRef]

- Abdallah, M.; Jahdaly, B.A.A.L.; Salem, M.M.; Fawzy, A.; Fattah, A.A.A. Pitting corrosion of nickel alloys and stainless steel in chloride solutions and its inhibition using some inorganic compounds. J. Mater. Environ. Sci. 2017, 8, 2599–2607. [Google Scholar]

- Söylev, T.A.; Richardson, M. Corrosion inhibitors for steel in concrete: State-of-the-art report. Constr. Build. Mater. 2008, 22, 609–622. [Google Scholar] [CrossRef]

- Brondel, D.; Edwards, R.; Hayman, A.; Hill, D.; Mehta, S.; Semerad, T. Corrosion in the oil industry. Oilfield Rev. 1994, 6, 4–18. [Google Scholar]

- Wu, W.; Cheng, G.; Hu, H.; Zhou, Q. Risk analysis of corrosion failures of equipment in refining and petrochemical plants based on fuzzy set theory. Eng. Fail. Anal. 2013, 32, 23–34. [Google Scholar] [CrossRef]

- Marcus, P. Corrosion Mechanisms in Theory and Practice; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Noor, E.A.; Al-Moubaraki, A.H. Corrosion behavior of mild steel in hydrochloric acid solutions. Int. J. Electrochem. Sci. 2008, 3, 806–818. [Google Scholar]

- Yadav, D.K.; Quraishi, M.A. Electrochemical investigation of Substituted Pyranopyrazoles Adsorption on Mild Steel in Acid Solution. Ind. Eng. Chem. Res. 2012, 51, 8194–8210. [Google Scholar] [CrossRef]

- Mészáros, L.; Lengyel, B.; Garai, T.; Trabanelli, G. Study of the inhibitory effect of N-decylpyridinium derivatives using AC-methods. Acta Chim. Hung. 1990, 127, 113–120. [Google Scholar]

- Allah, A.G.G.; Nassif, N.; Mikhail, T.F. Effect of temperature on the corrosion behavior of helwan steel in acid chloride solutions. Ann. Chim. 1992, 82, 49–71. [Google Scholar]

- Oakes, G.; West, J.M. Influence of Thiourea on the Dissolution of Mild Steel in Strong Hydrochloric Acid. Br. Corros. J. 1969, 4, 66–73. [Google Scholar] [CrossRef]

- Mathur, P.B.; Vasudevan, T. Reaction Rate Studies for the Corrosion of Metals in Acids—I, Iron in Mineral Acids. Corrosion 1982, 38, 171–178. [Google Scholar] [CrossRef]

- Bensouda, Z.; El Assiri, E.H.; Sfaira, M.; Touhami, M.E.; Farah, A.; Hammouti, B. Extraction, characterization and anticorrosion potential of an essential oil from orange zest as eco-friendly inhibitor for mild steel in acidic solution. J. Bio-Tribo-Corros. 2019, 5, 84. [Google Scholar] [CrossRef]

- Bockris, J.O.M.; Reddy, A.K.N. Modern Electrochemistry—An Introduction to an Interdisciplinary Area; Plenum Press: New York, NY, USA, 1970. [Google Scholar]

- Verma, C.; Lgaz, H.; Verma, D.; Ebenso, E.E.; Bahadur, I.; Quraishi, M. Molecular dynamics and Monte Carlo simulations as powerful tools for study of interfacial adsorption behavior of corrosion inhibitors in aqueous phase: A review. J. Mol. Liq. 2018, 260, 99–120. [Google Scholar] [CrossRef]

- John, S.; Joseph, A. Electroanalytical studies of the corrosion-protection properties of 4-amino-4H-1,2,4-triazole-3,5-dimethanol (ATD) on mild steel in 0.5 N sulfuric acid. Res. Chem. Intermed. 2011, 38, 1359–1373. [Google Scholar] [CrossRef]

- Zadeh, A.R.H.; Danaee, I.; Maddahy, M.H. Thermodynamic and Adsorption Behaviour of Medicinal Nitramine as a Corrosion Inhibitor for AISI Steel Alloy in HCl Solution. J. Mater. Sci. Technol. 2013, 29, 884–892. [Google Scholar] [CrossRef]

- Yadav, D.K.; Maiti, B.; Quraishi, M. Electrochemical and quantum chemical studies of 3,4-dihydropyrimidin-2(1H)-ones as corrosion inhibitors for mild steel in hydrochloric acid solution. Corros. Sci. 2010, 52, 3586–3598. [Google Scholar] [CrossRef]

- Verma, C.; Quraishi, M.A.; Olasunkanmi, L.O.; Ebenso, E.E. l-Proline-promoted synthesis of 2-amino-4-arylquinoline-3-carbonitriles as sustainable corrosion inhibitors for mild steel in 1 M HCl: Experimental and computational studies. RSC Adv. 2015, 5, 85417–85430. [Google Scholar] [CrossRef]

- Arslan, T.; Kandemirli, F.; Ebenso, E.; Love, I.; Alemu, H. Quantum chemical studies on the corrosion inhibition of some sulphonamides on mild steel in acidic medium. Corros. Sci. 2009, 51, 35–47. [Google Scholar] [CrossRef]

- Bentiss, F.; Lagrenée, M. Heterocyclic compounds as corrosion inhibitors for mild steel in hydrochloric: Acid medium-correlation between electronic structure and inhibition efficiency. J. Mater. Environ. Sci. 2011, 2, 13–17. [Google Scholar]

- Okafor, P.; Osabor, V.; Ebenso, E. Eco-friendly corrosion inhibitors: Inhibitive action of ethanol extracts of Garcinia kola for the corrosion of mild steel in H2SO4 solutions. Pigment Resin Technol. 2007, 36, 299–305. [Google Scholar] [CrossRef]

- Obot, I.B.; Obi-Egbedi, N.O.; Eseola, A.O. Anticorrosion Potential of 2-Mesityl-1H-imidazo[4,5-f][1,10]phenanthroline on Mild Steel in Sulfuric Acid Solution: Experimental and Theoretical Study. Ind. Eng. Chem. Res. 2011, 50, 2098–2110. [Google Scholar] [CrossRef]

- Verma, C.; Obot, I.B.; Bahadur, I.; Sherif, E.-S.M.; Ebenso, E.E. Choline based ionic liquids as sustainable corrosion inhibitors on mild steel surface in acidic medium: Gravimetric, electrochemical, surface morphology, DFT and Monte Carlo simulation studies. Appl. Surf. Sci. 2018, 457, 134–149. [Google Scholar] [CrossRef]

- Goyal, M.; Kumar, S.; Bahadur, I.; Verma, C.; Ebenso, E.E. Organic corrosion inhibitors for industrial cleaning of ferrous and non-ferrous metals in acidic solutions: A review. J. Mol. Liq. 2018, 256, 565–573. [Google Scholar] [CrossRef]

- McCafferty, E. Introduction to Corrosion Science; Springer Science and Business Media LLC: New York, NY, USA, 2010. [Google Scholar]

- Verma, C.B.; Quraishi, M.; Singh, A. 2-Aminobenzene-1,3-dicarbonitriles as green corrosion inhibitor for mild steel in 1 M HCl: Electrochemical, thermodynamic, surface and quantum chemical investigation. J. Taiwan Inst. Chem. Eng. 2015, 49, 229–239. [Google Scholar] [CrossRef]

- Verma, C.; Quraishi, M.; Singh, A. A thermodynamical, electrochemical, theoretical and surface investigation of diheteroaryl thioethers as effective corrosion inhibitors for mild steel in 1 M HCl. J. Taiwan Inst. Chem. Eng. 2016, 58, 127–140. [Google Scholar] [CrossRef]

- Deng, S.; Li, X.; Xie, X. Hydroxymethyl urea and 1,3-bis(hydroxymethyl) urea as corrosion inhibitors for steel in HCl solution. Corros. Sci. 2014, 80, 276–289. [Google Scholar] [CrossRef]

- Verma, C.; Olasunkanmi, L.O.; Ebenso, E.E.; Quraishi, M.A.; Obot, I.B. Adsorption Behavior of Glucosamine-Based, Pyrimidine-Fused Heterocycles as Green Corrosion Inhibitors for Mild Steel: Experimental and Theoretical Studies. J. Phys. Chem. C 2016, 120, 11598–11611. [Google Scholar] [CrossRef]

- Verma, C.; Quraishi, M.A.; Kluza, K.; Makowska-Janusik, M.; Olasunkanmi, L.; Ebenso, E.E. Corrosion inhibition of mild steel in 1M HCl by D-glucose derivatives of dihydropyrido[2,3-d:6,5-d′]dipyrimidine-2,4,6,8(1H,3H, 5H,7H)-tetraone. Sci. Rep. 2017, 7, srep44432. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Verma, C.; Verma, D.K.; Ebenso, E.E.; Quraishi, M.A. Sulfur and phosphorus heteroatom-containing compounds as corrosion inhibitors: An overview. Heteroat. Chem. 2018, 29, e21437. [Google Scholar] [CrossRef] [Green Version]

- Yıldırım, A.; Çetin, M. Synthesis and evaluation of new long alkyl side chain acetamide, isoxazolidine and isoxazoline derivatives as corrosion inhibitors. Corros. Sci. 2008, 50, 155–165. [Google Scholar] [CrossRef]

- Verma, C.; Olasunkanmi, L.; Ebenso, E.E.; Quraishi, M. Substituents effect on corrosion inhibition performance of organic compounds in aggressive ionic solutions: A review. J. Mol. Liq. 2018, 251, 100–118. [Google Scholar] [CrossRef]

- Lgaz, H.; Masroor, S.; Chafiq, M.; Damej, M.; Brahmia, A.; Salghi, R.; Benmessaoud, M.; Ali, I.H.; Alghamdi, M.M.; Chaouiki, A.; et al. Evaluation of 2-Mercaptobenzimidazole Derivatives as Corrosion Inhibitors for Mild Steel in Hydrochloric Acid. Metals 2020, 10, 357. [Google Scholar] [CrossRef] [Green Version]

- Salhi, A.; Tighadouini, S.; El-Massaoudi, M.; Elbelghiti, M.; Bouyanzer, A.; Radi, S.; El Barkany, S.; Bentiss, F.; Zarrouk, A. Keto-enol heterocycles as new compounds of corrosion inhibitors for carbon steel in 1 M HCl: Weight loss, electrochemical and quantum chemical investigation. J. Mol. Liq. 2017, 248, 340–349. [Google Scholar] [CrossRef]

- Olasunkanmi, L.O.; Obot, I.B.; Kabanda, M.M.; Ebenso, E.E. Some Quinoxalin-6-yl Derivatives as Corrosion Inhibitors for Mild Steel in Hydrochloric Acid: Experimental and Theoretical Studies. J. Phys. Chem. C 2015, 119, 16004–16019. [Google Scholar] [CrossRef]

- Abdallah, M.; Altass, H.; Al-Gorair, A.S.; Al-Fahemi, J.H.; Jahdaly, B.; Soliman, K. Natural nutmeg oil as a green corrosion inhibitor for carbon steel in 1.0 M HCl solution: Chemical, electrochemical, and computational methods. J. Mol. Liq. 2021, 323, 115036. [Google Scholar] [CrossRef]

- Singh, P.; Quraishi, M.A.; Ebenso, E.E. Microwave assisted green synthesis of bis-phenol polymer containing piperazine as a corrosion inhibitor for mild steel in 1M HCl. Int. J. Electrochem. Sci. 2013, 8, 10890–10902. [Google Scholar]

- Mahdavian-Ahadi, M.; Attar, M. Electrochemical behaviour of some transition metal acetylacetonate complexes as corrosion inhibitors for mild steel. Corros. Sci. 2009, 51, 409–414. [Google Scholar] [CrossRef]

- Xu, F.; Luo, L.; Xiong, L.; Liu, Y. Microstructure and corrosion behavior of ALD Al2O3 film on AZ31 magnesium alloy with different surface roughness. J. Magnes. Alloy. 2020, 8, 480–492. [Google Scholar] [CrossRef]

- Fekry, A.; Ameer, M. Electrochemical investigation on the corrosion and hydrogen evolution rate of mild steel in sulphuric acid solution. Int. J. Hydrog. Energy 2011, 36, 11207–11215. [Google Scholar] [CrossRef]

- Issaadi, S.; Douadi, T.; Zouaoui, A.; Chafaa, S.; Khan, M.; Bouet, G. Novel thiophene symmetrical Schiff base compounds as corrosion inhibitor for mild steel in acidic media. Corros. Sci. 2011, 53, 1484–1488. [Google Scholar] [CrossRef] [Green Version]

- Deyab, M.; Ashmawy, A.M.; Nessim, M.; Mohsen, Q. New Gemini surfactants based on alkyl benzenaminium: Synthesis and links to application of corrosion protection. J. Mol. Liq. 2021, 332, 115855. [Google Scholar] [CrossRef]

- Nnaji, N.; Nwaji, N.; Mack, J.; Nyokong, T. Corrosion Resistance of Aluminum against Acid Activation: Impact of Benzothiazole-Substituted Gallium Phthalocyanine. Molecules 2019, 24, 207. [Google Scholar] [CrossRef] [Green Version]

- Rajendran, S.R.; Jeyasundari, J.; Usha, P.; Selvi, J.A.; Narayanasamy, B.; Regis, A.P.P.; Rengan, P. Corrosion Behaviour of Aluminium in the Presence of an Aqueous Extract of Hibiscus Rosa-sinensis. Port. Electrochim. Acta 2009, 27, 153–164. [Google Scholar] [CrossRef]

- Kowsari, E.; Arman, S.; Shahini, M.; Zandi, H.; Ehsani, A.; Naderi, R.; PourghasemiHanza, A.; Mehdipour, M. In situ synthesis, electrochemical and quantum chemical analysis of an amino acid-derived ionic liquid inhibitor for corrosion protection of mild steel in 1M HCl solution. Corros. Sci. 2016, 112, 73–85. [Google Scholar] [CrossRef]

- Behzadnasab, M.; Mirabedini, S.M.; Kabiri, K.; Jamali, S. Corrosion performance of epoxy coatings containing silane treated ZrO2 nanoparticles on mild steel in 3.5% NaCl solution. Corros. Sci. 2011, 53, 89–98. [Google Scholar] [CrossRef]

- El Tamany, E.S.H.; Elsaeed, S.; Ashour, H.; Zaki, E.; El Nagy, H.A. Novel acrylamide ionic liquids as anti-corrosion for X-65 steel dissolution in acid medium: Adsorption, hydrogen evolution and mechanism. J. Mol. Struct. 2018, 1168, 106–114. [Google Scholar] [CrossRef]

- Fouda, A.S.; Shalabi, K.; E-Hossiany, A. Moxifloxacin Antibiotic as Green Corrosion Inhibitor for Carbon Steel in 1 M HCl. J. Bio-Tribo-Corros. 2016, 2, 18. [Google Scholar] [CrossRef] [Green Version]

- Mouaden, K.E.; Chauhan, D.; Quraishi, M.; Bazzi, L. Thiocarbohydrazide-crosslinked chitosan as a bioinspired corrosion inhibitor for protection of stainless steel in 3.5% NaCl. Sustain. Chem. Pharm. 2020, 15, 100213. [Google Scholar] [CrossRef]

- Chauhan, D.S.; Quraishi, M.; Carrière, C.; Seyeux, A.; Marcus, P.; Singh, A. Electrochemical, ToF-SIMS and computational studies of 4-amino-5-methyl-4H-1,2,4-triazole-3-thiol as a novel corrosion inhibitor for copper in 3.5% NaCl. J. Mol. Liq. 2019, 289, 111113. [Google Scholar] [CrossRef]

- Srivastava, M.; Tiwari, P.; Srivastava, S.K.; Prakash, R.; Ji, G. Electrochemical investigation of Irbesartan drug molecules as an inhibitor of mild steel corrosion in 1 M HCl and 0.5 M H2SO4 solutions. J. Mol. Liq. 2017, 236, 184–197. [Google Scholar] [CrossRef]

- Misra, A.; Kumar, P.; Srivastava, R.; Dhawan, S.K.; Kamalasanan, M.N.; Chandra, S. Electrochemical and optical studies of conjugated polymers for three primary colours. Indian J. Pure Appl. Phys. 2005, 43, 921–925. [Google Scholar]

- Shafiee, A.; Salleh, M.M.; Yahaya, M. Determination of HOMO and LUMO of [6,6]-phenyl C61-butyric acid 3-ethylthiophene ester and poly (3-octyl-thiophene-2,5-diyl) through voltametry characterization. Sains Malays. 2011, 40, 173–176. [Google Scholar]

- Qiang, Y.; Zhang, S.; Tan, B.; Chen, S. Evaluation of Ginkgo leaf extract as an eco-friendly corrosion inhibitor of X70 steel in HCl solution. Corros. Sci. 2018, 133, 6–16. [Google Scholar] [CrossRef]

- Kosari, A.; Moayed, M.H.; Davoodi, A.; Parvizi, R.; Momeni, M.; Eshghi, H.; Moradi, H. Electrochemical and quantum chemical assessment of two organic compounds from pyridine derivatives as corrosion inhibitors for mild steel in HCl solution under stagnant condition and hydrodynamic flow. Corros. Sci. 2014, 78, 138–150. [Google Scholar] [CrossRef]

- Yüce, A.O.; Kardaş, G. Adsorption and inhibition effect of 2-thiohydantoin on mild steel corrosion in 0.1M HCl. Corros. Sci. 2012, 58, 86–94. [Google Scholar] [CrossRef]

- Zhang, K.; Xu, B.; Yang, W.; Yin, X.; Liu, Y.; Chen, Y. Halogen-substituted imidazoline derivatives as corrosion inhibitors for mild steel in hydrochloric acid solution. Corros. Sci. 2015, 90, 284–295. [Google Scholar] [CrossRef]

- Łosiewicz, B.; Popczyk, M.; Szklarska, M.; Smołka, A.; Osak, P.; Budniok, A. Use of Scanning Vibrating Electrode Technique to Localized Corrosion Evaluation. Solid State Phenom. 2015, 228, 353–368. [Google Scholar] [CrossRef]

- Qiang, Y.; Guo, L.; Li, H.; Lan, X. Fabrication of environmentally friendly Losartan potassium film for corrosion inhibition of mild steel in HCl medium. Chem. Eng. J. 2021, 406, 126863. [Google Scholar] [CrossRef]

- Yang, D.; Ye, Y.; Su, Y.; Liu, S.; Gong, D.; Zhao, H. Functionalization of citric acid-based carbon dots by imidazole toward novel green corrosion inhibitor for carbon steel. J. Clean. Prod. 2019, 229, 180–192. [Google Scholar] [CrossRef]

- Chin, R.J.; Nobe, K. Electrochemical Characteristics of Iron in H2SO4 Containing Benzotriazole. J. Electrochem. Soc. 1971, 118, 545–548. [Google Scholar] [CrossRef]

- Vengatesh, G.; Sundaravadivelu, M. Non-toxic bisacodyl as an effective corrosion inhibitor for mild steel in 1 M HCl: Thermodynamic, electrochemical, SEM, EDX, AFM, FT-IR, DFT and molecular dynamics simulation studies. J. Mol. Liq. 2019, 287, 110906. [Google Scholar] [CrossRef]

- El Basiony, N.; Badr, E.E.; Baker, S.A.; El-Tabei, A. Experimental and theoretical (DFT&MC) studies for the adsorption of the synthesized Gemini cationic surfactant based on hydrazide moiety as X-65 steel acid corrosion inhibitor. Appl. Surf. Sci. 2021, 539, 148246. [Google Scholar] [CrossRef]

- Obot, I.B.; Obi-Egbedi, N.O.; Umoren, S.A. Adsorption characteristics and corrosion inhibitive properties of clotrimazole for aluminium corrosion in hydrochloric acid. Int. J. Electrochem. Sci. 2009, 4, 863–877. [Google Scholar]

- Omotosho, O.A.; Okeniyi, J.O.; Oni, A.B.; Makinwa, T.O.; Ajibola, O.B.; Fademi, E.O.J.; Obi, C.E.; Loto, C.A.; Popoola, A.P.I. Inhibition and mechanism of Terminalia catappa on mild-steel corrosion in sulphuric-acid environment. Prog. Ind. Ecol. 2016, 10, 398–413. [Google Scholar] [CrossRef]

- Cen, H.; Cao, J.; Chen, Z. Functionalized carbon nanotubes as a novel inhibitor to enhance the anticorrosion performance of carbon steel in CO2-saturated NaCl solution. Corros. Sci. 2020, 177, 109011. [Google Scholar] [CrossRef]

- Lim, B.; Kobayashi, H.; Camargo, P.H.C.; Allard, L.F.; Liu, J.; Xia, Y. New insights into the growth mechanism and surface structure of palladium nanocrystals. Nano Res. 2010, 3, 180–188. [Google Scholar] [CrossRef] [Green Version]

- Shyamala, M.; Kasthuri, P.K. The Inhibitory Action of the Extracts of Adathoda vasica, Eclipta alba, and Centella asiatica on the Corrosion of Mild Steel in Hydrochloric Acid Medium: A Comparative Study. Int. J. Corros. 2011, 2012, 852827. [Google Scholar] [CrossRef]

- Döner, A.; Solmaz, R.; Özcan, M.; Kardaş, G. Experimental and theoretical studies of thiazoles as corrosion inhibitors for mild steel in sulphuric acid solution. Corros. Sci. 2011, 53, 2902–2913. [Google Scholar] [CrossRef]

- Hegazy, M.; Rashwan, S.; Kamel, M.; El Kotb, M. Synthesis, surface properties and inhibition behavior of novel cationic gemini surfactant for corrosion of carbon steel tubes in acidic solution. J. Mol. Liq. 2015, 211, 126–134. [Google Scholar] [CrossRef]

- El-Din, M.R.N.; Al-Sabagh, A.M.; Hegazy, M. Study of the Inhibition Efficiency for Some Novel Surfactants on the Carbon Steel (Type H-11) Pipelines in 0.5 M HCl Solution by Potentiodynamic Technique. J. Dispers. Sci. Technol. 2012, 33, 1444–1451. [Google Scholar] [CrossRef]

- Bentiss, F.; Lebrini, M.; Lagrenée, M. Thermodynamic characterization of metal dissolution and inhibitor adsorption processes in mild steel/2,5-bis(n-thienyl)-1,3,4-thiadiazoles/hydrochloric acid system. Corros. Sci. 2005, 47, 2915–2931. [Google Scholar] [CrossRef]

- Noor, E.A.; Al-Moubaraki, A.H. Thermodynamic study of metal corrosion and inhibitor adsorption processes in mild steel/1-methyl-4[4′(-X)-styryl pyridinium iodides/hydrochloric acid systems. Mater. Chem. Phys. 2008, 110, 145–154. [Google Scholar] [CrossRef]

- Solmaz, R.; Kardaş, G.; Çulha, M.; Yazıcı, B.; Erbil, M. Investigation of adsorption and inhibitive effect of 2-mercaptothiazoline on corrosion of mild steel in hydrochloric acid media. Electrochim. Acta 2008, 53, 5941–5952. [Google Scholar] [CrossRef]

- Radovici, O. Corrosion of Iron in Acid Solutions in Presence of an Organic Inhibitor, Comptes Rendus du 2èrhe Symposium Européen sur les Inhibiteurs de Corrosion. Annali Univ. Ferrara 1966, 4, 449–456. [Google Scholar]

- Szauer, T.; Brandt, A. On the role of fatty acid in adsorption and corrosion inhibition of iron by amine—fatty acid salts in acidic solution. Electrochim. Acta 1981, 26, 1257–1260. [Google Scholar] [CrossRef]

- Morad, M.; El-Dean, A.K. 2,2′-Dithiobis(3-cyano-4,6-dimethylpyridine): A new class of acid corrosion inhibitors for mild steel. Corros. Sci. 2006, 48, 3398–3412. [Google Scholar] [CrossRef]

- Khomami, M.N.; Danaee, I.; Attar, A.A.; Peykari, M. Kinetic and thermodynamic studies of AISI 4130 steel alloy corrosion in ethylene glycol-water mixture in presence of inhibitors. Met. Mater. Int. 2013, 19, 453–464. [Google Scholar] [CrossRef]

- Lgaz, H.; Salghi, R.; Masroor, S.; Kim, S.-H.; Kwon, C.; Kim, S.Y.; Yang, Y.-J.; Chung, I.-M. Assessing corrosion inhibition characteristics of hydrazone derivatives on mild steel in HCl: Insights from electronic-scale DFT and atomic-scale molecular dynamics. J. Mol. Liq. 2020, 308, 112998. [Google Scholar] [CrossRef]

- Wazzan, N.A.; Obot, I.; Kaya, S. Theoretical modeling and molecular level insights into the corrosion inhibition activity of 2-amino-1,3,4-thiadiazole and its 5-alkyl derivatives. J. Mol. Liq. 2016, 221, 579–602. [Google Scholar] [CrossRef]

- Ansari, K.; Chauhan, D.S.; Quraishi, M.; Mazumder, M.A.; Singh, A. Chitosan Schiff base: An environmentally benign biological macromolecule as a new corrosion inhibitor for oil & gas industries. Int. J. Biol. Macromol. 2020, 144, 305–315. [Google Scholar] [CrossRef]

- Obot, I.B.; Macdonald, D.; Gasem, Z. Density functional theory (DFT) as a powerful tool for designing new organic corrosion inhibitors. Part 1: An overview. Corros. Sci. 2015, 99, 1–30. [Google Scholar] [CrossRef]

- Geerlings, P.; de Proft, A.F.; Langenaeker, W. Conceptual Density Functional Theory. Chem. Rev. 2003, 103, 1793–1874. [Google Scholar] [CrossRef]

- Pearson, R.G. Absolute electronegativity and hardness: Application to inorganic chemistry. Inorg. Chem. 1988, 27, 734–740. [Google Scholar] [CrossRef]

- Zhao, H.; Zhang, X.; Ji, L.; Hu, H.; Li, Q. Quantitative structure–activity relationship model for amino acids as corrosion inhibitors based on the support vector machine and molecular design. Corros. Sci. 2014, 83, 261–271. [Google Scholar] [CrossRef]

- Parr, R.G.; Pearson, R.G. Absolute hardness: Companion parameter to absolute electronegativity. J. Am. Chem. Soc. 1983, 105, 7512–7516. [Google Scholar] [CrossRef]

- Awad, M.; Metwally, M.; Soliman, S.; El-Zomrawy, A.; Bedair, M. Experimental and quantum chemical studies of the effect of poly ethylene glycol as corrosion inhibitors of aluminum surface. J. Ind. Eng. Chem. 2014, 20, 796–808. [Google Scholar] [CrossRef]

- Singh, A.; Kumar, A.; Pramanik, T. A Theoretical Approach to the Study of Some Plant Extracts as Green Corrosion Inhibitor for Mild Steel in HCl Solution. Orient. J. Chem. 2013, 29, 277–283. [Google Scholar] [CrossRef]

- Hegazy, M.; Badawi, A.; El Rehim, S.A.; Kamel, W. Corrosion inhibition of carbon steel using novel N-(2-(2-mercaptoacetoxy)ethyl)-N,N-dimethyl dodecan-1-aminium bromide during acid pickling. Corros. Sci. 2013, 69, 110–122. [Google Scholar] [CrossRef]

- Fu, J.-J.; Li, S.-N.; Wang, Y.; Cao, L.-H.; Lu, L.-D. Computational and electrochemical studies of some amino acid compounds as corrosion inhibitors for mild steel in hydrochloric acid solution. J. Mater. Sci. 2010, 45, 6255–6265. [Google Scholar] [CrossRef]

- Parr, R.G.; Szentpály, L.V.; Liu, S. Electrophilicity Index. J. Am. Chem. Soc. 1999, 121, 1922–1924. [Google Scholar] [CrossRef]

- Saha, S.K.; Dutta, A.; Ghosh, P.; Sukul, D.; Banerjee, P. Novel Schiff-base molecules as efficient corrosion inhibitors for mild steel surface in 1 M HCl medium: Experimental and theoretical approach. Phys. Chem. Chem. Phys. 2016, 18, 17898–17911. [Google Scholar] [CrossRef]

- Pramanik, S.; Dey, T.; Mukherjee, A.K. Five benzoic acid derivatives: Crystallographic study using X-ray powder diffraction, electronic structure and molecular electrostatic potential calculation. J. Mol. Struct. 2019, 1175, 185–194. [Google Scholar] [CrossRef]

- Sayin, K.; Jafari, H.; Mohsenifar, F. Effect of pyridyl on adsorption behavior and corrosion inhibition of aminotriazole. J. Taiwan Inst. Chem. Eng. 2016, 68, 431–439. [Google Scholar] [CrossRef]

- Yang, W.; Mortier, W.J. The use of global and local molecular parameters for the analysis of the gas-phase basicity of amines. J. Am. Chem. Soc. 1986, 108, 5708–5711. [Google Scholar] [CrossRef]

- Koumya, Y.; Idouhli, R.; Sayout, A.; Abouelfida, A.; Benyaich, A.; Romane, A. Experimental and Theoretical Approach on the Enhanced Inhibitory Effect of Tetracyclic Triterpenes for Stainless Steel Corrosion in Sulfuric Acid. Met. Mater. Trans. A 2019, 50, 3002–3012. [Google Scholar] [CrossRef]

- Morell, C.; Grand, A.; Toro-Labbe, A. Theoretical support for using the Δf(r) descriptor. Chem. Phys. Lett. 2006, 425, 342–346. [Google Scholar] [CrossRef]

- Roy, R.K.; Pal, S.; Hirao, K. On non-negativity of Fukui function indices. J. Chem. Phys. 1999, 110, 8236–8245. [Google Scholar] [CrossRef]

- Boussalah, N.; Ghalem, S.; El Kadiri, S.; Hammouti, B.; Touzani, R. Theoretical study of the corrosion inhibition of some bipyrazolic derivatives: A conceptual DFT investigation. Res. Chem. Intermed. 2012, 38, 2009–2023. [Google Scholar] [CrossRef]

- Xavier, S.; Periandy, S.; Ramalingam, S. NBO, conformational, NLO, HOMO–LUMO, NMR and electronic spectral study on 1-phenyl-1-propanol by quantum computational methods. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2015, 137, 306–320. [Google Scholar] [CrossRef] [PubMed]

- Tirado-Rives, J.; Jorgensen, W.L. Molecular dynamics of proteins with the OPLS potential functions. Simulation of the third domain of silver pheasant ovomucoid in water. J. Am. Chem. Soc. 1990, 112, 2773–2781. [Google Scholar] [CrossRef]

- Sun, H.; Ren, P.; Fried, J. The COMPASS force field: Parameterization and validation for phosphazenes. Comput. Theor. Polym. Sci. 1998, 8, 229–246. [Google Scholar] [CrossRef]

- Bunte, S.W.; Sun, H. Molecular Modeling of Energetic Materials: The Parameterization and Validation of Nitrate Esters in the COMPASS Force Field. J. Phys. Chem. B 2000, 104, 2477–2489. [Google Scholar] [CrossRef] [Green Version]

- El Aoufir, Y.; Aslam, R.; Lazrak, F.; Marzouki, R.; Kaya, S.; Skal, S.; Ghanimi, A.; Ali, I.; Guenbour, A.; Lgaz, H.; et al. The effect of the alkyl chain length on corrosion inhibition performances of 1,2,4-triazole-based compounds for mild steel in 1.0 M HCl: Insights from experimental and theoretical studies. J. Mol. Liq. 2020, 303, 112631. [Google Scholar] [CrossRef]

- Sun, H. COMPASS: An ab Initio Force-Field Optimized for Condensed-Phase Applications Overview with Details on Alkane and Benzene Compounds. J. Phys. Chem. B 1998, 102, 7338–7364. [Google Scholar] [CrossRef]

- Sun, H.; Jin, Z.; Yang, C.; Akkermans, R.L.C.; Robertson, S.H.; Spenley, N.A.; Miller, S.; Todd, S.M. COMPASS II: Extended coverage for polymer and drug-like molecule databases. J. Mol. Modeling 2016, 22, 47. [Google Scholar] [CrossRef]

- Guo, L.; Obot, I.B.; Zheng, X.; Shen, X.; Qiang, Y.; Kaya, S.; Kaya, C. Theoretical insight into an empirical rule about organic corrosion inhibitors containing nitrogen, oxygen, and sulfur atoms. Appl. Surf. Sci. 2017, 406, 301–306. [Google Scholar] [CrossRef]

- Kaya, S.; Guo, L.; Kaya, C.; Tüzün, B.; Obot, I.B.; Touir, R.; Islam, N. Quantum chemical and molecular dynamic simulation studies for the prediction of inhibition efficiencies of some piperidine derivatives on the corrosion of iron. J. Taiwan Inst. Chem. Eng. 2016, 65, 522–529. [Google Scholar] [CrossRef]

- Guo, L.; Kaya, S.; Obot, I.B.; Zheng, X.; Qiang, Y. Toward understanding the anticorrosive mechanism of some thiourea derivatives for carbon steel corrosion: A combined DFT and molecular dynamics investigation. J. Colloid Interface Sci. 2017, 506, 478–485. [Google Scholar] [CrossRef]

- Shokry, H. Molecular dynamics simulation and quantum chemical calculations for the adsorption of some Azo-azomethine derivatives on mild steel. J. Mol. Struct. 2014, 1060, 80–87. [Google Scholar] [CrossRef]

- Chen, S.; Chen, S.; Zhu, B.; Huang, C.; Li, W. Magnolia grandiflora leaves extract as a novel environmentally friendly inhibitor for Q235 steel corrosion in 1 M HCl: Combining experimental and theoretical researches. J. Mol. Liq. 2020, 311, 113312. [Google Scholar] [CrossRef]

- Bartley, J.; Huynh, N.; Bottle, S.; Flitt, H.; Notoya, T.; Schweinsberg, D. Computer simulation of the corrosion inhibition of copper in acidic solution by alkyl esters of 5-carboxybenzotriazole. Corros. Sci. 2003, 45, 81–96. [Google Scholar] [CrossRef]

- Hansen, J.-P.; McDonald, I.R. Theory of Simple Liquids; Academic Press: New York, NY, USA, 2013. [Google Scholar]

- Jorgensen, W.L.; Tirado-Rives, J. Potential energy functions for atomic-level simulations of water and organic and biomolecular systems. Proc. Natl. Acad. Sci. USA 2005, 102, 6665–6670. [Google Scholar] [CrossRef] [Green Version]

- Chaouiki, A.; Chafiq, M.; Rbaa, M.; Lgaz, H.; Salghi, R.; Lakhrissi, B.; Ali, I.H.; Masroor, S.; Cho, Y. New 8-Hydroxyquinoline-Bearing Quinoxaline Derivatives as Effective Corrosion Inhibitors for Mild Steel in HCl: Electrochemical and Computational Investigations. Coatings 2020, 10, 811. [Google Scholar] [CrossRef]

- Chaouiki, A.; Lgaz, H.; Chung, I.-M.; Ali, I.; Gaonkar, S.; Bhat, K.; Salghi, R.; Oudda, H.; Khan, M. Understanding corrosion inhibition of mild steel in acid medium by new benzonitriles: Insights from experimental and computational studies. J. Mol. Liq. 2018, 266, 603–616. [Google Scholar] [CrossRef]

- Golestani, G.; Shahidi-Zandi, M.; Ghazanfari, D. Electrochemical evaluation of antibacterial drugs as environment-friendly inhibitors for corrosion of carbon steel in HCl solution. Appl. Surf. Sci. 2014, 308, 347–362. [Google Scholar] [CrossRef]

- Eddy, N.O.; Odoemelam, S.A.; Ekwumemgbo, P. Inhibition of the corrosion of mild steel in H2SO4 by penicillin G. Sci. Res. Essays 2008, 4, 033–038. [Google Scholar]

- Alder, A.C.; McArdell, C.S.; Golet, E.M.; Ibric, S.; Molnar, E.; Nipales, N.S.; Giger, W. Occurrence and Fate of Fluoroquinolone, Macrolide, and Sulfonamide Antibiotics during Wastewater Treatment and in Ambient Waters in Switzerland. ACS Symp. Ser. 2001, 791, 56–69. [Google Scholar] [CrossRef]

- Farahati, R.; Mousavi-Khoshdel, S.M.; Ghaffarinejad, A.; Behzadi, H. Experimental and computational study of penicillamine drug and cysteine as water-soluble green corrosion inhibitors of mild steel. Prog. Org. Coat. 2020, 142, 105567. [Google Scholar] [CrossRef]

- Amin, M.A.; Khaled, K.; Mohsen, Q.; Arida, H. A study of the inhibition of iron corrosion in HCl solutions by some amino acids. Corros. Sci. 2010, 52, 1684–1695. [Google Scholar] [CrossRef]

- Petrović, M.B.; Radovanović, M.B.; Simonović, A.T.; Milić, S.M.; Antonijević, M.M. The effect of cysteine on the behaviour of copper in neutral and alkaline sulphate solutions. Int. J. Electrochem. Sci. 2012, 7, 9043–9057. [Google Scholar]

- Song, P.; Shen, S.; Li, C.-C.; Guo, X.-Y.; Wen, Y.; Yang, H.-F. Insight in layer-by-layer assembly of cysteamine and l-cysteine on the copper surface by electrochemistry and Raman spectroscopy. Appl. Surf. Sci. 2015, 328, 86–94. [Google Scholar] [CrossRef]

- Espinoza-Vázquez, A.; Rodríguez-Gómez, F.; Negrón-Silva, G.; González-Olvera, R.; Ángeles-Beltrán, D.; Palomar-Pardavé, M.; Miralrio, A.; Castro, M. Fluconazole and fragments as corrosion inhibitors of API 5L X52 steel immersed in 1M HCl. Corros. Sci. 2020, 174, 108853. [Google Scholar] [CrossRef]

- Obot, I.B.; Obi-Egbedi, N.O.; Umoren, S.A.; Ebenso, E.E. Adsorption and Kinetic Studies on the Inhibition Potential of Fluconazole for the Corrosion of al in Hcl Solution. Chem. Eng. Commun. 2011, 198, 711–725. [Google Scholar] [CrossRef]

- Obot, I.B.; Obi-Egbedi, N. Fluconazole as an inhibitor for aluminium corrosion in 0.1M HCl. Colloids Surf. A Physicochem. Eng. Asp. 2008, 330, 207–212. [Google Scholar] [CrossRef]

- Ahamad, I.; Prasad, R.; Quraishi, M. Inhibition of mild steel corrosion in acid solution by Pheniramine drug: Experimental and theoretical study. Corros. Sci. 2010, 52, 3033–3041. [Google Scholar] [CrossRef]

- Bhat, J.I.; Alva, V.D.P. Meclizine hydrochloride as a potential non-toxic corrosion inhibitor for mild steel in hydrochloric acid medium. Arch. Appl. Sci. Res. 2011, 3, 343–356. [Google Scholar]

- Ahamad, I.; Prasad, R.; Quraishi, M.A. Experimental and theoretical investigations of adsorption of fexofenadine at mild steel/hydrochloric acid interface as corrosion inhibitor. J. Solid State Electrochem. 2010, 14, 2095–2105. [Google Scholar] [CrossRef]

- Shukla, S.K.; Singh, A.K.; Ahamad, I.; Quraishi, M. Streptomycin: A commercially available drug as corrosion inhibitor for mild steel in hydrochloric acid solution. Mater. Lett. 2009, 63, 819–822. [Google Scholar] [CrossRef]

- Quraishi, M.; Rawat, J.; Ajmal, M. Dithiobiurets: A novel class of acid corrosion inhibitors for mild steel. J. Appl. Electrochem. 2000, 30, 745–751. [Google Scholar] [CrossRef]

- Pramer, D.; Starkey, R.L. Decomposition of Streptomycin. Science 1951, 113, 127. [Google Scholar] [CrossRef]

- Regna, P.P.; Wasselle, L.A.; Solomons, I. The Stability of Streptomycin. J. Biol. Chem. 1946, 165, 631–638. [Google Scholar] [CrossRef]

- Karthik, G.; Sundaravadivelu, M. Studies on the inhibition of mild steel corrosion in hydrochloric acid solution by atenolol drug. Egypt. J. Pet. 2016, 25, 183–191. [Google Scholar] [CrossRef] [Green Version]

- Fouda, A.S.; El-Ewady, G.Y.; Shalabi, K. Effect of b-blocker inhibitors on aluminum corrosion. J. Korean Chem. Soc. 2011, 55, 268–278. [Google Scholar] [CrossRef] [Green Version]

- Dohare, P.; Chauhan, D.S.; Sorour, A.; Quraishi, M. DFT and experimental studies on the inhibition potentials of expired Tramadol drug on mild steel corrosion in hydrochloric acid. Mater. Discov. 2017, 9, 30–41. [Google Scholar] [CrossRef]

- Prabhu, R.; Shanbhag, A.V.; Venkatesha, T.V. Influence of tramadol [2-[(dimethylamino)methyl]-1-(3-methoxyphenyl) cyclohexanol hydrate] on corrosion inhibition of mild steel in acidic media. J. Appl. Electrochem. 2007, 37, 491–497. [Google Scholar] [CrossRef]

- El-Naggar, M. Corrosion inhibition of mild steel in acidic medium by some sulfa drugs compounds. Corros. Sci. 2007, 49, 2226–2236. [Google Scholar] [CrossRef]

- Samide, A.; Tutunaru, B.; Negrila, C.; Trandafir, I.; Maxut, A. Effect of sulfacetamide on the composi-tion of corrosion products formed onto carbon steel surface in hydrochloric acid. Dig. J. Nanomater. Bios. 2011, 6, 663–673. [Google Scholar]

- Guo, W.; Wang, H.; Shi, Y.; Zhang, G. Sonochemical degradation of the antibiotic cephalexin in aqueous solution. Water SA 2010, 36. [Google Scholar] [CrossRef]

- Gece, G. Drugs: A review of promising novel corrosion inhibitors. Corros. Sci. 2011, 53, 3873–3898. [Google Scholar] [CrossRef]

- Shukla, S.K.; Quraishi, M. Cefalexin drug: A new and efficient corrosion inhibitor for mild steel in hydrochloric acid solution. Mater. Chem. Phys. 2010, 120, 142–147. [Google Scholar] [CrossRef]

- Bashir, S.; Sharma, V.; Lgaz, H.; Chung, I.-M.; Singh, A.; Kumar, A. The inhibition action of analgin on the corrosion of mild steel in acidic medium: A combined theoretical and experimental approach. J. Mol. Liq. 2018, 263, 454–462. [Google Scholar] [CrossRef]

- Addoun, A.; Bouyegh, S.; Dahmane, M.; Ferroukhi, O.; Trari, M. Thermodynamic investigation on the adhesion and corrosion inhibition properties of a non-steroidal anti-inflammatory drug in HCl electrolyte applied on mild steel material. Mater. Today Commun. 2019, 21, 100720. [Google Scholar] [CrossRef]

- Al-Fahemi, J.H.; Abdallah, M.; Gad, E.; Jahdaly, B. Experimental and theoretical approach studies for melatonin drug as safely corrosion inhibitors for carbon steel using DFT. J. Mol. Liq. 2016, 222, 1157–1163. [Google Scholar] [CrossRef]

- Bashir, S.; Lgaz, H.; Chung, I.-M.; Kumar, A. Potential of Venlafaxine in the inhibition of mild steel corrosion in HCl: Insights from experimental and computational studies. Chem. Pap. 2019, 73, 2255–2264. [Google Scholar] [CrossRef]

- Kumar, S.H.; Karthikeyan, S.; Vivekanand, P.A.; Rajakumari, S. Pioglitazone (PGZ) drug as potential inhibitor for the corrosion of mild steel in hydrochloric acid medium. Mater. Today: Proc. 2019, 36, 803–808. [Google Scholar] [CrossRef]

- Hossam, K.; Bouhlal, F.; Hermouche, L.; Merimi, I.; Labjar, H.; Chaouiki, A.; Labjar, N.; Malika, S.-I.; Dahrouch, A.; Chellouli, M.; et al. Understanding Corrosion Inhibition of C38 Steel in HCl Media by Omeprazole: Insights for Experimental and Computational Studies. J. Fail. Anal. Prev. 2020, 21, 213–227. [Google Scholar] [CrossRef]

- Shukla, S.K.; Quraishi, M.A. Ceftriaxone: A novel corrosion inhibitor for mild steel in hydrochloric acid. J. Appl. Electrochem. 2009, 39, 1517–1523. [Google Scholar] [CrossRef]

- Shukla, S.K.; Quraishi, M. Cefotaxime sodium: A new and efficient corrosion inhibitor for mild steel in hydrochloric acid solution. Corros. Sci. 2009, 51, 1007–1011. [Google Scholar] [CrossRef]

- Mashuga, M.E.; Olasunkanmi, L.O.; Adekunle, A.S.; Yesudass, S.; Kabanda, M.M.; Ebenso, E.E. Adsorption, Thermodynamic and Quantum Chemical Studies of 1-hexyl-3-methylimidazolium Based Ionic Liquids as Corrosion Inhibitors for Mild Steel in HCl. Materials 2015, 8, 3607–3632. [Google Scholar] [CrossRef]

- Guo, Y.; Xu, B.; Liu, Y.; Yang, W.; Yin, X.; Chen, Y.; Le, J.; Chen, Z. Corrosion inhibition properties of two imidazolium ionic liquids with hydrophilic tetrafluoroborate and hydrophobic hexafluorophosphate anions in acid medium. J. Ind. Eng. Chem. 2017, 56, 234–247. [Google Scholar] [CrossRef]

- Pereiro, A.B.; Tojo, E.; Rodriguez, A.; Canosa, J.; Tojo, J. Properties of ionic liquid HMIMPF6 with carbonates, ketones and alkyl acetates. J. Chem. Thermodyn. 2006, 38, 651–661. [Google Scholar] [CrossRef]

- Alcántara, R.; Canoira, L.; Guilherme-Joao, P.; Pérez-Mendo, J. Air oxidation of ethylbenzene catalysed by bis(acetylacetonate)nickel(II) and 1-n-butyl-3-methylimidazolium hexafluorophosphate. Appl. Catal. A Gen. 2001, 218, 269–279. [Google Scholar] [CrossRef]

- Sasikumar, Y.; Adekunle, A.; Olasunkanmi, L.; Bahadur, I.; Baskar, R.; Kabanda, M.; Obot, I.B.; Ebenso, E. Experimental, quantum chemical and Monte Carlo simulation studies on the corrosion inhibition of some alkyl imidazolium ionic liquids containing tetrafluoroborate anion on mild steel in acidic medium. J. Mol. Liq. 2015, 211, 105–118. [Google Scholar] [CrossRef]

- Al-Rashed, O.A.; Abdel-Nazeer, A. Ionic liquids with superior protection for mild steel in acidic media: Effects of anion, cation, and alkyl chain length. J. Mol. Liq. 2019, 288, 111015. [Google Scholar] [CrossRef]

- Ben Aoun, S. Microwave-assisted Synthesis of Green Inhibitor for Carbon Steel Acid Corrosion. Int. J. Electrochem. Sci. 2018, 3757–3776. [Google Scholar] [CrossRef]

- Ben Aoun, S. On the corrosion inhibition of carbon steel in 1 M HCl with a pyridinium-ionic liquid: Chemical, thermodynamic, kinetic and electrochemical studies. RSC Adv. 2017, 7, 36688–36696. [Google Scholar] [CrossRef] [Green Version]

- Bousskri, A.; Anejjar, A.; Messali, M.; Salghi, R.; Benali, O.; Karzazi, Y.; Jodeh, S.; Zougagh, M.; Ebenso, E.; Hammouti, B. Corrosion inhibition of carbon steel in aggressive acidic media with 1-(2-(4-chlorophenyl)-2-oxoethyl)pyridazinium bromide. J. Mol. Liq. 2015, 211, 1000–1008. [Google Scholar] [CrossRef]

- Messali, M.; Bousskri, A.; Anejjar, A.; Salghi, R.; Hammouti, B. Electrochemical studies of 1-(2-(4-nitrophenyl)-2-oxoethyl) pyridazinium bromide, on carbon steel corrosion in hydrochloric acid medium. Int. J. Electrochem. Sci. 2015, 10, 4532–4551. [Google Scholar]

- Kannan, P.; Varghese, A.; Mathew, A.T.; Palanisamy, K.; Abousalem, A.S.; Kalaiyarasan, M.; Rajendran, N. Exploring the inhibition performance of tetrachloroferrate ionic liquid in acid environment using scanning electrochemical microscope and theoretical approaches. Surf. Interfaces 2020, 20, 100594. [Google Scholar] [CrossRef]

- Fateh, A.; Aliofkhazraei, M.; Rezvanian, A. Review of corrosive environments for copper and its corrosion inhibitors. Arab. J. Chem. 2020, 13, 481–544. [Google Scholar] [CrossRef]

- Farag, A.A.; Migahed, M.A.; Badr, E.A. Thiazole Ionic Liquid as Corrosion Inhibitor of Steel in 1 M HCl Solution: Gravimetrical, Electrochemical, and Theoretical Studies. J. Bio-Tribo-Corros. 2019, 5, 53. [Google Scholar] [CrossRef]

- Özkır, D.; Kayakırılmaz, K.; Bayol, E.; Gürten, A.A.; Kandemirli, F. The inhibition effect of Azure A on mild steel in 1M HCl. A complete study: Adsorption, temperature, duration and quantum chemical aspects. Corros. Sci. 2012, 56, 143–152. [Google Scholar] [CrossRef]

- Wang, H.; Liu, S.; Huang, K.; Liu, Y.; Li, Z. Ethylbenzotriazolium Bromide Ionic Liquid: A New Water Soluble Inhibitor for Corrosion of Mild Steel in Acid Media. Asian J. Chem. 2013, 25, 954–956. [Google Scholar] [CrossRef]

- Feng, L.; Zhang, S.; Lu, Y.; Tan, B.; Chen, S.; Guo, L. Synergistic corrosion inhibition effect of thiazolyl-based ionic liquids between anions and cations for copper in HCl solution. Appl. Surf. Sci. 2019, 483, 901–911. [Google Scholar] [CrossRef]

- Ahmed, S.A.; Awad, M.I.; Althagafi, I.I.; Altass, H.M.; Morad, M.; Alharbi, A.; Obaid, R.J. Newly synthesized indolium-based ionic liquids as unprecedented inhibitors for the corrosion of mild steel in acid medium. J. Mol. Liq. 2019, 291, 111356. [Google Scholar] [CrossRef]

- Bousskri, A.; Anejjar, A.; Salghi, R.; Jodeh, S.; Touzani, R.; Bazzi, L.; Lgaz, H. Corrosion control of car-bon steel in hydrochloric acid by new eco-friendly picolinium-based ionic liquids derivative: Electrochemical and synergistic studies. J. Mater. Environ. Sci. 2016, 7, 4269–4289. [Google Scholar]

- Yildiz, M.; Gerengi, H.; Solomon, M.M.; Kaya, E.; Umoren, S.A. Influence of 1-butyl-1-methylpiperidinium tetrafluoroborate on St37 steel dissolution behavior in HCl environment. Chem. Eng. Commun. 2018, 205, 538–548. [Google Scholar] [CrossRef]

- Su, H.; Liu, Y.; Gao, X.; Qian, Y.; Li, W.; Ren, T.; Wang, L.; Zhang, J. Corrosion inhibition of magnesium alloy in NaCl solution by ionic liquid: Synthesis, electrochemical and theoretical studies. J. Alloys Compd. 2019, 791, 681–689. [Google Scholar] [CrossRef]

- Elsaeed, S.M.; El Tamany, E.S.H.; Ashour, H.; Zaki, E.G.; Khamis, E.A.; El Nagy, H.A. Corrosion and hydrogen evolution rate control for X-65 carbon steel based on chitosan polymeric ionic liquids: Experimental and quantum chemical studies. RSC Adv. 2018, 8, 37891–37904. [Google Scholar] [CrossRef] [Green Version]

- Deyab, M. Sulfonium-based ionic liquid as an anticorrosive agent for thermal desalination units. J. Mol. Liq. 2019, 296, 111742. [Google Scholar] [CrossRef]

- Likhanova, N.; Domínguez-Aguilar, M.A.; Olivares-Xometl, O.; Nava-Entzana, N.; Arce, E.; Dorantes-Rosales, H.J. The effect of ionic liquids with imidazolium and pyridinium cations on the corrosion inhibition of mild steel in acidic environment. Corros. Sci. 2010, 52, 2088–2097. [Google Scholar] [CrossRef]

- Deyab, M. Hydrogen generation during the corrosion of carbon steel in crotonic acid and using some organic surfactants to control hydrogen evolution. Int. J. Hydrog. Energy 2013, 38, 13511–13519. [Google Scholar] [CrossRef]

- Asefi, D.; Mahmoodi, N.M.; Arami, M. Effect of nonionic co-surfactants on corrosion inhibition effect of cationic gemini surfactant. Colloids Surf. A Physicochem. Eng. Asp. 2010, 355, 183–186. [Google Scholar] [CrossRef]

- Hegazy, M.; El-Tabei, A.; Ahmed, H. Synthesis of nonionic surfactants and their inhibitive action on carbon steel in hydrochloric acid. Corros. Sci. 2012, 64, 115–125. [Google Scholar] [CrossRef]

- Bedair, M.; El-Sabbah, M.; Fouda, A.E.A.E.S.; Elaryian, H. Synthesis, electrochemical and quantum chemical studies of some prepared surfactants based on azodye and Schiff base as corrosion inhibitors for steel in acid medium. Corros. Sci. 2017, 128, 54–72. [Google Scholar] [CrossRef]

- Hegazy, M.A.; El Rehim, S.S.A.; Badawi, A.M.; Ahmed, M.Y. Studying the corrosion inhibition of carbon steel in hydrochloric acid solution by 1-dodecyl-methyl-1H-benzo[d][1,2,3]triazole-1-ium bromide. RSC Adv. 2015, 5, 49070–49079. [Google Scholar] [CrossRef]

- Badawi, A.; Hegazy, M.; El-Sawy, A.; Ahmed, H.; Kamel, W. Novel quaternary ammonium hydroxide cationic surfactants as corrosion inhibitors for carbon steel and as biocides for sulfate reducing bacteria (SRB). Mater. Chem. Phys. 2010, 124, 458–465. [Google Scholar] [CrossRef]

- Badr, E.a.; Hefni, H.; Shafek, S.; Shaban, S.M. Synthesis of anionic chitosan surfactant and application in silver nanoparticles preparation and corrosion inhibition of steel. Int. J. Biol. Macromol. 2020, 157, 187–201. [Google Scholar] [CrossRef]

- Mondal, M.H.; Roy, A.; Malik, S.; Ghosh, A.; Saha, B. Review on chemically bonded geminis with cationic heads: Second-generation interfactants. Res. Chem. Intermed. 2015, 42, 1913–1928. [Google Scholar] [CrossRef]

- Li, B.; Zhang, Q.; Xia, Y.; Gao, Z. Surface properties and aggregation behavior of cationic gemini surfactants with dipropylammonium head-groups. Colloids Surf. A Physicochem. Eng. Asp. 2015, 470, 211–217. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, D.; Li, R.; Liu, H.; Hu, Y. Effect of the spacer group on the behavior of the cationic Gemini surfactant monolayer at the air/water interface. Thin Solid Films 2008, 516, 8782–8787. [Google Scholar] [CrossRef]

- Mondal, M.H.; Malik, S.; Roy, A.; Saha, R.; Saha, B. Modernization of surfactant chemistry in the age of gemini and bio-surfactants: A review. RSC Adv. 2015, 5, 92707–92718. [Google Scholar] [CrossRef]

- Ao, M.; Xu, G.; Zhu, Y.; Bai, Y. Synthesis and properties of ionic liquid-type Gemini imidazolium surfactants. J. Colloid Interface Sci. 2008, 326, 490–495. [Google Scholar] [CrossRef]

- Bhadani, A.; Kataria, H.; Singh, S. Synthesis, characterization and comparative evaluation of phenoxy ring containing long chain gemini imidazolium and pyridinium amphiphiles. J. Colloid Interface Sci. 2011, 361, 33–41. [Google Scholar] [CrossRef]

- Zhou, T.; Yuan, J.; Zhang, Z.; Xin, X.; Xu, G. The comparison of imidazolium Gemini surfactant [C14-4-C14im]Br2 and its corresponding monomer as corrosion inhibitors for A3 carbon steel in hydrochloric acid solutions: Experimental and quantum chemical studies. Colloids Surf. A Physicochem. Eng. Asp. 2019, 575, 57–65. [Google Scholar] [CrossRef]

- Motamedi, M.; Tehrani-Bagha, A.; Mahdavian, M. A comparative study on the electrochemical behavior of mild steel in sulfamic acid solution in the presence of monomeric and gemini surfactants. Electrochim. Acta 2011, 58, 488–496. [Google Scholar] [CrossRef]

- Aslam, R.; Mobin, M.; Aslam, J.; Lgaz, H.; Chung, I.-M. Inhibitory effect of sodium carboxymethylcellulose and synergistic biodegradable gemini surfactants as effective inhibitors for MS corrosion in 1 M HCl. J. Mater. Res. Technol. 2019, 8, 4521–4533. [Google Scholar] [CrossRef]

- Hegazy, M. A novel Schiff base-based cationic gemini surfactants: Synthesis and effect on corrosion inhibition of carbon steel in hydrochloric acid solution. Corros. Sci. 2009, 51, 2610–2618. [Google Scholar] [CrossRef]

- Prajapati, S.T.; Joshi, H.A.; Patel, C.N. Preparation and Characterization of Self-Microemulsifying Drug Delivery System of Olmesartan Medoxomil for Bioavailability Improvement. J. Pharm. 2012, 2013, 728425. [Google Scholar] [CrossRef]

- Aiad, I.; Emam, D.; El-Deeb, A.; Abd-Alrahman, E. Retracted: Novel Imidazolium-Based Gemini Surfactants: Synthesis, Surface Properties, Corrosion Inhibition and Biocidal Activity Against Sulfate-Reducing Bacteria. J. Surfactants Deterg. 2013, 16, 927–935. [Google Scholar] [CrossRef]

- Dehghani, A.; Bahlakeh, G.; Ramezanzadeh, B.; Ramezanzadeh, M. Aloysia citrodora leaves extract corrosion retardation effect on mild-steel in acidic solution: Molecular/atomic scales and electrochemical explorations. J. Mol. Liq. 2020, 310, 113221. [Google Scholar] [CrossRef]

- Dehghani, A.; Bahlakeh, G.; Ramezanzadeh, B.; Ramezanzadeh, M. Experimental complemented with microscopic (electronic/atomic)-level modeling explorations of Laurus nobilis extract as green inhibitor for carbon steel in acidic solution. J. Ind. Eng. Chem. 2020, 84, 52–71. [Google Scholar] [CrossRef]

- Wang, Q.; Tan, B.; Bao, H.; Xie, Y.; Mou, Y.; Li, P.; Chen, D.; Shi, Y.; Li, X.; Yang, W. Evaluation of Ficus tikoua leaves extract as an eco-friendly corrosion inhibitor for carbon steel in HCl media. Bioelectrochemistry 2019, 128, 49–55. [Google Scholar] [CrossRef]

- Majd, M.T.; Ramezanzadeh, M.; Bahlakeh, G.; Ramezanzadeh, B. Probing molecular adsorption/interactions and anti-corrosion performance of poppy extract in acidic environments. J. Mol. Liq. 2020, 304, 112750. [Google Scholar] [CrossRef]

- Muthukumarasamy, K.; Pitchai, S.; Devarayan, K.; Nallathambi, L. Adsorption and corrosion inhibition performance of Tunbergia fragrans extract on mild steel in acid medium. Mater. Today Proc. 2020, 33, 4054–4058. [Google Scholar] [CrossRef]

- Ji, G.; Anjum, S.; Sundaram, S.; Prakash, R. Musa paradisica peel extract as green corrosion inhibitor for mild steel in HCl solution. Corros. Sci. 2015, 90, 107–117. [Google Scholar] [CrossRef]

- Loganayagi, C.; Kamal, C.; Sethuraman, M.G. Opuntiol: An Active Principle of Opuntia elatior as an Eco-Friendly Inhibitor of Corrosion of Mild Steel in Acid Medium. ACS Sustain. Chem. Eng. 2014, 2, 606–613. [Google Scholar] [CrossRef]

- Bahlakeh, G.; Dehghani, A.; Ramezanzadeh, B.; Ramezanzadeh, M. Highly effective mild steel corrosion inhibition in 1 M HCl solution by novel green aqueous Mustard seed extract: Experimental, electronic-scale DFT and atomic-scale MC/MD explorations. J. Mol. Liq. 2019, 293, 111559. [Google Scholar] [CrossRef]

- Ji, G.; Shukla, S.K.; Dwivedi, P.; Sundaram, S.; Prakash, R. Inhibitive Effect of Argemone mexicana Plant Extract on Acid Corrosion of Mild Steel. Ind. Eng. Chem. Res. 2011, 50, 11954–11959. [Google Scholar] [CrossRef]

- Raja, P.B.; Fadaeinasab, M.; Qureshi, A.K.; Rahim, A.A.; Osman, H.; Litaudon, M.; Awang, K. Evaluation of Green Corrosion Inhibition by Alkaloid Extracts of Ochrosia oppositifolia and Isoreserpiline against Mild Steel in 1 M HCl Medium. Ind. Eng. Chem. Res. 2013, 52, 10582–10593. [Google Scholar] [CrossRef]

- Umoren, S.A.; Gasem, Z.M.; Obot, I.B. Natural Products for Material Protection: Inhibition of Mild Steel Corrosion by Date Palm Seed Extracts in Acidic Media. Ind. Eng. Chem. Res. 2013, 52, 14855–14865. [Google Scholar] [CrossRef]

- Buchweishaija, J. Phytochemicals as green corrosion inhibitors in various corrosive media: A review. Tanz. J. Sci. 2009, 35, 77–92. [Google Scholar]

- Al-Otaibi, M.; Al-Mayouf, A.; Khan, M.; Mousa, A.; Al-Mazroa, S.; Alkhathlan, H. Corrosion inhibitory action of some plant extracts on the corrosion of mild steel in acidic media. Arab. J. Chem. 2014, 7, 340–346. [Google Scholar] [CrossRef] [Green Version]

- Luft, J.H. Improvements in Epoxy Resin Embedding Methods. J. Cell Biol. 1961, 9, 409–414. [Google Scholar] [CrossRef]

- Damej, M.; Hsissou, R.; Berisha, A.; Azgaou, K.; Sadiku, M.; Benmessaoud, M.; Labjar, N.; El Hajjaji, S. New epoxy resin as a corrosion inhibitor for the protection of carbon steel C38 in 1M HCl. experimental and theoretical studies (DFT, MC, and MD). J. Mol. Struct. 2022, 1254, 132425. [Google Scholar] [CrossRef]

- Quraishi, M.; Shukla, S.K. Poly(aniline-formaldehyde): A new and effective corrosion inhibitor for mild steel in hydrochloric acid. Mater. Chem. Phys. 2009, 113, 685–689. [Google Scholar] [CrossRef]

- Thirumoolan, D.; Katkar, V.A.; Gunasekaran, G.; Kanai, T.; Basha, K.A. Hyperbranched poly(cyanurateamine): A new corrosion inhibitor for mild steel in hydrochloric acid medium. Prog. Org. Coat. 2014, 77, 1253–1263. [Google Scholar] [CrossRef]

- El-Din, M.N.; Khamis, E. Utilization of sulfidated poly (acrylamide-vinyl acetate) as a new corrosion inhibitor for carbon steel in acidic media. J. Ind. Eng. Chem. 2015, 24, 342–350. [Google Scholar] [CrossRef]

- Larabi, L.; Harek, Y.; Traisnel, M.; Mansri, A. Synergistic Influence of Poly(4-Vinylpyridine) and Potassium Iodide on Inhibition of Corrosion of Mild Steel in 1M HCl. J. Appl. Electrochem. 2004, 34, 833–839. [Google Scholar] [CrossRef]

- Rahiman, A.F.S.A.; Sethumanickam, S. Corrosion inhibition, adsorption and thermodynamic properties of poly(vinyl alcohol-cysteine) in molar HCl. Arab. J. Chem. 2017, 10, S3358–S3366. [Google Scholar] [CrossRef] [Green Version]

- Baskar, R.; Kesavan, D.; Gopiraman, M.; Subramanian, K. Corrosion inhibition of mild steel in 1.0M hydrochloric acid medium by new photo-cross-linkable polymers. Prog. Org. Coat. 2014, 77, 836–844. [Google Scholar] [CrossRef]

- Umoren, S.; Gasem, Z. Influence of Molecular Weight on Mild Steel Corrosion Inhibition Effect by Polyvinyl Alcohol in Hydrochloric Acid Solution. J. Dispers. Sci. Technol. 2014, 35, 1181–1190. [Google Scholar] [CrossRef]

- Khaled, M.M. The effect of molecular weight on the corrosion protection properties of polyvinylpyr-rolidone polymers on stainless steel. Arabian J. Sci. Eng. 2010, 35, 29–39. [Google Scholar]

- Karthikaiselvi, R.; Subhashini, S. Study of adsorption properties and inhibition of mild steel corrosion in hydrochloric acid media by water soluble composite poly (vinyl alcohol-omethoxy aniline). J. Assoc. Arab Univ. Basic Appl. Sci. 2014, 16, 74–82. [Google Scholar] [CrossRef] [Green Version]

- Bayol, E.; Gurten, A.; Dursun, M.; Kayakirilmaz, K. Adsorption Behavior and Inhibition Corrosion Effect of Sodium Carboxymethyl Cellulose on Mild Steel in Acidic Medium. Acta Phys.-Chim. Sin. 2008, 24, 2236–2243. [Google Scholar] [CrossRef]

- Abdeen, D.H.; El Hachach, M.; Koc, M.; Atieh, M.A. A Review on the Corrosion Behaviour of Nanocoatings on Metallic Substrates. Materials 2019, 12, 210. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Atta, A.M.; El-Mahdy, G.A.; Al-Lohedan, H.A.; Ezzat, A.-R.O. Synthesis of nonionic amphiphilic chitosan nanoparticles for active corrosion protection of steel. J. Mol. Liq. 2015, 211, 315–323. [Google Scholar] [CrossRef]

- Habibiyan, A.; Ramezanzadeh, B.; Mahdavian, M.; Kasaeian, M. Facile size and chemistry-controlled synthesis of mussel-inspired bio-polymers based on Polydopamine Nanospheres: Application as eco-friendly corrosion inhibitors for mild steel against aqueous acidic solution. J. Mol. Liq. 2020, 298, 111974. [Google Scholar] [CrossRef]

- Menaka, R.; Subhashini, S. Chitosan Schiff base as effective corrosion inhibitor for mild steel in acid medium. Polym. Int. 2016, 66, 349–358. [Google Scholar] [CrossRef]

- Obot, I.; Onyeachu, I.B.; Kumar, A. Sodium alginate: A promising biopolymer for corrosion protection of API X60 high strength carbon steel in saline medium. Carbohydr. Polym. 2017, 178, 200–208. [Google Scholar] [CrossRef]

- Berisha, A. Ab inito exploration of nanocars as potential corrosion inhibitors. Comput. Theor. Chem. 2021, 1201, 113258. [Google Scholar] [CrossRef]

- Azzam, E.; El-Aal, A.A. Corrosion inhibition efficiency of synthesized poly 12-(3-amino phenoxy) dodecane-1-thiol surfactant assembled on silver nanoparticles. Egypt. J. Pet. 2013, 22, 293–303. [Google Scholar] [CrossRef] [Green Version]

- El-Lateef, H.M.A.; Mohamed, I.; Zhu, J.-H.; Khalaf, M.M. An efficient synthesis of electrospun TiO2-nanofibers/Schiff base phenylalanine composite and its inhibition behavior for C-steel corrosion in acidic chloride environments. J. Taiwan Inst. Chem. Eng. 2020, 112, 306–321. [Google Scholar] [CrossRef]

- Umoren, S. Polymers as Corrosion Inhibitors for Metals in Different Media—A Review. Open Corros. J. 2009, 2, 175–188. [Google Scholar] [CrossRef]

- Arthur, D.E.; Jonathan, A.; Ameh, P.O.; Anya, C. A review on the assessment of polymeric materials used as corrosion inhibitor of metals and alloys. Int. J. Ind. Chem. 2013, 4, 2. [Google Scholar] [CrossRef] [Green Version]

- Sabirneeza, A.A.F.; Geethanjali, R.; Subhashini, S. Polymeric Corrosion Inhibitors for Iron and Its Alloys: A Review. Chem. Eng. Commun. 2014, 202, 232–244. [Google Scholar] [CrossRef]

- Tiu, B.D.; Advincula, R.C. Polymeric corrosion inhibitors for the oil and gas industry: Design principles and mechanism. React. Funct. Polym. 2015, 95, 25–45. [Google Scholar] [CrossRef]

- Shahini, M.; Ramezanzadeh, B.; Mohammadloo, H.E. Recent advances in biopolymers/carbohydrate polymers as effective corrosion inhibitive macro-molecules: A review study from experimental and theoretical views. J. Mol. Liq. 2021, 325, 115110. [Google Scholar] [CrossRef]

- Shahini, M.; Ramezanzadeh, M.; Ramezanzadeh, B.; Bahlakeh, G. The role of ethanolic extract of Stachys byzantina’s leaves for effective decreasing the mild-steel (MS) degradation in the acidic solution; coupled theoretical/experimental assessments. J. Mol. Liq. 2021, 329, 115571. [Google Scholar] [CrossRef]

- Geethamani, P.; Narmatha, M.; Dhanalakshmi, R.; Aejitha, S.; Kasthuri, P.K. Corrosion Inhibition and Adsorption Properties of Mild Steel in 1 M Hydrochloric Acid Medium by Expired Ambroxol Drug. J. Bio-Tribo-Corros. 2018, 5, 16. [Google Scholar] [CrossRef]

- Alhaffar, M.T.; Umoren, S.A.; Obot, I.B.; Ali, S.A. Isoxazolidine derivatives as corrosion inhibitors for low carbon steel in HCl solution: Experimental, theoretical and effect of KI studies. RSC Adv. 2018, 8, 1764–1777. [Google Scholar] [CrossRef] [Green Version]

- Verma, C.; Olasunkanmi, L.O.; Obot, I.B.; Ebenso, E.E.; Quraishi, M.A. 2,4-Diamino-5-(phenylthio)-5H-chromeno [2,3-b] pyridine-3-carbonitriles as green and effective corrosion inhibitors: Gravimetric, electrochemical, surface morphology and theoretical studies. RSC Adv. 2016, 6, 53933–53948. [Google Scholar] [CrossRef]

- Aslam, J.; Aslam, R.; Alrefaee, S.H.; Mobin, M.; Aslam, A.; Parveen, M.; Hussain, C.M. Gravimetric, electrochemical, and morphological studies of an isoxazole derivative as corrosion inhibitor for mild steel in 1M HCl. Arab. J. Chem. 2020, 13, 7744–7758. [Google Scholar] [CrossRef]

- Bashir, S.; Thakur, A.; Lgaz, H.; Chung, I.-M.; Kumar, A. Computational and experimental studies on Phenylephrine as anti-corrosion substance of mild steel in acidic medium. J. Mol. Liq. 2019, 293, 111539. [Google Scholar] [CrossRef]

- Singh, A.; Pramanik, T.; Kumar, A.; Gupta, M. Phenobarbital: A New and Effective Corrosion Inhibitor for Mild Steel in 1 M HCl Solution. Asian J. Chem. 2013, 25, 9808–9812. [Google Scholar] [CrossRef]

- Chami, R.; Boudalia, M.; Echihi, S.; el Fal, M. Thermodynamic study and electrochemical Investiga-tion of 4-chloro-1H-pyrazolo [3,4-d] pyrimidine as a corrosion Inhibitor for mild steel in hydrochloric acid Solution. J. Mater. Environ. Sci. 2017, 8, 4182–4192. [Google Scholar]

- Ma, X.; Jiang, X.; Xia, S.; Shan, M.; Li, X.; Yu, L.; Tang, Q. New corrosion inhibitor acrylamide methyl ether for mild steel in 1 M HCl. Appl. Surf. Sci. 2016, 371, 248–257. [Google Scholar] [CrossRef]

- Fouda, A.S.; Mahmoud, W.M.; Mageed, H.A.A. Evaluation of an Expired Nontoxic Amlodipine Besylate Drug as a Corrosion Inhibitor for Low-Carbon Steel in Hydrochloric Acid Solutions. J. Bio-Tribo-Corros. 2016, 2, 7. [Google Scholar] [CrossRef] [Green Version]

- Singh, P.; Chauhan, D.S.; Srivastava, K.; Srivastava, V.; Quraishi, M.A. Expired atorvastatin drug as corrosion inhibitor for mild steel in hydrochloric acid solution. Int. J. Ind. Chem. 2017, 8, 363–372. [Google Scholar] [CrossRef]

- Fouda, A.S.; El Morsi, M.A.; El Mogy, T. Studies on the inhibition of carbon steel corrosion in hydrochloric acid solution by expired Carvedilol drug. Green Chem. Lett. Rev. 2017, 10, 336–345. [Google Scholar] [CrossRef]

- Geethamani, P.; Kasthuri, P.K. The inhibitory action of expired asthalin drug on the corrosion of mild steel in acidic media: A comparative study. J. Taiwan Inst. Chem. Eng. 2016, 63, 490–499. [Google Scholar] [CrossRef]

- Kumar, S.H.; Karthikeyan, S. Inhibition of mild steel corrosion in hydrochloric acid solution by cloxacillin drug. J. Mater. Environ. Sci. 2012, 3, 925–934. [Google Scholar]

- Lgaz, H.; Salghi, R.; Jodeh, S.; Hammouti, B. Effect of clozapine on inhibition of mild steel corrosion in 1.0 M HCl medium. J. Mol. Liq. 2017, 225, 271–280. [Google Scholar] [CrossRef]

- Singh, A.; Avyaya, J.N.; Ebenso, E.E.; Quraishi, M.A. Schiff’s base derived from the pharmaceutical drug Dapsone (DS) as a new and effective corrosion inhibitor for mild steel in hydrochloric acid. Res. Chem. Intermed. 2012, 39, 537–551. [Google Scholar] [CrossRef]

- Shahabi, S.; Hamidi, S.; Ghasemi, J.B.; Norouzi, P.; Shakeri, A. Synthesis, experimental, quantum chemical and molecular dynamics study of carbon steel corrosion inhibition effect of two Schiff bases in HCl solution. J. Mol. Liq. 2019, 285, 626–639. [Google Scholar] [CrossRef]

- Dehghani, A.; Mostafatabar, A.H.; Bahlakeh, G.; Ramezanzadeh, B.; Ramezanzadeh, M. Detailed-level computer modeling explorations complemented with comprehensive experimental studies of Quercetin as a highly effective inhibitor for acid-induced steel corrosion. J. Mol. Liq. 2020, 309, 113035. [Google Scholar] [CrossRef]

- Daoud, D.; Douadi, T.; Hamani, H.; Chafaa, S.; Al-Noaimi, M. Corrosion inhibition of mild steel by two new S-heterocyclic compounds in 1 M HCl: Experimental and computational study. Corros. Sci. 2015, 94, 21–37. [Google Scholar] [CrossRef]

- Erami, R.S.; Amirnasr, M.; Meghdadi, S.; Talebian, M.; Farrokhpour, H.; Raeissi, K. Carboxamide derivatives as new corrosion inhibitors for mild steel protection in hydrochloric acid solution. Corros. Sci. 2019, 151, 190–197. [Google Scholar] [CrossRef]

- Singh, A.K.; Pandey, A.K.; Banerjee, P.; Saha, S.K.; Chugh, B.; Thakur, S.; Pani, B.; Chaubey, P.; Singh, G. Eco-friendly disposal of expired anti-tuberculosis drug isoniazid and its role in the protection of metal. J. Environ. Chem. Eng. 2019, 7, 102971. [Google Scholar] [CrossRef]

- Fouda, A.S.; El-Desoky, H.S.; Abdel-Galeil, M.A.; Mansour, D. Niclosamide and dichlorphenamide: New and effective corrosion inhibitors for carbon steel in 1M HCl solution. SN Appl. Sci. 2021, 3, 287. [Google Scholar] [CrossRef]

- Adejoro, I.; Ojo, F.; Obafemi, S. Corrosion inhibition potentials of ampicillin for mild steel in hydrochloric acid solution. J. Taibah Univ. Sci. 2015, 9, 196–202. [Google Scholar] [CrossRef] [Green Version]

- Srinivasulu, A.; Kasthuri, P.K. Study of Inhibition and Adsorption Properties of Mild Steel Corrosion by Expired Pharmaceutical Gentamicin Drug in Hydrochloric acid media. Orient. J. Chem. 2017, 33, 2616–2624. [Google Scholar] [CrossRef]

- Addoun, A.; Trari, M.; Ferroukhi, O. Corrosion Control of Mild Steel Material in HCl Electrolyte by a Non-Steroidal Anti-Inflammatory Drug: Electrochemical and Kinetic Study. Prot. Met. Phys. Chem. Surf. 2020, 56, 826–833. [Google Scholar] [CrossRef]

- Fouda, A.S.; El-Ewady, G.; Ali, A.H. Modazar as promising corrosion inhibitor of carbon steel in hydrochloric acid solution. Green Chem. Lett. Rev. 2017, 10, 88–100. [Google Scholar] [CrossRef]

- Kumar, S.H.; Karthikeyan, S. Torsemide and Furosemide as Green Inhibitors for the Corrosion of Mild Steel in Hydrochloric Acid Medium. Ind. Eng. Chem. Res. 2013, 52, 7457–7469. [Google Scholar] [CrossRef]

- Hameed, R.S.A.; Ismail, E.A.; Al-Shafey, H.I.; Abbas, M. Expired Indomethacin Therapeutics as Corrosion Inhibitors for Carbon Steel in 1.0 M Hydrochloric Acid Media. J. Bio-Tribo-Corros. 2020, 6, 114. [Google Scholar] [CrossRef]

- Yang, H. Investigation of Inhibition Effect of Ketoconazole on Mild Steel Corrosion in Hydrochloric Acid. Int. J. Electrochem. Sci. 2018, 9131–9144. [Google Scholar] [CrossRef]

- Hameed, R.S.A. Electrochemical Techniques for Evaluation of Expired Megavit Drugs as Corrosion Inhibitor for Steel in Hydrochloric Acid. Int. J. Electrochem. Sci. 2021, 16, 210446. [Google Scholar] [CrossRef]

- El-Hajjaji, F.; Ech-Chihbi, E.; Rezki, N.; Benhiba, F.; Taleb, M.; Chauhan, D.S.; Quraishi, M. Electrochemical and theoretical insights on the adsorption and corrosion inhibition of novel pyridinium-derived ionic liquids for mild steel in 1 M HCl. J. Mol. Liq. 2020, 314, 113737. [Google Scholar] [CrossRef]

- Kannan, P.; Karthikeyan, J.; Murugan, P.; Rao, T.S.; Rajendran, N. Corrosion inhibition effect of novel methyl benzimidazolium ionic liquid for carbon steel in HCl medium. J. Mol. Liq. 2016, 221, 368–380. [Google Scholar] [CrossRef]

- Gao, H.; Xie, N.; Wang, H.; Chen, M.; Zhang, J.; Sun, J.; Jin, Z. Evaluation of corrosion inhibition performance of a novel ionic liquid based on synergism between cation and anion. N. J. Chem. 2020, 44, 7802–7810. [Google Scholar] [CrossRef]

- Deyab, M.; Zaky, M.; Nessim, M. Inhibition of acid corrosion of carbon steel using four imidazolium tetrafluoroborates ionic liquids. J. Mol. Liq. 2017, 229, 396–404. [Google Scholar] [CrossRef]

- Nkuna, A.A.; Akpan, E.D.; Obot, I.; Verma, C.; Ebenso, E.E.; Murulana, L.C. Impact of selected ionic liquids on corrosion protection of mild steel in acidic medium: Experimental and computational studies. J. Mol. Liq. 2020, 314, 113609. [Google Scholar] [CrossRef]

- EL Hajjaji, F.; Salim, R.; Taleb, M.; Benhiba, F.; Rezki, N.; Chauhan, D.S.; Quraishi, M. Pyridinium-based ionic liquids as novel eco-friendly corrosion inhibitors for mild steel in molar hydrochloric acid: Experimental & computational approach. Surf. Interfaces 2020, 22, 100881. [Google Scholar] [CrossRef]

- Yesudass, S.; Olasunkanmi, L.; Bahadur, I.; Kabanda, M.; Obot, I.B.; Ebenso, E.E. Experimental and theoretical studies on some selected ionic liquids with different cations/anions as corrosion inhibitors for mild steel in acidic medium. J. Taiwan Inst. Chem. Eng. 2016, 64, 252–268. [Google Scholar] [CrossRef]

- El-Hajjaji, F.; Messali, M.; Aljuhani, A.; Aouad, M.; Hammouti, B.; Belghiti, M.; Chauhan, D.S.; Quraishi, M. Pyridazinium-based ionic liquids as novel and green corrosion inhibitors of carbon steel in acid medium: Electrochemical and molecular dynamics simulation studies. J. Mol. Liq. 2018, 249, 997–1008. [Google Scholar] [CrossRef]

- Kannan, P.; Rao, T.S.; Rajendran, N. Anti-corrosion behavior of benzimidazoliumtetrafluroborate ionic liquid in acid medium using electrochemical noise technique. J. Mol. Liq. 2016, 222, 586–595. [Google Scholar] [CrossRef]

- Ashassi-Sorkhabi, H.; Es’Haghi, M. Corrosion inhibition of mild steel in acidic media by [BMIm]Br Ionic liquid. Mater. Chem. Phys. 2009, 114, 267–271. [Google Scholar] [CrossRef]

- Subasree, N.; Selvi, J.A. Imidazolium based ionic liquid derivatives; synthesis and evaluation of inhibitory effect on mild steel corrosion in hydrochloric acid solution. Heliyon 2020, 6, e03498. [Google Scholar] [CrossRef] [Green Version]

- Kowsari, E.; Payami, M.; Amini, R.; Ramezanzadeh, B.; Javanbakht, M. Task-specific ionic liquid as a new green inhibitor of mild steel corrosion. Appl. Surf. Sci. 2014, 289, 478–486. [Google Scholar] [CrossRef]

- Zhang, Q.; Hua, Y. Corrosion inhibition of mild steel by alkylimidazolium ionic liquids in hydrochloric acid. Electrochim. Acta 2009, 54, 1881–1887. [Google Scholar] [CrossRef]

- Azeez, F.A.; Al-Rashed, O.A.; Nazeer, A.A. Controlling of mild-steel corrosion in acidic solution using environmentally friendly ionic liquid inhibitors: Effect of alkyl chain. J. Mol. Liq. 2018, 265, 654–663. [Google Scholar] [CrossRef]

- Ibrahim, M.A.M.; Messali, M.; Moussa, Z.; Alzahrani, A.Y.; Alamry, S.N.; Hammouti, B. Corrosion Inhibition of Carbon Steel by Imidazolium and Pyridinium Cations Ionic Liquids in Acidic Environment. Port. Electrochim. Acta 2011, 29, 375–389. [Google Scholar] [CrossRef]

- Guo, Y.; Chen, Z.; Zuo, Y.; Chen, Y.; Yang, W.; Xu, B. Ionic liquids with two typical hydrophobic anions as acidic corrosion inhibitors. J. Mol. Liq. 2018, 269, 886–895. [Google Scholar] [CrossRef]

- Verma, C.; Olasunkanmi, L.O.; Bahadur, I.; Lgaz, H.; Quraishi, M.; Haque, J.; Sherif, E.-S.M.; Ebenso, E.E. Experimental, density functional theory and molecular dynamics supported adsorption behavior of environmental benign imidazolium based ionic liquids on mild steel surface in acidic medium. J. Mol. Liq. 2019, 273, 1–15. [Google Scholar] [CrossRef]

- Lgaz, H.; Anejjar, A.; Salghi, R.; Jodeh, S.; Zougagh, M.; Warad, I.; Larouj, M.; Sims, P. Characterization of corrosion products formed on carbon steel in hydrochloric acid medium by 4-(dimethylamino)-1-(6-methoxy-6-oxohexyl)pyridinium bromide. Int. J. Corros. Scale Inhib. 2016, 5, 209–231. [Google Scholar] [CrossRef]

- El-Hajjaji, F.; Messali, M.; de Yuso, M.M.; Rodriguez-Castellon, E.; Almutairi, S.; Bandosz, T.J.; Algarra, M. Effect of 1-(3-phenoxypropyl)pyridazin-1-ium bromide on steel corrosion inhibition in acidic medium. J. Colloid Interface Sci. 2019, 541, 418–424. [Google Scholar] [CrossRef]

- Ardakani, E.K.; Kowsari, E.; Ehsani, A. Imidazolium-derived polymeric ionic liquid as a green inhibitor for corrosion inhibition of mild steel in 1.0 M HCl: Experimental and computational study. Colloids Surf. A Physicochem. Eng. Asp. 2020, 586, 124195. [Google Scholar] [CrossRef]

- Murulana, L.C.; Singh, A.K.; Shukla, S.K.; Kabanda, M.; Ebenso, E.E. Experimental and Quantum Chemical Studies of Some Bis(trifluoromethyl-sulfonyl) Imide Imidazolium-Based Ionic Liquids as Corrosion Inhibitors for Mild Steel in Hydrochloric Acid Solution. Ind. Eng. Chem. Res. 2012, 51, 13282–13299. [Google Scholar] [CrossRef]

- Arellanes-Lozada, P.; Olivares-Xometl, O.; Likhanova, N.V.; Lijanova, I.V.; Garcia, J.R.V.; Hernández-Ramírez, R.E. Adsorption and performance of ammonium-based ionic liquids as corrosion inhibitors of steel. J. Mol. Liq. 2018, 265, 151–163. [Google Scholar] [CrossRef]

- Aslam, R.; Mobin, M.; Huda; Obot, I. B.; Alamri, A.H. Ionic liquids derived from α-amino acid ester salts as potent green corrosion inhibitors for mild steel in 1M HCl. J. Mol. Liq. 2020, 318, 113982. [Google Scholar] [CrossRef]

- Hegazy, M.; Abdallah, M.; Ahmed, H. Novel cationic gemini surfactants as corrosion inhibitors for carbon steel pipelines. Corros. Sci. 2010, 52, 2897–2904. [Google Scholar] [CrossRef]

- Zhang, T.; Pan, Z.; Gao, H. Novel Synthesized Gemini Surfactant as Corrosion Inhibitor for Carbon Steel in HCl Solution. J. Surfactants Deterg. 2015, 18, 1003–1009. [Google Scholar] [CrossRef]

- Tawfik, S.M.; Abd-Elaal, A.; Aiad, I. Three gemini cationic surfactants as biodegradable corrosion inhibitors for carbon steel in HCl solution. Res. Chem. Intermed. 2015, 42, 1101–1123. [Google Scholar] [CrossRef]

- Tawfik, S.M. Ionic liquids based gemini cationic surfactants as corrosion inhibitors for carbon steel in hydrochloric acid solution. J. Mol. Liq. 2016, 216, 624–635. [Google Scholar] [CrossRef]

- Park, J.K.; Jeong, N.H. Corrosion inhibition effect of ester containing cationic gemini surfactants on low carbon steel, Iran. J. Chem. Chem. Eng. 2016, 35, 85–93. [Google Scholar]

- Han, T.; Guo, J.; Zhao, Q.; Wu, Y.; Zhang, Y. Enhanced corrosion inhibition of carbon steel by pyridyl gemini surfactants with different alkyl chains. Mater. Chem. Phys. 2019, 240, 122156. [Google Scholar] [CrossRef]

- Mobin, M.; Aslam, R.; Aslam, J. Non toxic biodegradable cationic gemini surfactants as novel corrosion inhibitor for mild steel in hydrochloric acid medium and synergistic effect of sodium salicylate: Experimental and theoretical approach. Mater. Chem. Phys. 2017, 191, 151–167. [Google Scholar] [CrossRef]

- Shaban, S.M.; Abd-Elaal, A.; Tawfik, S.M. Gravimetric and electrochemical evaluation of three nonionic dithiol surfactants as corrosion inhibitors for mild steel in 1 M HCl solution. J. Mol. Liq. 2016, 216, 392–400. [Google Scholar] [CrossRef]

- Negm, N.; El-Hashash, M.; Abd-Elaal, A.; Tawfik, S.M.; Gharieb, A. Amide type nonionic surfactants: Synthesis and corrosion inhibition evaluation against carbon steel corrosion in acidic medium. J. Mol. Liq. 2018, 256, 574–580. [Google Scholar] [CrossRef]

- Mobin, M.; Zehra, S.; Parveen, M. l-Cysteine as corrosion inhibitor for mild steel in 1 M HCl and synergistic effect of anionic, cationic and non-ionic surfactants. J. Mol. Liq. 2016, 216, 598–607. [Google Scholar] [CrossRef]

- Masroor, S.; Mobin, M.; Alam, M.J.; Ahmad, S. The novel iminium surfactant p-benzylidene benzyldodecyl iminium chloride as a corrosion inhibitor for plain carbon steel in 1 M HCl: Electrochemical and DFT evaluation. RSC Adv. 2017, 7, 23182–23196. [Google Scholar] [CrossRef] [Green Version]