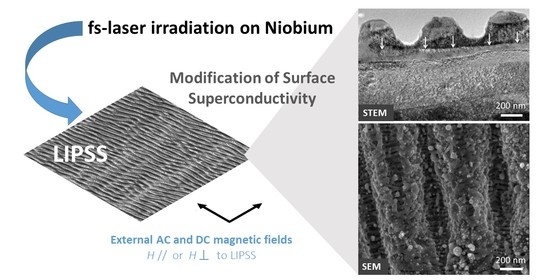

Surface Superconductivity Changes of Niobium Sheets by Femtosecond Laser-Induced Periodic Nanostructures

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Microstructural Characterization

3.2. Irreversible Magnetization and Upper Critical Field, Hc2

3.3. Surface Superconductivity Characterization

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dew-Hughes, D. The metallurgical enhancement of type II superconductors. Rep. Prog. Phys. 1971, 34, 821–873. [Google Scholar] [CrossRef]

- Bean, C.P.; Livingston, J.D. Surface barrier in type-II superconductors. Phys. Rev. Lett. 1964, 12, 14–16. [Google Scholar] [CrossRef]

- Zeldov, E.; Larkin, A.I.; Geshkenbein, V.B.; Konczykowski, M.; Majer, D.; Khaykovich, B.; Vinokur, V.M.; Shtrikman, H. Geometrical Barriers in high-temperature superconductors. Phys. Rev. Lett. 1994, 73, 1428–1431. [Google Scholar] [CrossRef] [PubMed]

- van der Klein, C.A.M.; Kes, P.H.; van Beelen, H.; de Klerk, D. The effect of neutron irradiation damage on the magnetic behavior of superconducting niobium in stationary fields. J. Low Temp. Phys. 1974, 16, 169–191. [Google Scholar] [CrossRef]

- Hopkins, J.R.; Finnemore, D.K. Surface superconductivity in niobium and niobium-tantalum alloys. Phys. Rev. B 1974, 9, 108–114. [Google Scholar] [CrossRef] [Green Version]

- Mishra, P.K.; Ravikumar, G.; Sahni, V.C.; Koblischka, M.R.; Grover, A.K. Surface pinning in niobium and a high-Tc superconductor. Physica C 1996, 269, 71–75. [Google Scholar] [CrossRef]

- Chen, D.-X.; Cross, R.W.; Sanchez, A. Effects of critical current density, equilibrium magnetization and surface barrier on magnetization of high temperature superconductors. Cryogenics 1993, 33, 695–702. [Google Scholar] [CrossRef]

- Konczykowski, M.; Burlachkov, L.I.; Yeshurun, Y.; Holtzberg, F. Evidence of surface barriers and their effect on irreversibility and lower critical field measurements in Y-Ba-Cu-O crystals. Phys. Rev. B 1991, 43, 13707–13710. [Google Scholar] [CrossRef]

- Saint-James, D.; de Gennes, P.G. Onset of superconductivity in decreasing fields. Phys. Lett. 1963, 7, 306–308. [Google Scholar] [CrossRef]

- Casalbuoni, S.; Knabbe, E.A.; Kötzler, J.; Lilje, L.; von Sawilski, L.; Schmüser, P.; Steffen, B. Surface superconductivity in niobium for superconducting RF cavities. Nucl. Instrum. Methods Phys. Res. Sect. A 2005, 538, 45–64. [Google Scholar] [CrossRef] [Green Version]

- Sung, Z.-H.; Dzyuba, A.; Lee, P.J.; Larbalestier, D.C.; Cooley, L.D. Evidence of incomplete annealing at 800 °C and the effects of 120 °C baking on the crystal orientation and the surface superconducting properties of cold-worked and chemically polished Nb. Supercond. Sci. Technol. 2015, 28, 075003. [Google Scholar] [CrossRef]

- Aburas, M.; Pautrat, A.; Bellido, N. Change of surface critical current in the surface superconductivity and mixed states of superconducting niobium. Supercond. Sci. Technol. 2017, 30, 015009. [Google Scholar] [CrossRef] [Green Version]

- Scola, J.; Pautrat, A.; Goupil, C.; Méchin, L.; Hardy, V.; Simon, C. Voltage noise and surface current fluctuation in the superconducting surface sheath. Phys. Rev. B 2005, 72, 012507. [Google Scholar] [CrossRef] [Green Version]

- Grassallino, A.; Romanenko, A.; Sergatskov, D.; Melnychuk, O.; Trenikhina, Y.; Crawford, A.; Rowe, A.; Wong, M.; Khabiboulline, T.; Barkov, F. Nitrogen and argon doping of niobium for superconducting radio frequency cavities: A pathway to highly efficient accelerating structures. Supercond. Sci. Technol. 2013, 26, 102001. [Google Scholar] [CrossRef]

- Lasagni, A.; Benke, D.; Kunze, T.; Bieda, M.; Eckhardt, S.; Roch, T.; Langheinrich, D.; Nerger, J. Bringing the Direct Laser Interference Patterning Method to Industry: A One Tool-Complete Solution for Surface Functionalization. J. Laser Micro/Nanoeng. 2015, 10, 340–344. [Google Scholar] [CrossRef]

- Pronko, P.P.; Dutta, S.K.; Squier, J.; Rudd, J.V.; Du, D.; Mourou, G. Machining of sub-micron holes using a femtosecond laser at 800 nm. Opt. Commun. 1995, 114, 106–110. [Google Scholar] [CrossRef]

- Bonse, J.; Höhm, S.; Kirner, S.V.; Rosenfeld, A.; Krüger, J. Laser-Induced Periodic Surface Structures—A Scientific Evergreen. IEEE J. Sel. Top. Quantum Electron. 2017, 23, 9000615. [Google Scholar] [CrossRef]

- Cubero, A.; Martínez, E.; Angurel, L.A.; de la Fuente, G.F.; Navarro, R.; Legall, H.; Krüger, J.; Bonse, J. Effects of laser-induced periodic surface structures on the superconducting properties of Niobium. Appl. Surf. Sci. 2020, 508, 145140. [Google Scholar] [CrossRef]

- Voisiat, B.; Gedvilas, M.; Indrisiunas, S.; Raciukaitis, G. Flexible microstructuring of thin films using multi-beam interference. J. Laser Micro/Nanoeng. 2011, 6, 185–190. [Google Scholar] [CrossRef]

- Gedvilas, M.; Indrišiūnas, S.; Voisiat, B.; Stankevičius, E.; Selskis, A.; Račiukaitis, G. Nanoscale thermal diffusion during the laser interference ablation using femto-, pico-, and nanosecond pulses in silicon. Phys. Chem. Chem. Phys. 2018, 20, 12166–12174. [Google Scholar] [CrossRef]

- Bonse, J.; Kirner, S.V.; Krüger, J. Laser-Induced Periodic Surface Structures (LIPSS). In Handbook of Laser Micro and Nano-Engineering; Sugioka, K., Ed.; Springer: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Bonse, J.; Gräf, S. Maxwell Meets Marangoni—A Review of Theories on Laser-Induced Periodic Surface Structures. Laser Photonics Rev. 2020, 14, 2000215. [Google Scholar] [CrossRef]

- Bonse, J. Quo Vadis LIPSS?—Recent and Future Trends on Laser-Induced Periodic Surface Structures. Nanomaterials 2020, 10, 1950. [Google Scholar] [CrossRef] [PubMed]

- Okamuro, K.; Hashida, M.; Miyasaka, Y.; Ikuta, Y.; Tokita, S.; Sakabe, S. Laser fluence dependence of periodic grating structures formed on metal surfaces under femtosecond laser pulse irradiation. Phys. Rev. B 2010, 82, 165417. [Google Scholar] [CrossRef] [Green Version]

- Hou, S.; Huo, Y.; Xiong, P.; Zhang, Y.; Zhang, S.; Jia, T.; Sun, Z.; Qiu, J.; Xu, Z. Formation of long-and short-periodic nanoripples on stainless steel irradiated by femtosecond laser pulses. J. Phys. D 2011, 44, 505401. [Google Scholar] [CrossRef]

- Gecys, P.; Vinciunas, A.; Gedvilas, M.; Kasparaitis, A.; Lazdinas, R.; Raciukaitis, G. Ripple formation by femtosecond laser pulses for enhanced absorptance of stainless steel. J. Laser Micro/Nanoeng. 2015, 10, 129–133. [Google Scholar] [CrossRef]

- Liu, J.M. Simple technique for measurements of pulsed Gaussian-beam spot sizes. Opt. Lett. 1982, 7, 196. [Google Scholar] [CrossRef] [PubMed]

- Zemaitis, A.; Gaidys, M.; Brikas, M.; Gecys, P.; Raciukaitis, G.; Gedvilas, M. Advanced laser scanning for highly efficient ablation and ultrafast surface structuring: Experiment and model. Sci. Rep. 2018, 8, 17376. [Google Scholar] [CrossRef]

- Golovashkin, A.I.; Leksina, I.E.; Motulevich, G.P.; Shubin, A.A. The optical properties of niobium. Sov. Phys. JETP 1969, 29, 27–34. [Google Scholar]

- Raether, H. Surface Plasmons on Smooth and Rough Surfaces and on Gratings; Springer: Berlin/Heidelberg, Germany, 1988. [Google Scholar]

- Derrien, T.J.Y.; Krüger, J.; Bonse, J. Properties of surface plasmon polaritons on lossy materials: Lifetimes, periods and excitation conditions. J. Opt. 2016, 18, 115007. [Google Scholar] [CrossRef] [Green Version]

- Gedvilas, M.; Raciukaitis, G.; Regelskis, K. Self-organization in a chromium thin film under laser irradiation. Appl. Phys. A 2008, 93, 203–208. [Google Scholar] [CrossRef]

- Kunz, C.; Bonse, J.; Spaltmann, D.; Neumann, C.; Turchanin, A.; Bartolomé, J.F.; Müller, F.A.; Gräf, S. Tribological performance of metal-reinforced ceramic composites selectively structured with femtosecond laser-induced periodic surface structures. Appl. Surf. Sci. 2020, 499, 143917. [Google Scholar] [CrossRef]

- Pan, A.; Dias, A.; Gomez-Aranzadi, M.; Olaizola, S.M.; Rodriguez, A. Formation of laser-induced periodic surface structures on niobium by femtosecond laser irradiation. J. Appl. Phys. 2014, 115, 173101. [Google Scholar] [CrossRef] [Green Version]

- Choudhury, T.; Saied, S.O.; Sullivan, J.L.; Abbot, A.M. Reduction of oxides of iron, cobalt, titanium and niobium by low-energy ion bombardment. J. Phys. D Appl. Phys. 1989, 22, 1185–1195. [Google Scholar] [CrossRef]

- Dacca, A.; Gemme, G.; Mattera, L.; Parodi, R. XPS analysis of the surface composition of niobium for superconducting RF cavities. Appl. Surf. Sci. 1998, 126, 219–230. [Google Scholar] [CrossRef]

- Yang, Z.; Lu, X.; Tan, W.; Zhao, J.; Yang, D.; Yang, Y. XPS studies of nitrogen doping niobium used for accelerator applications. Appl. Surf. Sci. 2018, 439, 1119–1126. [Google Scholar] [CrossRef] [Green Version]

- Kirner, S.V.; Wirth, T.; Sturm, H.; Krüger, J.; Bonse, J. Nanometer-resolved chemical analyses of femtosecond laser-induced periodic surface structures on titanium. J. Appl. Phys. 2017, 122, 104901. [Google Scholar] [CrossRef]

- Badrinarayanan, S.; Sinha, S. X-ray photoelectron spectroscopy studies of the reaction of N+2-ion beams with niobium and tantalum metals. J. Appl. Phys. 1991, 69, 1141–1146. [Google Scholar] [CrossRef]

- Prieto, P.; Galán, L.; Sanz, J.M. An XPS study of NbNx prepared by ion implantation and the near-surface effects induced by Ar+ bombardment. Surf. Sci. 1991, 251–252, 701–705. [Google Scholar] [CrossRef]

- van Gurp, G.J. The effect of structure on the superconducting properties of vanadium and niobium foils. Philips Res. Rep. 1967, 22, 10–35. [Google Scholar]

- Finnemore, D.K.; Stromberg, T.F.; Swenson, C.A. Superconducting properties of high-purity niobium. Phys. Rev. 1966, 149, 231–243. [Google Scholar] [CrossRef]

- Castel, X.; Guilloux-Viry, M.; Perrin, A.; Le Paven-Thivet, C.; Debuigne, J. Correlation between microwave surface resistance, AC susceptibility and in-plane ordering in YBa2Cu307 thin films epitaxially grown on (100) MgO substrates. Physica C 1995, 255, 281–292. [Google Scholar] [CrossRef]

| Sample | Laser | Atm. | P (W) | frep (kHz) | vL (mm/s) | ds (μm) | Fp (J/cm2) | Ip (GW/cm2) | F2D (J/cm2) |

|---|---|---|---|---|---|---|---|---|---|

| FS_Ar | L1 | Ar | 0.18 | 1 | 1 | 1000 | 0.61 | 2671 | 17.1 |

| FS_N | L1 | N2 | 0.18 | 1 | 1 | 1000 | 0.61 | 2671 | 17.1 |

| FS_air1 | L2 | Air | 0.02 | 1 | 6 | 20 | 0.15 | 5023 | 16.6 |

| FS_air2 | L2 | Air | 0.02 | 1 | 6 | 20 | 0.15 | 5023 | 16.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cubero, Á.; Martínez, E.; Angurel, L.A.; de la Fuente, G.F.; Navarro, R.; Legall, H.; Krüger, J.; Bonse, J. Surface Superconductivity Changes of Niobium Sheets by Femtosecond Laser-Induced Periodic Nanostructures. Nanomaterials 2020, 10, 2525. https://doi.org/10.3390/nano10122525

Cubero Á, Martínez E, Angurel LA, de la Fuente GF, Navarro R, Legall H, Krüger J, Bonse J. Surface Superconductivity Changes of Niobium Sheets by Femtosecond Laser-Induced Periodic Nanostructures. Nanomaterials. 2020; 10(12):2525. https://doi.org/10.3390/nano10122525

Chicago/Turabian StyleCubero, Álvaro, Elena Martínez, Luis A. Angurel, Germán F. de la Fuente, Rafael Navarro, Herbert Legall, Jörg Krüger, and Jörn Bonse. 2020. "Surface Superconductivity Changes of Niobium Sheets by Femtosecond Laser-Induced Periodic Nanostructures" Nanomaterials 10, no. 12: 2525. https://doi.org/10.3390/nano10122525