Abstract

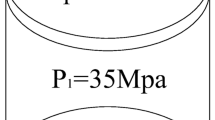

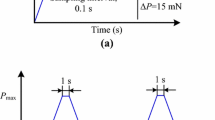

The accurate measurement on the compressibility and thermal expansion coefficients of density standard liquid at 2329kg/m3 (DSL-2329) plays an important role in the quality control for silicon single crystal manufacturing. A new method is developed based on hydrostatic suspension principle in order to determine the two coefficients with high measurement accuracy. Two silicon single crystal samples with known density are immersed into a sealed vessel full of DSL-2329. The density of liquid is adjusted with varying liquid temperature and static pressure, so that the hydrostatic suspension of two silicon single crystal samples is achieved. The compression and thermal expansion coefficients are then calculated by using the data of temperature and static pressure at the suspension state. One silicon single crystal sample can be suspended at different state, as long as the liquid temperature and static pressure function linearly according to a certain mathematical relationship. A hydrostatic suspension experimental system is devised with the maximal temperature control error ±50 μK; Silicon single crystal samples can be suspended by adapting the pressure following the PID method. By using the method based on hydrostatic suspension principle, the two key coefficients can be measured at the same time, and measurement precision can be improved due to avoiding the influence of liquid surface tension. This method was further validated experimentally, where the mixture of 1, 2, 3-tribromopropane and 1,2-dibromoethane is used as DSL-2329. The compressibility and thermal expansion coefficients were measured, as 8.5×10−4 K−1 and 5.4×1010 Pa−1, respectively.

Similar content being viewed by others

References

ELWENSPOEK M, JANSEN H. Silicon micromachinmg [M]. Beijing: Chemical Industry Press, 2006.

LI D S, YANG D R, QUE D L. Progress in study of crystal silicon mechanical properties[J]. Material Science and Engineering, 2000, 18(3): 100–104.

LUO Z Y, YANG L F, GU Y Z, et al. The absolute measurement of density of silicon crystals for determing avogadro constant[J]. Acta Me’irolocica Sinica, 2008, 29(3): 211–215.

FUJII K, TANAKA M, NEZU Y, et al. Determination of the Avogadro constant by accurate measurement of the molar volume of a silicon crystal[J]. Metrologia, 1999, 36: 455–464.

BECKER P. History and progress in the accurate determination of the avogadro constant[J]. Report on Progress in Physics, 2001, 64: 1945–2008.

KENICHI F J, MITSURU T. Density standard at NMIJ and related activities in the CCM WG on deastiy [C]//14th International Conference on The Properties of Water And Steam, Kyoto, Japan, August 29–September 3, 2006: 132–139.

HUI J, GUAN S C, CHEN H L. The progress of Avogadro constant and new definition of kilogram [J]. Physics, 1995, 24(7): 396–401.

TEGETMEIER A, DITTMAR D, FREDENHAGEN A, et al. Density and volume of water and triglyceride mixtures in contact with carbon dioxide[J]. Chemical Engineering and Processing, 2000, 39: 399–405.

WASEDA A, FUJII K, KURAMOTO N Development of a silicon density standard and precision density measurements of solid materials by hydrostatic weighing[J]. Meas. Sci. Technol., 2001, 12: 2039–2045.

KOZDON A F, SPIEWECK F. Determination of differences in the density of silicon single crystals[J]. IEEE Trans. Instrum. Meas., 1992,41:420–426.

XIE X Z, FANG J M, ZHANG X W, et al. The dynamic measurement of liquid volume modulus and its application in the dynamic pressure calibration [J]. Journal of Test and Measurement Technology of NOT, 2000, 14: 537–542.

FENG B, GONG G F, WANG J, et al. Structure design and FEA analysis of a measuring device for hydraulic oil bulk modulus[J]. Machine Tool & Hydraulics, 2007, 35(5): 177–179.

GEORGE H F, BARBER A. What is bulk modulus and when is it important[J]. Hydraulics & Pneumatics, 2007 (7): 34–39.

HAYWARD A T J. How to measure the isothermal compressibility ofliquidsaccurately[J]. J. Phys. D-Appl. Phys., 1971 (7): 938–949.

ZHANG F L, JI X. Measurement of liquid bulk modulus of elasticity [J]. Journal of Yanbian University(Natural Science), 2002, 28(3): 168–170.

WANG J, GONG G F, YANG H Y. Research and online measurement of bulk modulus of hydraulic oil[J]. Journal of Mechanical Engineering, 2009, 45(7): 120–125.

CHRISTOPHER N, JOHN K, KARTHIK B. Piezoelectric-based fluid bulk modulus sensor[J]. Journal of Intelligent Material Systems and Structures, 2004, 15(12): 893–899.

CHRISTOPHER D Lane, DAVID J H, ANDREW J L, et al. Measurement of the bulk modulus of a liquid using a pump-probe laser technique[J]. The Chemical Educator, 2001, 6(4): 235–237.

WANG Y G, SHAO L H. Ultrasonic testing research of HCL bulk modulus[J]. Journal of Tongji University, 1995, 2(23): 170–174.

MUSTAFA V, ALI B K, CANER K. Ultrasonic velocity measurements in ethanol-water and methanol-water mixtures[J]. Eur Food Res Technol, 2007, 225: 525–532.

LIU Y F, LIU Z Q. Based on SV-DH test instrument to calculate and measure of liquid compressibility [J]. Science Technology and Engineering, 2012, 12(16): 3941–3943.

MANRING N D. The effective fluid bulk-modulus within a hydrostatic transmission [J]. Journal of Dynamic Systems, Measurement, and Control, 1997, 119(3): 462–466.

AN J, SUN Y Q, ZHANG H P, et al. Online measuring elastic modulus of hydraulic medium[J]. Navigation of CHINA, 2008, 31(3): 248–251.

KARJALAINEN J P, KARJALAINEN R. Fluid dynamics-comparison and discussion on system-related differences[C]//Proc. 10th SICFP, Tampere, Finland, May 21–23, 2007, 2: 371–381.

YAN X L, GU L C H. Online measurement of effective bulk modulus in hydraulic system by the soft-sensing model[J]. Journal of Mechanical Engineering, 2011, 10(7): 126–132.

YAN H. Measuring liquid expansion coefficient using silicon force sensor[J]. Physics Experimentation, 2010, 30(4): 35–37.

FUJH K, WASEDA A, KURAMOTO N, et al. Present state of the avogadro constant determination from silicon crystals with natural isotopic compositions[J]. IEEE Transactions on Instrumentation and Measurement, 2005, 54(2): 854–859.

MARTIN J, BETTIN H, KUETGENS U, et al. About the existing discrepancy in the determinations of the avogadro constant[J]. IEEE Transactions on Instrumentation and Measurement, 1999, 48(2): 216–220.

FUJII K, TANAKA M, NEZU Y, et al. Determination of the Avogadro constant from accurate measurement of the molar volume of a silicon crystal[J], Metrologia, 1999, 36: 455–464.

KURAMOTO N, FUJII K. Volume determination of silicon sample using an improved interferometer with optical frequency tuning[J]. IEEE Transaction on Instrumentation & Measurement, 2005, 54(2): 868–871.

FUJII K. Present state of the solid and liquid density standards[J]. Metrologia, 2004, 41: 1–15.

NICOLAUS R A, FUJH K. Primary calibration of the volume of silicon samples[J]. Meas Sci Technol, 2006, 17: 2527–2539.

LUO Z Y, YANG L F, GU Y Z, et al. A study on solid density primary standard[J]. Chinese Science Bulletin, 2007, 52(21): 2881–2886.

NICOLAUS R A, BONSCH G. Absolute volume determination of a silicon sample with the spherical interferometer of PTB[J]. Metrologia, 2005, 42: 24–31.

LUO Z Y, GU Y Z, ZHANG J T, et al. Interferometric measurement of the diameter of a silicon sample with a mechanical scanning method[J]. IEEE Transaction on Instrumentation and Measurement, 2010, 59 (11): 2991–2996.

BETTIN H, GLASER M, SPIEWECK F, et al. International intercomparison of silicon density standards[J]. IEEE Transactions on Instrumentation and Measurement, 1997, 46(2): 556–559.

OSAMA I. Hydraulic hydrokineties[M]. Beijing: Science Press, 1980.

Author information

Authors and Affiliations

Corresponding author

Additional information

Supported by National Natural Science Foundation of China(Grant No. 51105347), and National Key Technology R&D Program of Ministry of Science and Technology of China(Grant No. 2011BAI02B03)

WANG Jintao, born in 1976, is currently an assistant research fellow at National Institute of Metrology, China. He received his PhD degree from Xi’an Jiaotong University, China, in 2006. His research interests include precise measurement on density and volume for liquid and solid.

LIU Ziyong, born in 1955, is currently a senior engineer at National Institute of Metrology, China. He received his bachelor degree on physics in Shanxi University, China, in 1978.

XU Changhong, born in 1978, is currently an assistant research associate at National Institute of Metrology, China. She received her master degree on physics in National Institute of Metrology, China, in 2006.

LI Zhanhong, born in 1974, is currently an assistant research associate at National Institute of Metrology, China. He received his master degree on instrument in Beijing Institute of Technology, China, in 2000.

Rights and permissions

About this article

Cite this article

Wang, J., Liu, Z., Xu, C. et al. Measurement method of compressibility and thermal expansion coefficients for density standard liquid at 2329 kg/m3 based on hydrostatic suspension principle. Chin. J. Mech. Eng. 27, 779–784 (2014). https://doi.org/10.3901/CJME.2014.0422.080

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3901/CJME.2014.0422.080