Long-Term Evaluation of Dip-Coated PCL-Blend-PEG Coatings in Simulated Conditions

Abstract

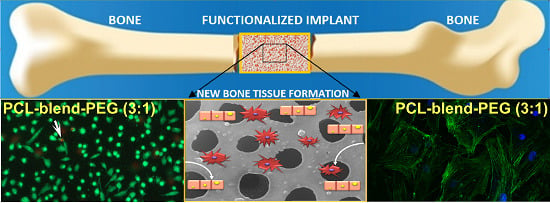

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Dip-Coating (DC) Deposition of PCL-Blend-PEG Coatings

2.3. Physico-Chemical Characterization of PCL-Blend-PEG Coatings

2.4. Surface Morphology of PCL-Blend-PEG Coatings

2.5. Electrochemical Behavior of PCL-Blend-PEG Coatings

2.6. Degradation Behavior of PCL-Blend-PEG Coatings

2.7. In Vitro Assays of PCL-Blend-PEG Coatings

3. Results

3.1. FTIR Investigations

3.2. GIXRD Investigations

3.3. Coatings Wettability

3.4. Coating Degradation Behavior

3.5. Biocompatibility of PCL-Blend-PEG Coatings

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Paul, F.M.; John, G.L.; Luke, M.G.; Clement, L.H. In vitro degradation and drug release from polymer blends based on poly(DL-lactide), poly(L-lactide-glycolide) and poly(ε-caprolactone). J. Mater. Sci. 2010, 45, 1284–1292. [Google Scholar]

- Dikmen, G.; Genç, L.; Güney, G. Advantage and disadvantage in drug delivery systems. J. Mater. Sci. Eng. 2011, 5, 468. [Google Scholar]

- Ummadi, S.; Shravani, B.; Rao, N.R.; Reddy, M.S.; Sanjeev, B. Overview on controlled release dosage form. System 2013, 7, 51–60. [Google Scholar]

- Hoque, M.E.; Hutmacher, D.W.; Feng, W.; Li, S.; Huang, M.-H.; Vert, M.; Wong, Y.S. Fabrication using a rapid prototyping system and in vitro characterization of PEG-PCL-PLA scaffolds for tissue engineering. J. Biomater. Sci. Polym. Ed. 2005, 16, 1595–1610. [Google Scholar] [CrossRef] [PubMed]

- Tang, X.; Yan, X. Dip-coating for fibrous materials: Mechanism, methods and applications. J. Sol-Gel Sci. Technol. 2017, 81, 378–404. [Google Scholar] [CrossRef]

- Soares, C.G.; Caseli, L.; Bertuzzi, D.L.; Santos, F.S.; Garcia, J.R.; Péres, L.O. Ultrathin films of poly (2, 5-dicyano-p-phenylene-vinylene)-co-(p-phenylene-vinylene) DCN-PPV/PPV: A Langmuir and Langmuir-Blodgett films study. Colloids Surf. A Physicochem. Eng. Asp. 2015, 467, 201–206. [Google Scholar] [CrossRef]

- Scriven, L.E. Physics and applications of dip coating and spin coating. MRS Online Proc. Libr. Arch. 1988, 121, 717. [Google Scholar] [CrossRef]

- Armentano, I.; Dottori, M.; Fortunati, E.; Mattioli, S.; Kenny, J.M. Biodegradable polymer matrix nanocomposites for tissue engineering: A review. Polym. Degrad. Stab. 2010, 95, 2126–2146. [Google Scholar] [CrossRef]

- Wei, X.; Gong, C.; Gou, M.; Fu, S.; Guo, Q.; Shi, S.; Luo, F.; Guo, G.; Qiu, L.; Qian, Z. Biodegradable poly (ɛ-caprolactone)–poly (ethylene glycol) copolymers as drug delivery system. Int. J. Pharm. 2009, 381, 1–18. [Google Scholar] [CrossRef]

- Kassab, R.; Moussa, D.; Yammine, P. POLYCAPROLACTONE AS DRUG CARRIER FOR AN ANTIFUNGAL AGENT. J. Drug Deliv. Ther. 2018, 8, 81–85. [Google Scholar] [CrossRef]

- Aishwarya, S.; Mahalakshmi, S.; Sehgal, P.K. Collagen-coated polycaprolactone microparticles as a controlled drug delivery system. J. Microencapsul. 2008, 25, 298–306. [Google Scholar] [CrossRef] [PubMed]

- Badri, W.; Miladi, K.; Robin, S.; Viennet, C.; Nazari, Q.A.; Agusti, G.; Fessi, H.; Elaissari, A. Polycaprolactone Based Nanoparticles Loaded with Indomethacin for Anti-Inflammatory Therapy: From Preparation to Ex Vivo Study. Pharm. Res. 2017, 34, 1773–1783. [Google Scholar] [CrossRef] [PubMed]

- Carreras, N.; Acuña, V.; Martí, M.; Lis, M.J. Drug release system of ibuprofen in PCL-microspheres. Colloid Polym. Sci. 2013, 291, 157–165. [Google Scholar] [CrossRef]

- Visan, A.; Cristescu, R.; Stefan, N.; Miroiu, M.; Nita, C.; Socol, M.; Florica, C.; Rasoga, O.; Zgura, I.; Sima, L.E. Antimicrobial polycaprolactone/polyethylene glycol embedded lysozyme coatings of Ti implants for osteoblast functional properties in tissue engineering. Appl. Surf. Sci. 2017, 417, 234–243. [Google Scholar] [CrossRef]

- Patrício, T.; Domingos, M.; Gloria, A.; Bártolo, P. Characterisation of PCL and PCL/PLA scaffolds for tissue engineering. Procedia Cirp 2013, 5, 110–114. [Google Scholar] [CrossRef]

- Woodruff, M.A.; Hutmacher, D.W. The return of a forgotten polymer—Polycaprolactone in the 21st century. Prog. Polym. Sci. 2010, 35, 1217–1256. [Google Scholar] [CrossRef] [Green Version]

- Merkli, A.; Tabatabay, C.; Gurny, R.; Heller, J. Biodegradable polymers for the controlled release of ocular drugs. Prog. Polym. Sci. 1998, 23, 563–580. [Google Scholar] [CrossRef]

- Freiberg, S.; Zhu, X.X. Polymer microspheres for controlled drug release. Int. J. Pharm. 2004, 282, 1–18. [Google Scholar] [CrossRef]

- Sinha, V.R.; Bansal, K.; Kaushik, R.; Kumria, R.; Trehan, A. Poly-ϵ-caprolactone microspheres and nanospheres: An overview. Int. J. Pharm. 2004, 278, 1–23. [Google Scholar] [CrossRef]

- Jia, W.J.; Gu, Y.C.; Gou, M.L.; Dai, M.; Li, X.Y.; Kan, B.; Yang, J.L.; Song, Q.F.; Wei, Y.Q.; Qian, Z.Y. Preparation of biodegradable polycaprolactone/poly (ethylene glycol)/polycaprolactone (PCEC) nanoparticles. Drug Deliv. 2008, 15, 409–416. [Google Scholar] [CrossRef]

- Jiang, X.; Li, J.; Ding, M.; Tan, H.; Ling, Q.; Zhong, Y.; Fu, Q. Synthesis and degradation of nontoxic biodegradable waterborne polyurethanes elastomer with poly (ε-caprolactone) and poly (ethylene glycol) as soft segment. Eur. Polym. J. 2007, 43, 1838–1846. [Google Scholar] [CrossRef]

- Jiang, H.; Hu, Y.; Li, Y.; Zhao, P.; Zhu, K.; Chen, W. A facile technique to prepare biodegradable coaxial electrospun nanofibers for controlled release of bioactive agents. J. Control. Release 2005, 108, 237–243. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Wang, C.; Wang, Y.; Luo, F.; Yan, X.; Qian, Z. Micelles of methoxy poly (ethylene glycol)–poly (ε-caprolactone) as a novel drug delivery vehicle for tacrolimus. J. Biomed. Nanotechnol. 2013, 9, 147–157. [Google Scholar] [CrossRef] [PubMed]

- Olivier, J.-C. Drug transport to brain with targeted nanoparticles. NeuroRx 2005, 2, 108–119. [Google Scholar] [CrossRef]

- Paun, I.A.; Ion, V.; Luculescu, C.-R.; Dinescu, M.; Canulescu, S.; Schou, J. In vitro studies of PEG thin films with different molecular weights deposited by MAPLE. Appl. Phys. A 2012, 109, 223–232. [Google Scholar] [CrossRef]

- Hu, Y.; Zhang, L.; Cao, Y.; Ge, H.; Jiang, X.; Yang, C. Degradation behavior of poly (ε-caprolactone)-b-poly (ethylene glycol)-b-poly (ε-caprolactone) micelles in aqueous solution. Biomacromolecules 2004, 5, 1756–1762. [Google Scholar] [CrossRef]

- Peng, H.; Ling, J.; Liu, J.; Zhu, N.; Ni, X.; Shen, Z. Controlled enzymatic degradation of poly (ɛ-caprolactone)-based copolymers in the presence of porcine pancreatic lipase. Polym. Degrad. Stab. 2010, 95, 643–650. [Google Scholar] [CrossRef]

- Ahmed, F.; Discher, D.E. Self-porating polymersomes of PEG–PLA and PEG–PCL: Hydrolysis-triggered controlled release vesicles. J. Control. Release 2004, 96, 37–53. [Google Scholar] [CrossRef]

- Díaz, E.; Sandonis, I.; Valle, M.B. In vitro degradation of poly (caprolactone)/nHA composites. J. Nanomater. 2014, 2014, 185. [Google Scholar] [CrossRef]

- Nawaz, A.; Hasan, F.; Shah, A.A. Degradation of poly (ε-caprolactone)(PCL) by a newly isolated Brevundimonas sp. strain MRL-AN1 from soil. FEMS Microbiol. Lett. 2015, 362, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Li, S.; Chen, X.; Gross, R.; McCarthy, S. Hydrolytic degradation of PCL/PEO copolymers in alkaline media. J. Mater. Sci. Mater. Med. 2000, 11, 227–233. [Google Scholar] [CrossRef]

- Puetz, J.; Aegerter, M.A. Dip coating Technique. In Sol-Gel Technologies for Glass Producers and Users; Springer: Berlin, Germany, 2004; pp. 37–48. [Google Scholar]

- Preda, N.; Enculescu, M.; Zgura, I.; Socol, M.; Matei, E.; Vasilache, V.; Enculescu, I. Superhydrophobic properties of cotton fabrics functionalized with ZnO by electroless deposition. Mater. Chem. Phys. 2013, 138, 253–261. [Google Scholar] [CrossRef]

- Kokubo, T. Bioactive glass ceramics: Properties and applications. Biomaterials 1991, 12, 155–163. [Google Scholar] [CrossRef]

- Miroiu, F.M.; Stefan, N.; Visan, A.I.; Nita, C.; Luculescu, C.R.; Rasoga, O.; Socol, M.; Zgura, I.; Cristescu, R.; Craciun, D. Composite biodegradable biopolymer coatings of silk fibroin–Poly (3-hydroxybutyric-acid-co-3-hydroxyvaleric-acid) for biomedical applications. Appl. Surf. Sci. 2015, 355, 1123–1131. [Google Scholar] [CrossRef]

- Wootton, R.; Reeve, J.; Veall, N. The clinical measurement of skeletal blood flow. Clin. Sci. 1976, 50, 261–268. [Google Scholar] [CrossRef] [PubMed]

- Sima, L.E.; Stan, G.E.; Morosanu, C.O.; Melinescu, A.; Ianculescu, A.; Melinte, R.; Neamtu, J.; Petrescu, S.M. Differentiation of mesenchymal stem cells onto highly adherent radio frequency-sputtered carbonated hydroxylapatite thin films. J. Biomed. Mater. Res. Part A 2010, 95, 1203–1214. [Google Scholar] [CrossRef]

- Edgell, C.-J.; McDonald, C.C.; Graham, J.B. Permanent cell line expressing human factor VIII-related antigen established by hybridization. Proc. Natl. Acad. Sci. USA 1983, 80, 3734–3737. [Google Scholar] [CrossRef] [Green Version]

- Rusen, L.; Mustaciosu, C.; Mitu, B.; Filipescu, M.; Dinescu, M.; Dinca, V. Protein-resistant polymer coatings obtained by matrix assisted pulsed laser evaporation. Appl. Surf. Sci. 2013, 278, 198–202. [Google Scholar] [CrossRef]

- Rusen, L.; Neacsu, P.; Cimpean, A.; Valentin, I.; Brajnicov, S.; Dumitrescu, L.N.; Banita, J.; Dinca, V.; Dinescu, M. In vitro evaluation of poly (ethylene glycol)-block-poly (ɛ-caprolactone) methyl ether copolymer coating effects on cells adhesion and proliferation. Appl. Surf. Sci. 2016, 374, 23–30. [Google Scholar] [CrossRef]

- Wang, W.; Yang, X.; Fang, Y.; Ding, J. Preparation and performance of form-stable polyethylene glycol/silicon dioxide composites as solid–liquid phase change materials. Appl. Energy 2009, 86, 170–174. [Google Scholar] [CrossRef]

- Zehnder, T.; Freund, T.; Demir, M.; Detsch, R.; Boccaccini, A.R. Fabrication of cell-loaded two-phase 3D constructs for tissue engineering. Materials 2016, 9, 887. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kweon, H.; Yoo, M.K.; Park, I.K.; Kim, T.H.; Lee, H.C.; Lee, H.-S.; Oh, J.-S.; Akaike, T.; Cho, C.-S. A novel degradable polycaprolactone networks for tissue engineering. Biomaterials 2003, 24, 801–808. [Google Scholar] [CrossRef]

- Chen, E.-C.; Wu, T.-M. Isothermal crystallization kinetics and thermal behavior of poly (ɛ-caprolactone)/multi-walled carbon nanotube composites. Polym. Degrad. Stab. 2007, 92, 1009–1015. [Google Scholar] [CrossRef]

- Fu, S.Z.; Wang, X.H.; Guo, G.; Shi, S.; Fan, M.; Liang, H.; Luo, F.; Qian, Z.Y. Preparation and properties of nano-hydroxyapatite/PCL-PEG-PCL composite membranes for tissue engineering applications. J. Biomed. Mater. Res. Part B Appl. Biomater. 2011, 97, 74–83. [Google Scholar] [CrossRef] [PubMed]

- Kasalkova, N.S.; Slepicka, P.; Kolska, Z.; Svorcik, V. Wettability and Other Surface Properties of Modified Polymers. Wetting Wettability 2015, 323–356. [Google Scholar] [CrossRef] [Green Version]

- Martinez-Diaz, S.; Garcia-Giralt, N.; Lebourg, M.; Gómez-Tejedor, J.-A.; Vila, G.; Caceres, E.; Benito, P.; Monleón Pradas, M.; Nogues, X.; Gomez Ribelles, J.L. In vivo evaluation of 3-dimensional polycaprolactone scaffolds for cartilage repair in rabbits. Am. J. Sports Med. 2010, 38, 509–519. [Google Scholar] [CrossRef]

- Schilp, S.; Kueller, A.; Rosenhahn, A.; Grunze, M.; Pettitt, M.E.; Callow, M.E.; Callow, J.A. Settlement and adhesion of algal cells to hexa (ethylene glycol)-containing self-assembled monolayers with systematically changed wetting properties. Biointerphases 2007, 2, 143–150. [Google Scholar] [CrossRef]

- Wei, Q.; Becherer, T.; Angioletti-Uberti, S.; Dzubiella, J.; Wischke, C.; Neffe, A.T.; Lendlein, A.; Ballauff, M.; Haag, R. Protein interactions with polymer coatings and biomaterials. Angew. Chem. Int. Ed. 2014, 53, 8004–8031. [Google Scholar] [CrossRef]

- Engineer, C.; Parikh, J.; Raval, A. Review on Hydrolytic Degradation Behavior of Biodegradable Polymers from Controlled Drug Delivery System. Trends Biomater. Artif. Organs 2011, 25, 79–85. [Google Scholar]

- Huang, M.-H.; Li, S.; Hutmacher, D.W.; Schantz, J.-T.; Vacanti, C.A.; Braud, C.; Vert, M. Degradation and cell culture studies on block copolymers prepared by ring opening polymerization of ϵ-caprolactone in the presence of poly (ethylene glycol). J. Biomed. Mater. Res. Part A Off. J. Soc. Biomater. Jpn. Soc. Biomater. Aust. Soc. Biomater. Korean Soc. Biomater. 2004, 69, 417–427. [Google Scholar]

- Göpferich, A. Mechanisms of polymer degradation and erosion. Biomaterials 1996, 17, 103–114. [Google Scholar] [CrossRef]

- Men, K.; Zeng, S.; Gou, M.; Guo, G.; Gu, Y.C.; Luo, F.; Zhao, X.; Wei, Y.; Qian, Z. Preparation of Magnetic Microspheres Based on Poly (ε-Caprolactone)-Poly (Ethylene Glycol) Poly (ε-Caprolactone) Copolymers by Modified Solvent Diffusion Method. J. Biomed. Nanotechnol. 2010, 6, 287–292. [Google Scholar] [CrossRef] [PubMed]

- Ryu, J.-G.; Jeong, Y.-I.; Kim, I.-S.; Lee, J.-H.; Nah, J.-W.; Kim, S.-H. Clonazepam release from core-shell type nanoparticles of poly (ε-caprolactone)/poly (ethylene glycol)/poly (ε-caprolactone) triblock copolymers. Int. J. Pharm. 2000, 200, 231–242. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhuo, R.-x. Synthesis and in vitro drug release behavior of amphiphilic triblock copolymer nanoparticles based on poly (ethylene glycol) and polycaprolactone. Biomaterials 2005, 26, 6736–6742. [Google Scholar] [CrossRef] [PubMed]

- Tamada, J.A.; Langer, R. Erosion kinetics of hydrolytically degradable polymers. Proc. Natl. Acad. Sci. USA 1993, 90, 552–556. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shen-Guo, W.; Bo, Q. Polycaprolactone–poly (ethylene glycol) block copolymer, I: Synthesis and degradability in vitro. Polym. Adv. Technol. 1993, 4, 363–366. [Google Scholar] [CrossRef]

- Bei, J.-Z.; Li, J.-M.; Wang, Z.-F.; Le, J.-C.; Wang, S.-G. Polycaprolactone–poly (ethylene-glycol) block copolymer. IV: Biodegradation behavior in vitro and in vivo. Polym. Adv. Technol. 1997, 8, 693–696. [Google Scholar] [CrossRef]

- Bossard, C.; Granel, H.; Wittrant, Y.; Jallot, É.; Lao, J.; Vial, C.; Tiainen, H. Polycaprolactone/bioactive glass hybrid scaffolds for bone regeneration. Biomed. Glasses 2018, 4, 108–122. [Google Scholar] [CrossRef]

- Chen, C.-H.; Shyu, V.B.-H.; Chen, J.-P.; Lee, M.-Y. Selective laser sintered poly-ε-caprolactone scaffold hybridized with collagen hydrogel for cartilage tissue engineering. Biofabrication 2014, 6, 015004. [Google Scholar] [CrossRef]

- Elsener, B.; Rota, A.; Böhni, H. Impedance study on the corrosion of PVD and CVD titanium nitride coatings. In Materials Science Forum; Trans Tech Publications Ltd.: Zurich, Switzerland, 1989. [Google Scholar]

- Stern, M.; Geary, A.L. Electrochemical polarization I. A theoretical analysis of the shape of polarization curves. J. Electrochem. Soc. 1957, 104, 56–63. [Google Scholar] [CrossRef]

- Hatamzadeh, M.; Najafi-Moghadam, P.; Beygi-Khosrowshahi, Y.; Massoumi, B.; Jaymand, M. Electrically conductive nanofibrous scaffolds based on poly (ethylene glycol) s-modified polyaniline and poly (ε-caprolactone) for tissue engineering applications. RSC Adv. 2016, 6, 105371–105386. [Google Scholar] [CrossRef]

- Yusoff, M.F.M.; Kadir, M.R.A.; Iqbal, N.; Hassan, M.A.; Hussain, R. Dipcoating of poly (ε-caprolactone)/hydroxyapatite composite coating on Ti6Al4V for enhanced corrosion protection. Surf. Coat. Technol. 2014, 245, 102–107. [Google Scholar] [CrossRef]

- Grellier, M.; Bordenave, L.; Amedee, J. Cell-to-cell communication between osteogenic and endothelial lineages: Implications for tissue engineering. Trends Biotechnol. 2009, 27, 562–571. [Google Scholar] [CrossRef] [PubMed]

- Krenning, G.; van Luyn, M.J.; Harmsen, M.C. Endothelial progenitor cell-based neovascularization: Implications for therapy. Trends Mol. Med. 2009, 15, 180–189. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Mao, K.; Cai, X.; Lai, S.; Chen, X. Poly (ethyl glycol) assisting water sorption enhancement of poly (ε-caprolactone) blend for drug delivery. J. Appl. Polym. Sci. 2011, 122, 2309–2316. [Google Scholar] [CrossRef]

- Luo, C.; Chen, W.; Gao, Y. Fractional crystallization behavior of PCL and PEG in blends. Polym. Sci. Ser. A 2016, 58, 196–205. [Google Scholar] [CrossRef]

- Nguyen Tri, P.; Prud’homme, R.E. Crystallization and segregation behavior at the submicrometer scale of PCL/PEG blends. Macromolecules 2018, 51, 7266–7273. [Google Scholar] [CrossRef]

- Lam, C.X.; Savalani, M.M.; Teoh, S.-H.; Hutmacher, D.W. Dynamics of in vitro polymer degradation of polycaprolactone-based scaffolds: Accelerated versus simulated physiological conditions. Biomed. Mater. 2008, 3, 034108. [Google Scholar] [CrossRef]

- Loh, X.J. The effect of pH on the hydrolytic degradation of poly (ε-caprolactone)-block-poly (ethylene glycol) copolymers. J. Appl. Polym. Sci. 2013, 127, 2046–2056. [Google Scholar] [CrossRef]

- Pitt, C.G. Poly-ε-caprolactone and its copolymers. Drugs Pharm. Sci. 1990, 45, 71–193. [Google Scholar]

- Bölgen, N.; Menceloğlu, Y.Z.; Acatay, K.; Vargel, I.; Pişkin, E. In vitro and in vivo degradation of non-woven materials made of poly(ε-caprolactone) nanofibers prepared by electrospinning under different conditions. J. Biomater. Sci. Polym. Ed. 2005, 16, 1537–1555. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Grossen, P.; Witzigmann, D.; Sieber, S.; Huwyler, J. PEG-PCL-based nanomedicines: A biodegradable drug delivery system and its application. J. Control. Release 2017, 260, 46–60. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.-Z.; You, M.-L.; Ding, Z.-Q.; Ye, W.-B. A review of emerging bone tissue engineering via PEG conjugated biodegradable amphiphilic copolymers. Mater. Sci. Eng. C 2019, 97, 1021–1035. [Google Scholar] [CrossRef] [PubMed]

- Harvestine, J.; Gonzalez-Fernandez, T.; Sebastian, A.; Hum, N.; Genetos, D.; Loots, G.; Leach, J. Osteogenic preconditioning in perfusion bioreactors improves vascularization and bone formation by human bone marrow aspirates. Sci. Adv. 2020, 6, 2387. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Sample | PEG | PCL-Blend-PEG (1:3) | PCL-Blend-PEG (3:1) | PCL | Bare Titanium |

|---|---|---|---|---|---|

| Average CA values ± SD [degree] | 28.3 ± 3.2 | 36.2 ± 0.9 | 62.1 ± 1.6 | 74.6 ± 4.3 | 117.1 ± 1.5 |

| Sample | Ecorr (mV) | icorr (nA/cm2) | Rp (ohm × cm2) | Pe (%) | P (%) |

|---|---|---|---|---|---|

| Ti | −358 ± 8.04 | 87.25 ± 1.09 | 425.43 ± 11.68 | NA | NA |

| PCL | −292 ± 4.92 | 41.06 ± 1.38 | 1169.85 ± 66.12 | 54.28 ± 1.75 | 30.33 ± 1.27 |

| PEG | −317 ± 9.42 | 83.18 ± 1.81 | 552.72 ± 14.74 | 7.10 ± 1.05 | 72.95 ± 1.98 |

| PCL-blend-PEG (1:3) | −356 ± 9.27 | 72.26 ± 1.05 | 486.02 ± 10.40 | 18.69 ± 0.94 | 82.35 ± 2.24 |

| PCL-blend-PEG (3:1) | −307 ± 3.56 | 60.32 ± 1.27 | 620.50 ± 18.30 | 32.31 ± 1.45 | 60.85 ± 1.47 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Visan, A.I.; Popescu-Pelin, G.; Gherasim, O.; Mihailescu, A.; Socol, M.; Zgura, I.; Chiritoiu, M.; Elena Sima, L.; Antohe, F.; Ivan, L.; et al. Long-Term Evaluation of Dip-Coated PCL-Blend-PEG Coatings in Simulated Conditions. Polymers 2020, 12, 717. https://doi.org/10.3390/polym12030717

Visan AI, Popescu-Pelin G, Gherasim O, Mihailescu A, Socol M, Zgura I, Chiritoiu M, Elena Sima L, Antohe F, Ivan L, et al. Long-Term Evaluation of Dip-Coated PCL-Blend-PEG Coatings in Simulated Conditions. Polymers. 2020; 12(3):717. https://doi.org/10.3390/polym12030717

Chicago/Turabian StyleVisan, Anita Ioana, Gianina Popescu-Pelin, Oana Gherasim, Andreea Mihailescu, Marcela Socol, Irina Zgura, Mari Chiritoiu, Livia Elena Sima, Felicia Antohe, Luminita Ivan, and et al. 2020. "Long-Term Evaluation of Dip-Coated PCL-Blend-PEG Coatings in Simulated Conditions" Polymers 12, no. 3: 717. https://doi.org/10.3390/polym12030717