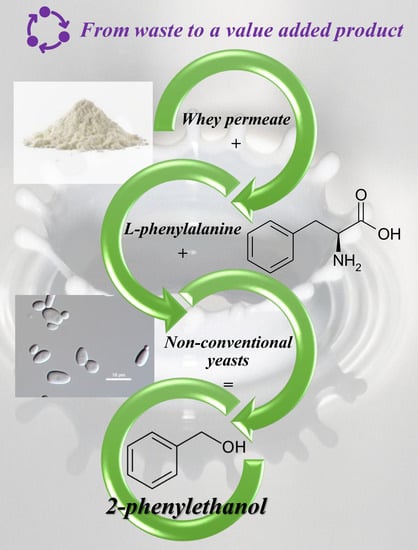

Development of a Continuous System for 2-Phenylethanol Bioproduction by Yeast on Whey Permeate-Based Medium

Abstract

:1. Introduction

2. Results and Discussion

2.1. Evaluation of the Potential of Newly Isolated Yeasts for 2-PE Production in Well-Defined Media

2.2. 2-PE Production on Whey Permeate Based Media in Batch Cultures: In Shaking Flasks and a 4.8 L Bioreactor

2.3. Continuous System for 2-PE Production on Whey Permeate Based Medium

3. Materials and Methods

3.1. Isolation, Identification, and Physiological Characterization of Yeast Strains

3.2. Batch Cultures for 2-PE Production in Shaking Flasks

3.3. Yeast Growth in the Presence of Exogenous 2-PE

3.4. Batch Cultures for 2-PE Production in WP2 Medium in a 4.8 L Bioreactor

3.5. Continuous Experimental System for 2-PE Biotransformation

3.6. 2-PE Extraction and Purification from Fermentation Broth

3.7. Analytical Methods

3.8. Calculations

3.9. Statistical Data Analyses

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Chintagunta, A.D.; Jacob, S.; Banerjee, R. Integrated bioethanol and biomanure production from potato waste. Waste Manag. 2016, 49, 320–325. [Google Scholar] [CrossRef] [PubMed]

- Uçkun Kiran, E.; Trzcinski, A.P.; Ng, W.J.; Liu, Y. Enzyme Production from Food Wastes Using a Biorefinery Concept. Waste and Biomass Valorization 2014, 5, 903–917. [Google Scholar] [CrossRef]

- Etschmann, M.M.W.; Sell, D.; Schrader, J. Screening of yeasts for the production of the aroma compound 2-phenylethanol in a molasses-based medium. Biotechnol. Lett. 2003, 25, 531–536. [Google Scholar] [CrossRef]

- Das, M.; Raychaudhuri, A.; Ghosh, S.K. Supply Chain of Bioethanol Production from Whey: A Review. Procedia Environ. Sci. 2016, 35, 833–846. [Google Scholar] [CrossRef]

- Lappa, I.K.; Papadaki, A.; Kachrimanidou, V. Cheese Whey Processing: Integrated Biorefinery. Foods 2019, 8, 347. [Google Scholar] [CrossRef] [Green Version]

- Lane, M.M.; Morrissey, J.P. Kluyveromyces marxianus: A yeast emerging from its sister’s shadow. Fungal Biol. Rev. 2010, 24, 17–26. [Google Scholar] [CrossRef]

- Lachance, M.A. Kluyveromyces van der Walt (1971). In The Yeasts, Fifth Edition: A Taxonomic Study, 5th ed.; Kurtzman, C.P., Fell, J.W., Boekhout, T., Eds.; Elsevier: Amsterdam, The Netherlands, 2011; pp. 471–481. [Google Scholar] [CrossRef]

- Karim, A.; Gerliani, N.; Aïder, M. Kluyveromyces marxianus: An emerging yeast cell factory for applications in food and biotechnology. Int. J. Food Microbiol. 2020, 333, 108818. [Google Scholar] [CrossRef]

- Valdez Castillo, M.; Pachapur, V.L.; Brar, S.K.; Naghdi, M.; Arriaga, S.; Ávalos Ramirez, A. Yeast-driven whey biorefining to produce value-added aroma, flavor, and antioxidant compounds: Technologies, challenges, and alternatives. Crit. Rev. Biotechnol. 2020, 40, 930–950. [Google Scholar] [CrossRef]

- Silver, S.; Wendt, L. Mechanism of action of phenethyl alcohol: Breakdown of the cellular permeability barrier. J. Bacteriol. 1967, 93, 560–566. [Google Scholar] [CrossRef] [Green Version]

- Liu, P.; Cheng, Y.; Yang, M.; Liu, Y.; Chen, K.; Long, C.; Deng, X. Mechanisms of action for 2-phenylethanol isolated from Kloeckera apiculata in control of Penicillium molds of citrus fruits. BMC Microbiol. 2014, 14, 242. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhu, Y.J.; Zhou, H.T.; Hu, Y.H.; Tang, J.Y.; Su, M.X.; Guo, Y.J.; Chen, Q.X.; Liu, B. Antityrosinase and antimicrobial activities of 2-phenylethanol, 2-phenylacetaldehyde and 2-phenylacetic acid. Food Chem. 2011, 124, 298–302. [Google Scholar] [CrossRef]

- Mierzejewska, J.; Dąbkowska, K.; Chreptowicz, K.; Sokołowska, A. Hydrolyzed corn stover as a promising feedstock for 2-phenylethanol production by nonconventional yeast. J. Chem. Technol. Biotechnol. 2019, 94, 777–784. [Google Scholar] [CrossRef]

- Martínez-Avila, O.; Sánchez, A.; Font, X.; Barrena, R. Fed-Batch and Sequential-Batch Approaches To Enhance the Bioproduction of 2-Phenylethanol and 2-Phenethyl Acetate in Solid-State Fermentation Residue-Based Systems. J. Agric. Food Chem. 2019, 67, 3389–3399. [Google Scholar] [CrossRef] [PubMed]

- Conde-Báez, L.; Castro-Rosas, J.; Villagómez-Ibarra, J.R.; Páez-Lerma, J.B.; Gómez-Aldapa, C. Evaluation of Waste of the Cheese Industry for the Production of Aroma of Roses (Phenylethyl Alcohol). Waste Biomass Valorization 2017, 8, 1343–1350. [Google Scholar] [CrossRef]

- Chreptowicz, K.; Sternicka, M.K.; Kowalska, P.D.; Mierzejewska, J. Screening of yeasts for the production of 2-phenylethanol (rose aroma) in organic waste-based media. Lett. Appl. Microbiol. 2018, 66, 153–160. [Google Scholar] [CrossRef]

- Conde-Báez, L.; López-Molina, A.; Gómez-Aldapa, C.; Pineda-Muñoz, C.; Conde-Mejía, C. Economic projection of 2-phenylethanol production from whey. Food Bioprod. Process. 2019, 115, 10–16. [Google Scholar] [CrossRef]

- Etschmann, M.; Bluemke, W.; Sell, D.; Schrader, J. Biotechnological production of 2-phenylethanol. Appl. Microbiol. Biotechnol. 2002, 59, 1–8. [Google Scholar]

- Eshkol, N.; Sendovski, M.; Bahalul, M.; Katz-Ezov, T.; Kashi, Y.; Fishman, A. Production of 2-phenylethanol from L-phenylalanine by a stress tolerant Saccharomyces cerevisiae strain. J. Appl. Microbiol. 2009, 106, 534–542. [Google Scholar] [CrossRef]

- Kim, T.Y.; Lee, S.W.; Oh, M.K. Biosynthesis of 2-phenylethanol from glucose with genetically engineered Kluyveromyces marxianus. Enzyme Microb. Technol. 2014, 61–62, 44–47. [Google Scholar] [CrossRef]

- de Lima, L.A.; Diniz, R.H.S.; de Queiroz, M.V.; Fietto, L.G.; da Silveira, W.B. Screening of Yeasts Isolated from Brazilian Environments for the 2-Phenylethanol (2-PE) Production. Biotechnol. Bioprocess Eng. 2018, 23, 326–332. [Google Scholar] [CrossRef]

- Seward, R.; Willets, J.; Dinsdale, M.; Lloyd, D. The effects of ethanol, hexan-1-ol, and 2-phenylethanol on cider yeast growth, viability, and energy status; synergistic inhibition. J. Inst. Brew. 1996, 102, 439–443. [Google Scholar] [CrossRef]

- Gao, F.; Daugulis, A.J. Bioproduction of the aroma compound 2-phenylethanol in a solid-liquid two-phase partitioning bioreactor system by Kluyveromyces marxianus. Biotechnol. Bioeng. 2009, 104, 332–339. [Google Scholar] [CrossRef]

- Etschmann, M.M.W.; Schrader, J. An aqueous–organic two-phase bioprocess for efficient production of the natural aroma chemicals 2-phenylethanol and 2-phenylethylacetate with yeast. Appl. Microbiol. Biotechnol. 2006, 71, 440–443. [Google Scholar] [CrossRef] [PubMed]

- Chreptowicz, K.; Mierzejewska, J. Enhanced bioproduction of 2-phenylethanol in a biphasic system with rapeseed oil. N. Biotechnol. 2018, 42, 56–61. [Google Scholar] [CrossRef]

- Adler, P.; Hugen, T.; Wiewiora, M.; Kunz, B. Modeling of an integrated fermentation/membrane extraction process for the production of 2-phenylethanol and 2-phenylethylacetate. Enzyme Microb. Technol. 2011, 48, 285–292. [Google Scholar] [CrossRef] [PubMed]

- Etschmann, M.M.W.; Sell, D.; Schrader, J. Production of 2-phenylethanol and 2-phenylethylacetate from L-phenylalanine by coupling whole-cell biocatalysis with organophilic pervaporation. Biotechnol. Bioeng. 2005, 92, 624–634. [Google Scholar] [CrossRef]

- Mihaľ, M.; Vereš, R.; Markoš, J. Investigation of 2-phenylethanol production in fed-batch hybrid bioreactor: Membrane extraction and microfiltration. Sep. Purif. Technol. 2012, 95, 126–135. [Google Scholar]

- Wang, H.; Dong, Q.; Meng, C.; Shi, X.; Guo, Y. A continuous and adsorptive bioprocess for efficient production of the natural aroma chemical 2-phenylethanol with yeast. Enzyme Microb. Technol. 2011, 48, 404–407. [Google Scholar] [CrossRef]

- Fonseca, G.G.; Gombert, A.K.; Heinzle, E.; Wittmann, C. Physiology of the yeast Kluyveromyces marxianus during batch and chemostat cultures with glucose as the sole carbon source. FEMS Yeast Res. 2007, 7, 422–435. [Google Scholar] [CrossRef] [Green Version]

- Hoffman, C.S.; Winston, F. A ten-minute DNA preparation from yeast efficiently releases autonomous plasmids for transformaion of Escherichia coli. Gene 1987, 57, 267–272. [Google Scholar] [CrossRef]

- Sipiczki, M. Candida zemplinina sp. nov., an osmotolerant and psychrotolerant yeast that ferments sweet botrytized wines. Int. J. Syst. Evol. Microbiol. 2003, 53, 2079–2083. [Google Scholar] [CrossRef] [Green Version]

- Chreptowicz, K.; Marlicka, K.; Milner-Krawczyk, M.; Korzeniowska, E.; Poterała, M.; Mierzejewska, J. Cystobasidium psychroaquaticum as a new promising source of valuable bioactive molecules. Biocatal. Agric. Biotechnol. 2021, 33, 101985. [Google Scholar] [CrossRef]

- Kurtzman, C.P.; Fell, J.W.; Boekhout, T.; Robert, V. Chapter 7–Methods for Isolation, Phenotypic Characterization and Maintenance of Yeasts. In The Yeasts, Fifth Edition: A Taxonomic Study, 5th ed.; Kurtzman, C.P., Fell, J.W., Boekhout, T., Eds.; Elsevier: Amsterdam, The Netherlands, 2011; pp. 87–110. [Google Scholar] [CrossRef]

- Chreptowicz, K.; Mierzejewska, J.; Tkacova, J.; Młynek, M.; Certic, M. Carotenoid-Producing Yeasts: Identification and Characteristics of Environmental Isolates with a Valuable Extracellular Enzymatic Activity. Microorganisms 2019, 7, 653. [Google Scholar] [CrossRef] [Green Version]

- Mierzejewska, J.; Tymoszewska, A.; Chreptowicz, K.; Krol, K. Mating of 2 Laboratory Saccharomyces cerevisiae Strains Resulted in Enhanced Production of 2-Phenylethanol by Biotransformation of L-Phenylalanine. J. Mol. Microbiol. Biotechnol. 2017, 27, 81–90. [Google Scholar] [CrossRef]

- Chreptowicz, K.; Wielechowska, M.; Główczyk-Zubek, J.; Rybak, E.; Mierzejewska, J. Production of natural 2-phenylethanol: From biotransformation to purified product. Food Bioprod. Process. 2016, 100, 275–281. [Google Scholar] [CrossRef]

| Growth Temperature | Time | WUT175 | WUT216 | WUT240 |

|---|---|---|---|---|

| 25 °C | 24 h | 0.89 ± 0.04 | 1.13 ± 0.09 | 1.62 ± 0.05 |

| 48 h | 1.63 ± 0.01 | 2.74 ± 0.34 | 2.25 ± 0.04 | |

| 30 °C | 24 h | 0.77 ± 0.01 | 1.58 ± 0.08 | 1.85 ± 0.07 |

| 48 h | 1.24 ± 0.03 | 2.21 ± 0.07 | 2.14 ± 0.01 | |

| 37 °C | 24 h | - 1 | 1.57 ± 0.02 | 1.85 ± 0.07 |

| 48 h | - 1 | 1.85 ± 0.02 | 1.82 ± 0.01 |

| Medium | Growth Temperature | Time | WUT175 | WUT216 | WUT240 |

|---|---|---|---|---|---|

| WP1 | 25 °C | 24 h | 1.37 ± 0.09 | 1.14 ± 0.28 | 1.94 ± 0.08 |

| 48 h | 1.78 ± 0.19 | 1.65 ± 0.24 | 1.99 ± 0.08 | ||

| 30 °C | 24 h | 1.48 ± 0.01 | 1.59 ± 0.17 | 1.00 ± 0.04 | |

| 48 h | 1.65 ± 0.01 | 1.90 ± 0.21 | 1.16 ± 0.05 | ||

| WP2 | 25 °C | 24 h | 1.97 ± 0.12 | 1.08 ± 0.03 | 1.34 ± 0.40 |

| 48 h | 2.12 ± 0.19 | 1.00 ± 0.03 | 2.14 ± 0.40 | ||

| 30 °C | 24 h | 1.74 ± 0.07 | 1.14 ± 0.07 | 1.68 ± 0.13 | |

| 48 h | 1.87 ± 0.05 | 1.64 ± 0.19 | 2.07 ± 0.32 |

| Parameter | Batch 1 | Batch 2 | Batch 3 | Batch 4 | Batch 5 |

|---|---|---|---|---|---|

| final OD600 (−) | 6.84 ± 0.02 | 6.96 ± 0.08 | 8.39 ± 0.02 | 7.83 ± 0.01 | 6.26 ± 0.07 |

| μ (h−1) | 0.25 ± 0.01 | 0.26 ± 0.02 | 0.17 ± 0.01 | 0.35 ± 0.01 | 0.36 ± 0.00 |

| 2-PE (g L−1) | 1.66 ± 0.01 | 1.76 ± 0.03 | 1.80 ± 0.05 | 2.10 ± 0.11 | 2.59 ± 0.15 |

| L-phe (g L−1) | 2.64 ± 0.08 | 2.56 ± 0.04 | 2.47 ± 0.18 | 2.19 ± 0.18 | 1.88 ± 0.08 |

| lactose (g L−1) | nd | nd | nd | nd | nd |

| ethanol (g L−1) | 6.23 ± 0.09 | 5.07 ± 0.01 | nd | nd | 3.65 ± 0.26 |

| P2-PE (mg L−1 h−1) | 34.58 | 36.67 | 37.50 | 43.75 | 53.96 |

| Y2-PE (−) | 0.45 | 0.48 | 0.49 | 0.47 | 0.70 |

| YP/L-phe0 (−) | 0.33 | 0.35 | 0.36 | 0.42 | 0.52 |

| YP/L-phe0 (−) | 0.33 | 0.35 | 0.36 | 0.42 | 0.52 |

| ZL-phe (%) | 47.20 | 48.80 | 50.60 | 58.00 | 62.40 |

| Parameter | Continuous 1 (0.05 h−1 Dilution Rate) | Continuous 2 (0.1 h−1 Dilution Rate) |

|---|---|---|

| final OD600 (−) | 2.65 ± 0.06 | 2.86 ± 0.14 |

| DCW (g L−1) | 1.30 ± 0.00 | 1.30 ± 0.04 |

| μ (h−1) | 0.28 ± 0.02 | 0.36 ± 0.02 |

| 2-PE (g L−1) | 1.15 ± 0.12 | 0.85 ± 0.07 |

| amount of 2-PE (g) 1 | 8.29 ± 0.82 | 5.63 ± 0.54 |

| L-phe (g L−1) | 0.47 ± 0.03 | 0.08 ± 0.04 |

| lactose (g L−1) | nd | nd |

| ethanol (g L−1) | nd | nd |

| P2-PE (mg L−1 h−1) | 57.50 | 39.10 |

| Y2-PE (−) | 1.12 | 0.76 |

| YP/L-phe0 (−) | 0.33 | 0.35 |

| YP/L-phe0 (−) | 0.83 | 0.56 |

| ZL-phe (%) | 90.6 | 85.0 |

| Medium | Composition | Reference |

|---|---|---|

| SAB | 5 g L−1 meat peptone, 5 g L−1 casein peptone, 20 g L−1 glucose (Merck, Darmstadt) pH 5.6 | - |

| 8 | 15 g L−1 glucose, 8 g L−1 sucrose, 5 g L−1 L-Phe (BioShop, Burlington, Canada; purity min. 98.5%), 0.5 g L−1 MgSO4, 1.7 g L−1 YNB without amino acids and ammonium sulfate (Conda, Madrid, Spain), pH 4.6 | [36] |

| WP1 | 15 g L−1 whey permeate 1 (SM Mlekovita, Wysokie Mazowieckie, Poland), 5 g L−1 L-phe | this work |

| WP2 | 25 g L−1 whey permeate1, 5 g L−1 L-phe | this work |

| Parameter | Batch 1 | Batch 2 | Batch 3 | Batch 4 | Batch 5 |

|---|---|---|---|---|---|

| inoculum titer | 2% | 2% | 2% | 2% | 2% |

| bioreactor working volume | 2 L | 2 L | 2 L | 2 L | 2 L |

| temperature | 25 °C | 25 °C | 25 °C | 30 °C | 30 °C |

| initial pH | 5 | 5 | 5 | 5 | 5 |

| air flow rate | 1.5 L min−1 | 3.0 L min−1 | 3.0 L min−1 | 3.0 L min−1 | 1.5 L min−1 |

| stirring speed | 250 rpm | 250 rpm | 500 rpm | 500 rpm | 250 rpm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Drężek, K.; Kozłowska, J.; Detman, A.; Mierzejewska, J. Development of a Continuous System for 2-Phenylethanol Bioproduction by Yeast on Whey Permeate-Based Medium. Molecules 2021, 26, 7388. https://doi.org/10.3390/molecules26237388

Drężek K, Kozłowska J, Detman A, Mierzejewska J. Development of a Continuous System for 2-Phenylethanol Bioproduction by Yeast on Whey Permeate-Based Medium. Molecules. 2021; 26(23):7388. https://doi.org/10.3390/molecules26237388

Chicago/Turabian StyleDrężek, Karolina, Joanna Kozłowska, Anna Detman, and Jolanta Mierzejewska. 2021. "Development of a Continuous System for 2-Phenylethanol Bioproduction by Yeast on Whey Permeate-Based Medium" Molecules 26, no. 23: 7388. https://doi.org/10.3390/molecules26237388