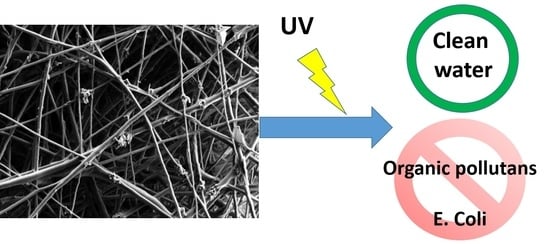

TiO2-Doped Electrospun Nanofibrous Membrane for Photocatalytic Water Treatment

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. PA6 and TiO2 Modified PA6 Electrospun Nanofibres Membranes Preparation

2.3. PA6 and TiO2 Modified PA6 Electrospun Nanofibres Membranes Characterization

2.4. Photocatalytic Performance of Electrospun Nanofibres Membranes

3. Results and Discussion

3.1. PA6 and TiO2-Modified PA6 Electrospun Nanofibres Membranes Characterization

3.2. Evaluation of the Photocalytic Activity of the Membrane

4. Conclusions

Supplementary Materials

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Lee, S.-Y.; Park, S.-J. TiO2 photocatalyst for water treatment applications. J. Ind. Eng. Chem. 2013, 19, 1761–1769. [Google Scholar] [CrossRef]

- Korina, E.; Stoilova, O.; Manolova, N.; Rashkov, I. Polymer fibers with magnetic core decorated with titanium dioxide prospective for photocatalytic water treatment. J. Environ. Chem. Eng. 2018, 6, 2075–2084. [Google Scholar] [CrossRef]

- Ahmed, S.; Rasul, M.G.; Brown, R.; Hashib, M.A. Influence of parameters on the heterogeneous photocatalytic degradation of pesticides and phenolic contaminants in wastewater: A short review. J. Environ. Manag. 2011, 92, 311–330. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Elmolla, E.S.; Chaudhuri, M. Photocatalytic degradation of amoxicillin, ampicillin and cloxacillin antibiotics in aqueous solution using UV/TiO2 and UV/H2O2/TiO2 photocatalysis. Desalination 2010, 252, 46–52. [Google Scholar] [CrossRef]

- Hoffmann, M.R.; Martin, S.T.; Choi, W.; Bahnemann, D.W. Environmental applications of semiconductor photocatalysis. Chem. Rev. 1995, 95, 69–96. [Google Scholar] [CrossRef]

- Gar Alalm, M.; Tawfik, A.; Ookawara, S. Enhancement of photocatalytic activity of TiO2 by immobilization on activated carbon for degradation of pharmaceuticals. J. Environ. Chem. Eng. 2016, 4, 1929–1937. [Google Scholar] [CrossRef]

- Kwon, S.; Fan, M.; Cooper, A. Photocatalytic Applications of Micro- and Nano-TiO2 in Environmental Engineering. Crit. Rev. Environ. Sci. Technol. 2008, 38, 197–226. [Google Scholar] [CrossRef]

- Chong, M.N.; Jin, B.; Chow, C.W.K.; Saint, C. Recent developments in photocatalytic water treatment technology: A review. Water. Res. 2010, 44, 2997–3027. [Google Scholar] [CrossRef] [PubMed]

- Di Paola, A.; García-López, E.; Marcí, G.; Palmisano, L. A survey of photocatalytic materials for environmental remediation. J. Hazard Mater. 2012, 211–212, 3–29. [Google Scholar] [CrossRef] [PubMed]

- Van Gerven, T.; Mul, G.; Moulijn, J.; Stankiewicz, A. A review of intensification of photocatalytic processes. Chem. Eng. Process 2007, 46, 781–789. [Google Scholar] [CrossRef]

- Lu, X.; Jiang, J.; Sun, K.; Cui, D. Applied surface science characterization and photocatalytic activity of Zn2+/TiO2/AC composite photocatalyst. Appl. Surf. Sci. 2011, 258, 1656–1661. [Google Scholar] [CrossRef]

- Sampaio, M.J.; Silva, C.G.; Silva, A.M.T.; Vilar, V.J.P.; Boaventura, R.A.R.; Faria, J.L. Photocatalytic activity of TiO2-coated glass raschig rings on the degradation of phenolic derivatives under simulated solar light irradiation. Chem. Eng. J. 2013, 224, 32–38. [Google Scholar] [CrossRef]

- Yap, P.S.; Lim, T.T.; Srinivasan, M. Nitrogen-doped TiO2/AC bi-functional composite prepared by two-stage calcination for enhanced synergistic removal of hydrophobic pollutant using solar irradiation. Catal. Today 2011, 161, 46–52. [Google Scholar] [CrossRef]

- Hinojosa-Reyes, M.; Arriaga, S.; Diaz-Torres, L.A.; Rodríguez-González, V. Gasphase photocatalytic decomposition of ethylbenzene over perlite granules coated with indium doped TiO2. Chem. Eng. J. 2013, 224, 106–113. [Google Scholar] [CrossRef]

- Geltmeyer, J.; Teixido, H.; Meire, M.; Van Acker, T.; Deventer, K.; Vanhaecke, F.; Van Hulle, S.; De Buysser, K.; De Clerck, K. TiO2 functionalized nanofibrous membranes for removal of organic (micro)pollutants from water. Sep. Purif. Technol. 2017, 179, 533–541. [Google Scholar] [CrossRef]

- Mishra, A.; Mehta, A.; Basu, S. Clay supported TiO2 nanoparticles for photocatalytic degradation of environmental pollutants: A review. J. Environ. Chem. Eng. 2018, 6, 6088–6107. [Google Scholar] [CrossRef]

- Xue, H.; Jiang, Y.; Yuan, K.; Yang, T.; Hou, J.; Cao, C.; Feng, K.; Wang, X. Floating photocatalyst of B-N-TiO2/expanded perlite: A sol-gel synthesis with optimized mesoporous and high photocatalytic activity. Sci. Rep. 2016, 6, 29902–29910. [Google Scholar] [CrossRef]

- M’Bra, I.C.; García-Muñoz, P.; Drogui, P.; Keller, N.; Trokourey, A. Didier Robert. Heterogeneous photodegradation of Pyrimethanil and its commercial formulation with TiO2 immobilized on SiC foams. J. Photochem. Photobiol. A Chem. 2019, 368, 1–6. [Google Scholar]

- Agarwal, S.; Greiner, A.; Wendorff, J.H. Functional materials by electrospinning of polymers. Progr. Polym. Sci. 2013, 38, 963–991. [Google Scholar] [CrossRef]

- Wang, P.; Cheng, L.; Zhang, Y.; Wu, H.; Zheng, L. Flexible, hydrophobic SiC ceramic nanofibers used as high frequency electromagnetic wave absorbers. Ceram. Int. 2017, 43, 7424–7435. [Google Scholar] [CrossRef]

- Zahedi, P.; Rezaeian, I.; Ranaei-Siadat, S.O.; Jafari, S.H.; Supaphol, P. A review on wound dressings with an emphasis on electrospun nanofibrous polymeric bandages. Polym. Adv. Technol. 2010, 21, 77–95. [Google Scholar] [CrossRef]

- Pant, H.R.; Pant, B.; Pokharel, P.; Kim, H.J.; Tijing, L.D.; Park, C.H.; Lee, D.S.; Kim, H.Y.; Kim, C.S. Photocatalytic TiO2-RGO/nylon-6 spider-wave-like nano-nets via electrospinning and hydrothermal treatment. J. Membr. Sci. Technol. 2013, 429, 225–234. [Google Scholar] [CrossRef]

- Shalumon, K.; Anulekha, K.; Nair, S.V.; Nair, S.; Chennazhi, K.; Jayakumar, R. Sodium alginate/poly (vinyl alcohol)/nano ZnO composite nanofibers for antibacterial wound dressings. Int. J. Biol. Macromol. 2011, 49, 247–254. [Google Scholar] [CrossRef]

- Lee, K.; Lee, S. Multifunctionality of poly (vinyl alcohol) nanofiber webs containing titanium dioxide. J. Appl. Polym. Sci. 2012, 124, 4038–4046. [Google Scholar] [CrossRef]

- Quirós, J.; Boltes, K.; Aguado, S.; de Villoria, R.G.; Vilatela, J.J.; Rosal, R. Antimicrobial metal–organic frameworks incorporated into electrospun fibers. Chem. Eng. J. 2015, 262, 189–197. [Google Scholar] [CrossRef]

- Amna, T.; Hassan, M.S.; Barakat, N.A.; Pandeya, D.R.; Hong, S.T.; Khil, M.S.; Kim, H.Y. Antibacterial activity and interaction mechanism of electrospun zinc-doped titania nanofibers. World J. Microbiol. Biotechnol. 2012, 93, 743–751. [Google Scholar] [CrossRef]

- Kumar, S.; Lively, B.; Sun, L.L.; Li, B.; Zhong, W.H. Highly dispersed and electrically conductive polycarbonate/oxidized carbon nanofiber composites for electrostatic dissipation applications. Carbon 2010, 48, 3846–3857. [Google Scholar] [CrossRef]

- Monteserín, C.; Blanco, M.; Murillo, N.; Pérez-Márquez, A.; Maudes, J.; Gayoso, J.; Laza, J.M.; Aranzabe, E.; Vilas, J.L. Effect of Different Types of Electrospun Polyamide 6 Nanofibres on the Mechanical Properties of Carbon Fibre/Epoxy Composites. Polymers 2018, 10, 1190. [Google Scholar] [CrossRef] [PubMed]

- Cardoso, N.F.; Pinto, R.B.; Lima, E.C.; Calvete, T.; Amavisca, C.V.; Royer, B.; Cunha, M.L.; Fernandes, T.H.M.; Pinto, I.S. Removal of remazol black B textile dye from aqueous solution by adsorption. Desalination 2011, 269, 92–103. [Google Scholar] [CrossRef]

- Chen, C.Y.; Cheng, M.C.; Chen, A.H. Photocatalytic decolorization of Remazol Black 5 and Remazol Brilliant Orange 3R by mesoporous TiO2. J. Environ. Manag. 2012, 102, 125–133. [Google Scholar] [CrossRef]

- Helali, S.; Polo-López, M.; Fernández-Ibáñez, P.; Ohtani, B.; Amano, F.; Malato, S.; Guillard, C. Solar photocatalysis: A green technology for E. coli contaminated water disinfection. Effect of concentration and different types of suspended catalyst. J. Photochem. Photobiol. A 2013, 276, 31–40. [Google Scholar] [CrossRef]

- Rhee, S.; White, J.L. Crystalline structure and morphology of biaxially oriented polyamide-11 films. J. Polym. Sci. Part. B: Polym. Phys. 2002, 40, 2624–2640. [Google Scholar] [CrossRef]

- Lei, Y.; Zhang, C.; Lei, H.; Huo, H. Visible light photocatalytic activity of aromatic polyamide dendrimer/TiO2 composites functionalized with spirolactam-based molecular switch. J. Colloid Interface Sci. 2013, 406, 178–185. [Google Scholar] [CrossRef] [PubMed]

- Mansourpanah, Y.; Madaeni, S.S.; Rahimpour, A.; Farhadian, A.; Taheri, A.H. Formation of appropriate sites on nanofiltration membrane surface for binding TiO2 photo-catalyst: Performance, characterization and fouling-resistant capability. J. Memb. Sci. 2009, 330, 297–306. [Google Scholar] [CrossRef]

| Sample | Average Diameter (nm) | Areal Weight (g/m2) |

|---|---|---|

| PA6 | 60–100 | 1.94 |

| PA6/25 wt.% TiO2 | 110–260 | 4.30 |

| Incubation Time (h) | PA6 Electrospun Nanofibre Membranes | PA6 Electrospun Nanofibre Membranes | PA6/25 wt.% TiO2 Electrospun Nanofibre Membranes | PA6/25 wt.% TiO2 Electrospun Nanofibre Membranes |

|---|---|---|---|---|

| Without UV | With UV | Without UV | With UV | |

| 24 |  |  |  |  |

| 96 |  |  |  |  |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Blanco, M.; Monteserín, C.; Angulo, A.; Pérez-Márquez, A.; Maudes, J.; Murillo, N.; Aranzabe, E.; Ruiz-Rubio, L.; Vilas, J.L. TiO2-Doped Electrospun Nanofibrous Membrane for Photocatalytic Water Treatment. Polymers 2019, 11, 747. https://doi.org/10.3390/polym11050747

Blanco M, Monteserín C, Angulo A, Pérez-Márquez A, Maudes J, Murillo N, Aranzabe E, Ruiz-Rubio L, Vilas JL. TiO2-Doped Electrospun Nanofibrous Membrane for Photocatalytic Water Treatment. Polymers. 2019; 11(5):747. https://doi.org/10.3390/polym11050747

Chicago/Turabian StyleBlanco, Miren, Cristina Monteserín, Adrián Angulo, Ana Pérez-Márquez, Jon Maudes, Nieves Murillo, Estíbaliz Aranzabe, Leire Ruiz-Rubio, and Jose Luis Vilas. 2019. "TiO2-Doped Electrospun Nanofibrous Membrane for Photocatalytic Water Treatment" Polymers 11, no. 5: 747. https://doi.org/10.3390/polym11050747