Abstract

We investigated the effects of a 1,2-dimyristoyl-sn-glycerol-3-phosphocholine (DMPC) molecular film surrounding microbubbles on their collapse under ultrasound irradiation. We defined the ejection of the internal gas from the microbubble (i.e. "daughter" bubbles) as bubble collapse. In particular, we measured the sound-pressure thresholds for microbubble collapse in water and a DMPC solution. Bubbles with the DMPC film had a smaller resonance size than naked bubbles. The measured contact angles of the bubbles were lower after collapse, implying that DMPC molecules on the bubble surface partially desorbed between the processes of vibration and collapse.

Export citation and abstract BibTeX RIS

Microbubbles have applications in medical diagnosis, such as contrast agents for ultrasound imaging, 1,2) and in therapeutic ultrasound techniques. In vascular drug therapies, side effects on healthy tissue need to be minimized. Drug-delivery systems are a potential candidate for localizing drug release to address this problem. In drug-delivery systems that use ultrasound, drug- or gene-containing microbubbles with a diameter of several micrometers are injected into blood vessels and transported through the blood flow. 3–6) Ultrasound excitation can trigger the bubbles to vibrate and collapse to release the drug locally.

Typical contrast agents used in medical ultrasound imaging are coated with phospholipids or proteins. They are also filled with a perfluorocarbon gas that is poorly soluble in water to prolong their lifetime in blood vessels. 7–9) Understanding the behavior of microbubbles under ultrasound irradiation is important for medical ultrasound imaging techniques because the molecular film surrounding the gas core of the bubble affects bubble vibration and the scattered sound signal. Accordingly, this behavior has been investigated experimentally 10–12) and theoretically. 13,14) Similarly, for ultrasound-assisted drug-delivery systems that are based on ultrasound contrast agents, the molecular film plays an important role in drug release.

When a micrometer-sized bubble is subjected to a low-amplitude acoustic pressure field (under approximately 1 kPa for megahertz-range ultrasound), it vibrates spherically (i.e. with expansion and contraction cycles that are synchronized with the pressure change). As the sound pressure increases, non-spherical vibration modes appear, with surface waves propagating on the bubble surface. 15–22) The vibration mode of microbubbles mainly depends on the relationship between the sound pressure, driving frequency, and bubble size. Further increase in the sound pressure above a threshold induces the collapse of the microbubble with a microjet of the surrounding liquid penetrating the molecular film because the bubble cannot maintain its shape during the violent collapse.

In ultrasound-assisted drug-delivery systems, local drug release can be achieved by exploiting the collapse of microbubbles adsorbed on the target tissues. More specifically, the jet flow generated by bubble collapse can penetrate the cell membrane and release the drug inside the cell through small pores (i.e. "sonoporation"). 23,24) For the safe administration of drugs via ultrasound-assisted drug release, the behavior of the molecular film surrounding the microbubble and the process that occurs between the microbubble vibration and collapse under ultrasound irradiation should be clarified to control the drug administration.

In our previous work, 25) we observed the vibration and collapse of microbubbles with a phospholipid shell optically and investigated the sound-pressure threshold for collapse. However, the effect of the molecular film on the resonance condition of bubbles and the sound-pressure threshold have not yet been clarified. In addition, to the best of our knowledge, changes in the formation of the molecular film on the bubble surface have not been evaluated previously. In this Brief Note, we report on the effects of the molecular film on the sound-pressure threshold for microbubble collapse and the resonance condition under ultrasound irradiation.

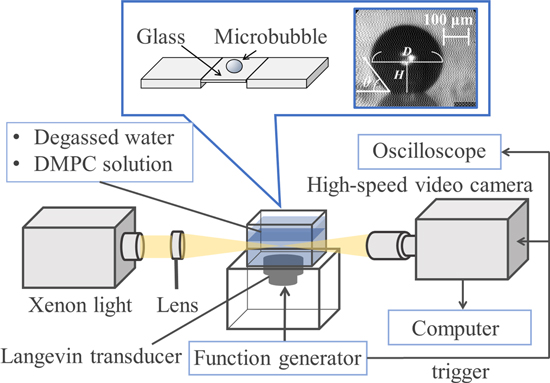

The surface tension on the bubble wall depends on the adsorption of the surfactant molecules. 26) In this study, the contact angle, θ, between the bubble and a solid surface was measured to investigate the effects of bubble collapse on adsorption and to estimate the formation of the molecular film (Fig. 1). θ is defined as:

where H is the distance from the center of the microbubble to the solid (i.e. glass) surface and D is the horizontal diameter of the microbubble. Adsorption of surfactant molecules at the gas/liquid interface decreases the surface tension of the bubble, resulting in a decrease of θ.

Fig. 1. (Color online) Observational system for measuring the contact angle and collapse of a microbubble under ultrasound irradiation.

Download figure:

Standard image High-resolution imageThe surfactant used was the phospholipid 1,2-dimyristoyl-sn-glycerol-3-phosphocholine (DMPC; NOF Corporation). Fluorocarbon-enriched (C4F8 8% and N2 92%) was used as the internal gas, and bubbles with a radius of 77–234 μm were fabricated using an injector with a microneedle. The vibration and collapse of the microbubbles under ultrasound irradiation were observed using the optical system shown in Fig. 1. The microbubbles were attached to a 1.2 mm thick glass plate and immersed in a rectangular glass observational cell filled with 0.3 mM DMPC solution, resulting in the adsorption of the DMPC molecules at the gas/liquid interface (i.e. the bubble surface) in the solution. The microbubbles were exposed to 15-cycle pulsed ultrasonic waves at 38.8 kHz, which were generated by a Langevin transducer attached to the bottom of the cell. Considering the time constant of the adsorption of DMPC molecules to the bubble surface, 27) the electrical signal was input to the transducer 1000 s after the fabrication of the bubbles. Continuous light from a xenon light source was focused on the position where the microbubbles were attached, and the vibration and collapse of the microbubbles were observed using a high-speed camera (Shimadzu, HPV-1; recording speed: 63 kfps). For comparison, the same procedure was conducted using perfluorocarbon gas microbubbles that were fabricated in degassed water. We define the ejection of the internal gas from the microbubble (i.e. "daughter" bubbles) as bubble collapse. The sound pressure was measured using a calibrated needle hydrophone. All experiments were conducted at room temperature (22 °C).

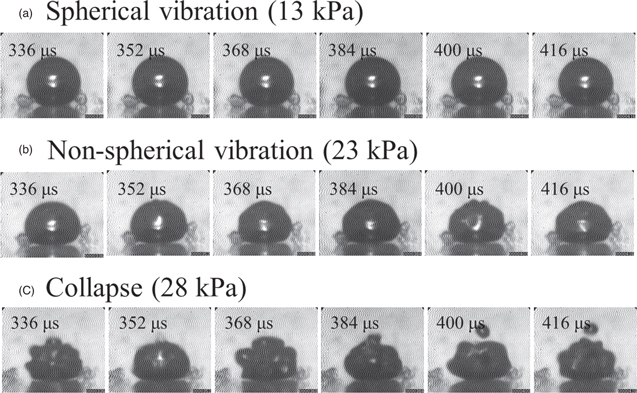

Figure 2 shows representative sequential photographs of the vibration and collapse of the microbubble with a monomolecular DMPC film when the sound pressure was gradually increased (photographs were taken every 16 μs, with one ultrasound cycle being 26 μs). Although several microbubbles were attached to the glass plate, the distance between them was sufficiently large. Regardless of the bubble size, the contact angle of the bubbles on the glass plate before ultrasound irradiation was 34.5° ± 2.3° in the 0.3 mM DMPC solution, which corresponded with the measured value in our previous work (32.6° ± 0.5°). 27) In Fig. 2, the initial bubble radius in the horizontal direction was 142 μm. When the bubble was exposed to a low sound pressure [13 kPa in Fig. 2(a), see supplementary data], it maintained its spherical shape and the low-resonance vibration mode appeared on the bubble (strictly, a viscous boundary layer on the glass surface distorts the spherical vibration). When the sound pressure was increased to 23 kPa, the vibrational displacement on the bubble increased and the bubble began to assume a non-spherical harmonic vibration mode with surface waves propagating on the bubble surface [Fig. 2(b), see supplementary data]. Further increase in the sound pressure to a threshold of 28 kPa induced the higher non-spherical vibration mode and bubble collapse with the ejection of a daughter bubble [Fig. 2(c), see supplementary data].

Fig. 2. Non-spherical vibration and collapse of a bubble with an initial radius of 142 μm under ultrasound irradiation of (a) 13, (b) 23 and (c) 28 kPa.

Download figure:

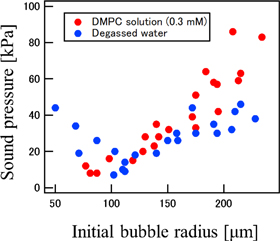

Standard image High-resolution imageThe same procedure was conducted for 22 and 23 microbubbles with different radii in water and the DMPC solution, respectively. Figure 3 shows the relationships between the initial bubble radius and the sound-pressure thresholds for bubble collapse in the two liquids. According to general bubble dynamics, microbubbles with the resonance radius should have the smallest sound-pressure threshold for collapse because a greater vibrational displacement under the resonance condition induces bubble collapse. 15) The results in Fig. 3 indicate that the resonance bubble radius in the DMPC solution was smaller than that in water: 81 and 102 μm in the DMPC and water, respectively. This is because the surface tension of microbubbles was decreased by the DMPC shell, resulting in a decrease in the elasticity of the bubble. We observed the same trend in our previous study. 28) Several researchers have noted that the resonance frequency of microbubbles with a lipid shell is higher than that of a naked bubble owing to the viscoelasticity of the shell. 10,29) Therefore, the results shown in Fig. 3 imply that the DMPC shell increases the additional mass for the bubble vibration, but does not increase the elasticity for microbubbles with radii of tens of micrometers. The vibration modes of the microbubbles became more complex and shifted to higher modes as the bubble size increased. This tendency was enhanced in the DMPC solution because of the lower surface tension. We note that there was no significant difference in the sound-pressure threshold for bubble collapse under each resonant condition (i.e. 7 and 8 kPa in water and the DMPC solution, respectively).

Fig. 3. (Color online) Relationship between the initial bubble radius and the sound-pressure threshold for bubble collapse.

Download figure:

Standard image High-resolution imageUnderstanding the adsorption kinetics at the bubble surface is important for clarifying the physical process of the microbubble collapse. The contact angle of the bubbles on the glass plate was measured after pulsed ultrasonic irradiation to evaluate the desorption of DMPC molecules from the bubble surface. Figure 4 shows sequential photographs of a microbubble ejecting a daughter bubble in the non-spherical vibration mode in the DMPC solution (see supplementary data). The average value of the contact angle of bubbles for 23 samples changed from 34.5° ± 2.3° to 43.7° ± 5.5° before and after ultrasound irradiation, meaning that DMPC molecules at the bubble surface desorbed between vibration and collapse processes under ultrasound irradiation. In our previous work, 27) we investigated the relationship between the DMPC concentration and the contact angle of a microbubble on a glass plate in DMPC solutions. Under the assumption that the molecular density on the bubble surface was equivalent to the DMPC concentration in the solution, the molecular density of the bubble decreased from 0.49 to 0.06 mM by ultrasound irradiation.

Fig. 4. (Color online) Sequential photographs of a microbubble ejecting a daughter bubble in the non-spherical vibration mode in the DMPC solution.

Download figure:

Standard image High-resolution imageIn summary, we reported the effects of the molecular film surrounding a microbubble on the collapse process and the sound-pressure threshold for bubble collapse. Encapsulated bubbles had a smaller resonance size than naked bubbles, and surfactant molecules on the bubble surface desorbed partially between the vibration and collapse processes.

Acknowledgments

We thank Adam Brotchie, PhD., from Liwen Bianji (Edanz) (www.liwenbianji.cn) for editing the English text of a draft of this manuscript.